Patents

Literature

37results about How to "Play a role in reducing friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium alloy surface multi-element laser alloyed layer and preparation method thereof

ActiveCN103966598AGood metallurgical bondImprove wettabilityMetallic material coating processesWear resistantComposite ceramic

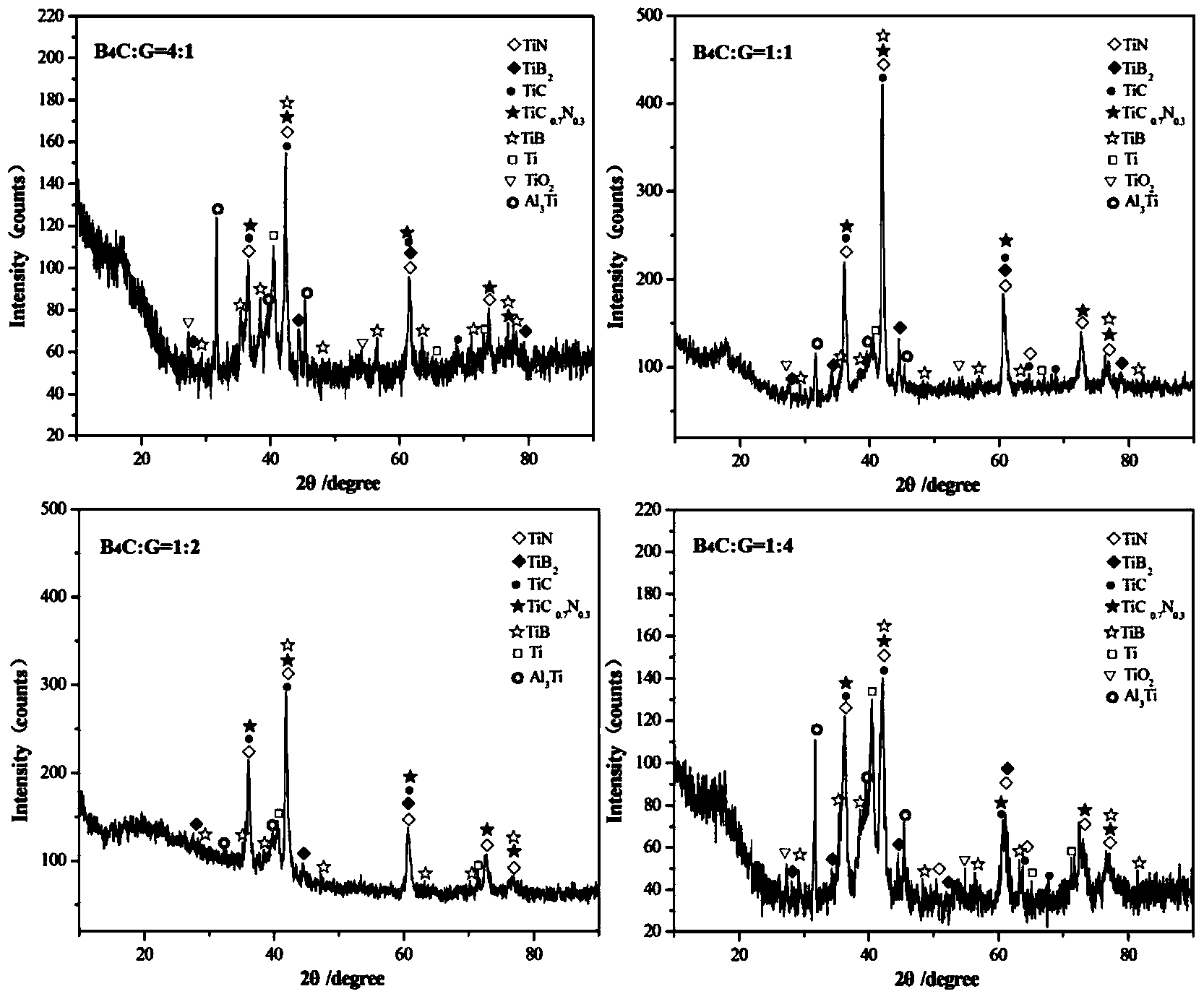

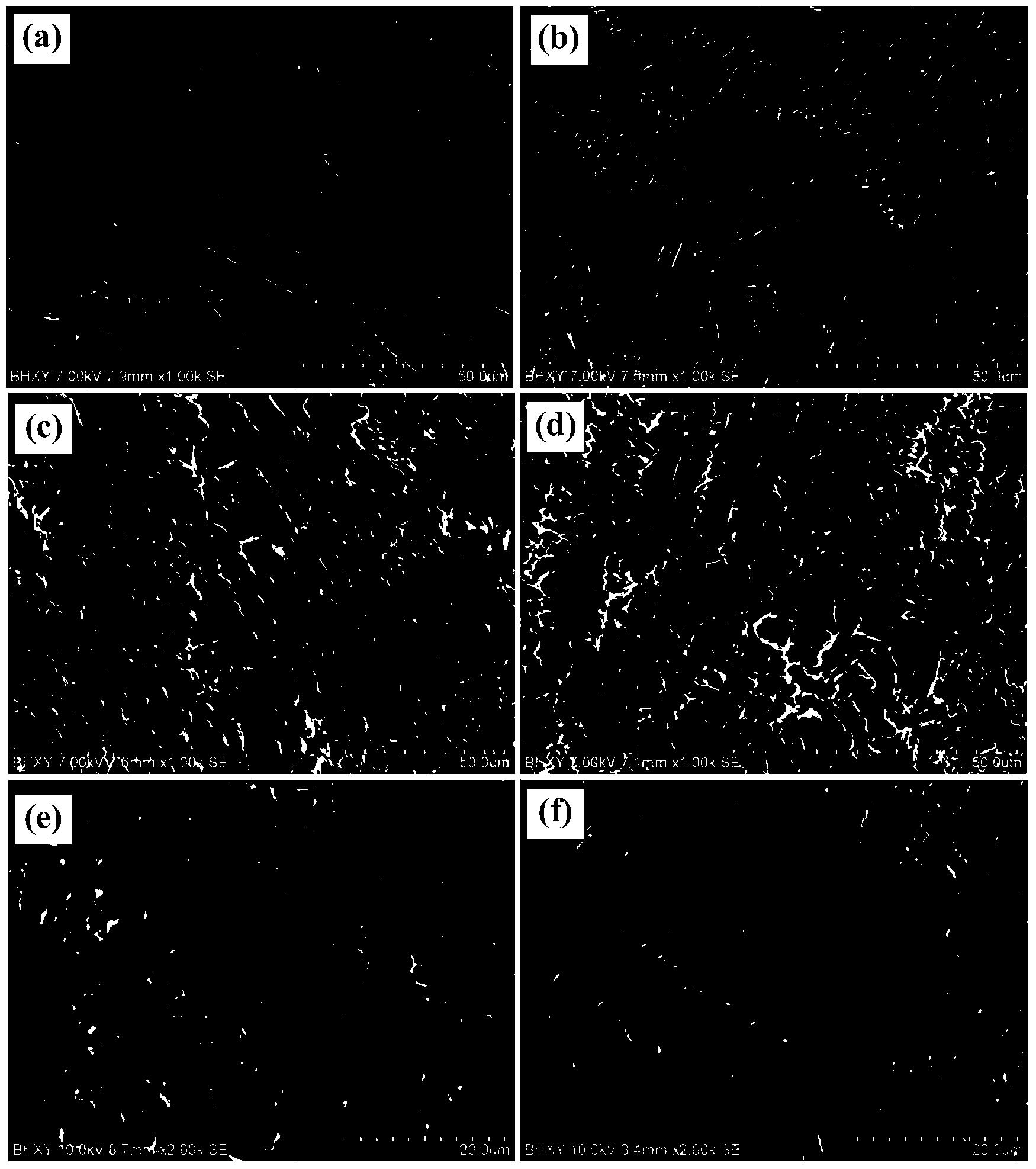

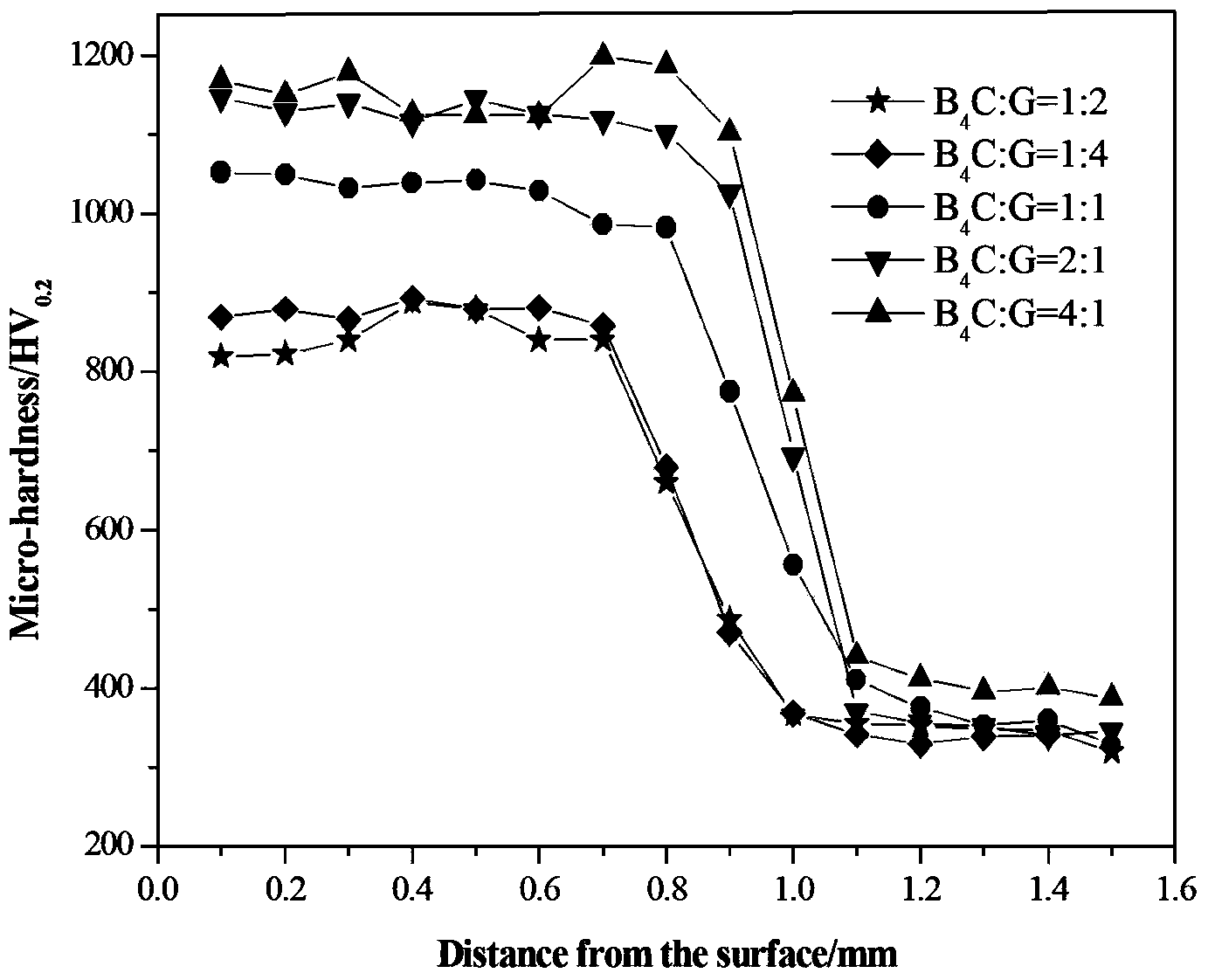

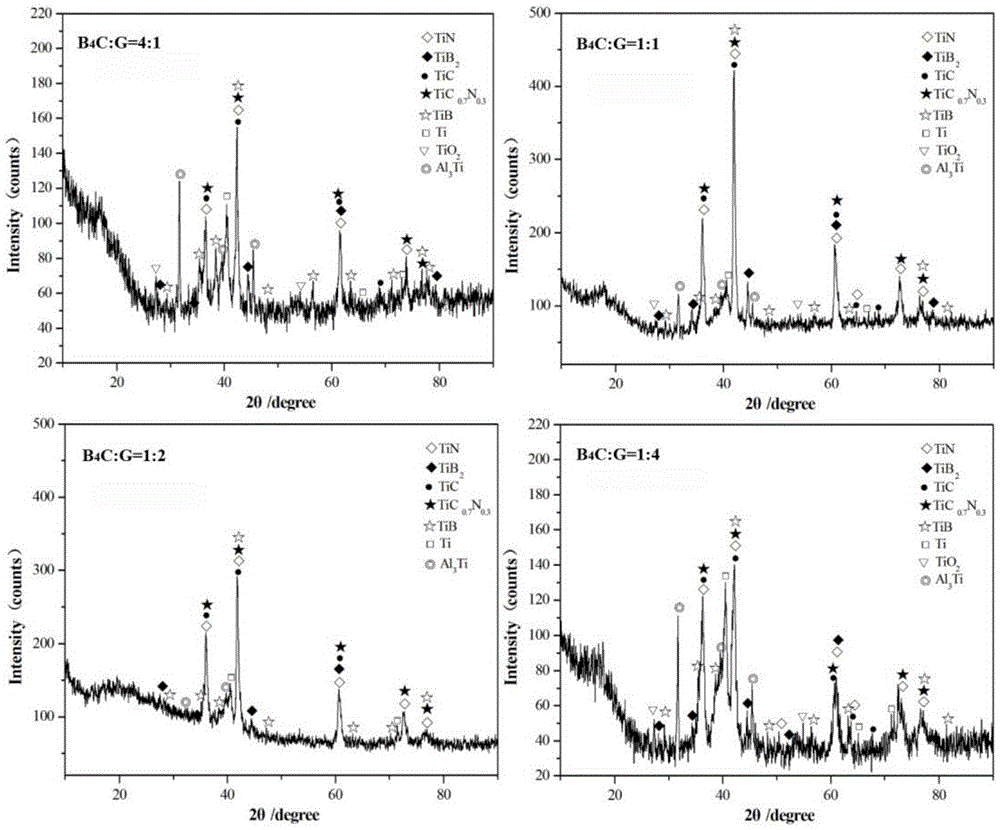

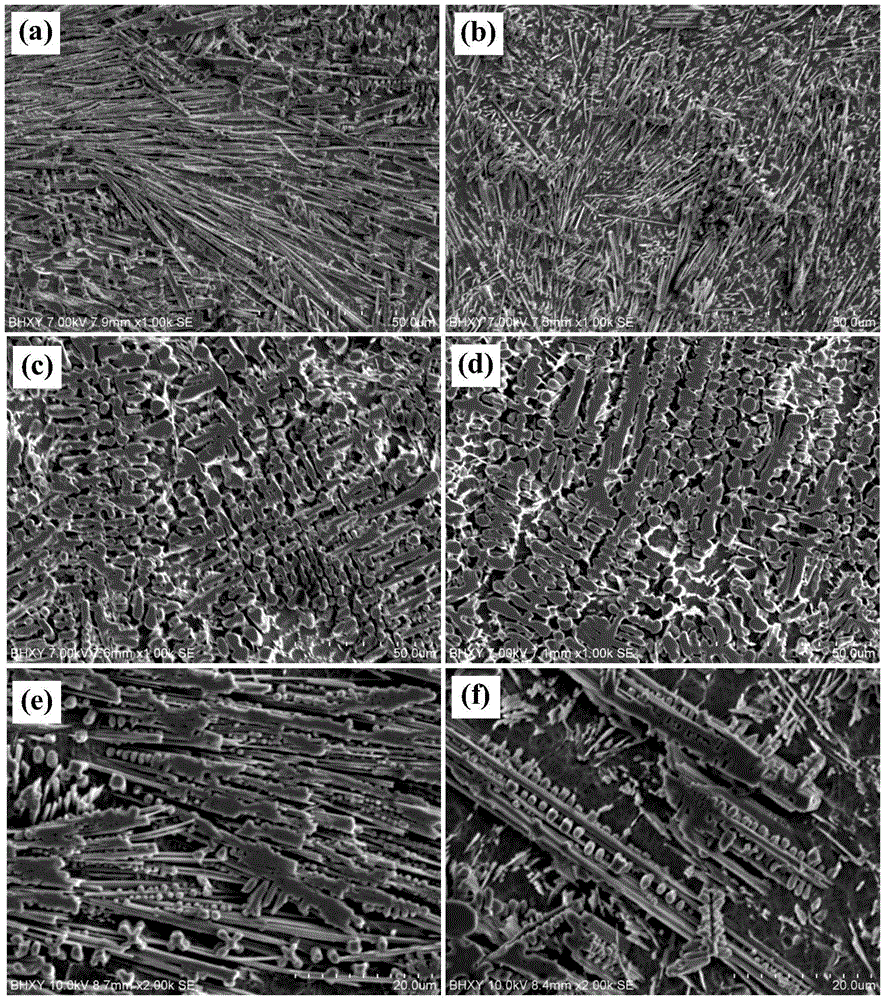

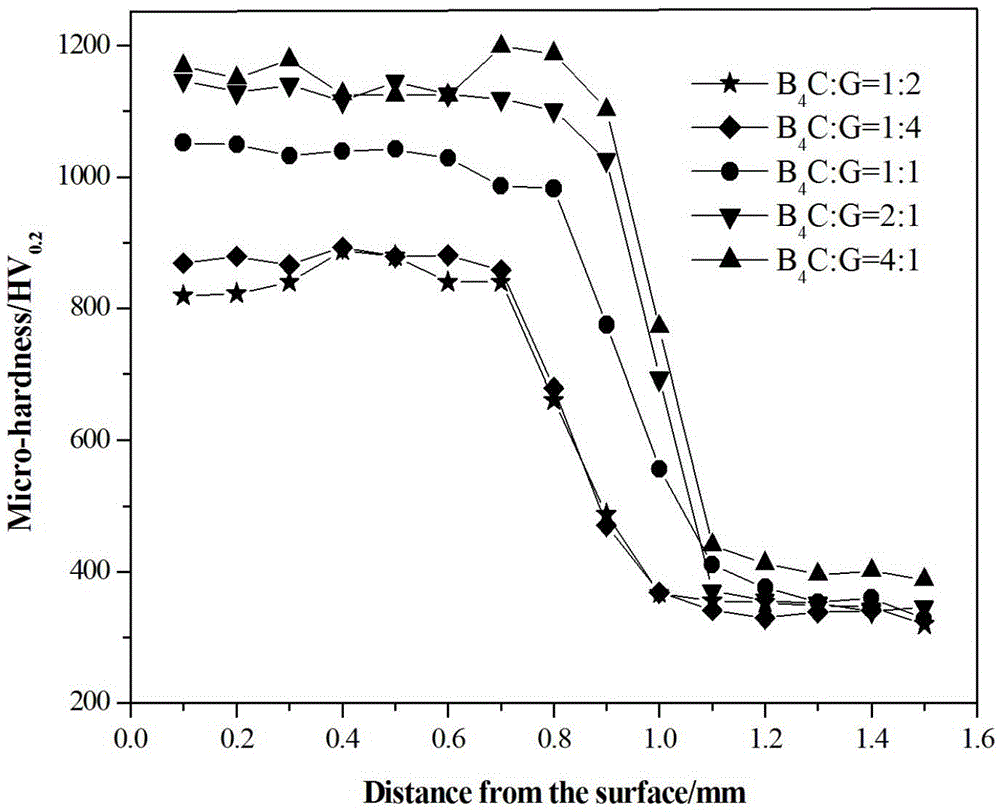

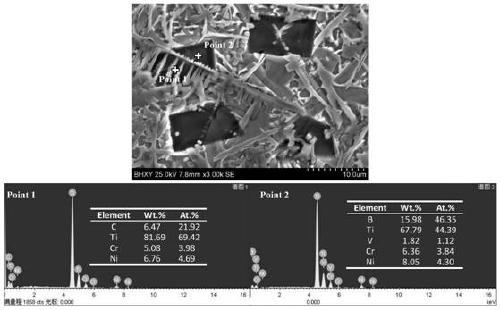

