Patents

Literature

37results about How to "Play a role in sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

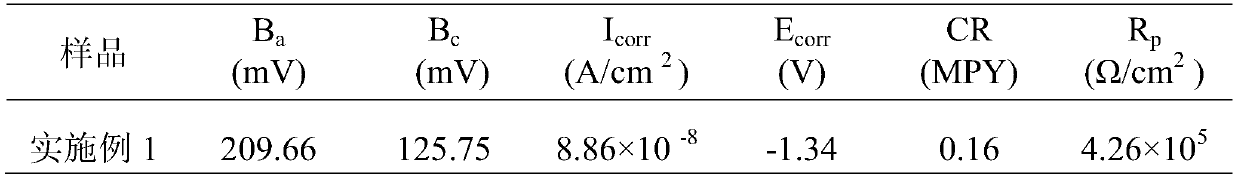

Neodymium-iron-boron magnet of aluminum or aluminum alloy composite coating and preparation method thereof

ActiveCN102031522AImprove processing efficiencyLow costVacuum evaporation coatingSputtering coatingHigh humidityAlloy composite

The invention discloses a neodymium-iron-boron magnet of an aluminum or aluminum alloy composite coating and a preparation method thereof. An aluminum or aluminum alloy film is deposited on the neodymium-iron-boron magnet by adopting multi-arc ion plating technology, and then phosphate treatment is performed. The coating is uniform and dense, and is well combined with a matrix. The neodymium-iron-boron magnet applied with the aluminum composite coating with thickness of 10 to 20 microns tolerates high pressure and high humidity (100 to 130 DEG C, 2 to 2.6atm, and 95 to 100 percent RH) for over 200 hours, and tolerates NaCl salt fog corrosion (3.5 to 5 weight percent of NaCl and 25 to 35 DEG C) for over 500 hours. The coating process has high efficiency and low cost; and the prepared composite coating has good corrosion resistance and adhesion performance, and has no influence on the magnetism of the neodymium-iron-boron matrix (mainly small-size magnet).

Owner:北京钐元新材料股份有限公司

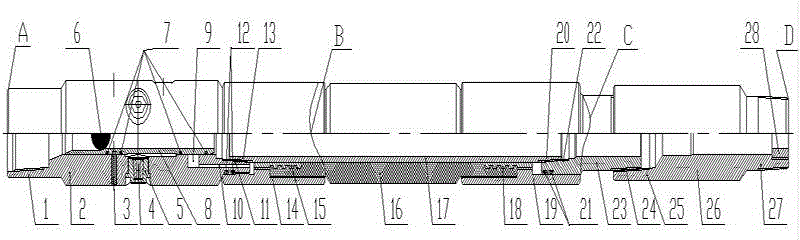

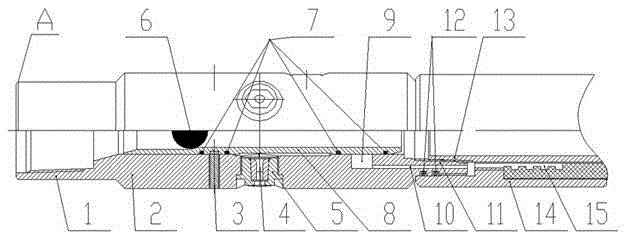

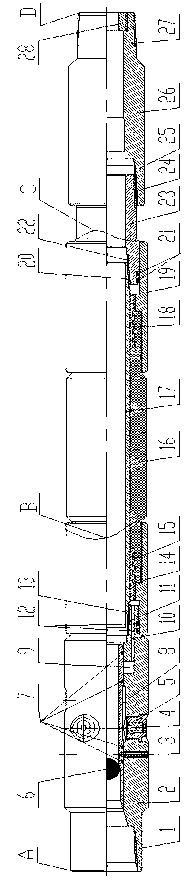

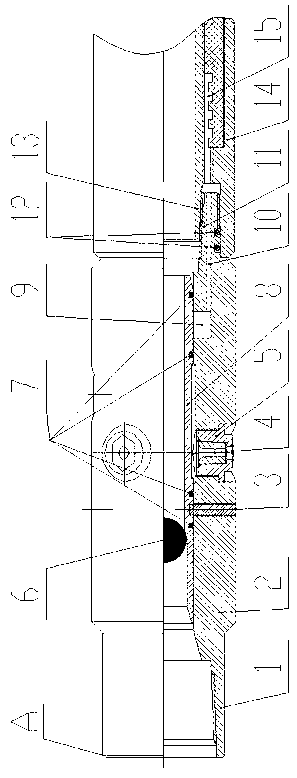

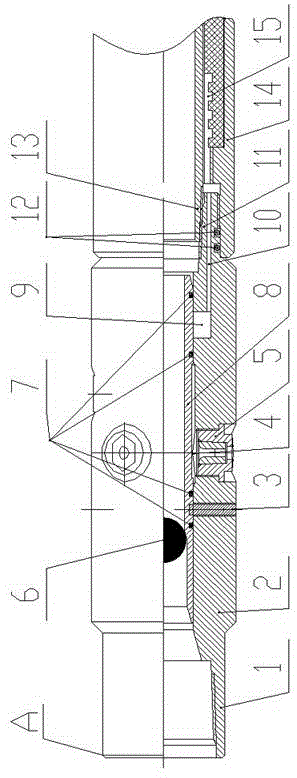

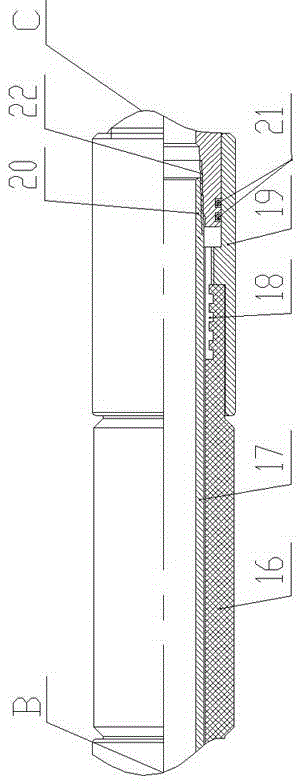

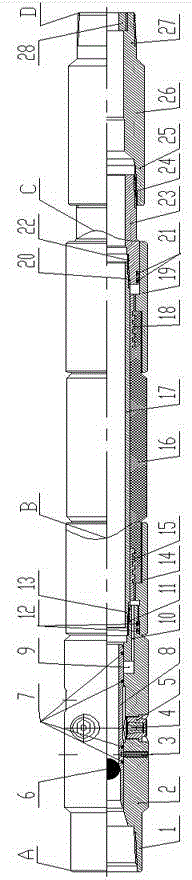

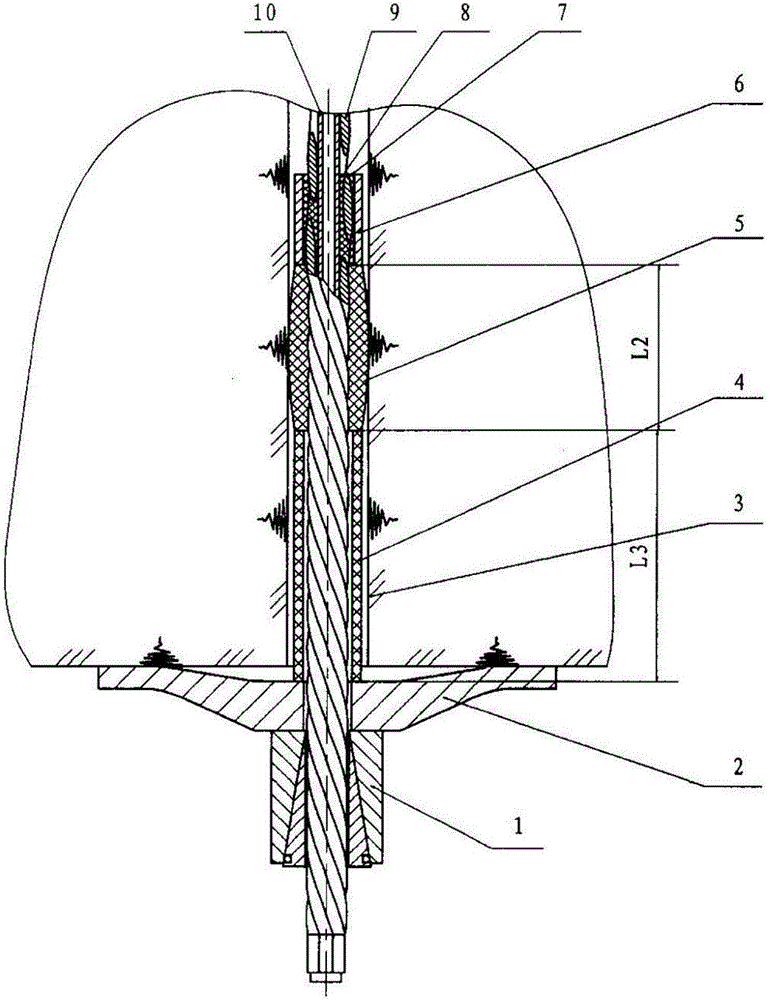

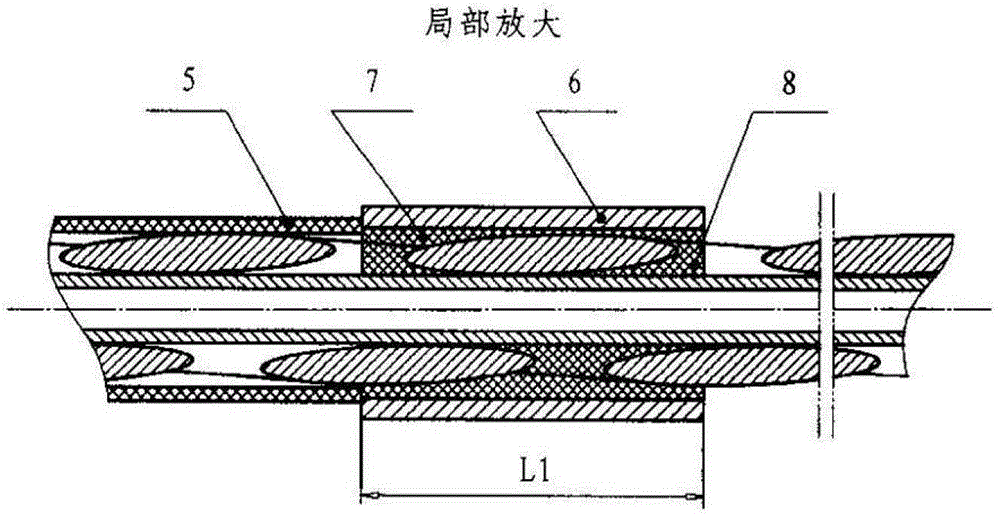

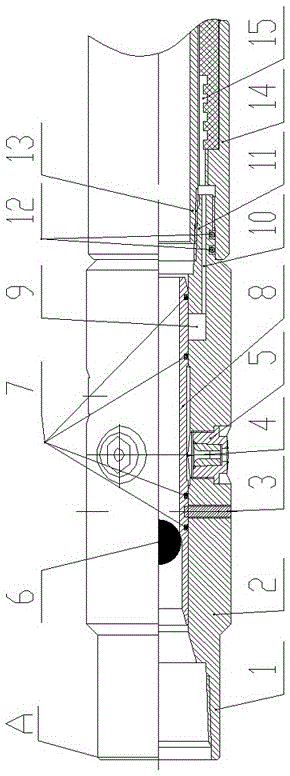

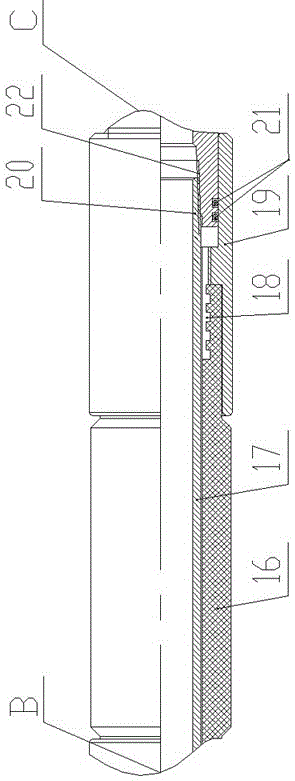

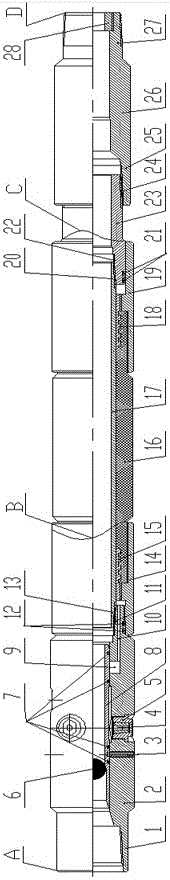

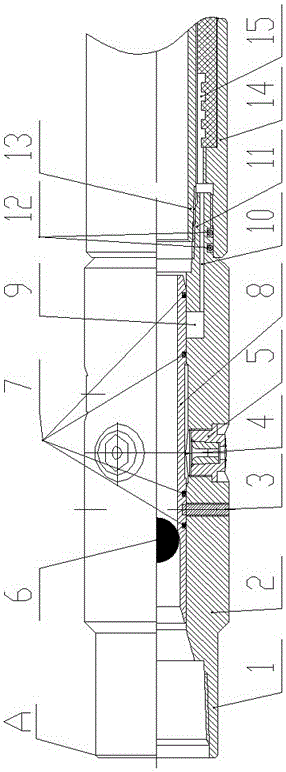

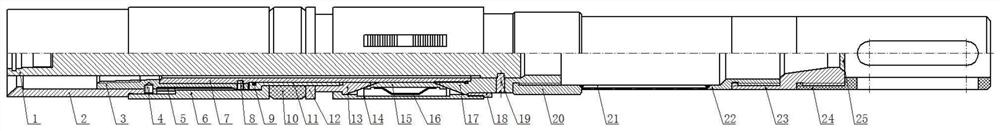

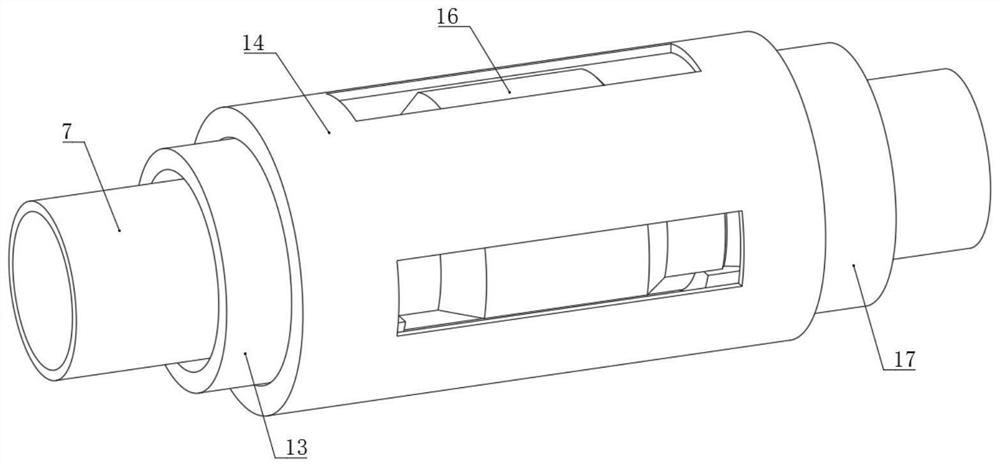

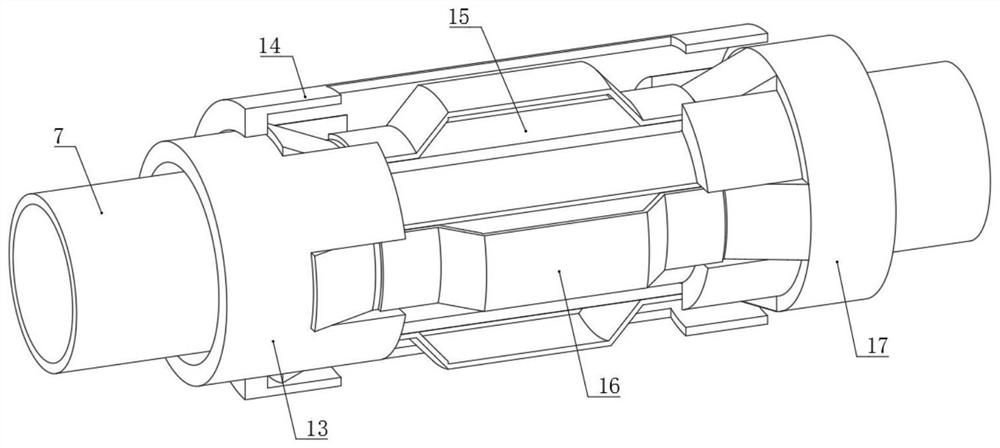

Hydraulic jet packer applicable to multilevel hydraulic jet fracturing

InactiveCN103184856AGuaranteed compactnessWill not colludeFluid removalSealing/packingAbrasive blastingAcid fracturing

