Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

A composite coating, aluminum alloy technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of poor bonding force between aluminum film and substrate, low production efficiency, low coating rate, etc. Achieve the effects of good corrosion resistance and surface adhesion, good corrosion resistance and adhesion, and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

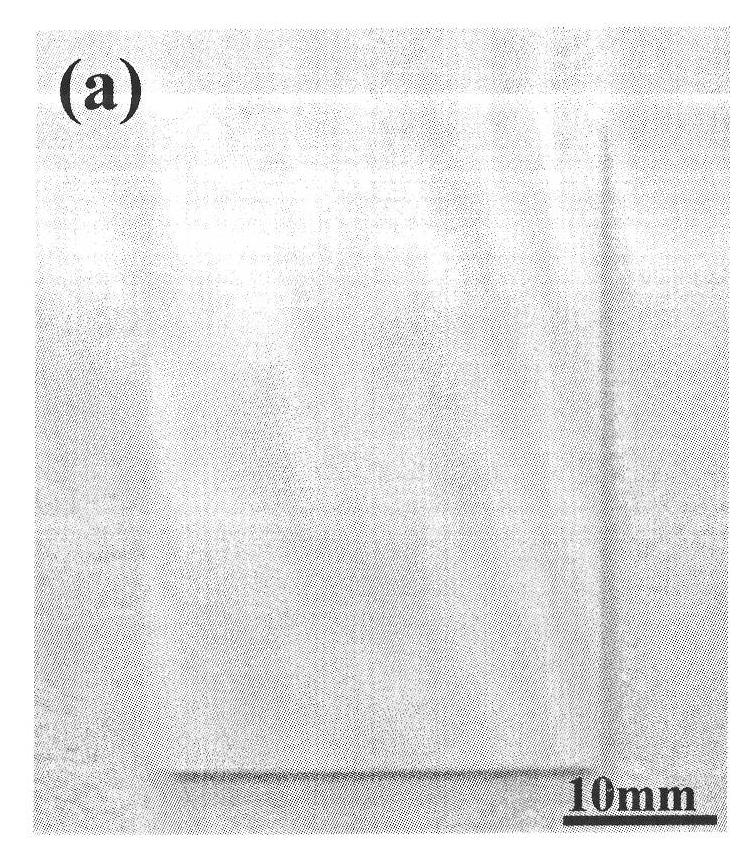

[0029] Embodiment 1: A kind of preparation method of the neodymium-iron-boron magnet of composite aluminum or aluminum alloy coating, adopt multi-arc ion coating technology, on the neodymium-iron-boron magnet, plate the pure aluminum thin film, and then coat the pure aluminum thin film that has been plated Phosphating treatment is carried out on the NdFeB magnet to obtain the NdFeB magnet with aluminum composite coating. The prepared aluminum composite coating has excellent protective properties for sintered NdFeB magnets.

[0030] Multi-arc ion coating process, coating aluminum film on various NdFeB magnets. Specifically: on the Φ600×550mm vertical small multi-arc (arc source target Φ60-100mm, quantity 4) coating equipment, the magnet is placed in a plurality of stainless steel wire woven nets, and the stainless steel wire nets are fixed to the ion coating machine on the stand of the vacuum chamber. The stainless steel wire mesh can rotate and revolve with the support (rota...

