Manufacturing method of cold-drawing seamless steel tube for oxygen supplying bottles

A technology for seamless steel pipes and oxygen cylinders, applied in the field of metallurgy, can solve the problems of undiscovered manufacturing process and method of cold-drawn seamless steel pipes, poor surface quality of gas cylinders, poor safety and reliability, etc., and achieve light weight, simple structure, The effect of prolonged oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples, and the following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

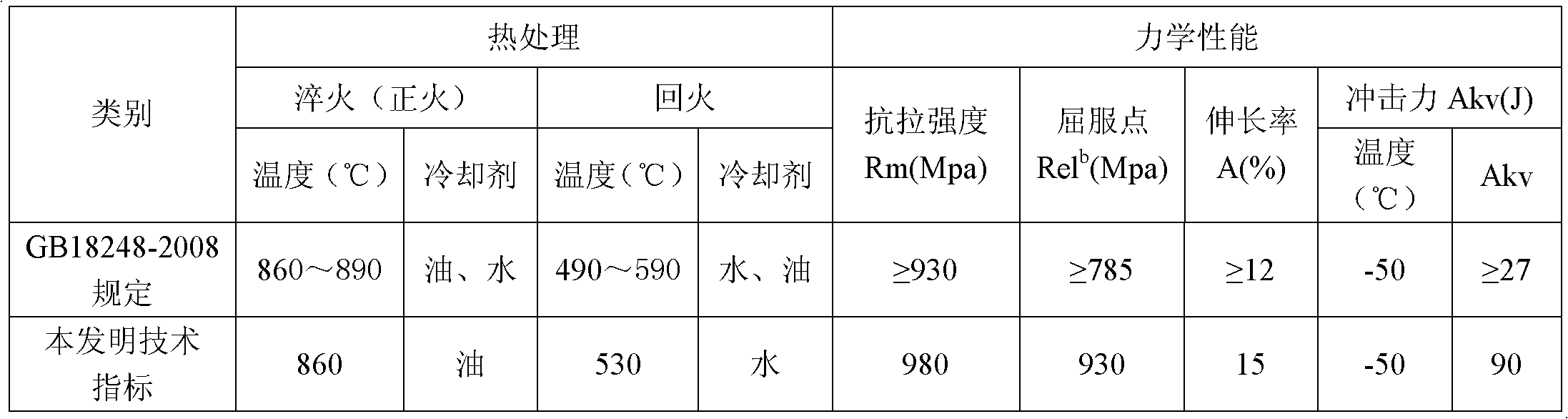

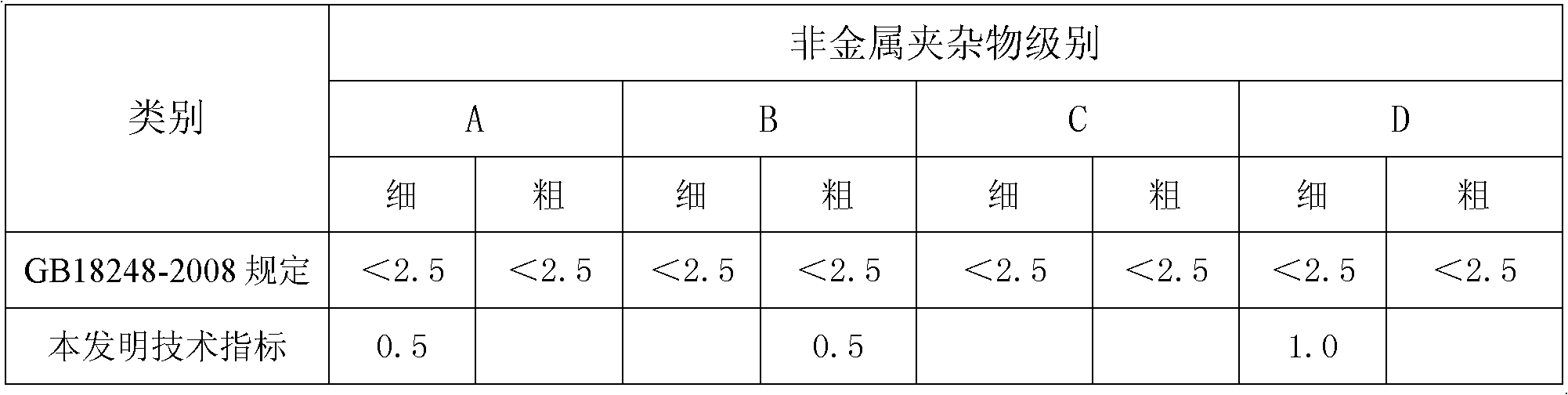

[0021] The following takes the Φ178×4.8mm specification as an example to describe the process flow of cold drawn seamless steel pipe:

[0022] Incoming inspection of hot-rolled raw steel pipe → pickling → phosphating → saponification → cold drawing → straightening → inspection (inner and outer surface quality, wall thickness, outer diameter, curvature) → ultrasonic flaw detection → compactness test → sawing (cutting head , cut tail, cut unqualified parts)→sampling→performance inspection→storage.

[0023] A preparation method of a cold-drawn seamless steel pipe for an oxygen cylinder with a specification of Φ178×4.8mm:

[0024] (1) Inspection: The hot-rolled raw steel pipe is inspected at the factory. The raw steel pipe used is Φ182...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com