The invention discloses a hydraulic jet packer applicable to multilevel hydraulic jet fracturing, and relates to the technical field of design and manufacture of acid fracturing technical equipment. The hydraulic jet packer comprises a spray gun, a packer and a sliding sleeve standing joint, wherein one end of the packer is connected with the spray gun, and the other end thereof is connected with the sliding sleeve standing joint; a sliding sleeve is arranged in the spray gun, and the inner diameter of the sliding sleeve is variable; and in the direction from the spray gun to the sliding sleeve standing joint, the inner wall of the sliding sleeve is composed of three structures with smaller inner diameters in proper sequence; and a ball seat is arranged in the sliding sleeve. With adoption of the hydraulic jet packer, selectable seat sealing can be realized; multilevel hydraulic jet fracturing construction can be completed; and integration of abrasive blasting perforation and mechanical sealing and separation is also realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Nanometer hole sealing agent for ceramic spayed coating and application of nanometer hole sealing agent

ActiveCN105670365AReduce porosityReduce penetrationMolten spray coatingAnti-corrosive paintsNanometreWater soluble

The invention relates to a nanometer hole sealing agent for a ceramic spayed coating. The nanometer hole sealing agent comprises the following components in parts by weight: 30-80 parts of water-soluble resin, 10-40 parts of inorganic nanoparticles, 10-30 parts of a corrosion inhibitor, 1-40 parts of fillings, 1-20 parts of a curing agent and 1-10 parts of other aids.