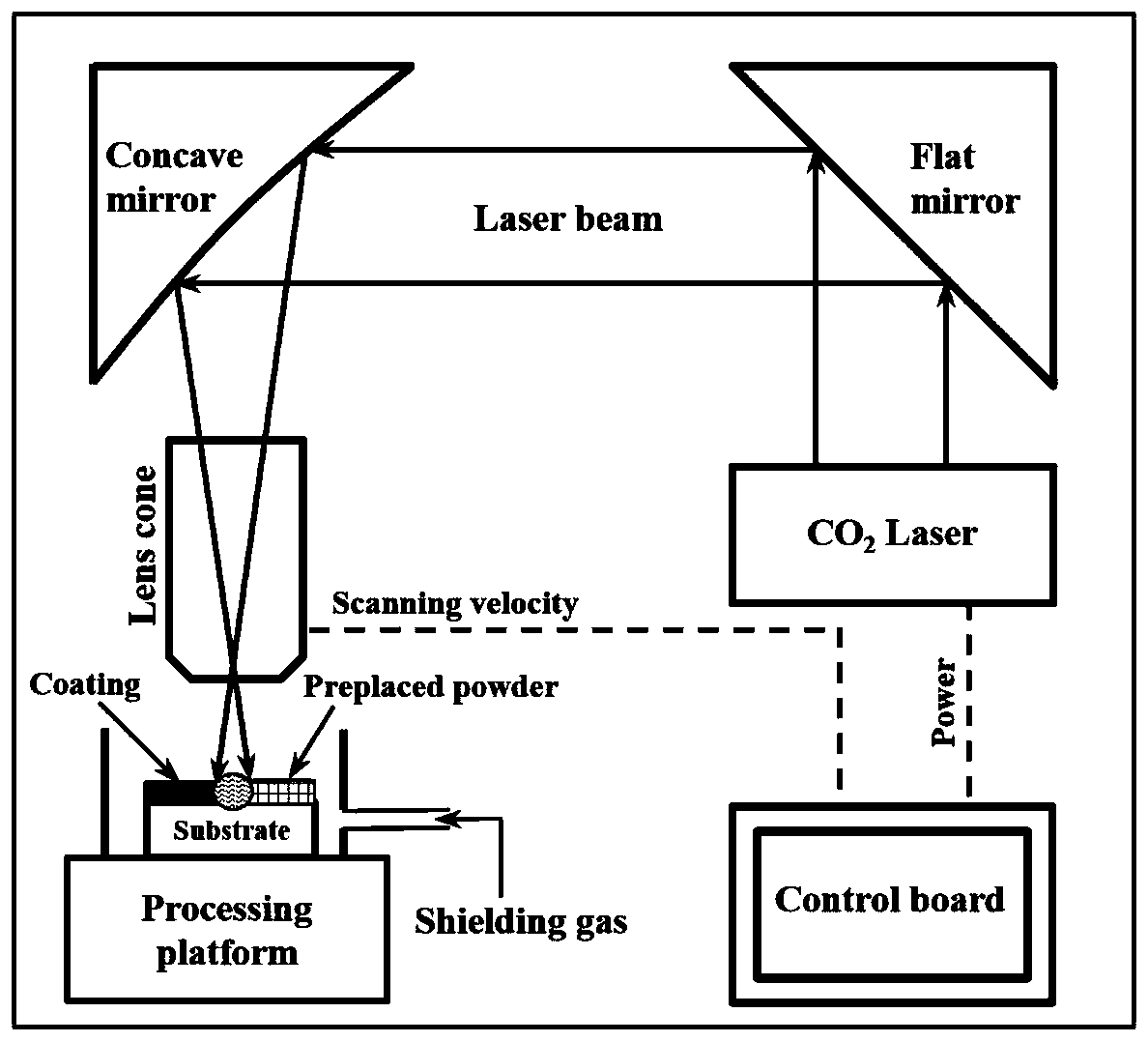

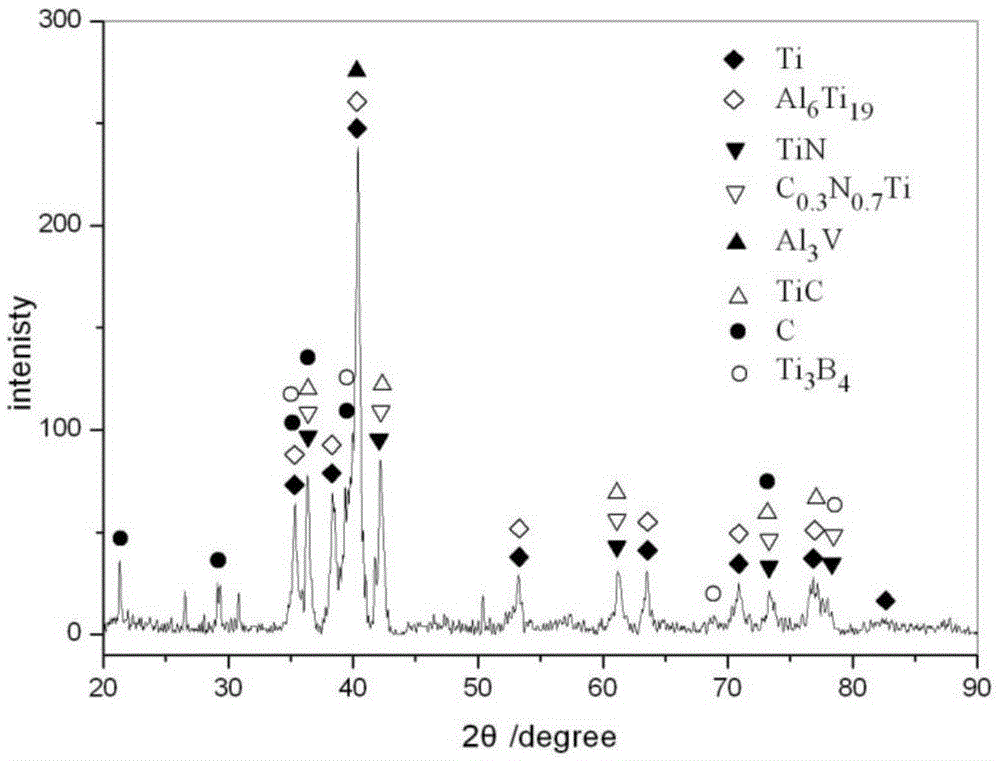

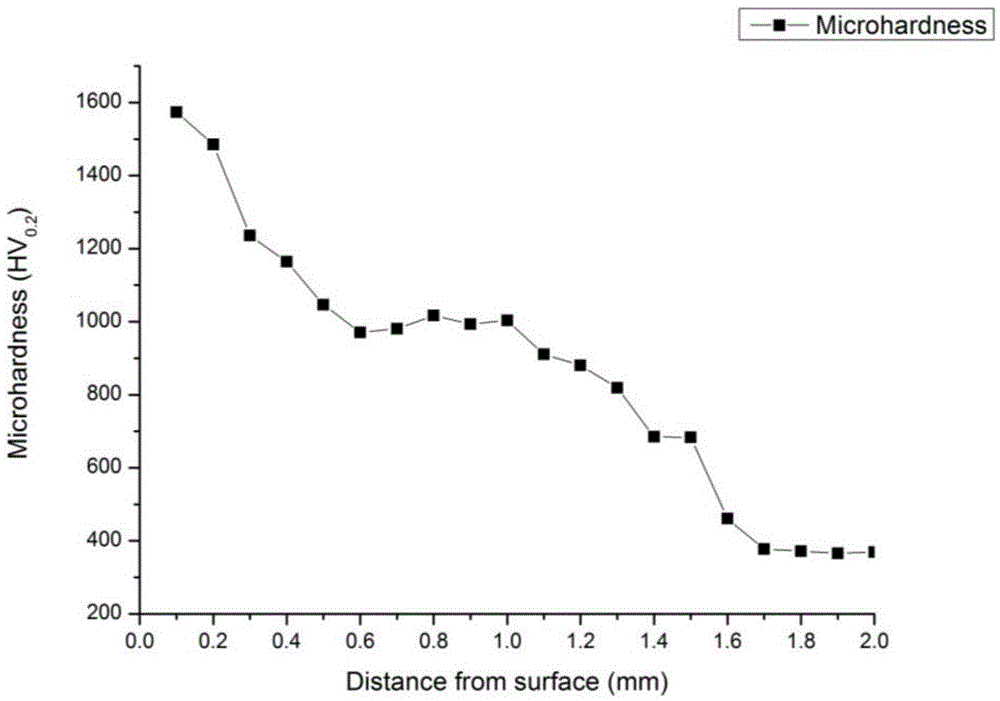

The invention relates to a titanium alloy surface multi-element laser alloyed layer and a preparation method thereof. The preparation method comprises the following steps: by using titanium alloy as a base material, applying mixed powder of B4C, graphite, Ti powder and rare-earth oxides Y2O3 used as a coating material onto the titanium alloy surface, and carrying out laser scanning while blowing nitrogen gas to perform alloying, wherein the coating material comprises the following components in percentage by mass: 10-90% of B4C, 10-90% of graphite powder, 0-50% of Ti powder and 0-4% of Y2O3.In an open N2 environment, the B4C and graphite powder are subjected to boron-carbon-nitrogen multi-element composite laser alloying on the titanium alloy surface to prepare the high-hardness wear-resistant composite ceramic coating. The simultaneous addition of the Ti powder and rare-earth oxides Y2O3 is beneficial to enhancing the microhardness and wear resistance of the alloyed layer; and the proper amount of Ti can promote the in-situ reaction in the alloyed layer, and the Y2O3 can refine the structure, thereby enhancing the comprehensive mechanical properties of the coating.

