Medium-high temperature solar selective absorption composite coating and preparation method thereof

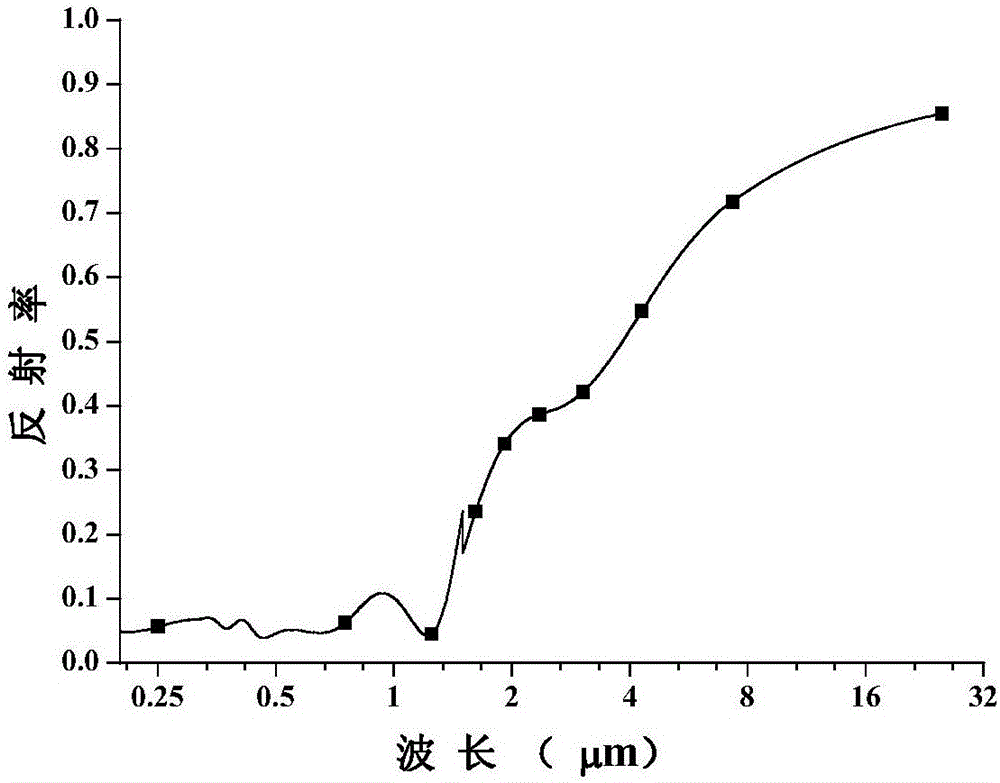

A composite coating and selective technology, which is applied in the field of solar thermal utilization, can solve the problems of poor coating adhesion and high temperature stability, poor optical selectivity, and limited temperature tolerance, so as to improve the overall corrosion resistance and high Selective absorption capacity, effect of improving binding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

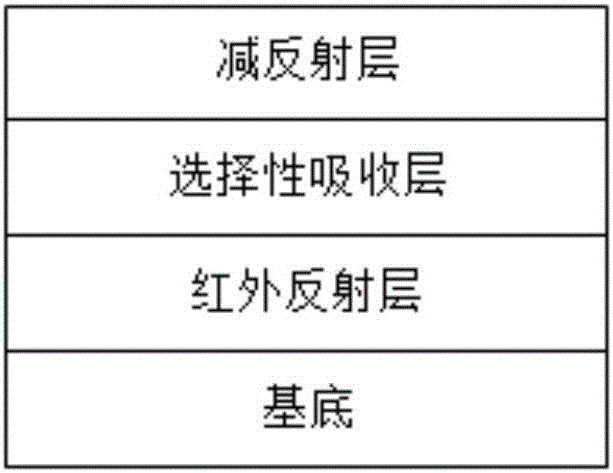

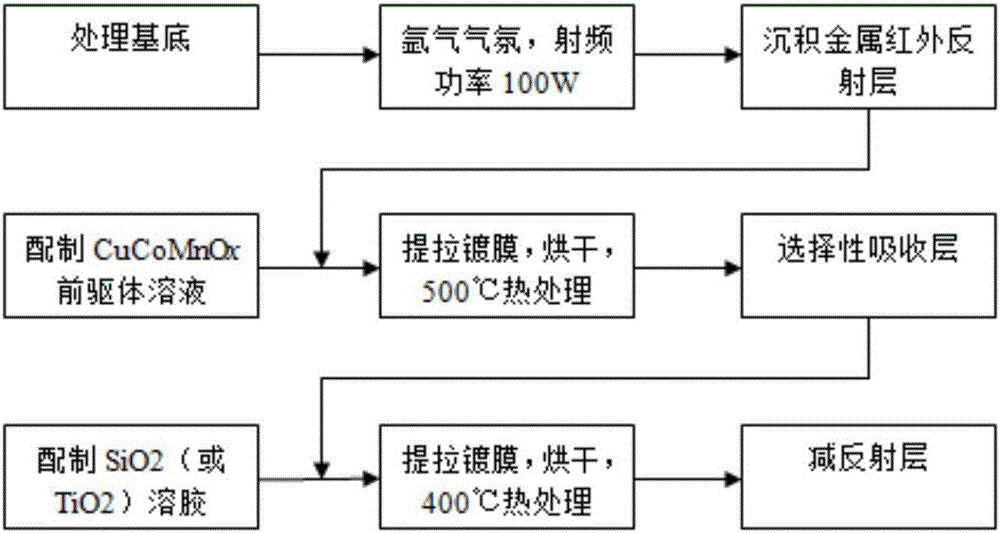

[0049] The solar selective absorption composite coating of the present embodiment has a 4-layer structure, which is respectively a base, an infrared reflection layer, a selective absorption layer and an anti-reflection layer from bottom to top; the base is a highly polished 304 type stainless steel substrate, The infrared reflective layer is a metal Ti film, the selective absorbing layer is a CuCoMnOx spinel film, and the antireflection layer is a SiO2 film; the infrared reflective layer is prepared by magnetron sputtering, and both the selective absorbing layer and the antireflective layer are made of sol-gel Glue preparation.

[0050] The preparation method of solar selective absorption composite coating is as follows:

[0051] Step 1, preparation of CuCoMnOx composite sol A: Weigh 3.62g copper nitrate trihydrate, 1.46g cobalt nitrate hexahydrate and 3.67g manganese acetate tetrahydrate and dissolve them in 100ml ethanol, stir magnetically until completely dissolved; weigh 7.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com