A kind of volcanic slag concrete composite self-insulation block

A technology of self-insulating blocks and volcanic slag, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of leakage of insulation materials, affecting insulation performance and compressive strength, etc., to improve insulation performance and molding quality Easy to control, simple mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

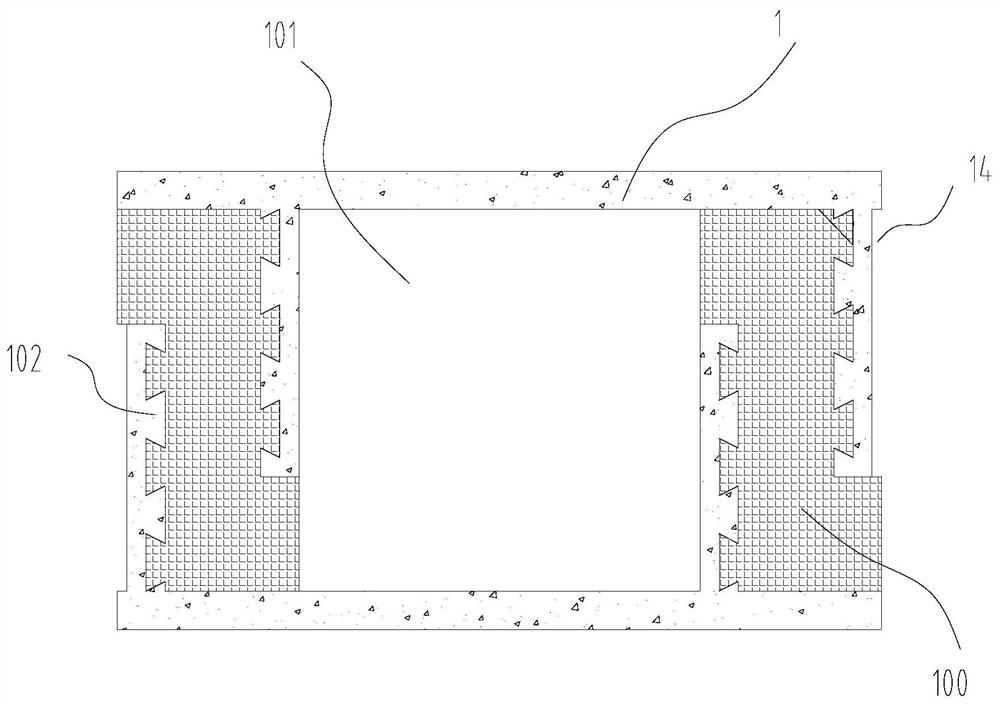

[0056] Embodiment Figure 1-1 ~ 1-9 Distance

[0057] Both the same shape of the load base A and the load bearing substrate B have a facade 10, a side face 11, and a side face two 12; side faces 11 and the side face two 12 relative to the facade bias 1, so that three The F-shaped substrate 1 is formed; the side faces 11 and the side face two 12 are provided with a dovetail groove 13 for 卯, in the surface of the F-shaped side; in the side face two 12 toward the roof top The surface is sinking, forming a belt storage surface 14;

[0058] The load bearing substrate A and the load base B (actually the F-shaped substrate 1 consistent with two shapes) are relatively placed, so that the respective side faces 11 and the side faces 2 12 are in the interleaved position; the insulation connection block 101 has two pieces. Each insulation connection block 101 is provided between the rendering base A and the dovetail groove 13 on the load base B, so that the two insulation connecting blocks 10...

Embodiment 2

[0060] Example two Figure 2-1 ~ 2-4 Distance

[0061] The structure of the load base A and the load base B is all U-shaped, the U-shaped substrate 2 has a plate-shaped vertical sheet, and the same side face 22 in the two shapes of the plate-shaped vertical sheet; the end of the two side faces 22 The head is provided with a tank 23, respectively, and a masonry material receiving groove 24 is provided on the outer surface of the two side faces 22.