Owner:SHANDONG UNIV

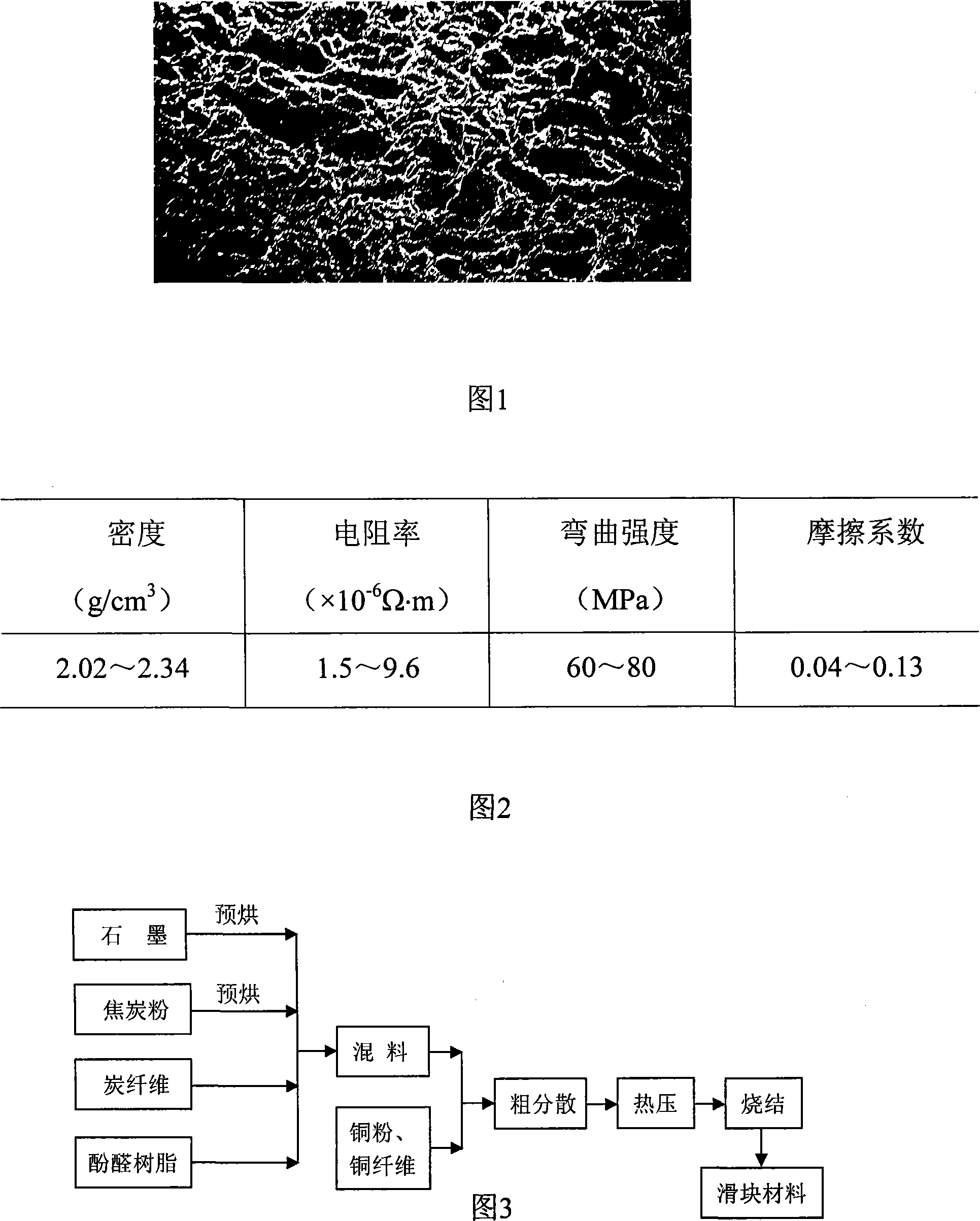

Carbon base composite material for collector shoe sliding block and its preparation method

InactiveCN101165818AImprove conductivityHigh mechanical strengthNon-metal conductorsNon-conductive material with dispersed conductive materialFiberHigh volume manufacturing

The invention comprises: using the one of graphite and coke materials or their mixture as basal body; it has 40%-60% of total component mass percent; using the chopped carbon fiber as the reinforcing agent, which has 1%-5% of total component mass percent; using the self-solidifying phenolic resin as the bonding agent, which has 15-30% of total component mass percent; using the one of copper powder and copper fiber or their mixture as conducting component, which has 5-30% of total component mass percent. The fabrication method comprises: 1) pre-drying; 2) blending procedure; 3) pressing procedure; 4) post-processing procedure.