Owner:BEIJING XINLI MACHINERY

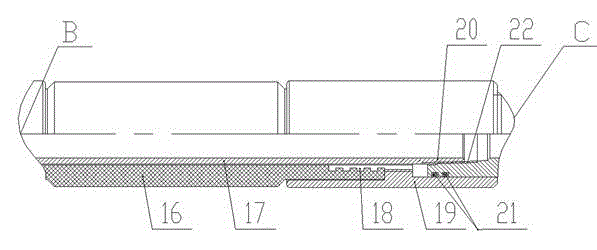

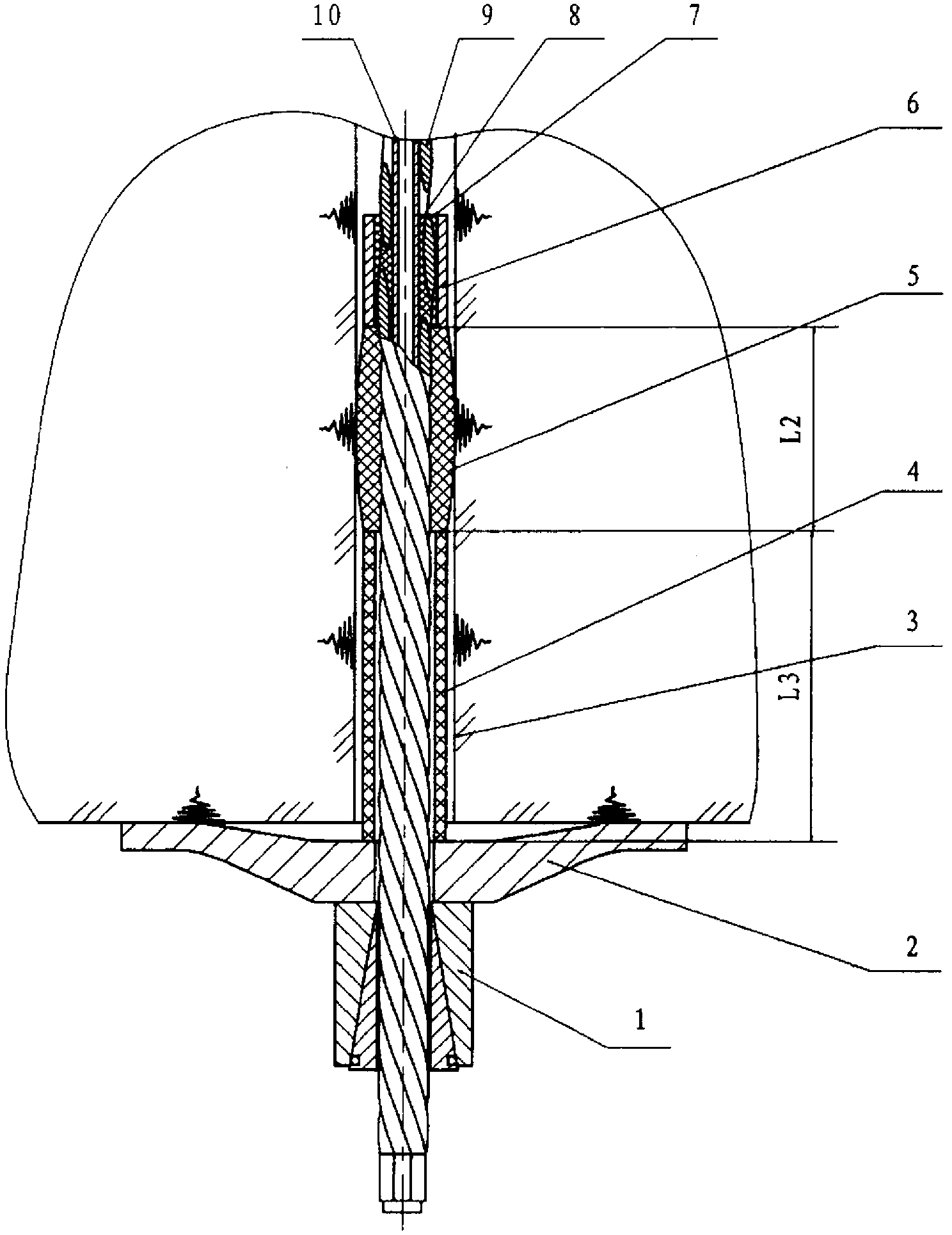

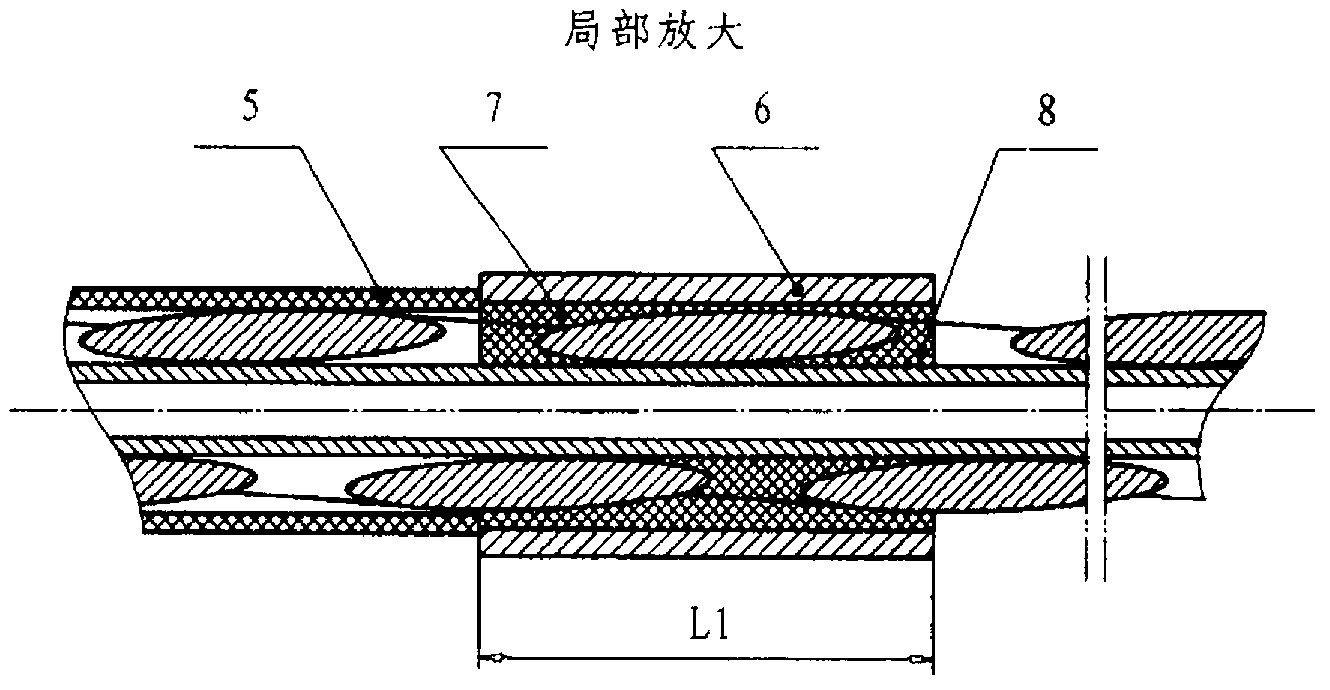

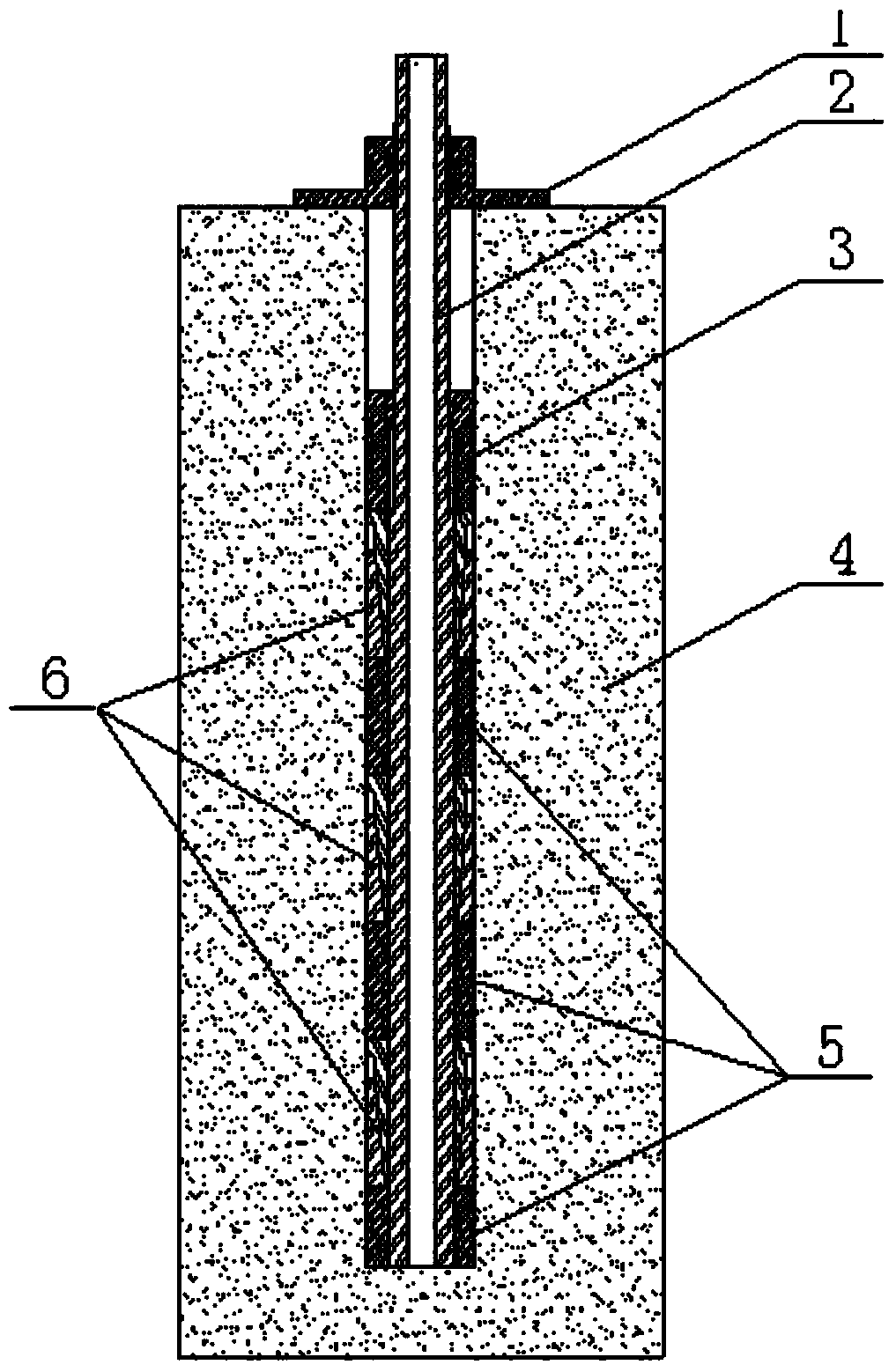

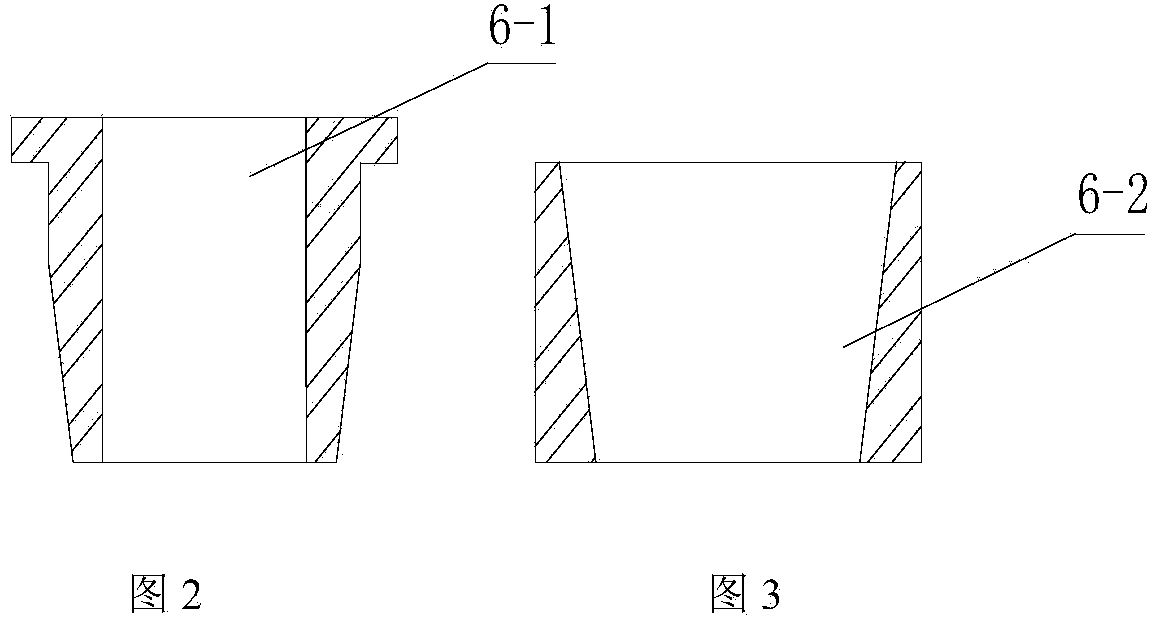

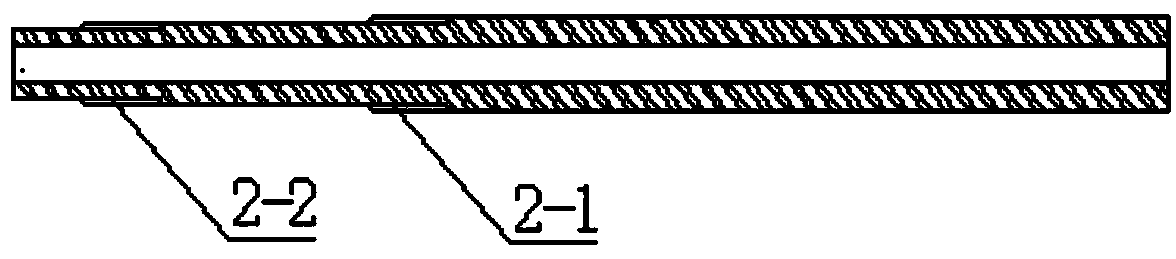

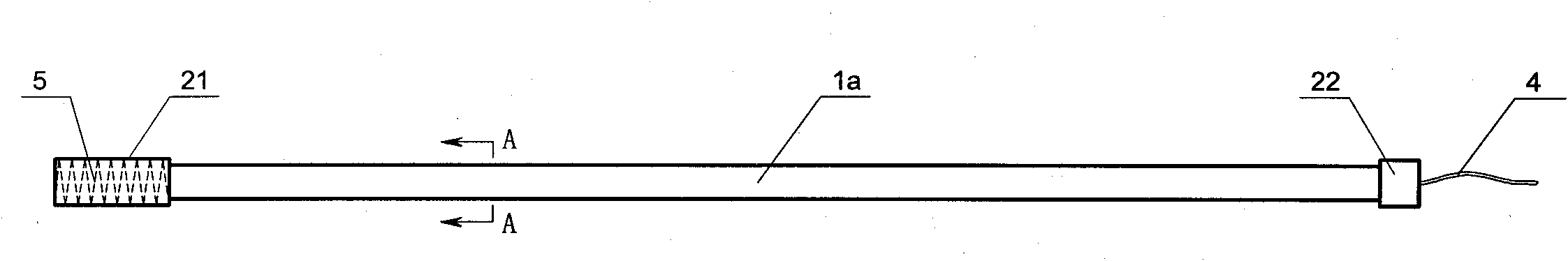

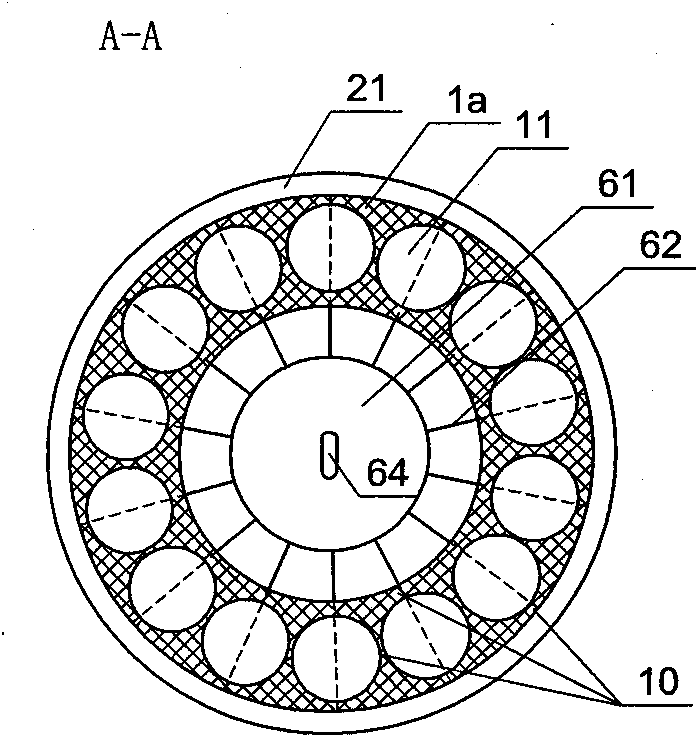

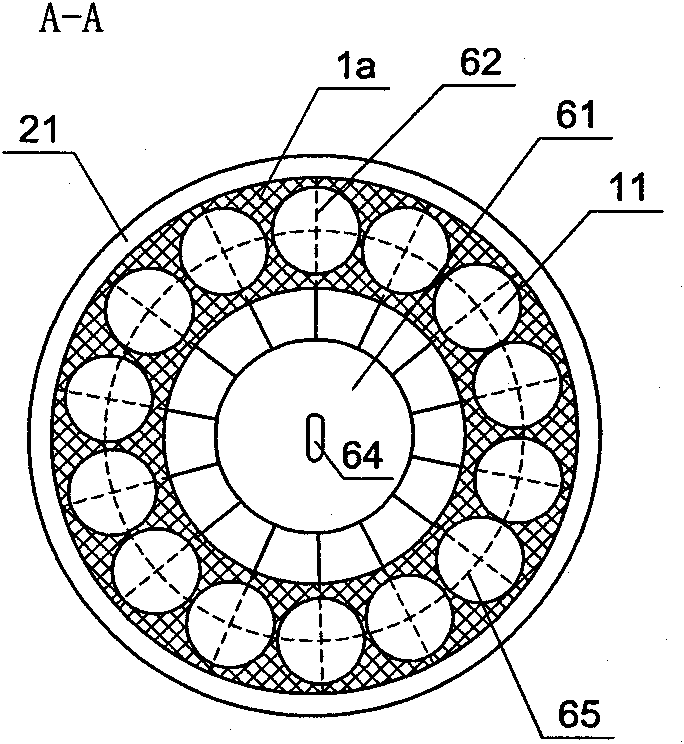

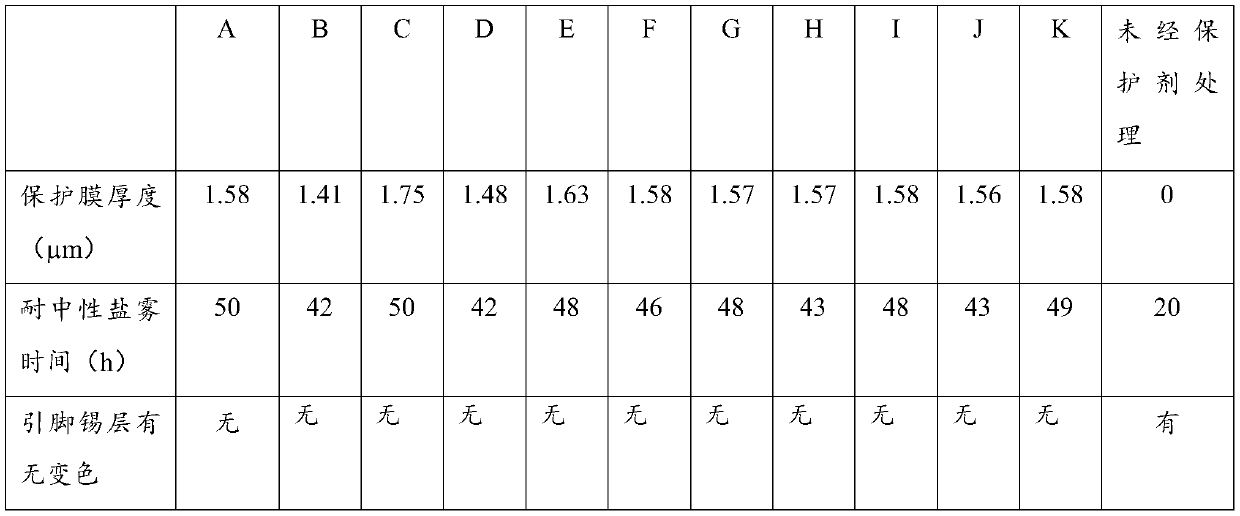

Grouting and Grouting-stopping anchor cable inside hole

ActiveCN102704971AAvoid pollutionExpand the scope of diffusionBulkheads/pilesAnchoring boltsRigid coreEngineering

The invention discloses a grouting and grouting-stopping anchor cable inside a hole. The grouting and grouting-stopping anchor cable comprises an anchor cable body, a cable anchor body, a tray, a grouting-stopping assembly inside a hole and a rigid core tube. The grouting-stopping assembly inside the hole comprises an inner sleeve, an outer sleeve, a tightening metal tube, an elastic sleeve and a hard sleeve. The hard sleeve, the elastic sleeve and the outer sleeve are connected in an end-to-end manner and sleeved on the cable anchor body in sequence. The lower end of the hard sleeve is fixed against the tray. The tightening metal tube, the inner and outer sleeves are arranged on the same position of the cable anchor body; the tightening metal tube is sleeved on the outer sleeve, and the inner sleeve is sleeved on the rigid core tube; and the inner and outer sleeves are hoses, tightened by the tightening metal tube, and plugged in inner and outer seams of a cable anchor body steel wire. The anchor cable can seal the hole at any drilling position, so that the hole is sealed firmly and the slurry can be prevented from leaking from the cracks around the hole, thus improving the grouting effects; the anchor cable has a simple structure and is convenient to install. The grouting and grouting-stopping anchor cable inside the hole not only can be used for a mineral hollow grouting anchor cable to seal a hole and stop grouting, but also can be used for a hollow threaded grouting anchor rod to seal a hole and stop grouting, and a common anchor cable / anchor rod to plug water.

Owner:济南澳科矿山工程技术有限公司

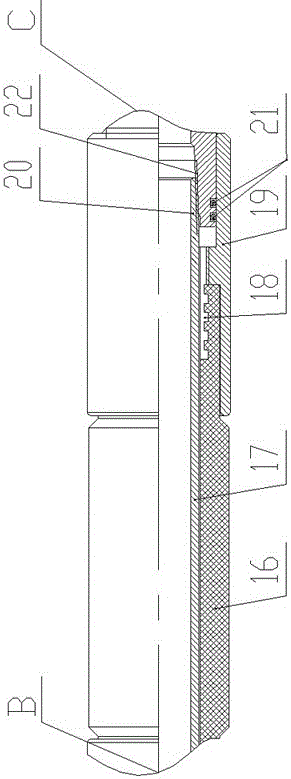

Jet packer ground simulation method applicable to multilevel hydraulic jet fracturing

ActiveCN103184867AReduce security risksReduce tool changeConstructionsFluid removalLine tubingEngineering

The invention discloses a jet packer ground simulation method applicable to multilevel hydraulic jet fracturing. The method comprises the following steps: a, connecting in series jet packers of corresponding amount and other required tools on a construction test string according to the required designed level amount of an oil well and a gas well, placing a steel ball in an inlet of the construction test string, and connecting a high-pressure pipeline; b, gradually increasing the discharge capacity, if a sliding sleeve is hit off by the steel ball and pushed to pass through a central pipe of the packer continually and enter a sliding sleeve standing joint connected onto the lower part of the packer, and a water hole of a spray gun normally jets water, performing next-level test for the jet packer; c, if the sliding sleeve is not hit off by the steel ball, checking the mounting position of the sliding sleeve and the gap between the sliding sleeve and the spray gun, checking the position of a shear pin, and performing the test and detection in step b; and repeating steps a, b and c until completing all set tests. With adoption of the method, opening of all packers and jet tools, and jet of the spray gun can be observed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

