A kind of preparation method of non-ferrous alloy anticorrosion layer

A non-ferrous alloy, anti-corrosion layer technology, applied in the direction of metal material coating process, coating, surface reaction electrolytic coating, etc., to achieve the effect of improving coverage, reducing surface gaps, and overcoming surface pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

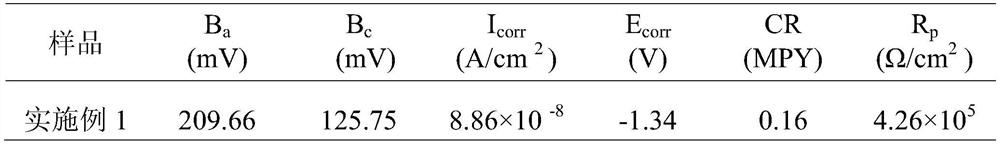

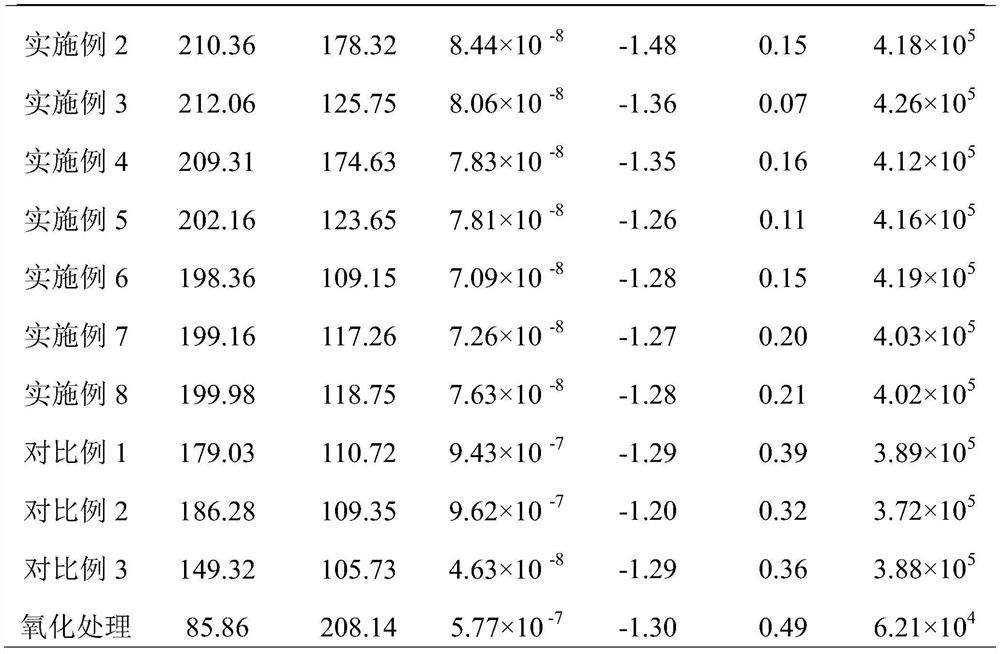

Examples

Embodiment 1

[0019] A method for preparing a nonferrous alloy anticorrosion layer: comprising the following steps:

[0020] S1. The sol-gel solution includes the following raw materials in parts by weight: 20 parts of ethyl silicate, 15 parts of ethanol, 13 parts of silicon dioxide, 3 parts of graphite particles, 5 parts of zinc sulfide particles, and 100 parts of water. The particle size of zinc sulfide is 0.1μm, the particle size of zinc sulfide is 0.05μm, and the water is deionized water;

[0021] S2. Preparation of sol: mix ethanol with water, adjust the pH value of the system to 4, then perform magnetic stirring at a magnetic stirring speed of 300 rpm and a temperature of 20°C, then add ethyl silicate and silicon dioxide, and stir for 1 hour;

[0022] S3. Preparation of sol-gel solution: adding graphite particles and zinc sulfide particles under the action of magnetic stirring for stirring, the magnetic stirring rate is 500rpm, the temperature is 50°C, and the stirring is continued fo...

Embodiment 2

[0026] A method for preparing a nonferrous alloy anticorrosion layer: comprising the following steps:

[0027] S1. The sol-gel solution includes the following raw materials in parts by weight: 60 parts of ethyl silicate, 45 parts of ethanol, 19 parts of silicon dioxide, 15 parts of graphite particles, 20 parts of zinc sulfide particles, and 240 parts of water. The particle size of zinc sulfide is 0.3μm, the particle size of zinc sulfide is 0.15μm, and the water is deionized water;

[0028] S2. Preparation of sol: mix ethanol with water, adjust the pH value of the system to 6, and then perform magnetic stirring at a magnetic stirring speed of 800 rpm and a temperature of 80° C., then add ethyl silicate and silicon dioxide, and stir for 3 hours;

[0029] S3. Preparation of sol-gel solution: adding graphite particles and zinc sulfide particles under the action of magnetic stirring, the magnetic stirring rate is 1000rpm, the temperature is 120°C, and the stirring is continued for ...

Embodiment 3

[0033] A method for preparing a nonferrous alloy anticorrosion layer: comprising the following steps:

[0034] S1. The sol-gel solution includes the following raw materials in parts by weight: 40 parts of ethyl silicate, 30 parts of ethanol, 16 parts of silicon dioxide, 9 parts of graphite particles, 13 parts of zinc sulfide particles, and 170 parts of water. The particle size of zinc sulfide is 0.2μm, the particle size of zinc sulfide is 0.10μm, and the water is deionized water;

[0035] S2. Preparation of sol: mix ethanol with water, adjust the pH value of the system to 5, and then perform magnetic stirring at a magnetic stirring speed of 500 rpm and a temperature of 50° C., then add ethyl silicate and silicon dioxide, and stir for 2 hours;

[0036] S3. Preparation of sol-gel solution: adding graphite particles and zinc sulfide particles under the action of magnetic stirring, stirring at a magnetic stirring rate of 700 rpm, at a temperature of 80° C., and continuously stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com