Digitalized preparation method of titanium mesh cranial prosthesis

A technology for prosthetics and skulls, which is applied in the fields of electrical digital data processing, bone implants, and special data processing applications. The effect of high precision and easy processing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

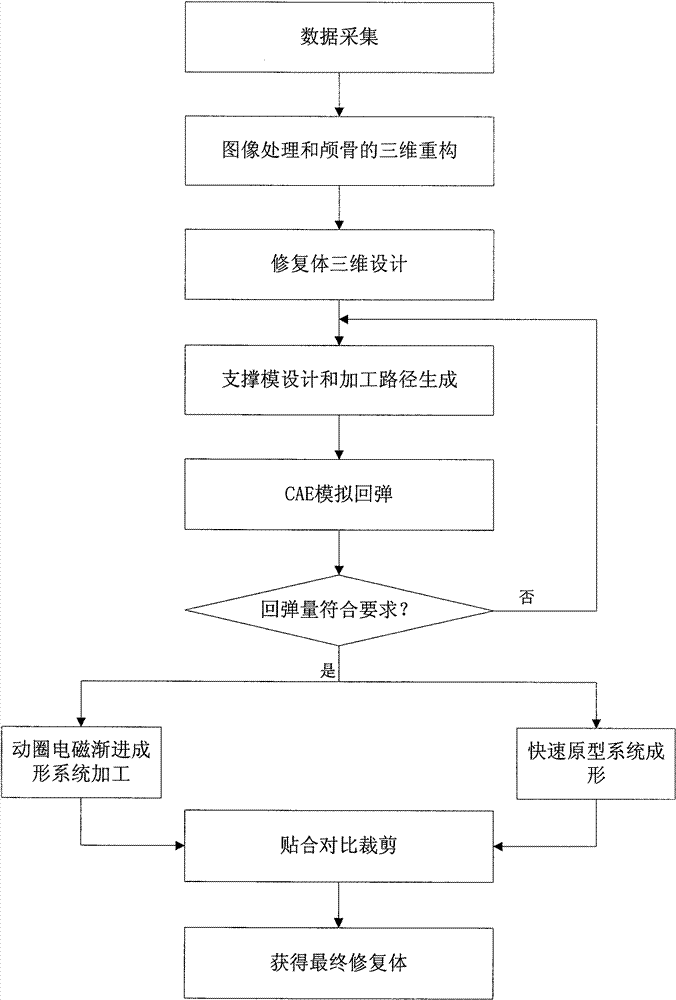

Method used

Image

Examples

Embodiment

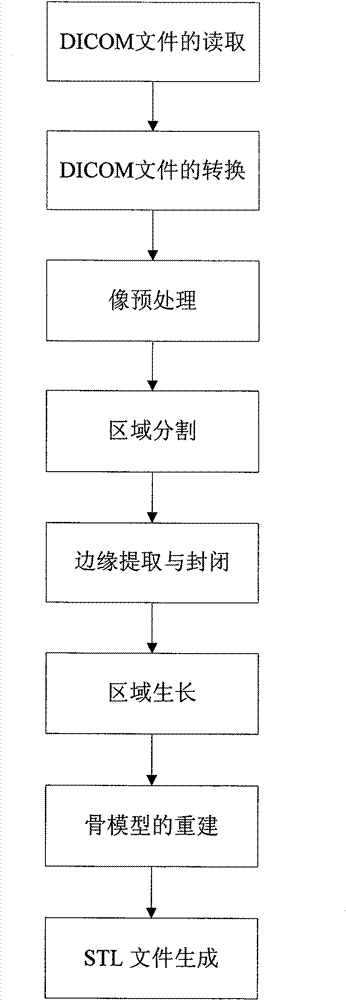

[0066] The CT scan in this example uses GEHGH SPEED 16-row CT machine to collect CT data of the head part of the human body. The head scan adopts 5mm layer thickness (1-1.5mm should be used for specific applications, 1mm for complex curved surface area, and 1.5mm for gentle curved surface area), 150KV, 160m As, and finally scanned about 32 layers of data; after scanning The data is transmitted from the CT host to the imaging workstation through the DICOM interface, and then it is carved into a CD in DICOM format for the next step. Use MIMICS to input multiple images in standard DICOM format at one time, and then recognize and convert them into internal common formats for processing, and then preprocess the images to remove noise. Set a threshold value T=800, divide the bone and soft tissue into bright and dark categories, realize the binary segmentation of the image, and extract the bone part. Select the required bone area at a certain level as the seed area, then click the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com