[0062] The load bearing substrate A and the load base B relative to the gap, the insulation connection block 201 has two pieces, and the two ends of the insulation connection block 201 are provided with a mortuary that matches the side face 22 end. ,

[0063] The cavity 200 retains between the load base A and the load base B.

[0064] Example 2 Optimization Technical Measures in a pair of load-bearing matrix docking strength: at least one auxiliary connection groove 21 is provided on the U-shaped bottom surface of the load base A and th...

Embodiment 3

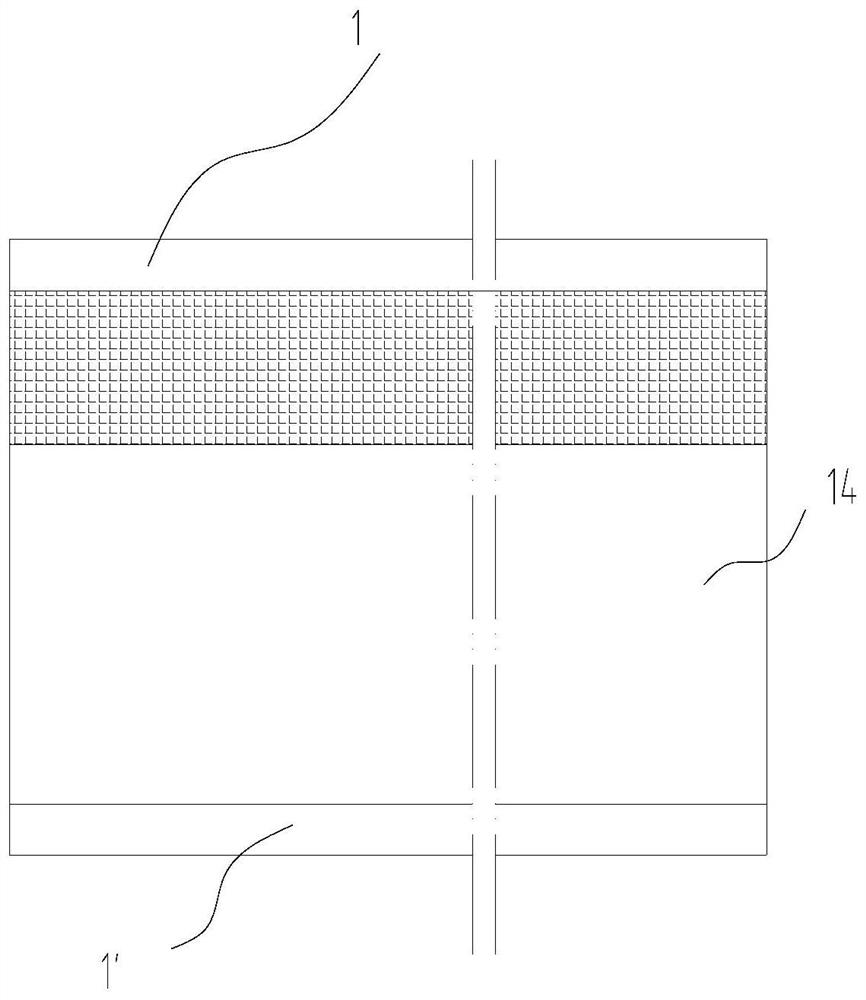

[0067] Example three Figure 3-1 ~ 3-4 Distance

[0068] The load bearing substrate A (hereinafter referred to as frame-shaped substrate 3) is formed in a frame, and the load bearing substrate B (hereinafter referred to as a word type substrate 30) is shown; with the top of the frame base 3 and the top of the one-character substrate 30 Yu 榫 卯 槽; the frame matrix 3 and the one-shaped substrate 30 are disposed opposite, and there is a heat-insulation connection block 301 having a dovetail groove 33 between the two sides, and the three are connected; on one side of the load bearing substrate A. There is a masonry material receiving groove 34, and at least one cavity 300 is provided in the internal height direction of the frame matrix 3.

[0069] One side surface of the load base A (frame matrix 3) is provided with an inner seam 31, and the other side is provided with an socket strip 32. When using, several blocks are placed, the first block is connected, and the front block of the blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com