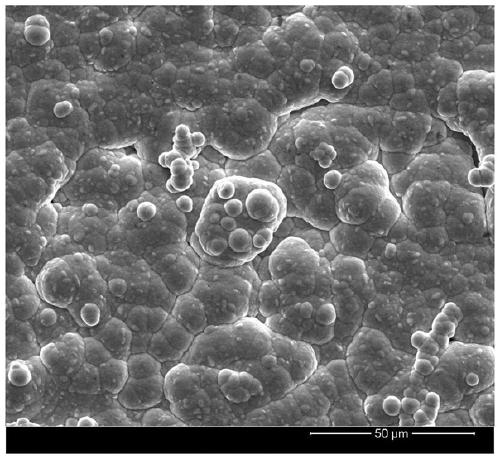

Composite film and preparation method thereof

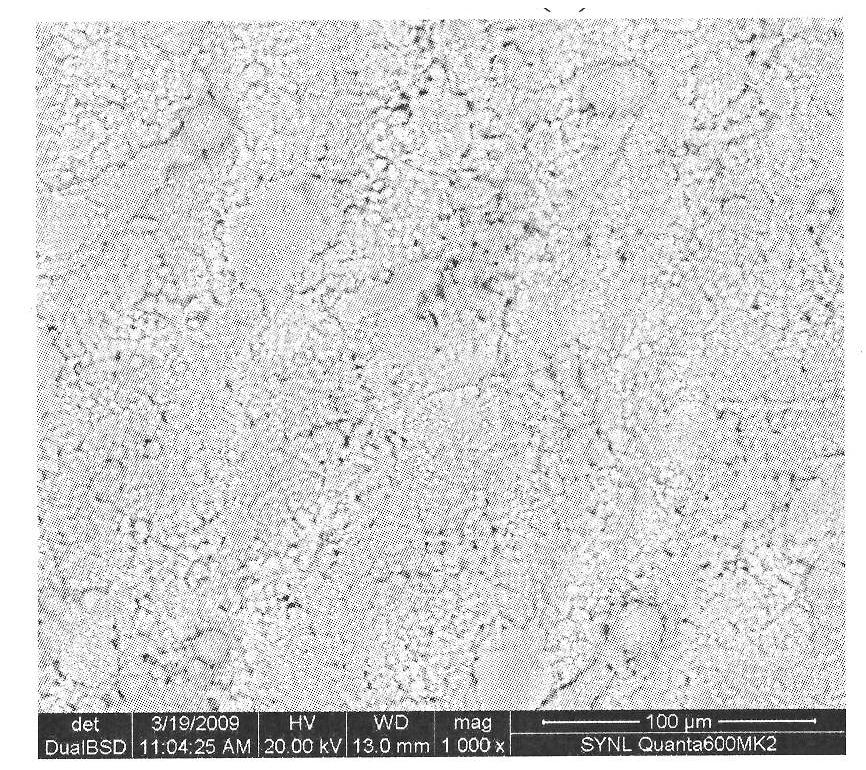

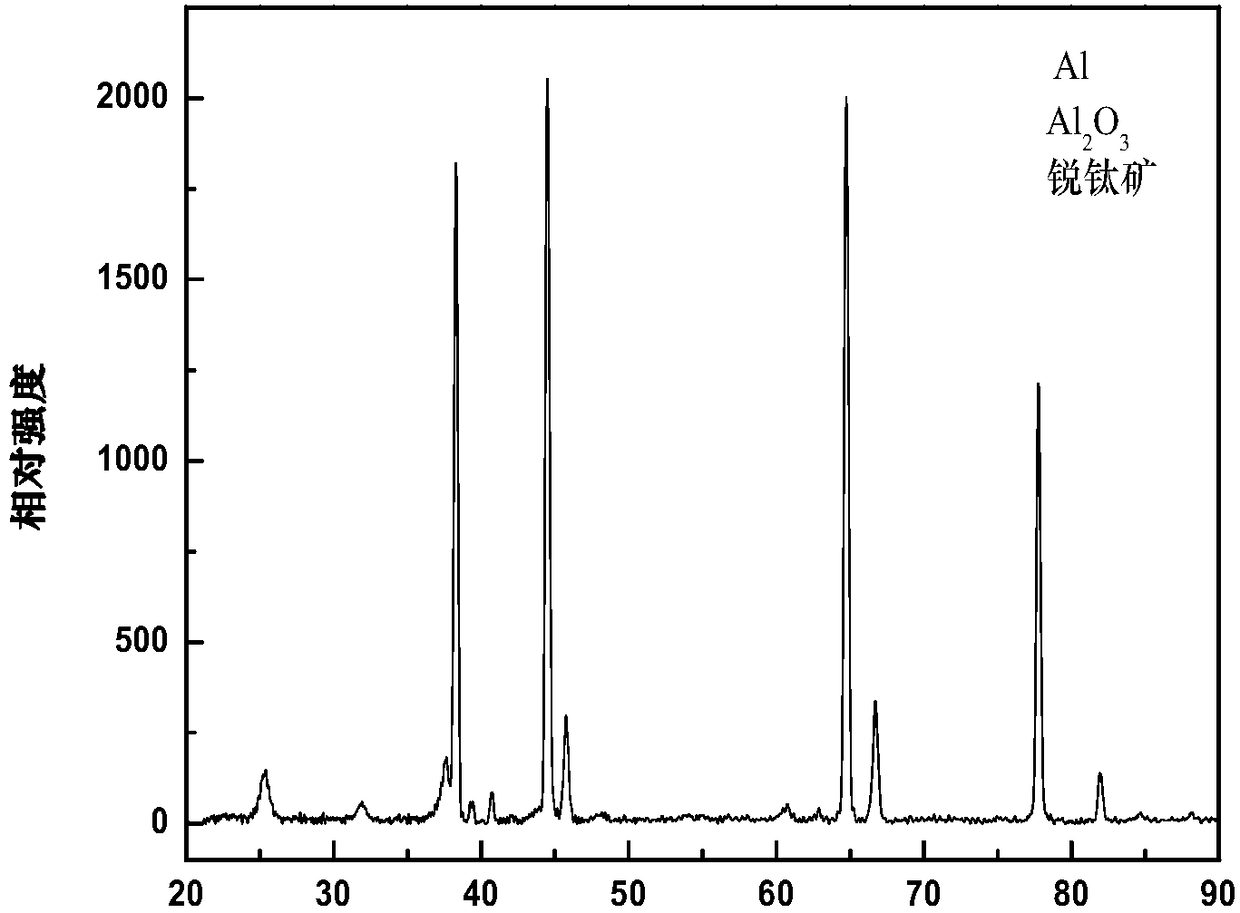

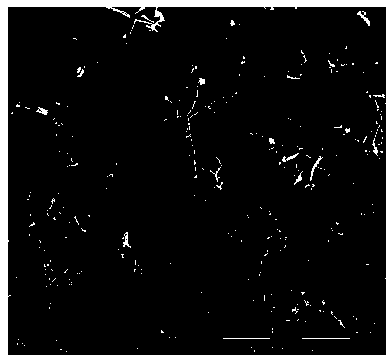

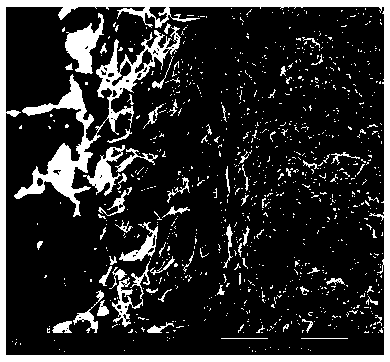

InactiveCN108385150AImprove bindingSolve many defectsSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingComposite filmMicro arc oxidation

The invention provides a preparation method of a composite film and belongs to the field of composite films. The preparation method comprises the following steps of: sequentially carrying out oil removal, grinding by using abrasive paper and washing on a base body to obtain a pretreated base body; carrying out micro-arc oxidation coating on the pretreated base body in electrolyte which contains nanometer titanium dioxide to obtain a micro-arc oxidation film; carrying out sol-gel coating on the micro-arc oxidation film to obtain a composite film precursor; and sequentially drying and annealingthe composite film precursor to obtain the composite film. According to the preparation method provided by the invention, micro-arc oxidation coating and sol-gel coating are combined, a sol-gel methodis used for coating sol to prepare the composite film, thus a sol-gel film totally clings to the surface of the micro-arc oxidation film, the binding force of the sol-gel film is increased, a hole sealing effect is also achieved on a surface hole structure of the micro-arc oxidation film , and the defect that the surface of a single micro-arc oxidation film has lots of holes and the defect that asingle sol-gel film has poor binding force with the base body are overcome.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

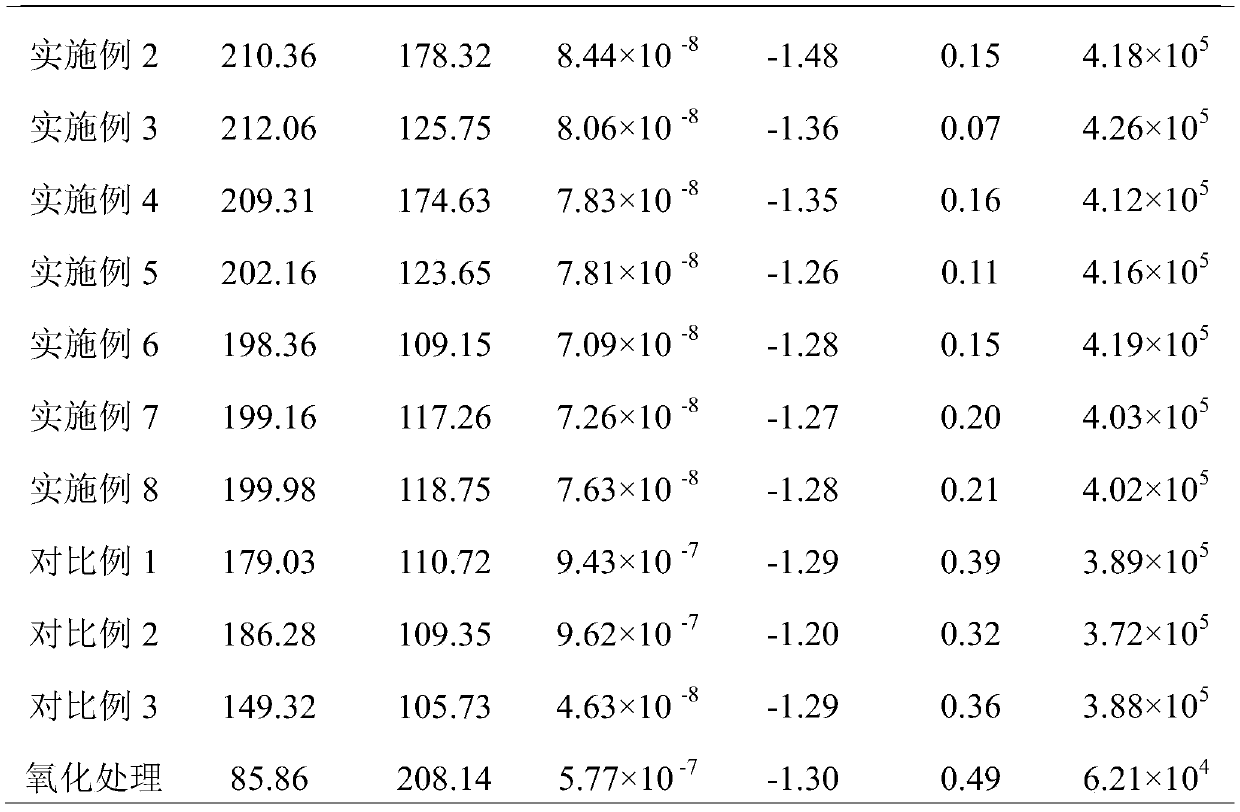

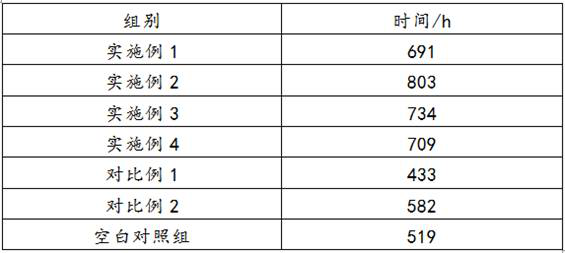

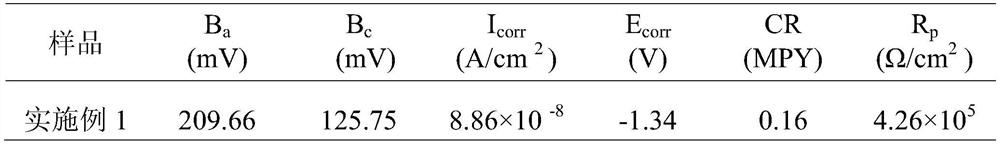

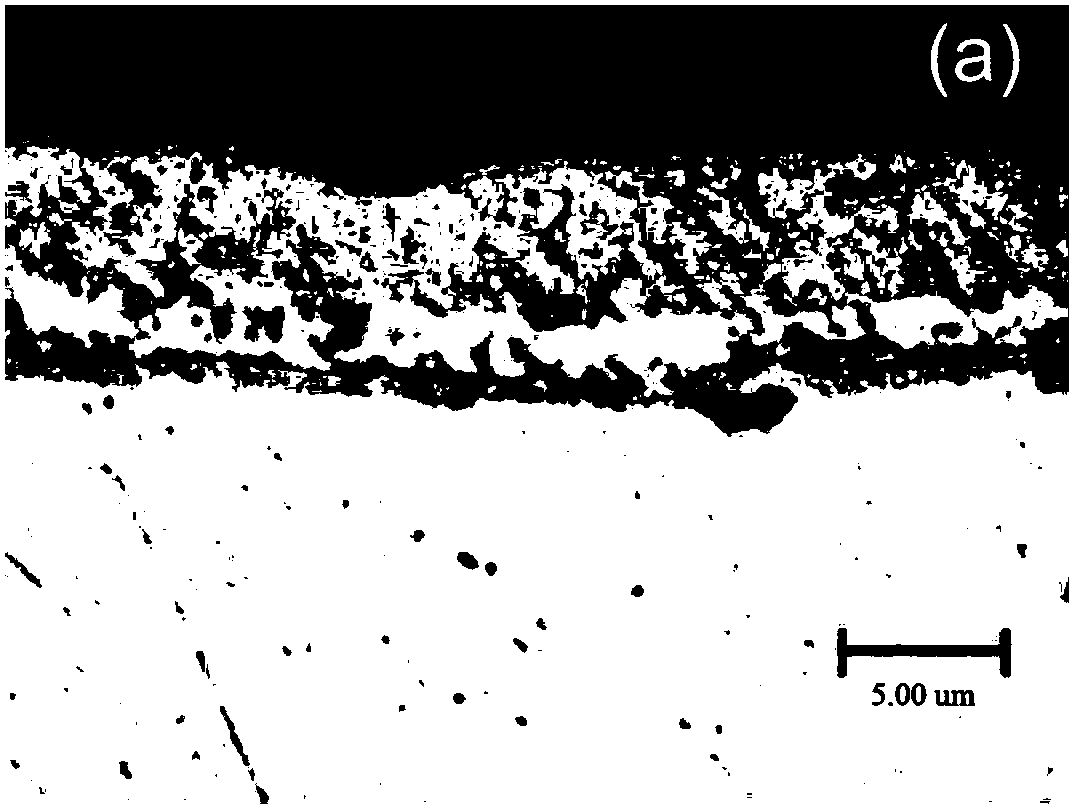

Preparation method of corrosion-resistant double coatings of improved sintered Nd-Fe-B magnet

ActiveCN111005050AImprove corrosion resistanceReduce contact areaAnodisationMetallic material coating processesElectrolytic agentMicro arc oxidation

The invention provides a preparation method of corrosion-resistant double coatings of an improved sintered Nd-Fe-B magnet. The preparation method comprises the steps of S1, conducting acid pickling, derusting and degreasing treatment, specifically, feeding the sintered Nd-Fe-B magnet into a nitric acid solution for acid pickling to remove rust and grease on the surface of the sintered Nd-Fe-B magnet; S2, conducting micro-arc oxidation treatment, specifically, feeding the sintered Nd-Fe-B magnet subjected to acid pickling into an electrolyte prepared from sodium aluminate, sodium hypophosphiteand deionized water for micro-arc oxidation treatment; S3, conducting spraying treatment, specifically, conducting spraying treatment on the sintered Nd-Fe-B magnet subjected to micro-arc oxidation treatment in the step S2 through a mixture comprising zinc oxide whiskers and polydimethyl siloxane; and S4, conducting natural drying, specifically, naturally drying the sintered Nd-Fe-B magnet subjected to spraying treatment in the step S3 in the environment and eventually forming a corrosion-resistant double-coating structure composed of the micro-arc oxidation ceramic coating and the zinc oxidewhisker / polydimethyl siloxane super-hydrophobic coating on the surface of the sintered Nd-Fe-B magnet.

