Ground Simulation Method for Isolation Jet Tool Applicable to Multi-Stage Hydraulic Jet Fracturing

A technology of hydraulic jetting and ground simulation, applied in the directions of sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve the problems of increasing labor intensity, prolonging construction period, increasing the number of tool replacements, etc., and reducing replacement The number of tools, the reduction of well control safety risks, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

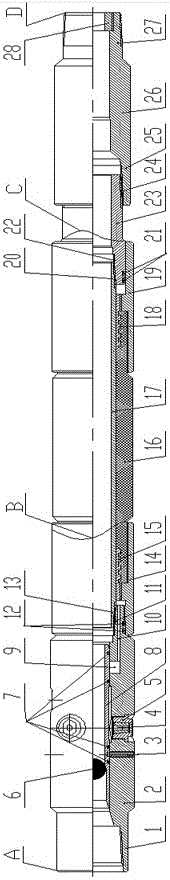

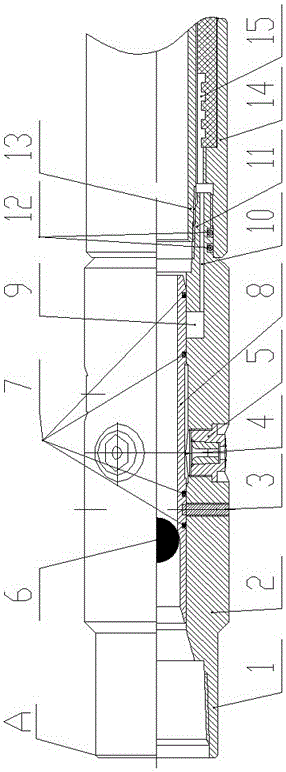

[0050] The purpose of this invention is to detect whether the packer and injection tool can run smoothly, that is, under the set pressure, whether the steel ball can be successfully knocked out of the sliding sleeve, and whether the steel ball will push the sliding sleeve after the sliding sleeve is knocked out. The sliding sleeve continues to pass through the center pipe of the packer and smoothly enters the seating joint connected under the packer. After the sliding sleeve leaves the spray gun, can the water eye of the spray gun spray water? After the steel ball reaches the seating joint, whether the water eye of the spray gun continues to spray water normally? , while the water outlet at the connector port stops. In order to achieve this purpose, the tools for connecting the pipe strings on the ground simulation test include: according to the design needs to implement the stages of hydraulic jet fracturing, set the wellhead as the upward direction, each stage needs to connec...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, the main difference is:

[0063] Before the ground simulation, the sealing test is carried out on the isolation injection tool, and the sealing test specifically includes the following steps:

[0064] Step 1: Test the pressure with clean water to 50MPa, stabilize the pressure for 20 minutes, no leakage, no pressure drop, it is qualified;

[0065] Step 2: After immersing in diesel oil at 120°C for 6 hours, test the pressure at 50MPa, test the upper pressure at 50MPa under the rated setting pressure, and stabilize the pressure for 20 minutes. If there is no leakage and no pressure drop, it is qualified;

[0066] Step 3: Then install only the upper three sealing rings on the sliding sleeve, install them into the spray gun body, pressurize 3MPa, check whether the packer is set, if it is normally set, continue to pressurize to 35MPa, and stabilize the pressure for 5 minutes , no leakage is qualified;

[0067] Step 4: I...

Embodiment 3

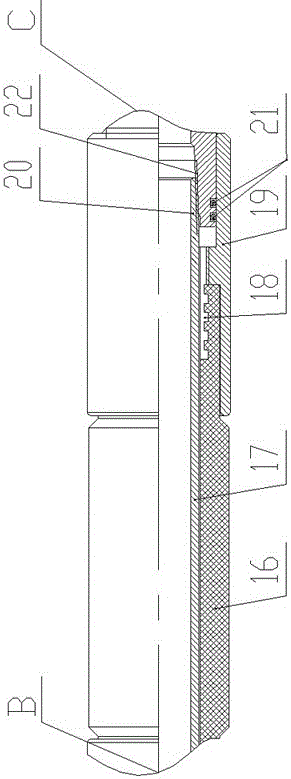

[0071] This embodiment is basically the same as Embodiment 2, the main difference is that the sealing test specifically includes the following steps:

[0072] a. First test the pressure with clean water to 40MPa, and stabilize the pressure for 10 minutes;

[0073] b. After immersing in diesel oil at 100°C for 7 hours, test the pressure to 40MPa, test the upper pressure to 50MPa under the rated setting pressure, and stabilize the pressure for 10min;

[0074] c. Install the upper three sealing rings on the sliding sleeve, then install the sliding sleeve into the spray gun body, pressurize at 5MPa, check whether the packer is set, if it is normally set, continue to pressurize to 40MPa, and stabilize the pressure for 7 minutes ;

[0075] d. Install four sealing rings on the sliding sleeve, install the sliding sleeve into the spray gun body again, pressurize 40MPa, and stabilize the pressure for 7 minutes;

[0076] e. Put steel balls from the upper end of the hydraulic jet sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com