Owner:BEIHANG UNIV

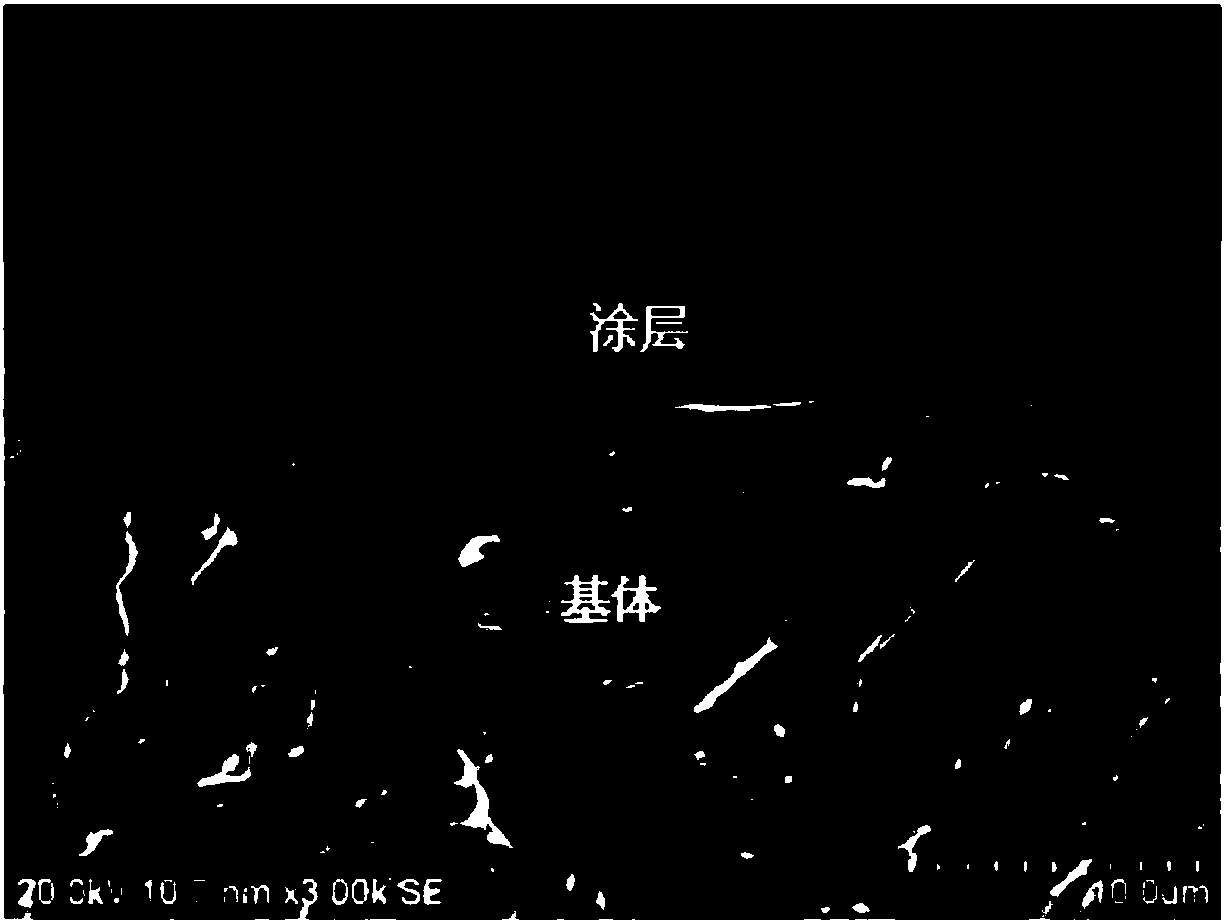

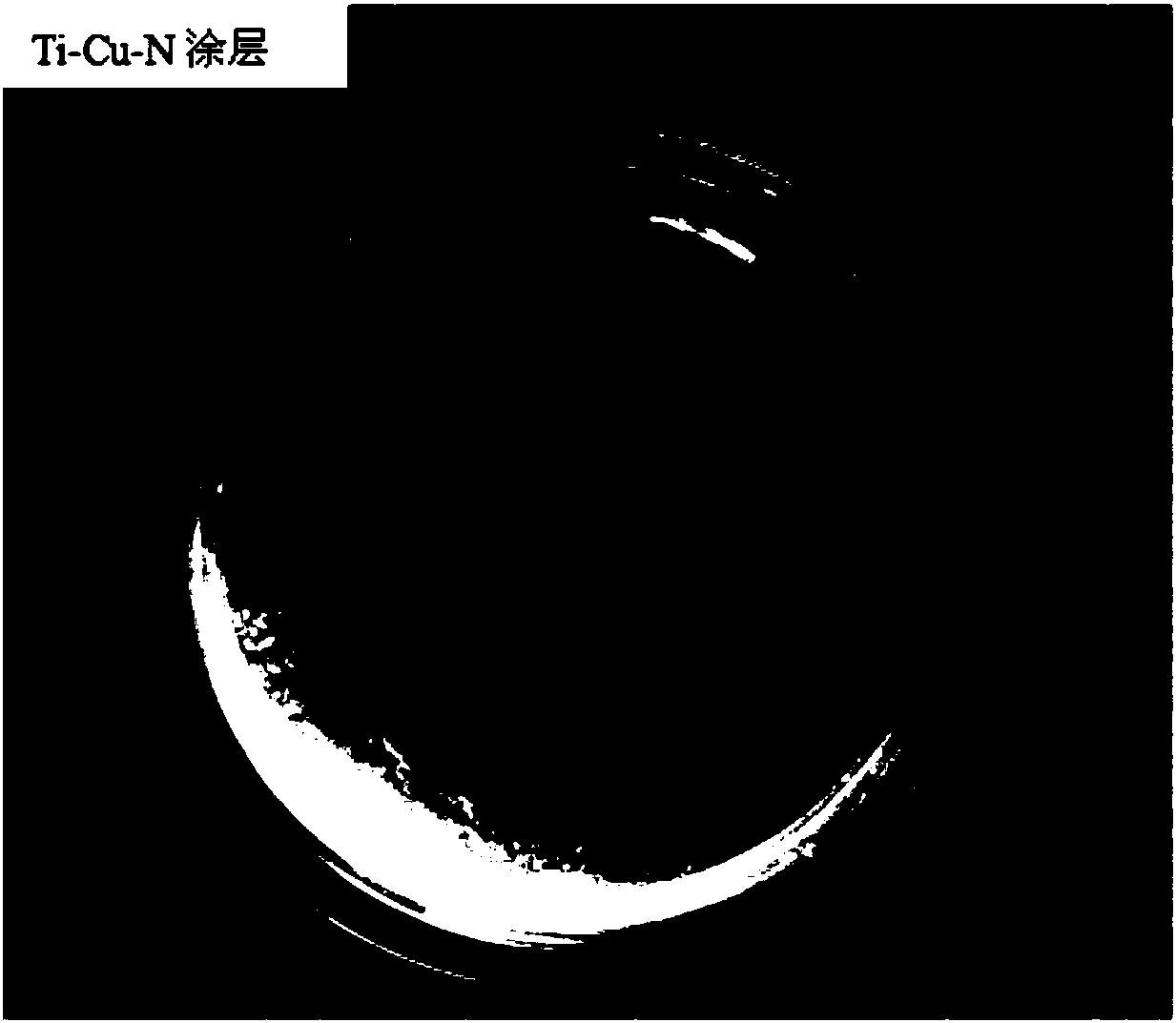

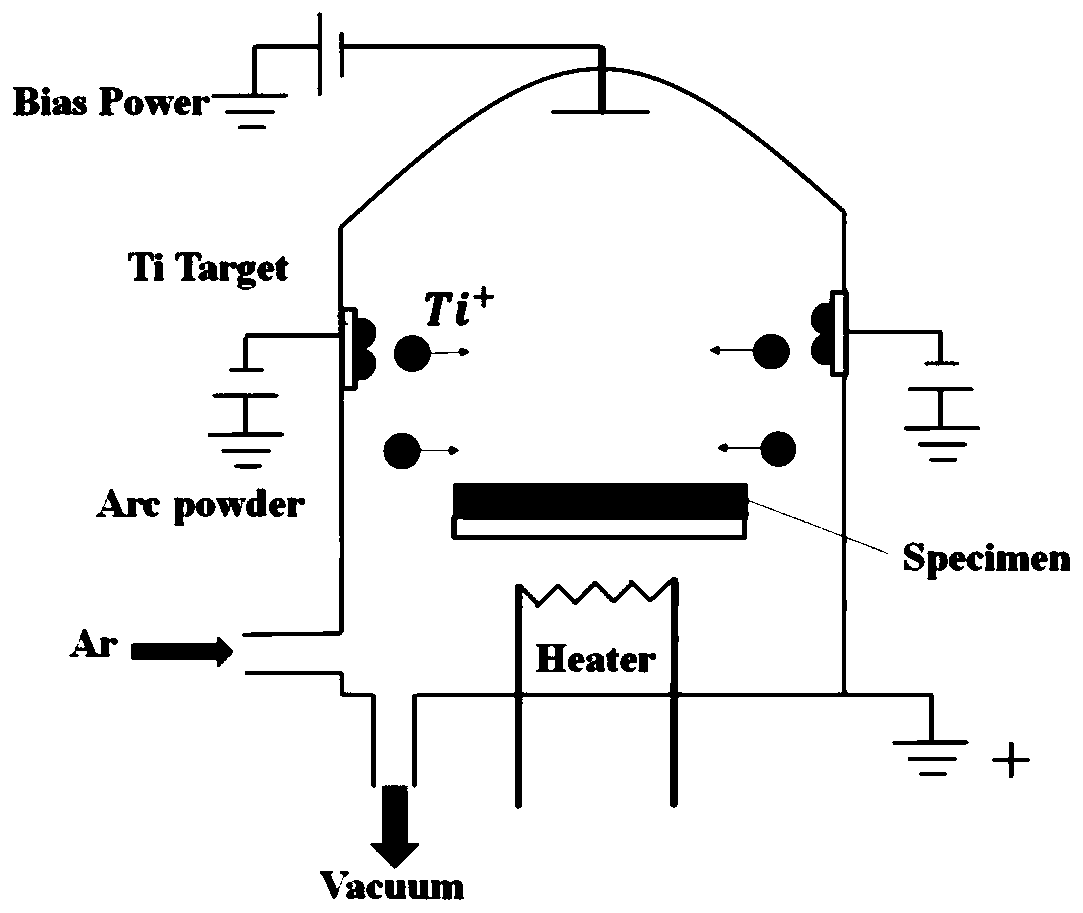

Ti-Cu-N nanometer composite anti-microbial coating and preparation method thereof

InactiveCN108070829ARefine the grain sizeReduce internal stressVacuum evaporation coatingSputtering coatingMicrometerHardness

The invention belongs to the technical field of metal material surface deposition nanometer composite anti-microbial coatings and particularly relates to a titanium nitride copper (called Ti-Cu-N in the following) nanometer composite anti-microbial coating and a preparation method thereof. A transition layer formed by a Ti film, a middle layer formed by a TiN film and a Ti-Cu-N layer are sequentially arranged on the surface of a base body, and the thickness of the Ti-Cu-N nanometer composite anti-microbial coating ranges from 1 micrometer to 10 micrometers. According to the coating, the magnetic field enhancement arc ion plating technology is adopted for completion, and the nanometer composite anti-microbial coating prepared through the method has good anti-microbial performance and also has the beneficial effects of being high in hardness, good in coating toughness, resistant to abrasion and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

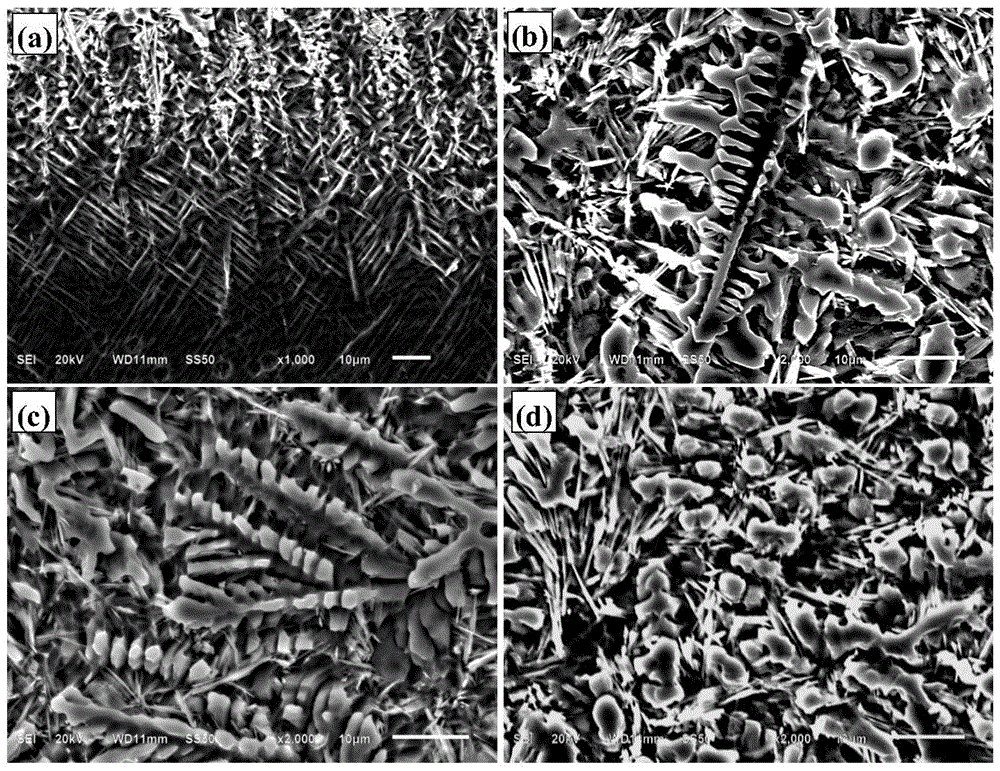

Laser alloying layer on titanium alloy surface and preparation process thereof

The invention relates to a laser alloying layer on a titanium alloy surface and a preparation process thereof. Titanium or titanium alloy is used as a matrix material, and BN or BN and graphite powder are used as a coating material which is applied to the matrix material; a continuous laser is used for scanning a sample, wherein the service power is 800-1,200W, the diameter of a light spot is kept at 4mm, and the scanning speed is 2-10mm / s; in a scanning process of a laser beam, argon is blown to protect a molten pool and a laser lens barrel, and the argon pressure is kept at 0.2-0.4MPa. In the invention, the BN and graphite powder have similar structure and relatively good compatibility; after laser treatment, possible residual BN and graphite particles on the alloying layer can realize an antifriction effect to a certain degree; the surface of the alloying layer is relatively flat, the microstructure is dense, and the hardness is remarkably improved over the matrix.

Owner:SHANDONG UNIV

Preparation method for copper element modified copper base graphite wear-resistance hydraulic plunger pump cylinder blocks

InactiveCN109676130AGuaranteed service lifeNo generationTransportation and packagingMetal-working apparatusChemical platingHydraulic pump

The invention discloses a preparation method for copper element modified copper base graphite wear-resistance hydraulic plunger pump cylinder blocks. Graphite powder is cleaned, sensitized, activated,reduced and dried; then, a chemical plating method is adopted to put the graphite powder in plating liquid to plate copper metal layers on the surfaces; and then, the graphite powder and metal powderare poured in a mold for cold pressing, sintering, repressing and reburning, and are cooled for demolding to obtain the copper base graphite wear-resistance hydraulic plunger pump cylinder blocks. Inthe prepared hydraulic plunger pump cylinder blocks, graphite is dispersed in copper basal bodies; and when the hydraulic pump cylinder blocks are relatively rubbed with oil distribution discs, the friction reducing effect can be achieved through self-lubricating effect of graphite, so that the wear resistance of the hydraulic plunger pump cylinder blocks is improved.

