Seamless steel pipe for long pipe trailer and manufacturing method for seamless steel pipe

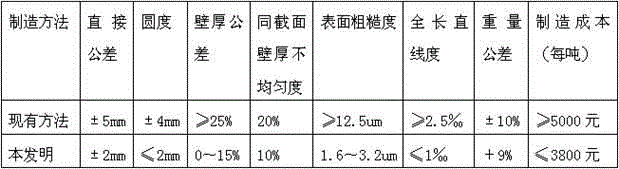

A technology of seamless steel pipes and manufacturing methods, applied in the direction of manufacturing tools, slender elements, building elements, etc., can solve the problems of reduced production efficiency, not smooth enough, metal loss, etc., and achieve high quality and pass rate of finished products, transportation High efficiency and low metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The outer diameter of the seamless steel pipe is 720mm, the wall thickness is 27mm, and the length is 11000mm.

[0039] The manufacturing method of the above-mentioned seamless steel pipe includes the following sequential steps:

[0040] 1). Select waste pipes with a diameter of 728mm, a wall thickness of 30mm, and a length of 10540mm, and re-inspect the selected waste pipes; make chucks for the re-inspected waste pipes;

[0041] 2). Use an external shot blasting machine to perform shot blasting on the outer surface of the waste pipe. The projectiles of the external shot blasting machine are composed of steel shot and steel sand in a ratio of 6:4. The diameter of these projectiles is 1.2mm. The speed of the shot treatment is 1.2m / min; the inner surface of the waste pipe is shot peened by an internal shot blasting machine. The projectiles of the internal shot blasting machine are composed of steel shot and steel sand in a ratio of 8:2. 1.2mm, the speed of shot peening t...

Embodiment 2

[0050] The outer diameter of the seamless steel pipe is 660mm, the wall thickness is 19mm, and the length is 12000mm.

[0051] The manufacturing method of the above-mentioned seamless steel pipe includes the following sequential steps:

[0052] 1). Select waste tubes with a diameter of 660mm, a wall thickness of 22mm, and a length of 11000mm, and re-inspect the selected waste tubes; make chucks for the re-inspected waste tubes;

[0053] 2). Use an external shot blasting machine to perform shot blasting on the outer surface of the waste pipe. The projectiles of the external shot blasting machine are composed of steel shot and steel sand in a ratio of 5:3. The diameter of these projectiles is 1.1mm. The speed of the shot treatment is 1.0m / min; the inner surface of the waste pipe is shot peened by an internal shot blasting machine. The projectiles of the internal shot blasting machine are composed of steel shot and steel sand in a ratio of 7:1. 1.1mm, the speed of shot peening t...

Embodiment 3

[0062] The outer diameter of the seamless steel pipe is 630mm, the wall thickness is 21.5mm, and the length is 12500mm.

[0063] The manufacturing method of the above-mentioned seamless steel pipe includes the following sequential steps:

[0064] 1). Select waste tubes with a diameter of 630mm, a wall thickness of 25mm, and a length of 11400mm, and re-inspect the selected waste tubes; make chucks for the re-inspected waste tubes;

[0065] 2). Use an external shot blasting machine to perform shot blasting on the outer surface of the waste pipe. The projectiles of the external shot blasting machine are composed of steel shot and steel sand in a ratio of 7:5. The diameter of these projectiles is 1.3mm. The speed of the shot treatment is 0.9m / min; the inner surface of the waste pipe is shot peened by an internal shot blasting machine. The projectiles of the internal shot blasting machine are composed of steel shot and steel sand in a ratio of 8:2. 1.0mm, the speed of shot peening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com