Coiled rectangular pole group

A winding and rectangular technology, which is applied in the fields of winding pole groups, lead-acid battery pole groups, and winding rectangular pole groups, can solve the problems of low battery space utilization and achieve high manufacturing efficiency and forming molds. Simple, consistent quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

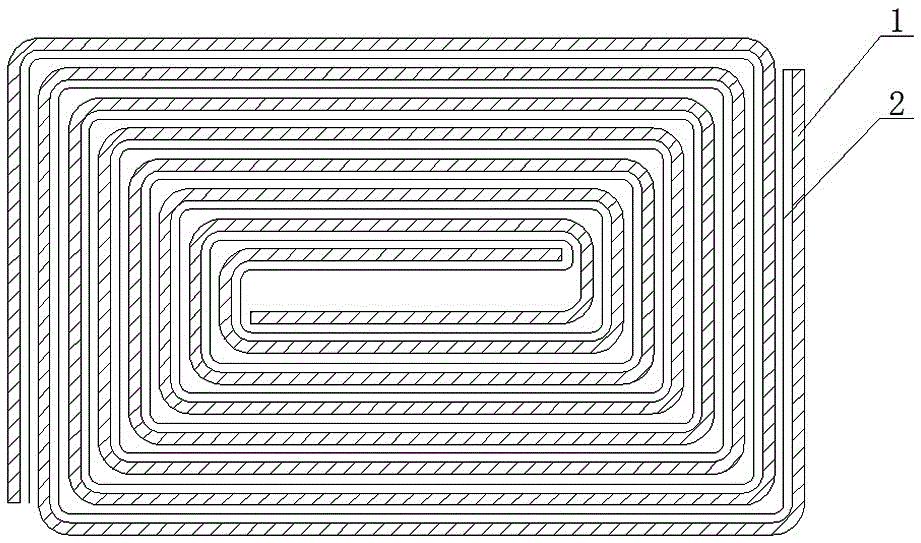

[0014] figure 1 The shown coiled rectangular pole group has different length and width sides, and its cross-sectional shape is a rectangle. The positive electrode plate 1 and the negative electrode plate 2 used in the electrode group are cut into strips of equal length and width. During production, the positive electrode plate 1 and the negative electrode plate 2 are aligned and stacked together, and wound in a counterclockwise direction along with a predetermined forming die. Under the premise that the sizes of the positive plate 1 and the negative plate 2 are determined, the number of winding layers depends on the capacity of the supporting battery. In this embodiment, the cross-sectional shape of the coiled pole group is a unequal-sided rectangle, and such a rectangular pole group is easy to fit closely with a rectangular battery case, thereby achieving the purpose of making full use of the internal space.

Embodiment 2

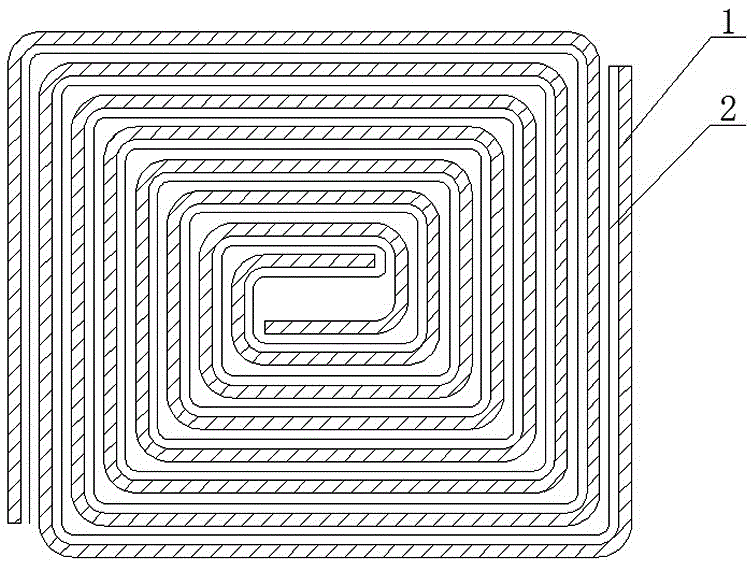

[0016] figure 2 The long and wide sides of the coiled rectangular pole group shown are equal in size, and its cross-sectional shape is a square. Except that the aspect ratio of the pole group is different from that of Embodiment 1, the other structural features are the same, and the effect of the applied technology is also the same, so the description will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com