Owner:NANCHANG HANGKONG UNIVERSITY

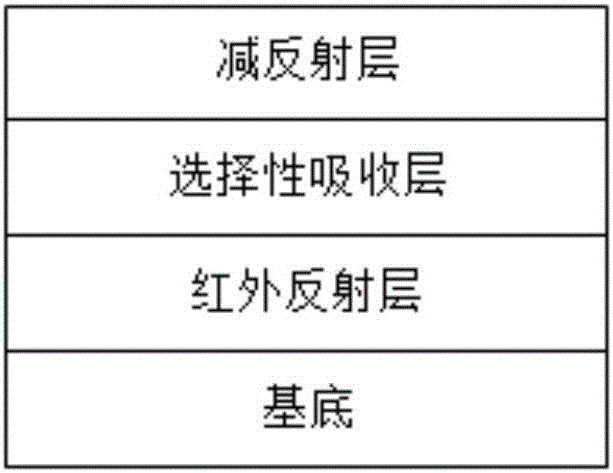

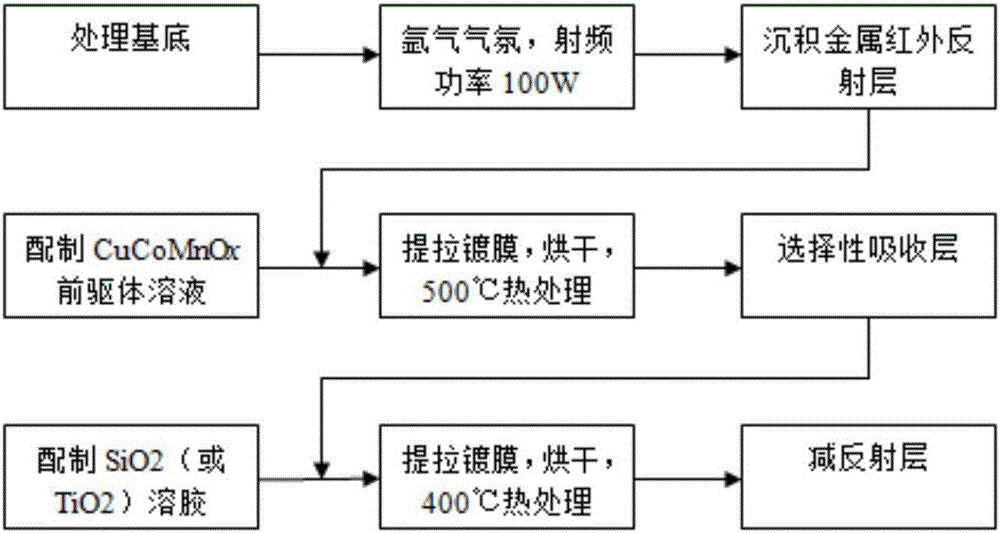

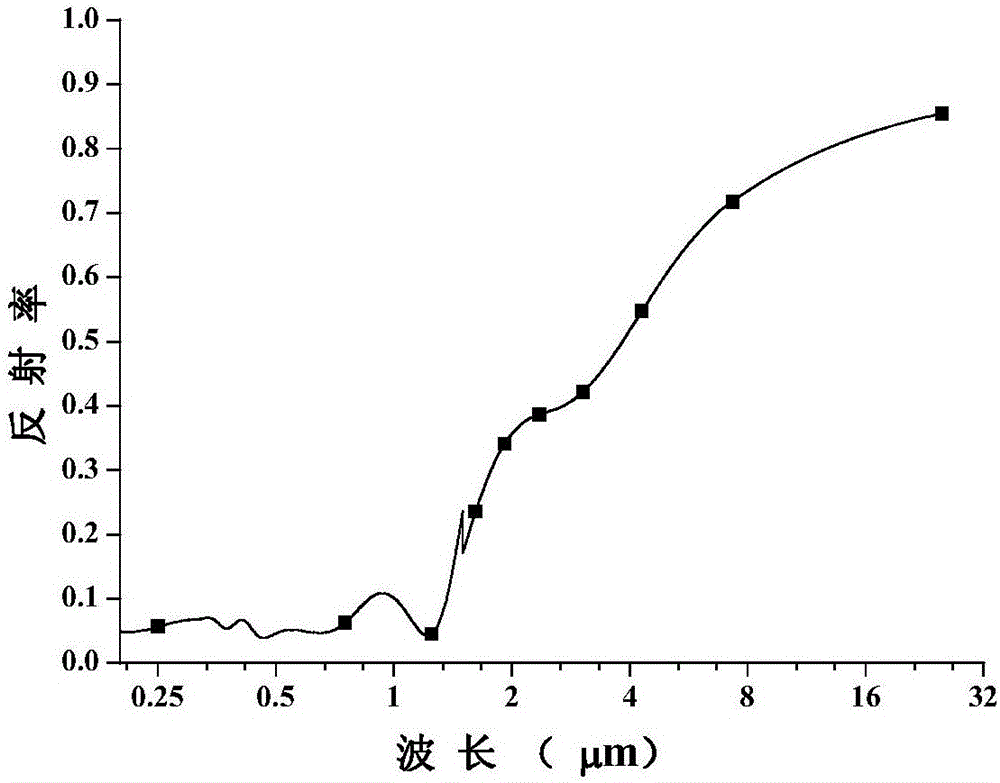

Medium-high temperature solar selective absorption composite coating and preparation method thereof

InactiveCN107523827AImproved infrared reflectivity and thermal stabilityHigh degree of bindingSolar heat devicesVacuum evaporation coatingWave bandCorrosion

The invention discloses a medium-high temperature solar selective absorption composite coating and a preparation method thereof. The composite coating comprises four layers of structures from inside to outside, namely the substrate layer, the infrared reflection layer, the selective absorption layer and the antireflection layer; and the substrate layer is a stainless steel substrate, the infrared reflection layer is a metal thin film, the selective absorption layer is a CuCoMnOx spinel thin film, and the antireflection layer is a SiO2 or TiO2 thin film. The medium-high temperature solar selective absorption composite coating has a high absorption rate at the visible-near infrared wave band and has low emissivity at the medium-far infrared wave band, has good high-temperature resistance and corrosion resistance and can work stably at a medium-high temperature and meanwhile is simple in preparation process and low in cost.

Owner:LIANYUNGANG RES INST NANJING UNIV OF SCI & TECH

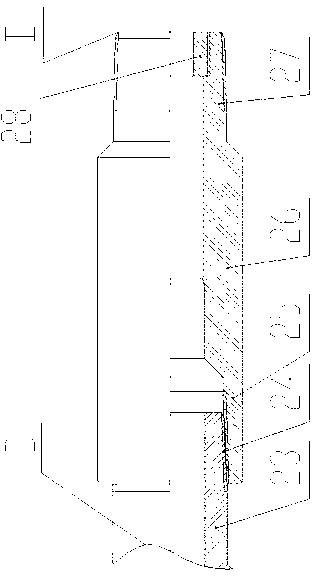

Water sealing device applied to hydraulic fracture experiment under high-temperature and high-pressure condition

ActiveCN104374637AEasy to transformOvercoming the disadvantages of failureMaterial strength using tensile/compressive forcesHigh pressure waterRock sample

The invention discloses a water sealing device applied to hydraulic fracture experiment under high-temperature and high-pressure condition. The water sealing device comprises a hole sealing nut, a metal water pipe, a locking nut, metal washers and wedge-shaped sealing red copper rings, wherein the wedge-shaped sealing red copper rings sleeve the metal water pipe which extends into drill hole inside a rock sample, are partitioned by the metal washers, and each wedge-shaped sealing red copper ring is formed by oppositely buckling two copper seals with slopes; the inner surface and the outer surface of each wedge-shaped sealing red copper ring are vertical surfaces; the wedge-shaped sealing red copper rings expand in a tester under the condition that the maximum temperature can reach 600 DEG C; the inner vertical surfaces and the outer vertical surfaces are used for pressing the metal water pipe and rock hole wall respectively, so that the initial hole sealing is implemented; the wedge-shaped sealing red copper rings are pressed and deformed to expand in the process of applying load to the rock sample by the tester; the outer vertical surfaces are on close contact with the hole wall of the rock sample; the inner vertical surface is in close contact with the metal water pipe, so that the high-pressure water sealing in the experiment process is implemented. According to the water sealing device, the wedge-shaped sealing red copper rings are additionally arranged outside the metal water pipe, so that the water sealing under the high-temperature, high-load and high-pressure condition is realized; the device is simple in structure, reliable in performance and high in stability, and is applied to the hydraulic fracture experiment of the rock under the high-temperature and high-pressure condition.

Owner:CHINA UNIV OF MINING & TECH

Hydrazine hydrate chemical nickel plating solution and preparation method and nickel plating method thereof

ActiveCN109852952AMeet environmental protection requirementsEasy to addLiquid/solution decomposition chemical coatingSuperimposed coating processAcetic acidSodium Hypophosphite Monohydrate

The invention discloses a hydrazine hydrate chemical nickel plating solution and a preparation method and nickel plating method of the hydrazine hydrate chemical nickel plating solution, and belongs to the technical field of chemical nickel plating. The problems that in the prior art, a sodium hypophosphite chemical nickel plating solution and the environment are damaged and polluted by the element phosphorus in the nickel plating solution, and the speed is low when hydrazine hydrate is adopted for chemical nickel plating are solved. The hydrazine hydrate chemical nickel plating solution is prepared from nickel sulfate, hydrazine hydrate, sodium citrate, potassium sodium tartrate, cobalt sulfate and lead acetate. The hydrazine hydrate chemical nickel plating solution and the preparation method and nickel plating method of the hydrazine hydrate chemical nickel plating solution are suitable for chemical nickel plating of matrix materials.

Owner:ZHEJIANG INNUOVO MAGNETICS +1

Seal test method applicable to hydraulic jet sealing and separating tool

ActiveCN103185655AUnderstanding Sealing EffectsReduce security risksMeasurement of fluid loss/gain rateSpray nozzleSteel ball

The invention discloses a seal test method applicable to a hydraulic jet sealing and separating tool. The seal test method comprises the following steps of: testing pressure of clear water to 50MPa, and stabilizing the pressure for 20minutes; then soaking for 6 hours in diesel oil at the temperature of 120 DEG C, then testing the pressure to 50MPa, testing upper pressure to 50MPa under rated setting pressure, and stabilizing the pressure for 20minutes; mounting three sealing rings at the upper part of a sliding sleeve, pressurizing to 3MPa, checking whether a packer is set or not, if the packer is normally set, continuously pressurizing to 35MPa, and stabilizing the pressure for 5minutes; and mounting four sealing rings on the sliding sleeve, pressurizing to 35MPa, and stabilizing the pressure for 5minutes; and throwing steel balls from the upper end, prying and injecting the steel balls into a pipeline by connecting a pump at the upper end, turning on the pump and building the pressure to 9MPa, so that the sliding sleeve drops and is inserted into a sliding sleeve locating joint at the lower end, a nozzle at the upper end discharges a liquid, a channel at the lower end is plugged, and a liquid flow stops. By adopting the seal test method applicable to the hydraulic jet sealing and separating tool, opening and sealing of the packer and a jet tool can be visually reflected, and the sealing effect of jetting a sealing and separating tool is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

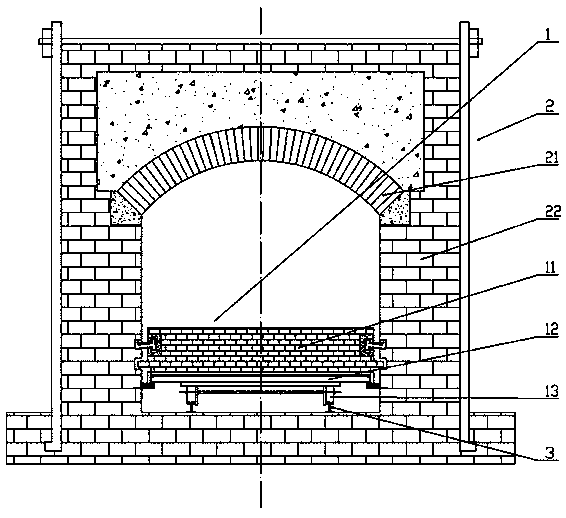

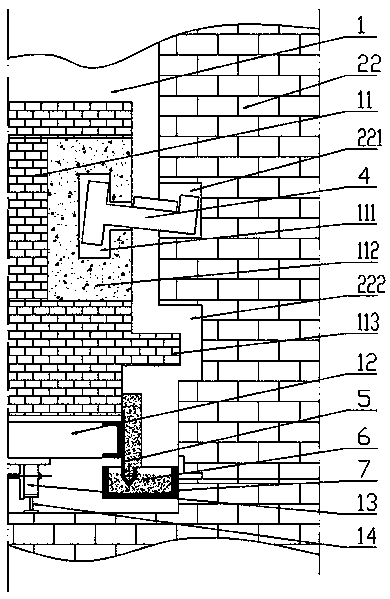

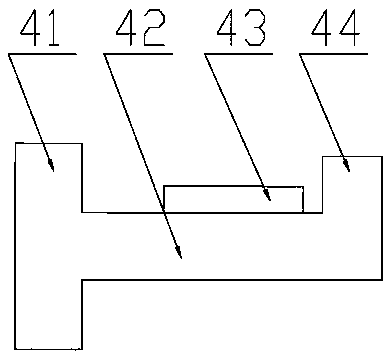

High-airtightness tunnel kiln

PendingCN108826969ABarrier deliveryImprove sealingFurnace typesCeramic materials productionTunnel kilnBrick

The invention discloses a high-airtightness tunnel kiln. The high-airtightness tunnel kiln comprises a kiln body composed of kiln walls and a kiln top, and a kiln car composed of a car frame, car wheels and a kiln car lining portion and operating on kiln rails. T-shaped grooves are formed in the side surfaces of the kiln car lining portion and formed along the full length of the kiln car. A plurality of packer bricks are movably inserted into the T-shaped grooves correspondingly and arranged in the length directions of the T-shaped grooves in sequence. Packer grooves are formed in the kiln walls correspondingly, and the external extending ends of the packer bricks are movably arranged in the packer grooves correspondingly. Skirt plates are arranged on the side surfaces of the car frame, sand sealing grooves containing kiln sand are formed in the kiln walls correspondingly, each skirt plate comprises a skirt plate body, the lower lateral side of each skirt plate body is connected with asand sealing inserting portion in a groove shape, the upper portion of each sand sealing inserting portion is connected with a skirt plate brick body, and the sand sealing inserting portions are inserted into the kiln sand. By adopting the high-airtightness tunnel kiln, good sealing isolation protection can be formed for the bottom of the tunnel kiln, heat is effectively prevented from being transmitted to the bottom of the tunnel kiln, and in addition, it can be guaranteed that the kiln car operates in the kiln walls without hindrance.

Owner:DONGTAI CENT HEAT RESISTANT MATERIALS

Magazine clip type hole packer

The invention relates to a magazine clip type hole packer, which comprises a closed or combined supporting pipe; annular powder gut cavities are uniformly distributed on the pipe wall of the supporting pipe; a powder gut is filled in each powder gut cavity; expansion powder A and expansion powder B are filled in the adjacent powder guts respectively, and the expansion powder A and the expansion powder B can be quickly expanded and fixed after being mixed; and a combined cutter is arranged at one end of the closed supporting pipe, the edges of blades of the combined cutter correspond to the powder guts respectively, meanwhile, a puller is fixed on the combined cutter, the puller passes through the pipe cavity or the powder gut cavities, and the other end of the puller extends out of the closed supporting pipe. The expansion powder A and the expansion powder B are delivered to the deep position of a drilled hole by using the supporting pipe, and the powder guts of the two kinds of powder are lacerated by using the cutter, so that the two kinds of powder are quickly reacted and expanded to pack the hole. The hole packer has a simple structure, and is practical, convenient and good in using effect.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of nonferrous alloy anti-corrosion layer

ActiveCN111041538AHigh bonding strengthEnhance coverage and wettabilityAnodisationLiquid/solution decomposition chemical coatingAlloySol-gel

The invention provides a preparation method of a nonferrous alloy anti-corrosion layer. The preparation method comprises the following steps of raw material proportioning of a sol-gel solution, sol preparing, preparing of the sol-gel solution, film layer dipping and film layer drying. According to the method, sol-gel solution hole sealing is carried out on the porous microarc oxidization film, aneven film layer is obtained, surface clearances are reduced, binding force and smoothness are better, the coverage rate of a ceramic layer after nonferrous alloy oxidization is improved, the functionof hole sealing is achieved, the anti-friction function is also achieved, and the defects of surface needle holes, cracks and the like are overcome.

