Seal test method applicable to hydraulic jet sealing and separating tool

A technology of hydraulic jetting and sealing test, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the fluid's acceleration and deceleration rate. problems such as large, prolonged construction period, etc., to achieve the effect of easier operation of sealing test, reduction of tripping and changing of tools, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

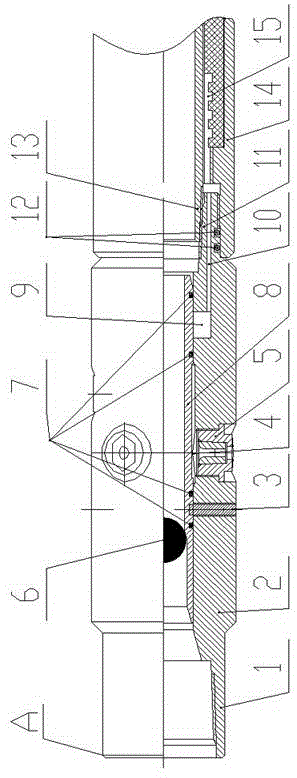

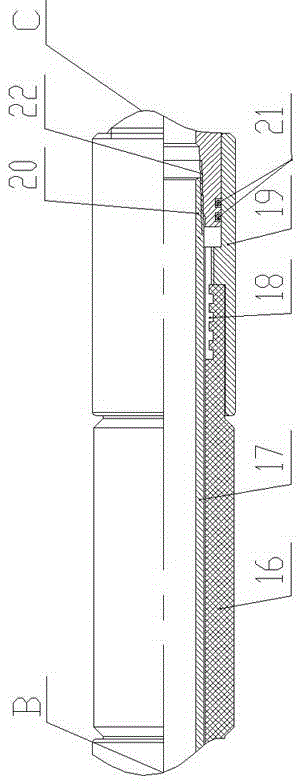

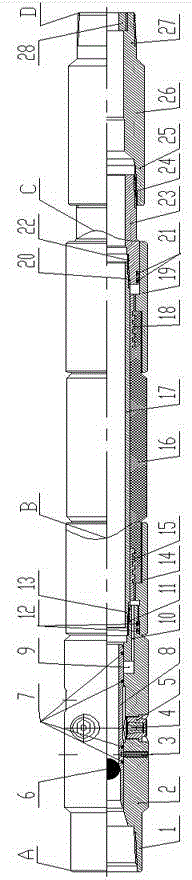

Image

Examples

Embodiment 1

[0044] A sealing test method suitable for hydrojet sealing tools, comprising the following steps:

[0045] Step 1: Test the pressure with clean water to 50MPa, stabilize the pressure for 20 minutes, no leakage, no pressure drop, it is qualified;

[0046] Step 2: After immersing in diesel oil at 120°C for 6 hours, test the pressure at 50MPa, test the upper pressure at 50MPa under the rated setting pressure, and stabilize the pressure for 20 minutes. If there is no leakage and no pressure drop, it is qualified;

[0047] Step 3: Then install only the upper three sealing rings on the sliding sleeve, install them into the spray gun body, pressurize 3MPa, check whether the packer is set, if it is normally set, continue to pressurize to 35MPa, and stabilize the pressure for 5 minutes , no leakage is qualified;

[0048] Step 4: Install all four sealing rings on the sliding sleeve, install them into the spray gun body again, pressurize at 35MPa, stabilize the pressure for 5 minutes, n...

Embodiment 2

[0052] A sealing test method suitable for hydrojet sealing tools, comprising the following steps:

[0053] a. First test the pressure with clean water to 40MPa, and stabilize the pressure for 10 minutes;

[0054] b. After immersing in diesel oil at 100℃ for 7 hours, test the pressure to 40MPa, test the upper pressure to 50MPa under the rated setting pressure, and stabilize the pressure for 10min;

[0055] c. Install the upper three sealing rings on the sliding sleeve, then install the sliding sleeve into the spray gun body, pressurize at 5MPa, check whether the packer is set, if it is normally set, continue to pressurize to 40MPa, and stabilize the pressure for 7 minutes ;

[0056] d. Install four sealing rings on the sliding sleeve, install the sliding sleeve into the spray gun body again, pressurize 40MPa, and stabilize the pressure for 7 minutes;

[0057] e. Put steel balls from the upper end of the hydraulic jet sealing tool, and then connect the pump to pry the injectio...

Embodiment 3

[0060] A sealing test method suitable for hydrojet sealing tools, comprising the following steps:

[0061] a. First test the pressure with clean water to 45MPa, and stabilize the pressure for 15 minutes;

[0062] b. After immersing in diesel oil at 110°C for 4 hours, test the pressure at 45MPa, test the upper pressure at 50MPa under the rated setting pressure, and stabilize the pressure for 10-20min;

[0063] c. Install the upper three sealing rings on the sliding sleeve, then install the sliding sleeve into the spray gun body, pressurize at 2MPa, check whether the packer is set, if it is normally set, continue to pressurize to 30MPa, and stabilize the pressure for 4min ;

[0064] d. Install four sealing rings on the sliding sleeve, install the sliding sleeve into the spray gun body again, pressurize 30MPa, and stabilize the pressure for 4 minutes;

[0065] e. Put steel balls from the upper end of the hydraulic jet sealing tool, and then connect the pump to pry the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com