Owner:XI AN JIAOTONG UNIV +1

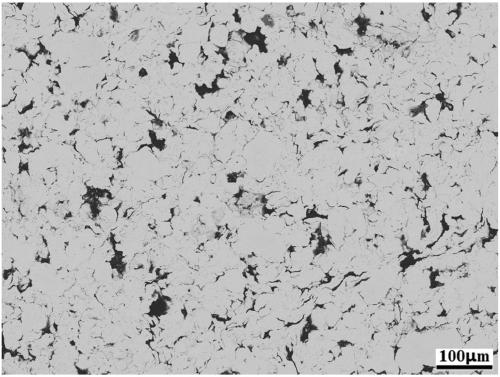

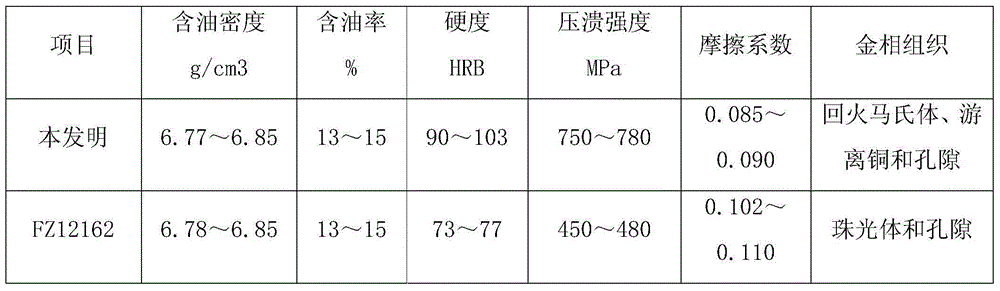

High-strength and wear-resisting iron based powder metallurgic bearing

The invention discloses a high-strength wearproof iron-based powder metallurgy bearing material and a preparation method thereof. The high-strength wearproof iron-based powder metallurgy bearing material is characterized by being composed of the following components by weight percent: 16.0%-18.0% of copper, 0.80%-0.90% of carbon, 0.01%-1.0% of cerium fluoride and the balance of iron, wherein the total amount of impurities is not higher than 2%. The process for preparing the iron-based powder metallurgy bearing material comprises the steps of mixing powder, pressing, sintering, heat treatment and vacuum oil immersion. The iron-based powder metallurgy bearing material provided by the invention has high-strength wear-resisting properties, specifically, the crushing strength of the bearing material ranges from 720 MPa to 780 MPa, the Rockwell hardness of the bearing material ranges from 90 HRB to 110 HRB, the oil length of the bearing material ranges from 13% to 16% and the oiling friction coefficient of the bearing material ranges from 0.08 to 0.09. The material provided by the invention is used as oil cylinder bearings of engineering machinery, such as an excavator and a bulldozer.

Owner:合肥波林新材料股份有限公司

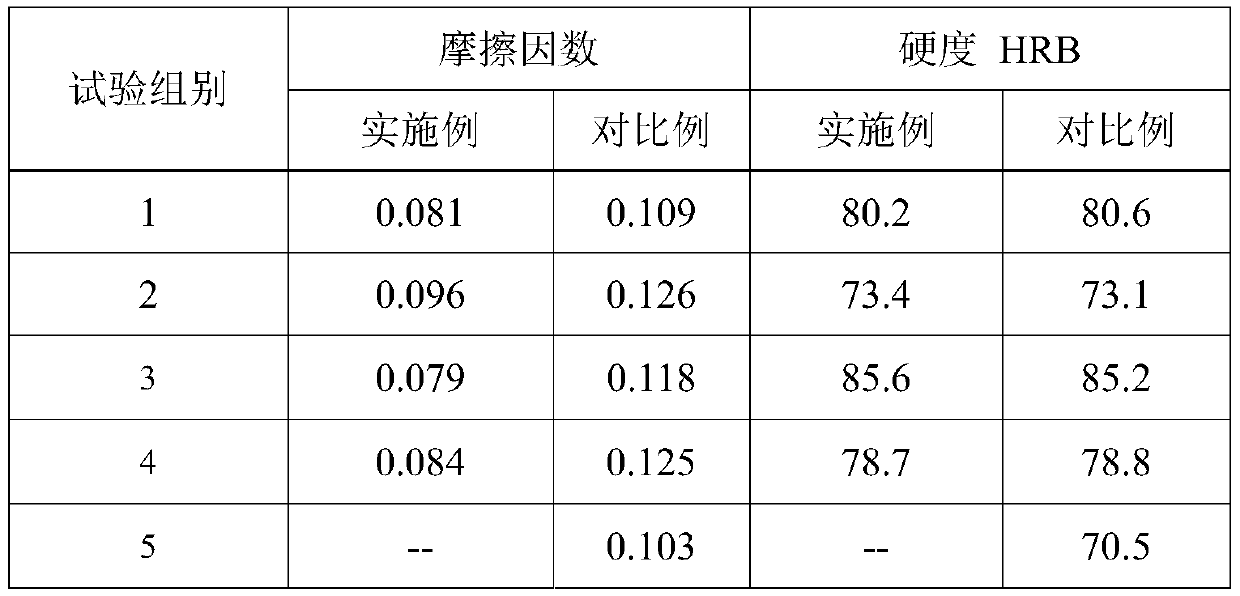

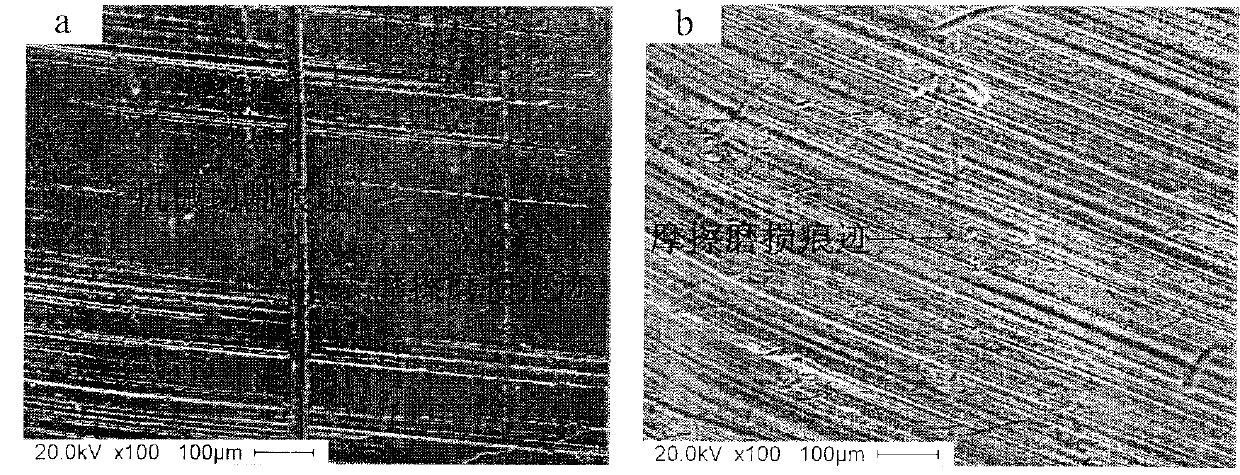

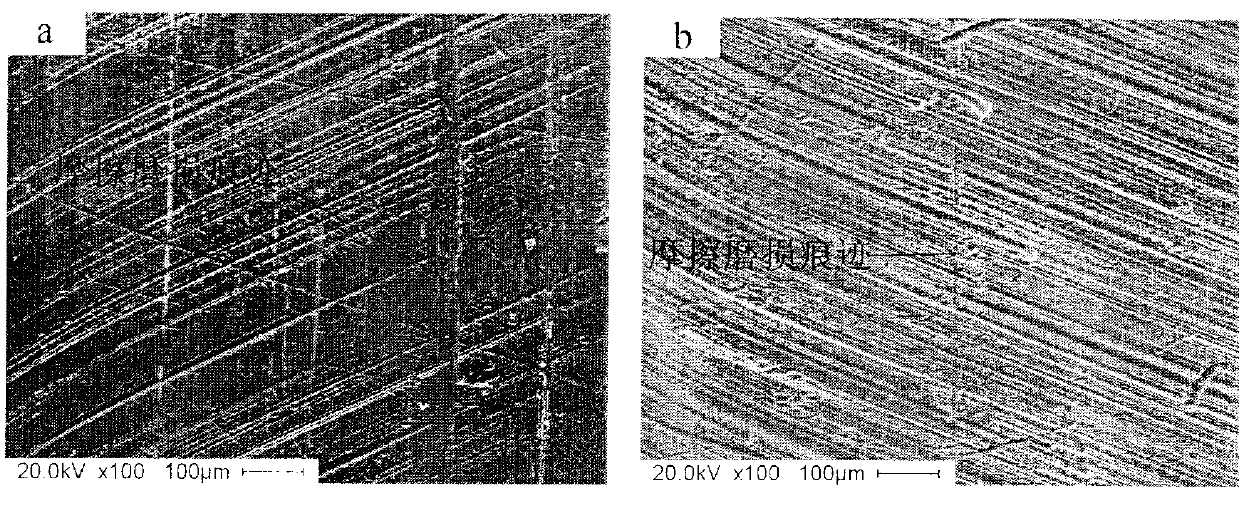

Iron-base sintered and vulcanized material, preparing method thereof, iron-base side plate and oil distribution disc

ActiveCN110735106AGood anti-frictionLow friction factorSolid state diffusion coatingGear pumpSulfidation

The invention provides an iron-base sintered and vulcanized material. The material compositions of the iron-base sintered and vulcanized material include Fe, Cu and S, and Cu2S exists in the microscopic structure. The invention further provides a preparing method of the iron-base sintered and vulcanized material. Raw materials are mixed, pressed and sintered, the surface of a sintered material iscoated with sulfur in a coated mode, the material is put at a temperature higher than the melting point of the sulfur for heat preservation so that the sulfur can enter pores of the sintered material,and then the sintered and vulcanized material is obtained. In the vulcanizing process, the sulfur with which the surface of the sintered material is coated enters the pores of the sintered material through heat preservation and reacts with Cu around the pores to generate Cu2S. The Cu2S is a friction reducing component and can improve the friction reducing effect of the sintered material and reduce the friction coefficient. Meanwhile, the invention further discloses a gear pump side plate, blade pump or plunger pump oil distribution disk prepared from the iron-base sintered and vulcanized material.