Owner:八龙应用材料科技(海南)有限公司

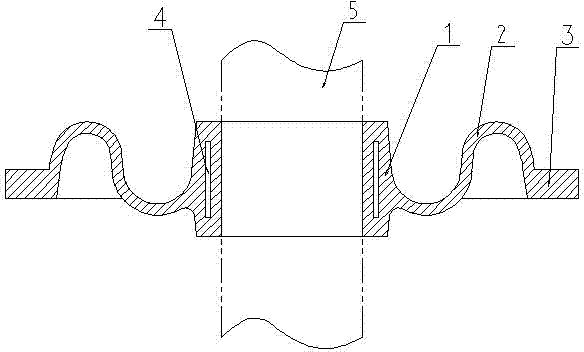

Drill rod hole sealing device for coal mine punching

The invention discloses a drill rod hole sealing device for coal mine punching and relates to a sealing device. The sealing device is composed of a sealing part and a fixing part connected to the periphery of the sealing part, wherein the fixing part is fixedly connected with the periphery of a drill rod hole, the sealing part is made of an elastic material and is of a ripple structure provided with continuous crests and troughs, an annular sealing lip allowing a punching drill rod to penetrate through is arranged on the sealing part, the sealing surface of the sealing lip is matched with the peripheral surface of the punching drill rod, and a supporting frame is arranged inside the sealing lip. The sealing device is used for punching of a coal mine, can seal the drill rod hole and is good in sealing effect.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

Titanium dioxide ceramic material prepared by sol-gel method

ActiveCN113185281AImprove corrosion resistancePlay a role in sealingAnodisationSurgeryRare-earth elementComposite ceramic

The invention relates to a titanium dioxide ceramic material prepared by a sol-gel method. Rare earth elements cerium and yttrium are doped on the surface of titanium dioxide porous ceramic by an ion implantation method. Essentially, ion implantation of rare earth elements can play a role in hole sealing, after ion implantation, a TiO2-Ce-Y composite ceramic material is formed on the surface of titanium dioxide ceramic or a near-surface area, and the corrosion resistance of porous titanium dioxide is improved. It is worthy of noting that the implantation amount of rare earth elements needs to be controlled within a reasonable range, if the implantation amount of the rare earth elements is too large, a Ce-Y film is formed on the surface of titanium dioxide ceramic, and if the implantation amount of the rare earth elements is too small, a proper hole sealing effect cannot be achieved, and the situations are not beneficial to improvement of the corrosion resistance of the porous titanium dioxide ceramic material.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Grouting anchor cable in hole

ActiveCN102704971BAvoid pollutionExpand the scope of diffusionBulkheads/pilesAnchoring boltsRigid coreRock bolt

Owner:济南澳科矿山工程技术有限公司

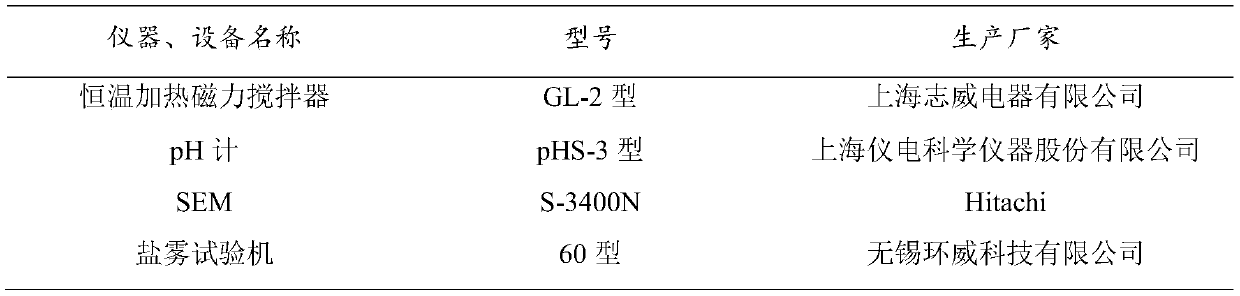

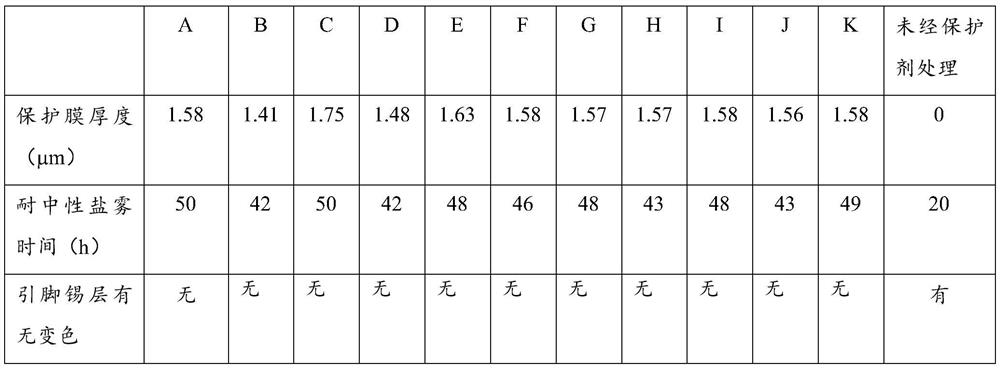

Protective agent for electronic component pin tin coating

ActiveCN110564244APrevent oxidation and discolorationImprove corrosion resistanceAnti-corrosive paintsWater basedAcrylic resin

The invention discloses a protective agent for an electronic component pin tin coating. The protective agent comprises 100-200 g / L of a water-based acrylic resin, 30-50 g / L of silica sol, 5-15 g / L ofzinc gluconate, 5-15 g / L of dimethylethanolamine and 1-2 g / L of benzotriazole. The protective agent can improve the corrosion resistance of the electronic component pin tin coating and prevent oxidation discoloring of the pin tin plating layer of the electronic component pin tin coating.

Owner:DONGGUAN TONGKE ELECTRONICS CO LTD

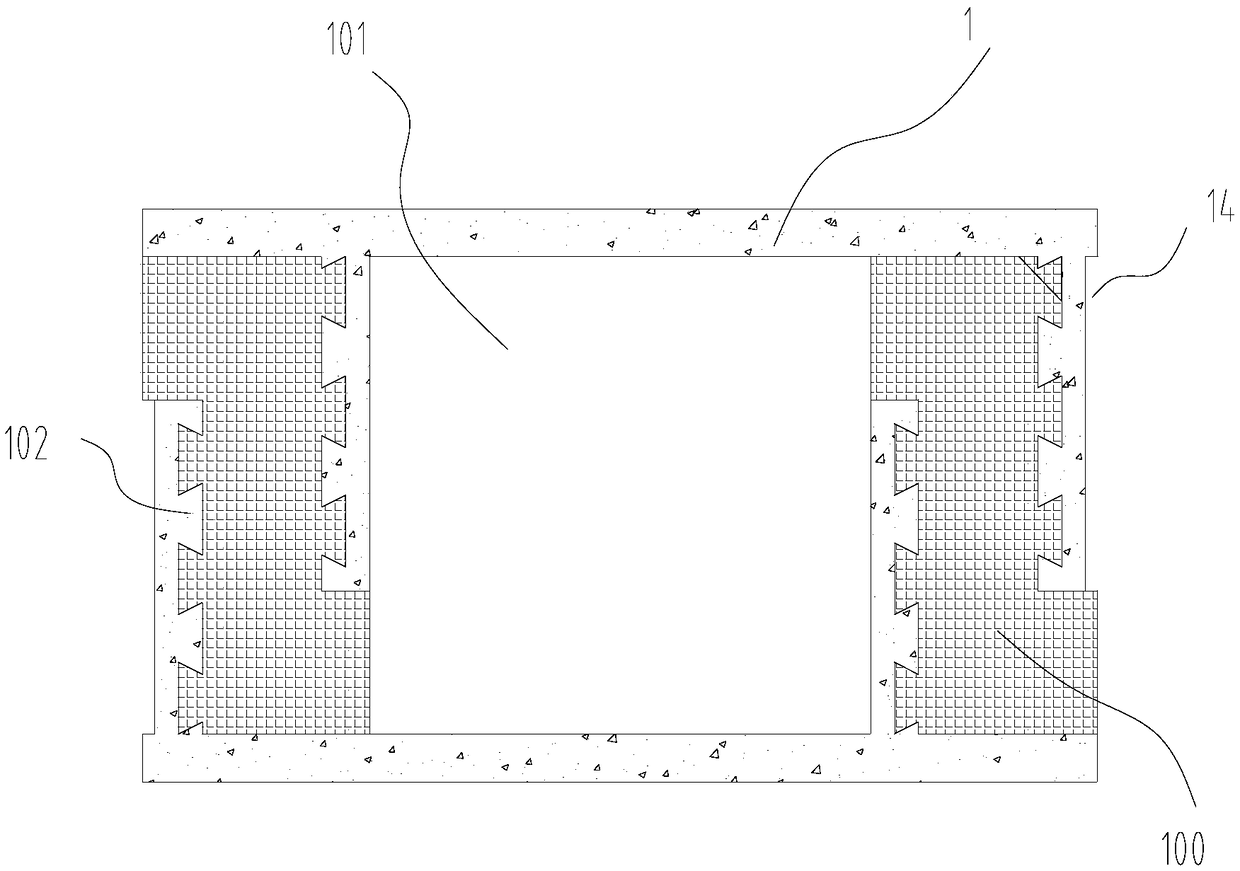

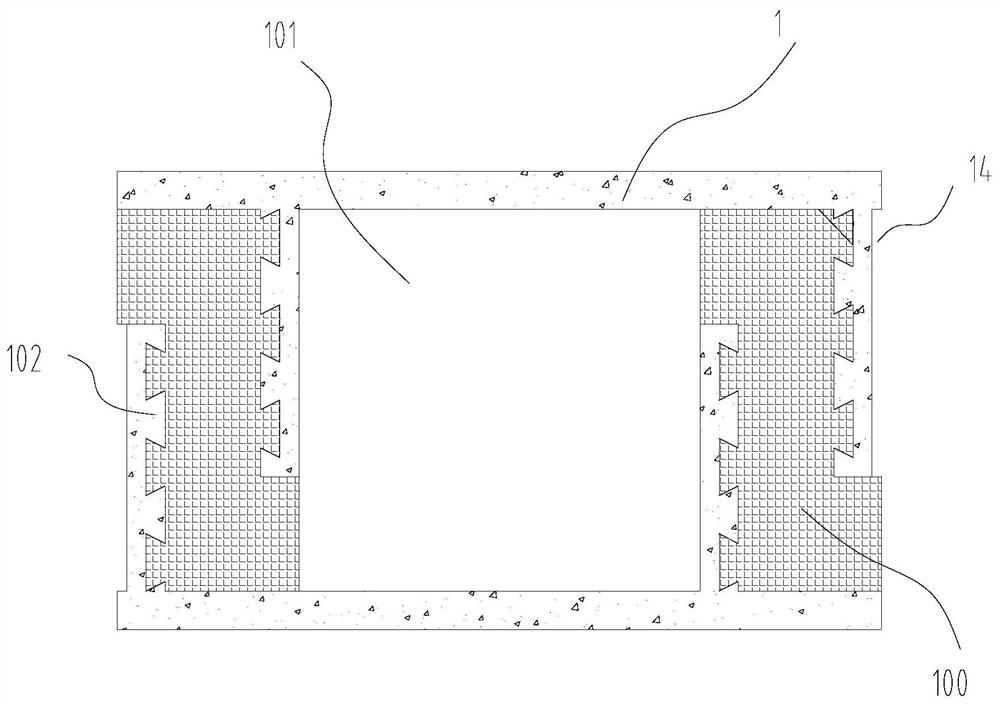

Cinder and concrete compound self-insulating building block and processing method thereof

ActiveCN109403537AForming mold is simplePlay a role in sealingConstruction materialCeramic shaping apparatusMortise and tenonMaterials science

The invention discloses a cinder and concrete compound self-insulating building block and a processing method thereof, and relates to the field of green energy-saving building wall insulating materials, in particular to a compound self-insulating building block prepared from cinders and a processing method thereof. The cinder and concrete compound self-insulating building block and the processingmethod thereof are provided, wherein the cost is saved, the natural lightweight aggregate performance of cinders can be fully optimized, and the mechanical performance and the insulating performance of the self-insulating building block are guaranteed. The cinder and concrete compound self-insulating building block comprises an insulating connection block, and further comprises two cinder bearingsubstrates A and B, wherein the bearing substrate A and the bearing substrate B are integrated into one by the insulating connection block through mortise and tenon joint structures to form the building block; in the building block, cavities are formed. The shape of the bearing substrate A and the bearing substrate B are the same or not the same. According to the cinder and concrete compound self-insulating building block and the processing method thereof, the cinders are fully used, and the performance of the cinder and concrete building block is maximized and optimized.

Owner:CHINA BUILDING MATERIALS ACAD

Protective agent for tin-plated layer of electronic component pins

ActiveCN110564244BPrevent oxidation and discolorationImprove corrosion resistanceAnti-corrosive paintsAcrylic resinTin plating

The invention discloses a protective agent for the tin-plated layer of electronic component pins. The protective agent comprises the following components: water-based acrylic resin, 100-200g / L; silica sol, 30-50g / L; glucose Zinc acid, 5-15g / L; dimethylethanolamine, 5-15g / L; and benzotriazole, 1-2g / L. The beneficial effect of the invention is to improve the corrosion resistance of the tin coating on the pins of the electronic components and prevent the oxidation and discoloration of the tin coating on the pins of the electronic components.