Embodiment 2

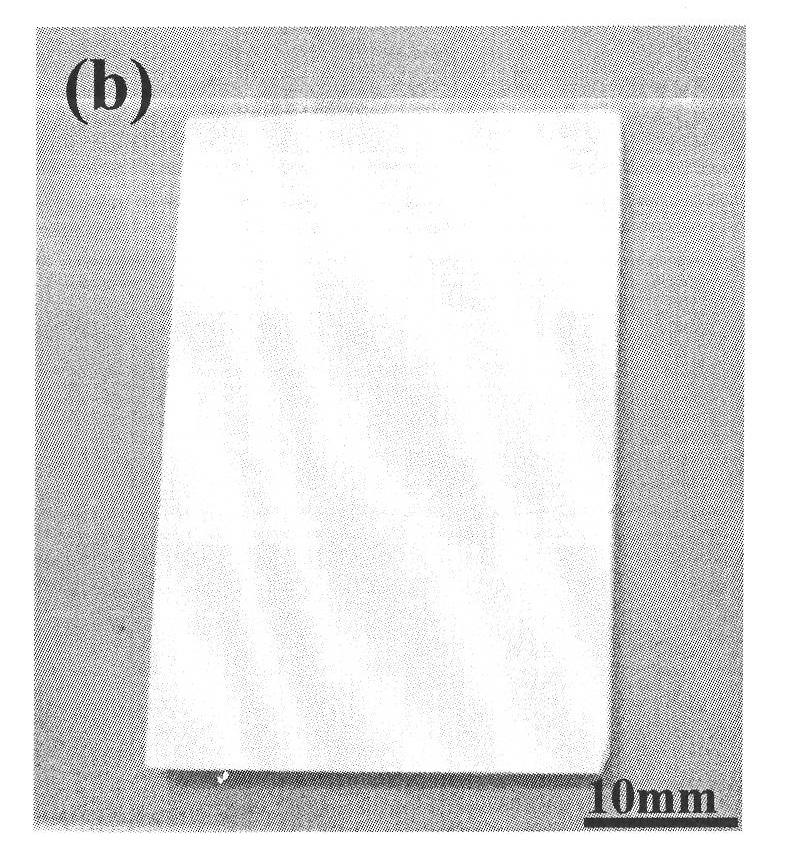

[0034]Embodiment 2: A kind of preparation method of the neodymium-iron-boron magnet of composite aluminum or aluminum alloy coating, adopt multi-arc ion plating film technology, on the neodymium-iron-boron magnet, plate the aluminum alloy thin film, after the coated aluminum alloy thin film Phosphating treatment is carried out on the NdFeB magnet to obtain an aluminum alloy coated NdFeB magnet. The prepared aluminum composite coating has excellent protective properties for sintered NdFeB magnets.

[0035] Multi-arc ion coating process, coating aluminum alloy film on various NdFeB magnets. Specifically: on the Φ600×550mm vertical small multi-arc (arc source target Φ60-100mm, quantity 4) coating equipment, the magnet is placed in a plurality of stainless steel wire woven nets, and the stainless steel wire nets are fixed to the ion coating machine on the stand of the vacuum chamber. The stainless steel wire mesh can rotate and revolve with the support (rotation speed 12 rpm) to...

Embodiment 3

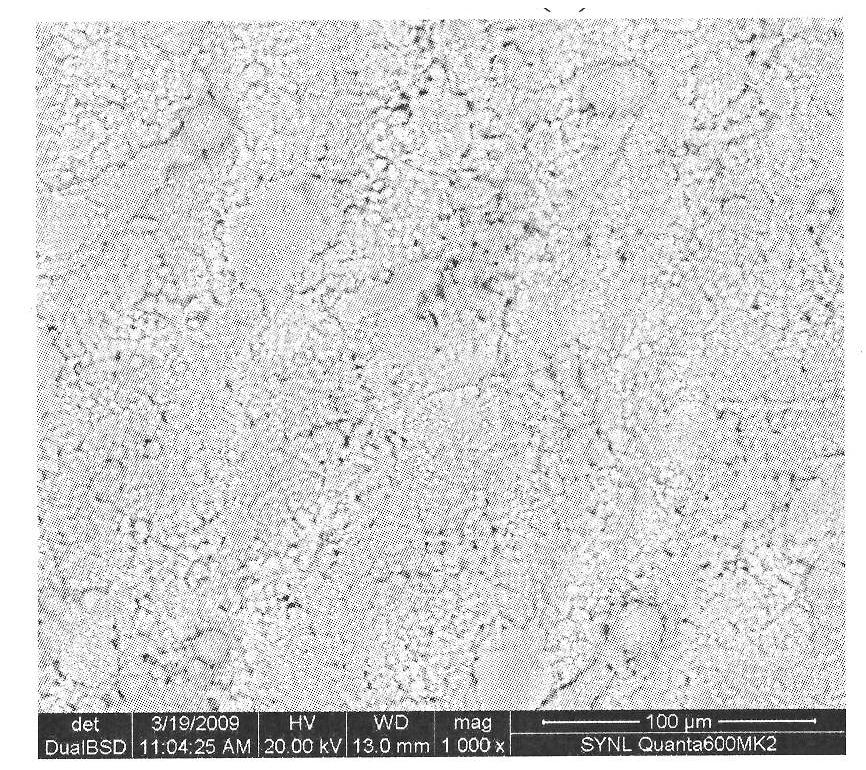

[0039] Embodiment 3: A kind of preparation method of the NdFeB magnet of composite aluminum or aluminum alloy coating, adopts multi-arc ion plating film technology, on NdFeB magnet, is coated with pure aluminum or aluminum alloy thin film, after the pure aluminum that has plated Phosphating treatment is carried out on the NdFeB magnets of aluminum or aluminum alloy films to obtain composite aluminum or aluminum alloy coated NdFeB magnets. The prepared aluminum composite coating has excellent protective properties for sintered NdFeB magnets.

[0040] Multi-arc ion coating process, coating aluminum or aluminum alloy films on various NdFeB magnets. Specifically: on the Φ600×550mm vertical small multi-arc (arc source target Φ60-100mm, quantity 4) coating equipment, the magnet is placed in a plurality of stainless steel wire woven nets, and the stainless steel wire nets are fixed to the ion coating machine on the stand of the vacuum chamber. The stainless steel wire mesh can rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com