Owner:合肥波林新材料股份有限公司

Novel antifriction lubricant additive containing nano ferrous sulphide

InactiveCN103289790AGood dispersion and stabilityImprove lubrication performanceAdditivesPetrochemicalMetallurgy

The invention relates to a lubricant additive containing nano ferrous sulphide granules. The lubricant additive is composed of 1-20wt% of nano ferrous sulphide granules and 80-99wt% of basic lubricating oil, and granularity of nano ferrous sulphide is 10-50nm. The lubricant additive can serve as additives of multifunctional lubricating oil and lubricating grease and also can serve as a repairing antiwear agent for a lubricating system of large-scale mechanical equipment used for various vehicles, ships, petrochemical engineering and mines.

Owner:梅滨 +1

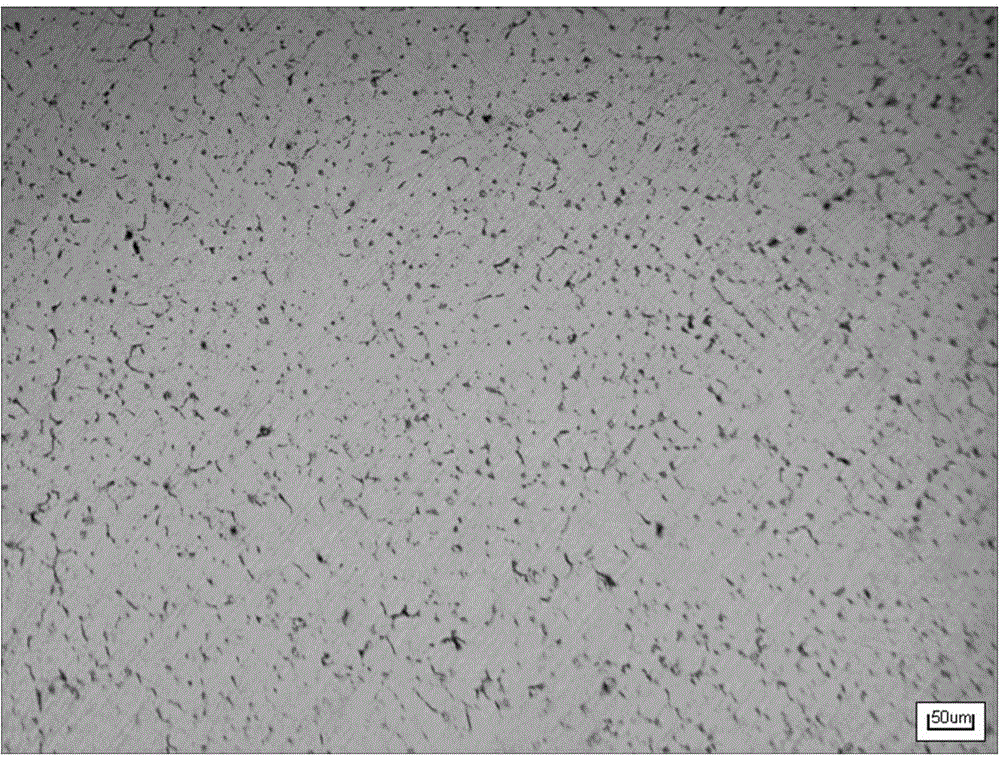

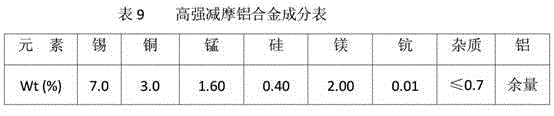

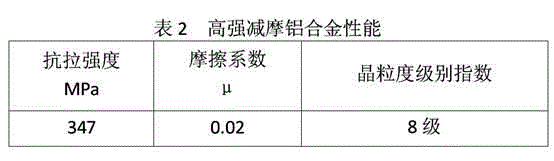

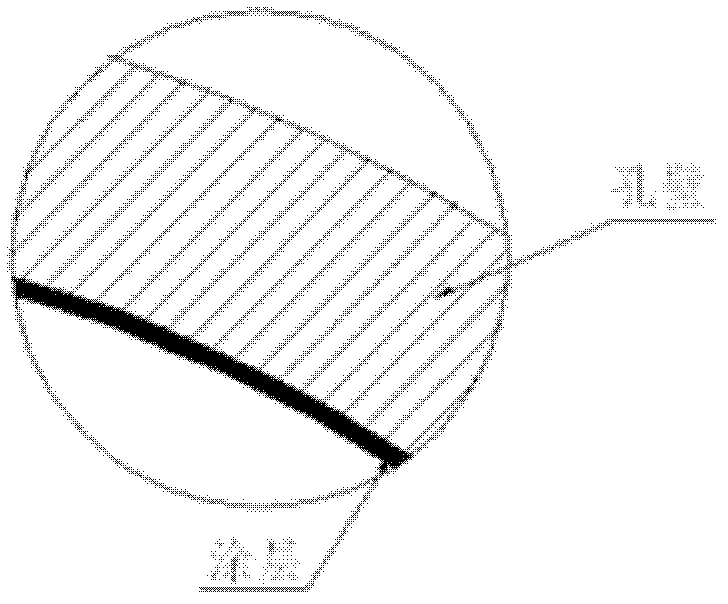

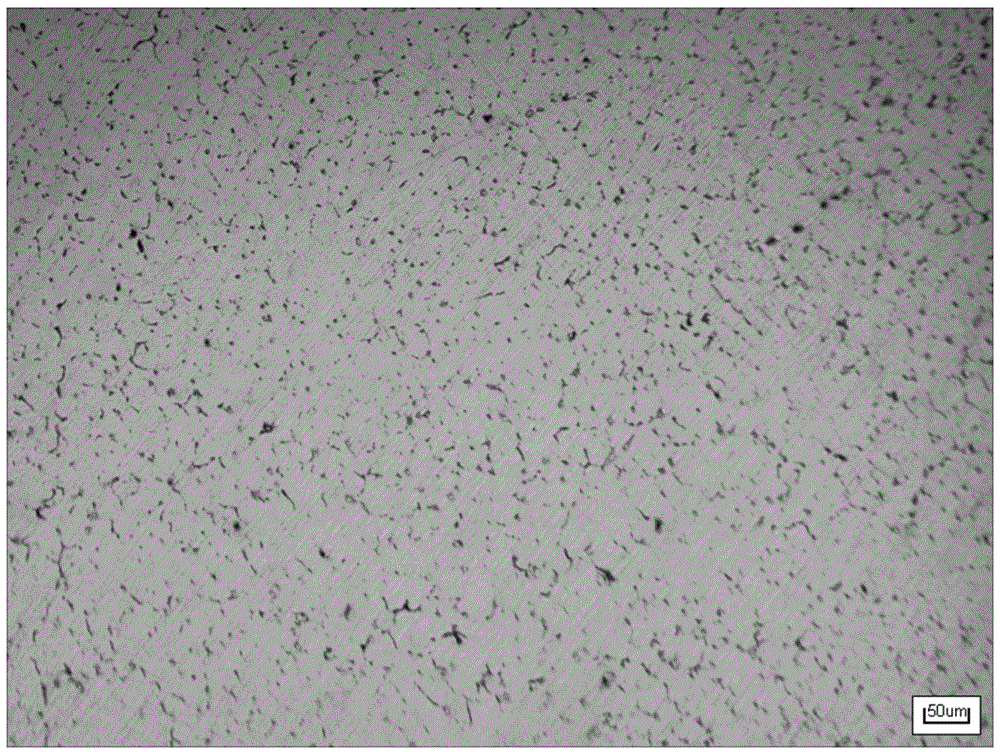

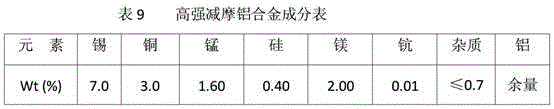

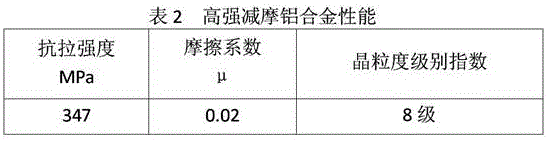

High-strength antifriction aluminum alloy

ActiveCN104561706AHigh strengthInhibition of recrystallizationRare-earth elementChemical composition

The invention discloses a high-strength antifriction aluminum alloy which comprises the following chemical components in percentage by weight: 1.0-7.0% of tin, 3.0-7.0% of copper, 0.20-1.60% of manganese, 0.40-1.60% of silicon, 0.40-2.0% of magnesium, 0.01-1.0% of rare earth element scandium, at most 0.70% of impurities and the balance of aluminum. The aluminum alloy has the advantages of uniform and segregation-free components, fine structure and high tensile strength (up to 320-350 MPa). The friction factor is less than 0.02, and the aluminum alloy has excellent antifriction property and wear resistance. The aluminum alloy has the advantages of favorable processability and low cost.