Owner:DONGGUAN TONGKE ELECTRONICS CO LTD

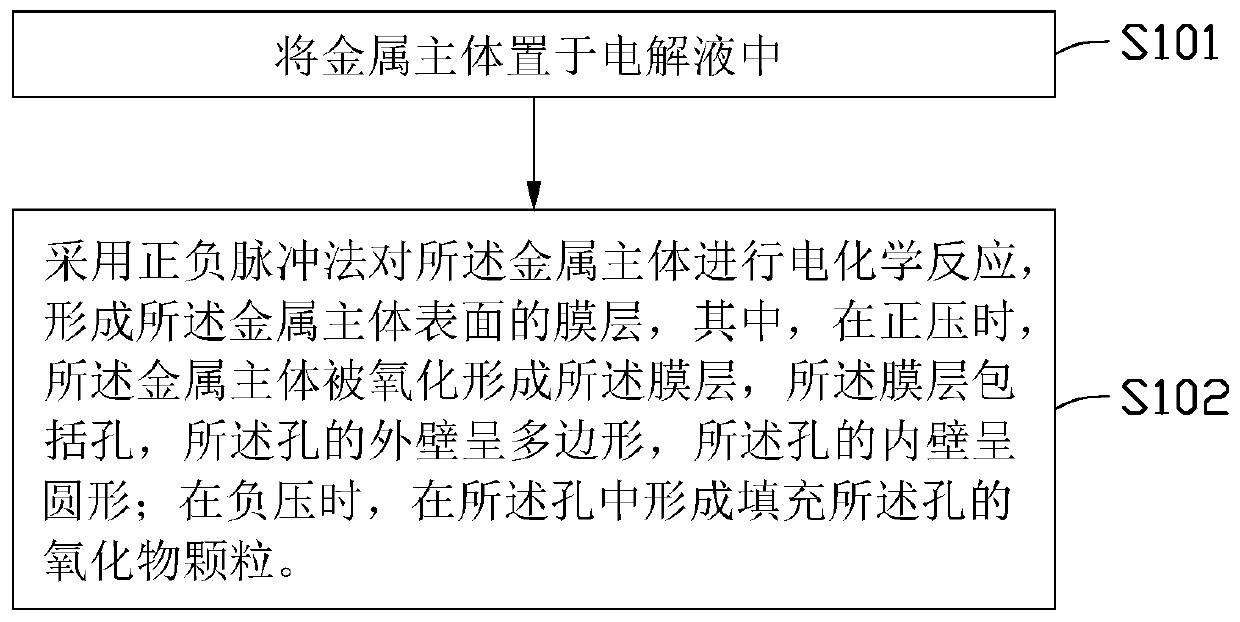

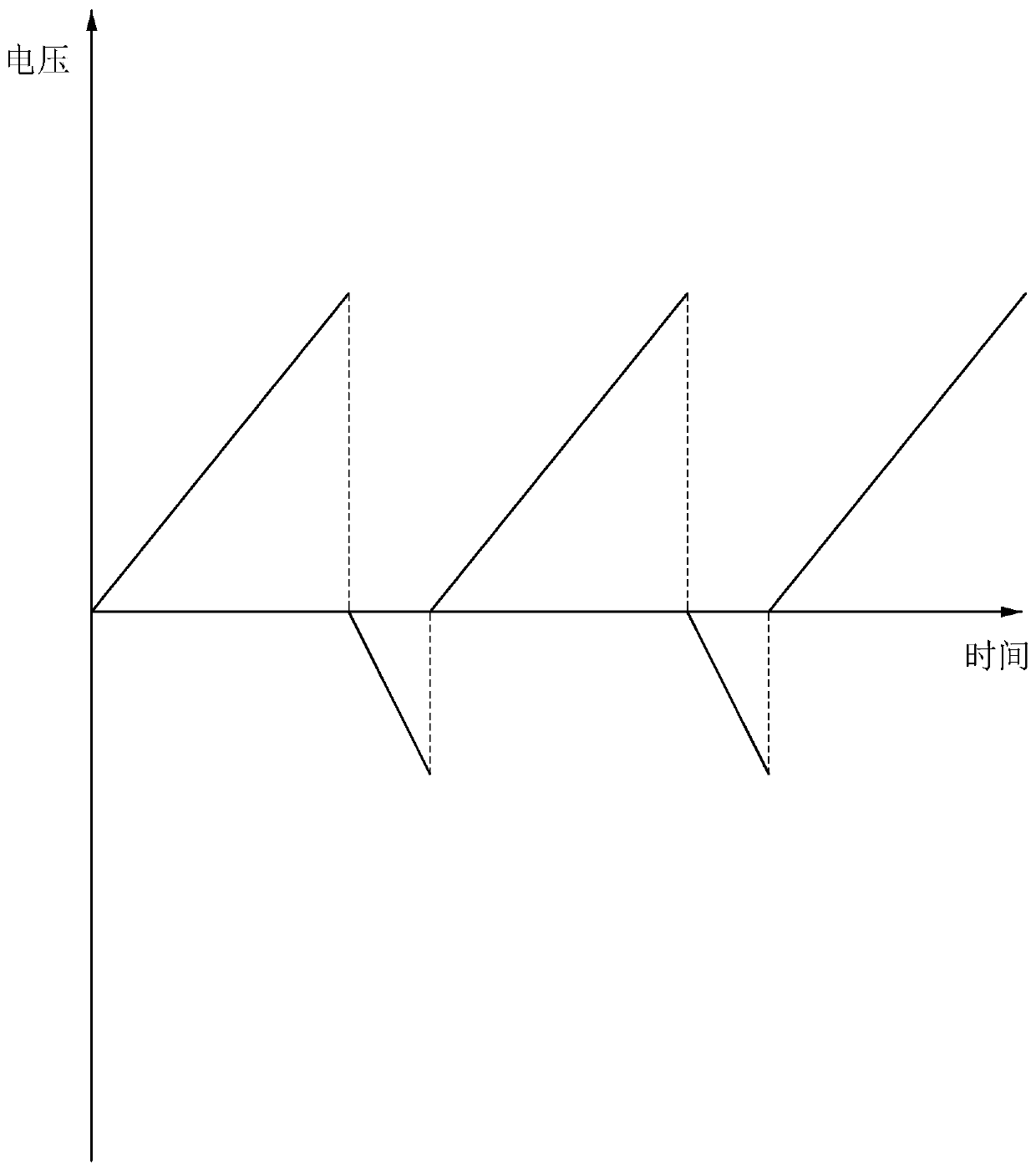

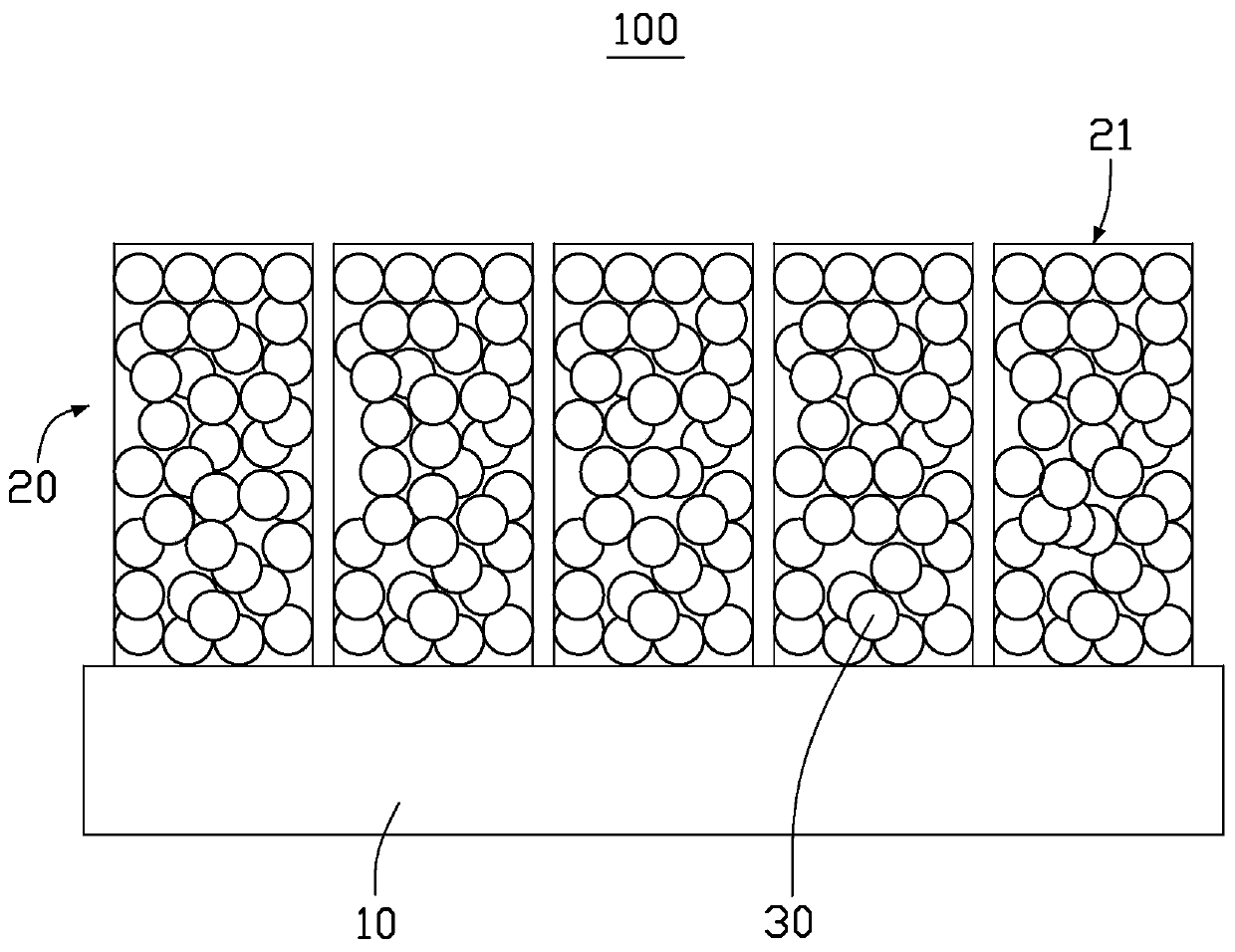

Metal product and preparation method thereof

ActiveCN111172578AImprove corrosion resistancePlay a role in sealingAnodisationElectrochemical responseElectrolytic agent

The invention provides a metal product. The metal product comprises a metal main body and a film layer, wherein the film layer is arranged on the surface of the metal main body, and comprises holes; the outer walls of the hole are polygonal; the inner walls of the holes are circular; and the holes are filled with oxide particles. A preparation method of the metal product comprises the following steps of placing the metal main body in an electrolyte; and electrochemically reacting the metal main body by adopting a positive and negative pulse method to form the film layer on the surface of the metal main body, wherein under positive pressure, the metal main body is oxidized to form the film layer, the film layer comprises the holes, the outer walls of the holes are polygonal, the inner wallsof the holes are circular, and under negative pressure, the oxide particles for filling the holes are arranged in the holes.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

Leak test method for hydrojet containment tools

ActiveCN103185655BUnderstanding Sealing EffectsReduce security risksMeasurement of fluid loss/gain rateSpray nozzleEngineering

The invention discloses a seal test method applicable to a hydraulic jet sealing and separating tool. The seal test method comprises the following steps of: testing pressure of clear water to 50MPa, and stabilizing the pressure for 20minutes; then soaking for 6 hours in diesel oil at the temperature of 120 DEG C, then testing the pressure to 50MPa, testing upper pressure to 50MPa under rated setting pressure, and stabilizing the pressure for 20minutes; mounting three sealing rings at the upper part of a sliding sleeve, pressurizing to 3MPa, checking whether a packer is set or not, if the packer is normally set, continuously pressurizing to 35MPa, and stabilizing the pressure for 5minutes; and mounting four sealing rings on the sliding sleeve, pressurizing to 35MPa, and stabilizing the pressure for 5minutes; and throwing steel balls from the upper end, prying and injecting the steel balls into a pipeline by connecting a pump at the upper end, turning on the pump and building the pressure to 9MPa, so that the sliding sleeve drops and is inserted into a sliding sleeve locating joint at the lower end, a nozzle at the upper end discharges a liquid, a channel at the lower end is plugged, and a liquid flow stops. By adopting the seal test method applicable to the hydraulic jet sealing and separating tool, opening and sealing of the packer and a jet tool can be visually reflected, and the sealing effect of jetting a sealing and separating tool is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Titanium dioxide ceramic material prepared by a sol-gel method

ActiveCN113185281BImprove corrosion resistancePlay a role in sealingAnodisationSurgeryRare-earth elementComposite ceramic

A titanium dioxide ceramic material prepared by a sol-gel method, and rare earth elements cerium and yttrium are doped on the surface of titanium dioxide porous ceramics by an ion implantation method. In essence, ion implantation of rare earth elements can play a role in sealing pores. After ion implantation, TiO is formed on the surface or near-surface area of titania ceramics. 2 ‑Ce‑Y composite ceramic material with improved corrosion resistance of porous titanium dioxide. It is worth noting that the injection amount of rare earth elements needs to be controlled within a reasonable range. If the injection amount of rare earth elements is too large, a Ce-Y film will be formed on the surface of the titania ceramic. Pore effect, which is not conducive to the improvement of the corrosion resistance of porous titanium dioxide ceramic materials.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Ground Simulation Method for Isolation Jet Tool Applicable to Multi-Stage Hydraulic Jet Fracturing

ActiveCN103184867BReduce security risksReduce tool changeConstructionsFluid removalHydraulic fracturingSteel ball

The invention discloses a jet packer ground simulation method applicable to multilevel hydraulic jet fracturing. The method comprises the following steps: a, connecting in series jet packers of corresponding amount and other required tools on a construction test string according to the required designed level amount of an oil well and a gas well, placing a steel ball in an inlet of the construction test string, and connecting a high-pressure pipeline; b, gradually increasing the discharge capacity, if a sliding sleeve is hit off by the steel ball and pushed to pass through a central pipe of the packer continually and enter a sliding sleeve standing joint connected onto the lower part of the packer, and a water hole of a spray gun normally jets water, performing next-level test for the jet packer; c, if the sliding sleeve is not hit off by the steel ball, checking the mounting position of the sliding sleeve and the gap between the sliding sleeve and the spray gun, checking the position of a shear pin, and performing the test and detection in step b; and repeating steps a, b and c until completing all set tests. With adoption of the method, opening of all packers and jet tools, and jet of the spray gun can be observed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

A kind of cadmium arsenic contaminated soil remediation agent

ActiveCN110669524BImprove adsorption capacityAvoid remeltingAgriculture tools and machinesContaminated soil reclamationMolten stateArsenic pollution

The invention belongs to the technical field of soil remediation agents, and specifically relates to a cadmium-arsenic contaminated soil remediation agent, which is obtained by mixing manganese slag and goethite slag until passing through a 200-mesh sieve to obtain a mixed powder; calcining the mixed powder until it is melted State, after adding 15-20% surfactant of mixed powder and heat preservation treatment for 20-30min, cool to normal temperature, and get final product through flash explosion treatment and passivation treatment; the restoration agent of the present invention is effective for the soil polluted by cadmium and arsenic Restoration, but also has the function of inhibiting harmful microorganisms, and also prevents heavy metals from re-dissolving. Use goethite and manganese slag as solidifying agents for cadmium and arsenic to reduce ion mobility and resolvation, and improve solidification. By adding surfactants in the molten state, the specific surface area is increased and the resistance to cadmium and arsenic in the soil is increased. The adsorption capacity enables cadmium and arsenic in the soil to enter the lattice.

Owner:铜仁市万山区植保植检站

A kind of volcanic slag concrete composite self-insulation block

ActiveCN109403537BForming mold is simplePlay a role in sealingConstruction materialCeramic shaping apparatusPozzolanaArchitectural engineering

The invention discloses a cinder and concrete compound self-insulating building block and a processing method thereof, and relates to the field of green energy-saving building wall insulating materials, in particular to a compound self-insulating building block prepared from cinders and a processing method thereof. The cinder and concrete compound self-insulating building block and the processingmethod thereof are provided, wherein the cost is saved, the natural lightweight aggregate performance of cinders can be fully optimized, and the mechanical performance and the insulating performance of the self-insulating building block are guaranteed. The cinder and concrete compound self-insulating building block comprises an insulating connection block, and further comprises two cinder bearingsubstrates A and B, wherein the bearing substrate A and the bearing substrate B are integrated into one by the insulating connection block through mortise and tenon joint structures to form the building block; in the building block, cavities are formed. The shape of the bearing substrate A and the bearing substrate B are the same or not the same. According to the cinder and concrete compound self-insulating building block and the processing method thereof, the cinders are fully used, and the performance of the cinder and concrete building block is maximized and optimized.

