Production equipment convenient for sealing element test

A technology for production equipment and seals, which is applied in the field of seals manufacturing, can solve the problems that the sealing between the molding cavity and the injection head is not tight, affects the sealing effect of the seals, and affects the shape of the seals, so as to achieve rapid collection, ensure stability, and avoid Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

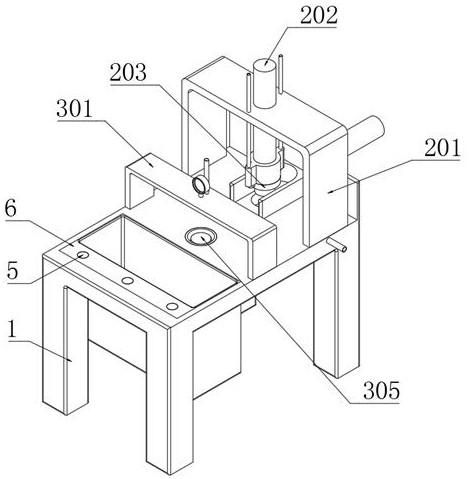

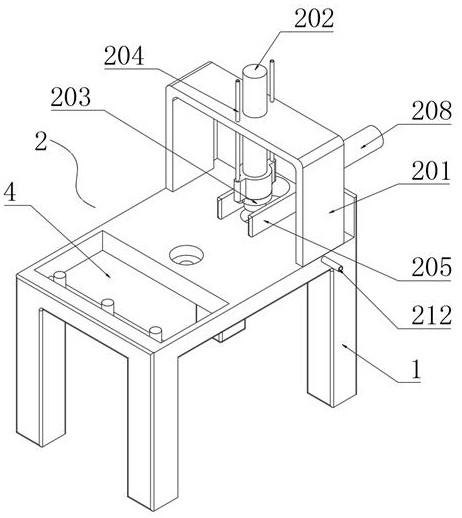

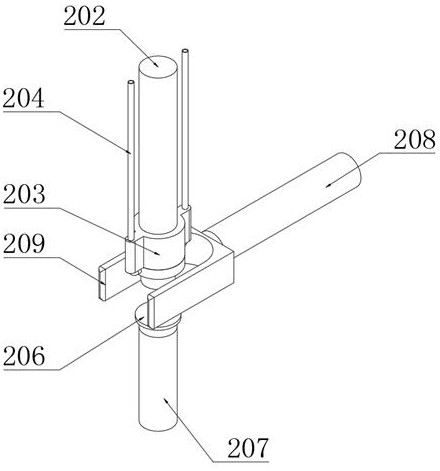

[0033] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a production equipment that is convenient for seal testing, including a fixed support frame 1, a molding assembly 2 is installed on one side of the fixed support frame 1, and the molding assembly 2 includes a fixed mounting frame 201, a press-down Hydraulic cylinder 202, injection head 203, liquid injection pipe 204, molding cavity 205, push plate 206, lifting electric push rod 207, pushing electric push rod 208, 匚-shaped discharge plate 209, cooling tank 210, water inlet pipe 211 and outlet water pipe 212;

[0034] A fixed installation frame 201 is welded on one side of the top of the fixed support frame 1, and a downward pressure hydraulic cylinder 202 runs through the middle of the top of the fixed installation frame 201. Injection tube 204, the top of the injection tube 204 is installed through one end of the fixed installation frame 201 to ensure that the pipe will not be b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com