Grouting and Grouting-stopping anchor cable inside hole

A technology for grouting anchor cables and grouting, which is applied in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve problems such as impossible to be very strict, and achieve the effect of improving the effect, avoiding the leakage of grouting, and achieving high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

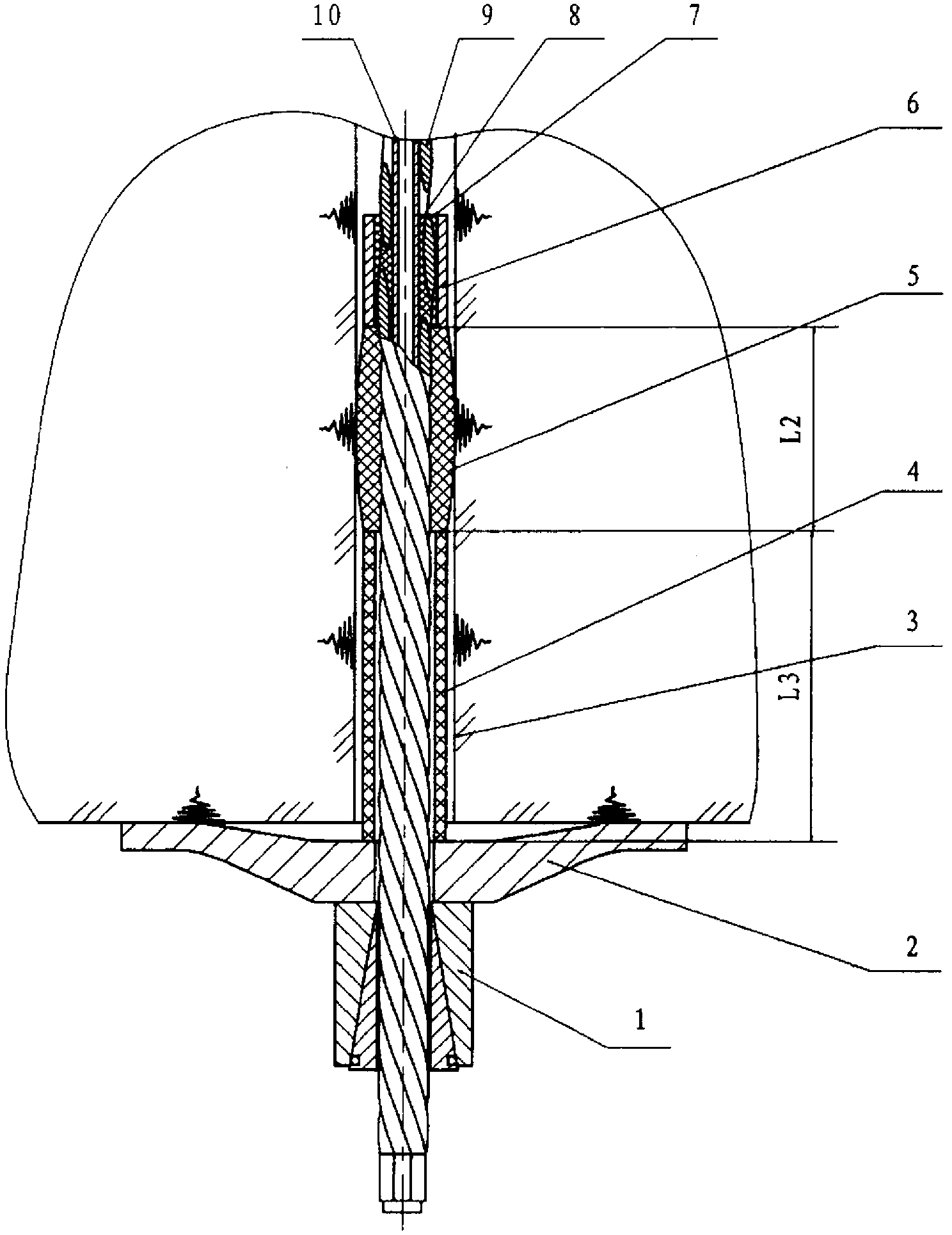

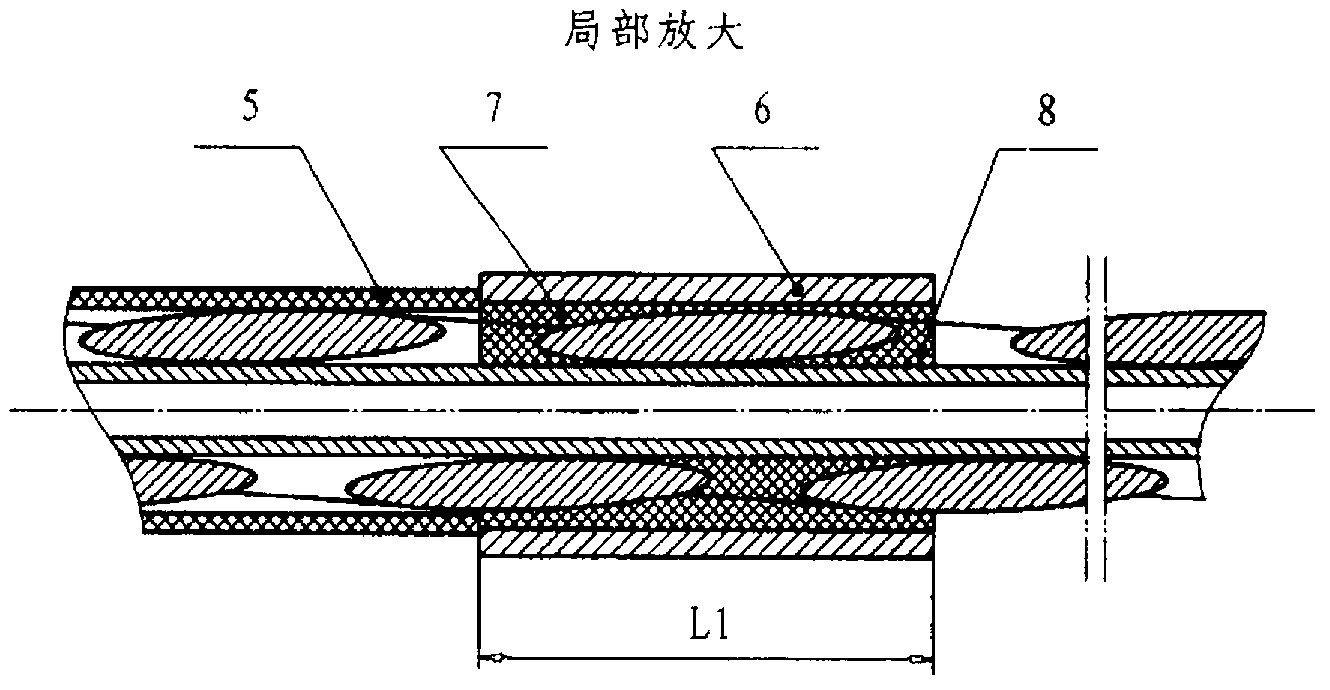

[0015] exist figure 1 , 2 The structure of the grouting anchor cable in the hole of the present invention is shown in . The grouting anchor cable is composed of a hollow anchor cable body 9, an anchor cable anchorage 1, a tray 2, a grout stop component in a hole, a rigid core pipe 10, and the like. The anti-slurry assembly in the hole is composed of an inner casing 8, an outer casing 7, a tight hoop metal pipe 6, an elastic casing 5 and a hard casing 4.

[0016] The hard casing 4, the elastic casing 5, and the outer casing 7 are connected end-to-end from bottom to top and are sequentially sleeved on the hollow anchor cable body 9. The lower end of the hard casing 4 is pushed against the top of the tray 2 . Tightening metal tube 6, inner casing 8 and outer casing 7 have the same length, and are located on the same position of the anchor cable body; tightening metal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com