Owner:CHINA BUILDING MATERIALS ACAD

A kind of preparation method of non-ferrous alloy anticorrosion layer

ActiveCN111041538BHigh bonding strengthEnhance coverage and wettabilityAnodisationLiquid/solution decomposition chemical coatingAlloySol-gel

The invention provides a preparation method of a nonferrous alloy anti-corrosion layer. The preparation method comprises the following steps of raw material proportioning of a sol-gel solution, sol preparing, preparing of the sol-gel solution, film layer dipping and film layer drying. According to the method, sol-gel solution hole sealing is carried out on the porous microarc oxidization film, aneven film layer is obtained, surface clearances are reduced, binding force and smoothness are better, the coverage rate of a ceramic layer after nonferrous alloy oxidization is improved, the functionof hole sealing is achieved, the anti-friction function is also achieved, and the defects of surface needle holes, cracks and the like are overcome.

Owner:八龙应用材料科技(海南)有限公司

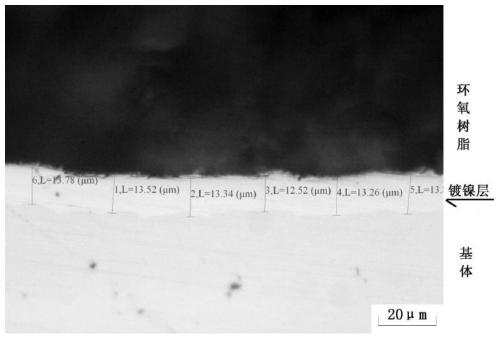

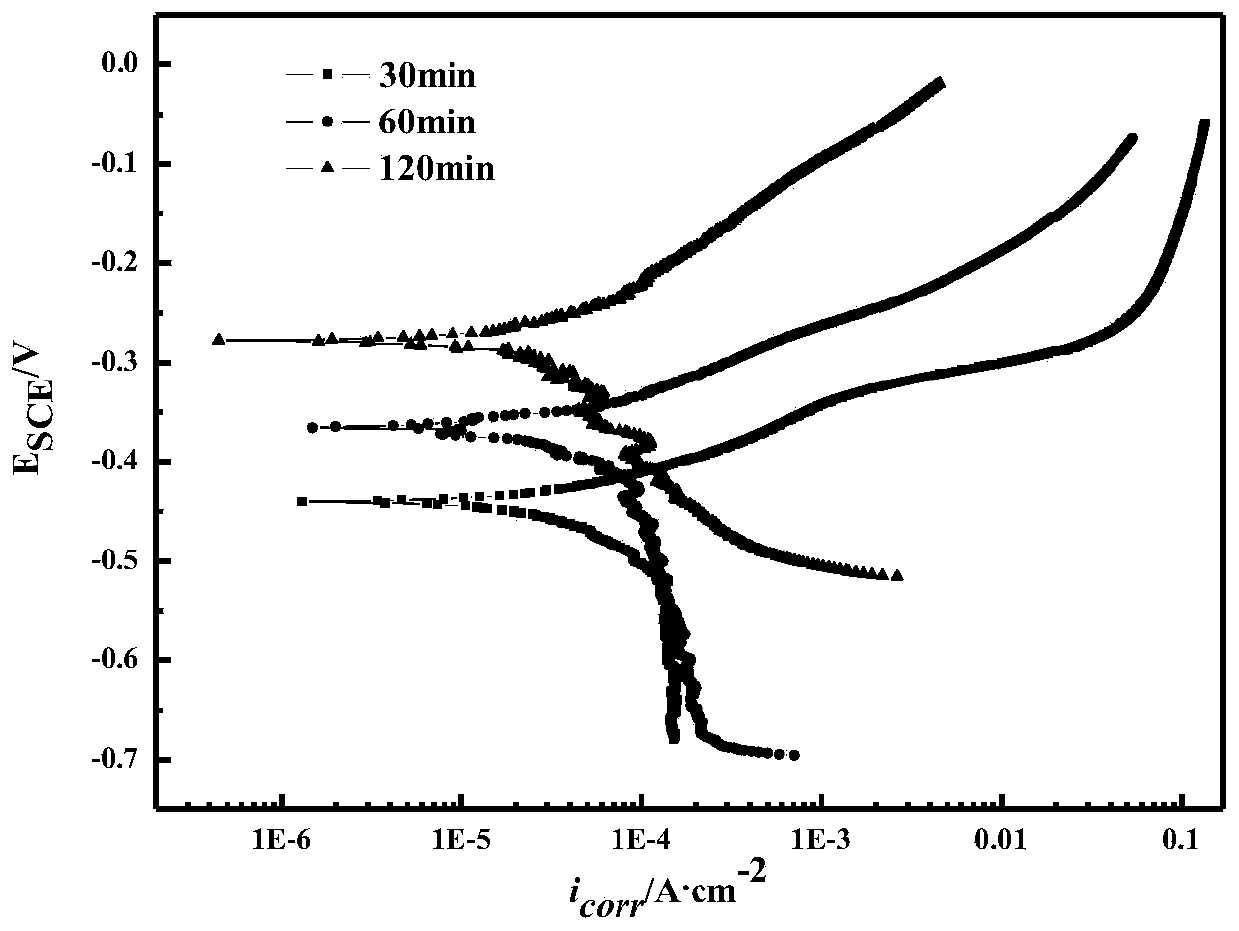

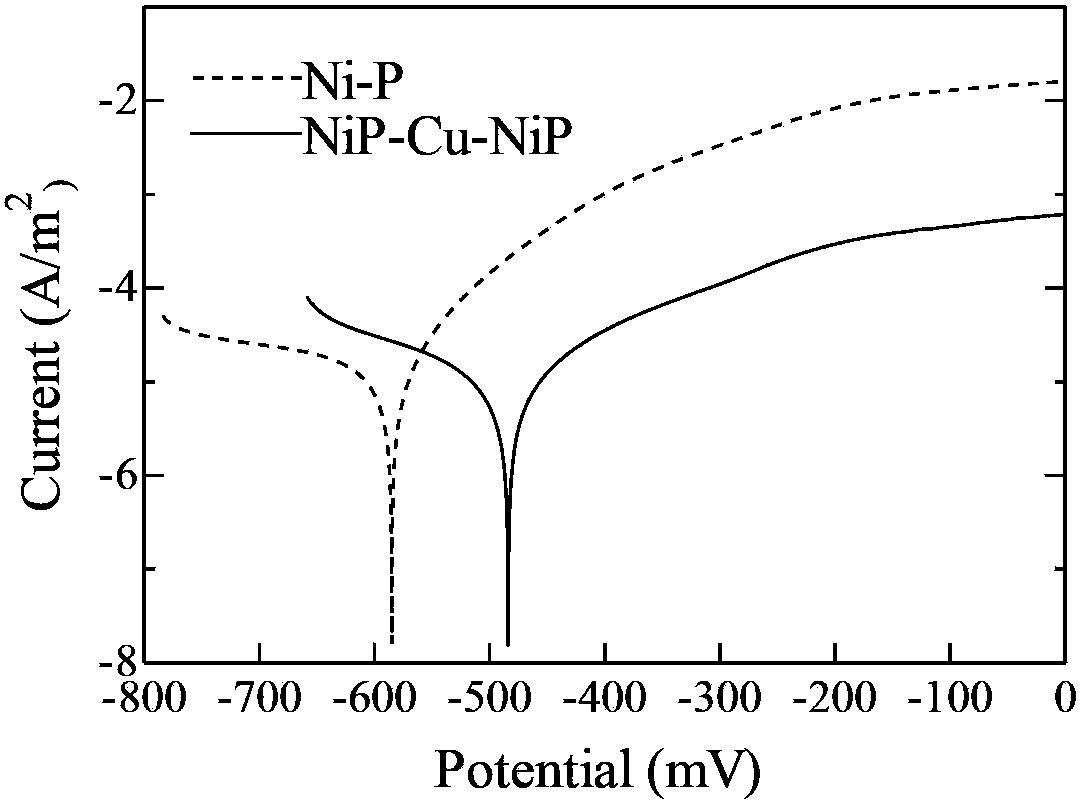

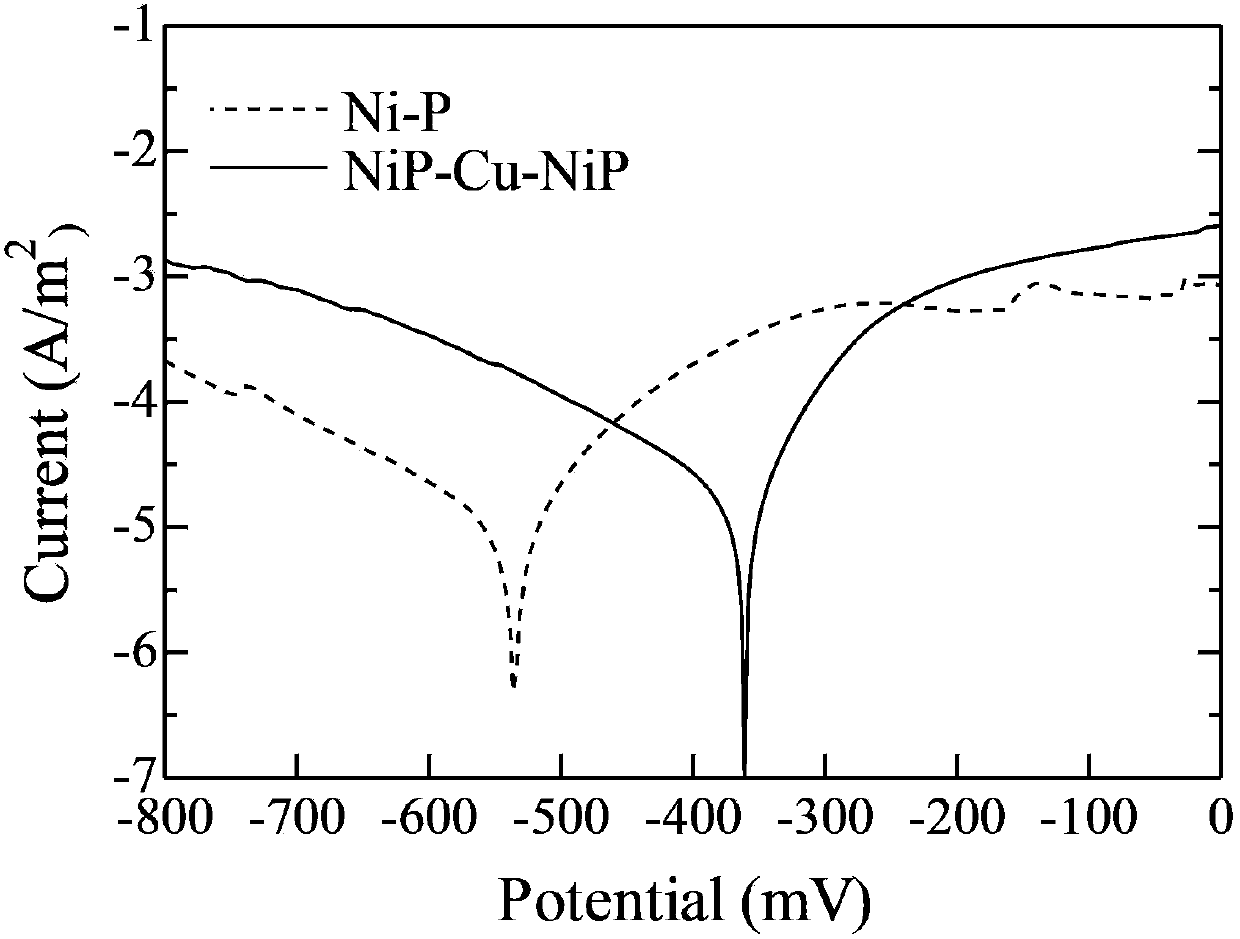

Method for improving corrosion resistance of nickel-phosphorus chemical coating

InactiveCN102899642BReduce bond strengthGuaranteed bonding strengthLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to a method for improving corrosion resistance of a nickel-phosphorus chemical coating. The method comprises the following steps: plating a thin layer of nickel and phosphorus on the surface of a carbon steel substrate, and plating a layer of copper using a chemical exchange method; and then plating a layer of nickel and phosphorus. According to the invention, chemical copper plating is adopted for sealing holes and improving corrosion potential; in the process of the primary nickel and phosphorus plating, nickel and phosphorus are plated on most of the carbon steel substrate, so that the possibility that lower bonding strength of the coating is caused by reaction between copper and iron in a large amount during the secondary copper plating step is reduced, thereby ensuring the bonding strength of the coating. The method is suitable for occasions that the corrosion resistance of the coating is reduced due to small thickness and high porosity of the coating. By using the method, the corrosion resistance effect can be greatly improved under the condition that the thin coating is obtained.

Owner:SHANDONG UNIV

Reverse gravel throwing device

PendingCN113638712ATo flowPlay a role in sealingFluid removalSealing/packingClassical mechanicsUranium mine

The invention discloses a reverse gravel throwing device, and relates to the technical field of uranium mine development corollary equipment. The problems of insufficient gravel throwing filling and great loss caused by prone collapse in the later stage due to the fact that gravel materials are prone to floating out of a shaft are solved. The reverse gravel throwing device comprises an upper cone, a slip cylinder and a screen pipe; the lower end of a locking ring sleeve, a rubber sleeve and a rubber sleeve pressing ring sleeve the outer side of a rubber sleeve lining; the upper end of the upper cone is in threaded connection with the outer side of the lower end of the rubber sleeve lining; the screen pipe is fixedly connected with the lower end of a connector and the upper end of a lower connector through welding; the outer side of the lower end of the lower connector is in threaded connection with the inner side of the upper end of a sealing seat; the outer side of the lower end of the sealing seat is in threaded connection with the inner side of the upper end of a circulating sleeve; and a group of hinge switches are arranged at the lower end of the sealing seat. The reverse gravel throwing device is stable in performance, gravel materials cannot be circularly brought out of a shaft in the gravel throwing process, all the thrown gravel materials are thrown to a production layer and cannot return to the shaft after well completion, and huge loss is effectively avoided.

Owner:阜宁县宏达石化机械有限公司

Health-preserving hot and spicy sauce baked by traditional process

PendingCN111000214ARaw materials are easy to getDeliciousFood preservationFood ingredient functionsBiotechnologyPork meat

The invention relates to a health-preserving hot and spicy sauce baked by a traditional process, wherein the hot and spicy sauce with characteristics of delicious taste, good mouth feel, rich nutrition and long shelf life is finally prepared by baking raw materials of peanuts, black beans, wheat, corn, Yangjiang fermented soya beans, chili powder, beef, pork, chicken, shrimp meat, seasonings and blend oil according to a proper weight ratio through a traditional process. According to the invention, the health-preserving hot and spicy sauce baked by the traditional process is free of preservatives, so that the safety of the product is ensured, and the shelf life is as long as 12 months; the method is suitable for various cooking and wide in application range; the health-preserving hot and spicy sauce baked by the traditional process can effectively strengthen spleen and stomach, expel wind-damp, help digestion and improve appetite, and is deeply loved by consumers; and the method has characteristics of easily available raw materials, simpleness and short production period, is suitable for home-made, and is further suitable for large-scale mass production.

Owner:杨烈国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com