Owner:安徽熠辉新材料有限公司

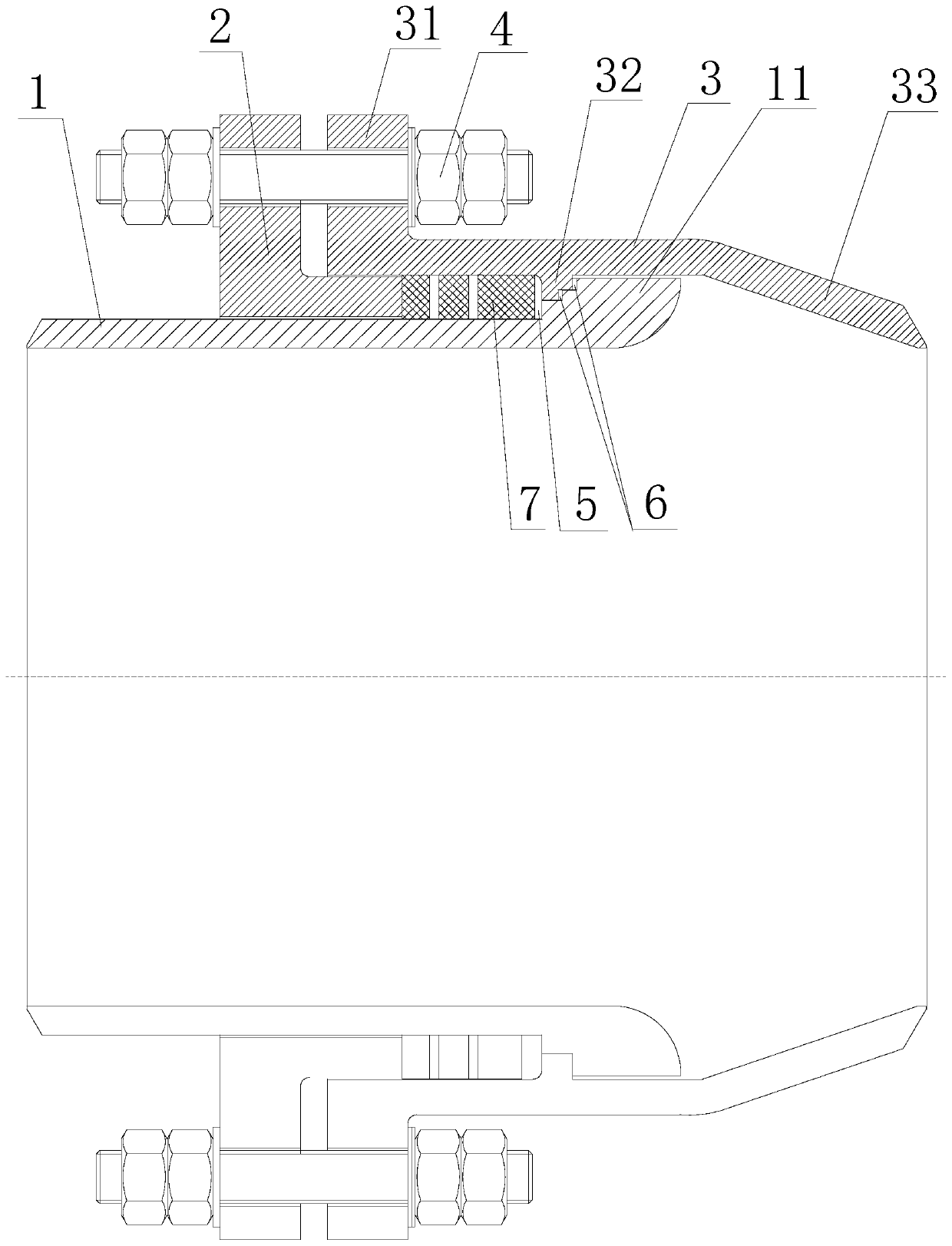

Combined multi-channel end face sealing rotary compensator

PendingCN110657308AImprove sealingFlexible operationPipeline expansion-compensationAdjustable jointsEngineeringFace seal

The invention relates to a combined multi-channel end face sealing rotary compensator. The combined multi-channel end face sealing rotary compensator comprises a rotary seat, a rotary core tube and apacking gland, wherein a sealing filler is arranged in a sealing cavity; an inner convex ring is arranged on the inner wall of the rotary seat; a stepped outer boss is arranged at the right end of therotary core pipe; and an assembly gap between the outer boss and the inner convex ring is positioned at the middle position of the bottom of the sealing cavity; the outer boss of the rotary core tubeis provided with at least two steps, and an end face sealing ring is embedded between the side surface of the step and the inner convex ring. The sealing filler comprises a pressure-change metal ringand a nonmetallic flexible filler, wherein the pressure-change metal ring generates radial expansion and deformation under the action of an external force, and the inner and outer side edges of the pressure-change metal ring are closely matched with the side wall of the sealing cavity. According to the combined multi-channel end face sealing rotary compensator, a multistage end face sealing ringis arranged between the outer boss of the rotary core tube and the inner boss of the outer sleeve, and the sealing ring forms a positive correlation self-sealing effect along with the change of the pressure of the pipeline medium, so that the sealing effect is enhanced. The combined multi-channel end face sealing rotary compensator has the advantages of strong high temperature resistance, high pressure resistance, good sealing effect, long service life and convenient installation.

Owner:JIANGSU YONGLI PIPELINE CO LTD

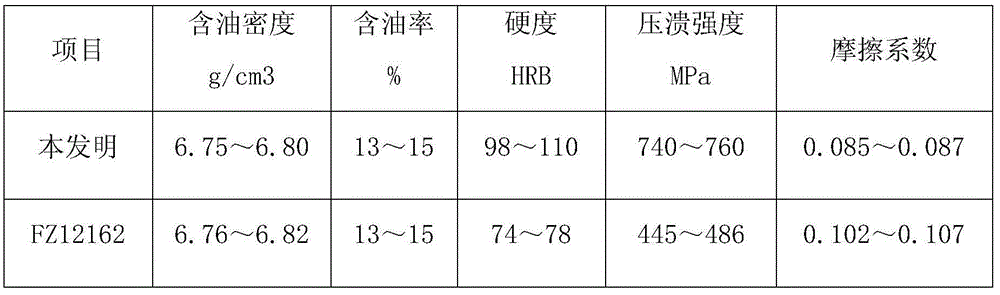

High-antifriction iron-based sulfide powder metallurgy oil-containing bearing material as well as preparation method and application thereof

ActiveCN111001813AImproved anti-friction effectReduce coefficient of frictionShaftsBearing componentsPowder metallurgyTungsten

The invention discloses a high-antifriction iron-based sulfide powder metallurgy oil-containing bearing material as well as a preparation method and application thereof. The material is prepared fromthe following components in percentage by weight: 18.0%-22.0% of copper, 0.60%-1.1% of carbon, 0.8%-2.6% of tungsten, 0.6%-2.2% of chromium, 0.8%-2.8% of molybdenum, 0.8%-3.2% of nickel, 0.8%-2.2% ofvanadium, 0.08%-1.2% of sulfur and the balance iron, and Cu2S is distributed in pores of a microstructure of the material. Due to the existence of pores in the sintered material, in the vulcanizationprocess, sulfur coated on the surface of the sintered material is heated to be in a molten state, enters the communicated pores of the sintered material, reacts with Cu in a sintered material matrix and generates Cu2S. Cu2S is an antifriction component, so that the antifriction effect of the material can be improved, and the friction coefficient is reduced, and the high-antifriction iron-based sulfide powder metallurgy oil-containing bearing material is obtained.

Owner:合肥波林新材料股份有限公司

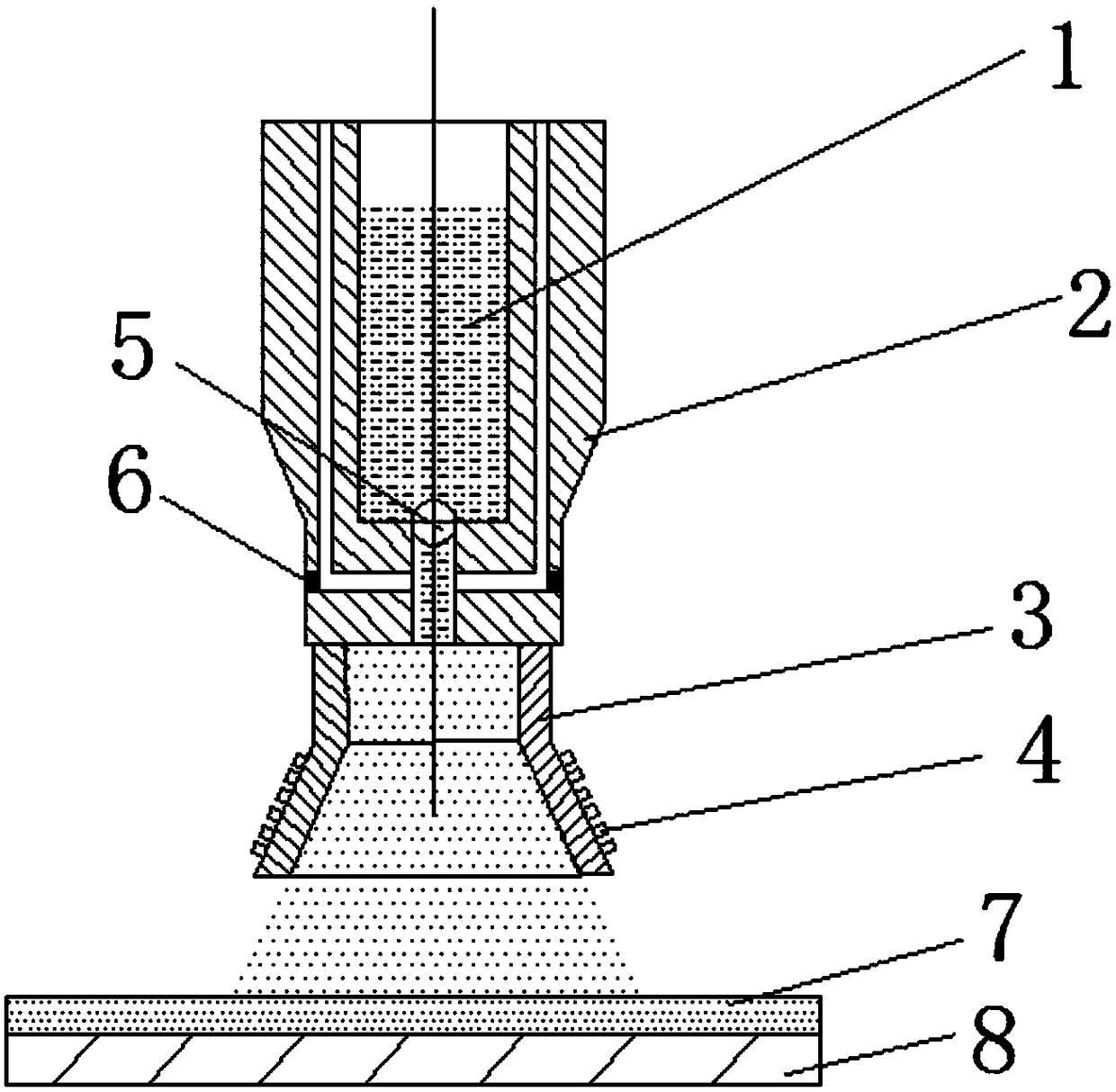

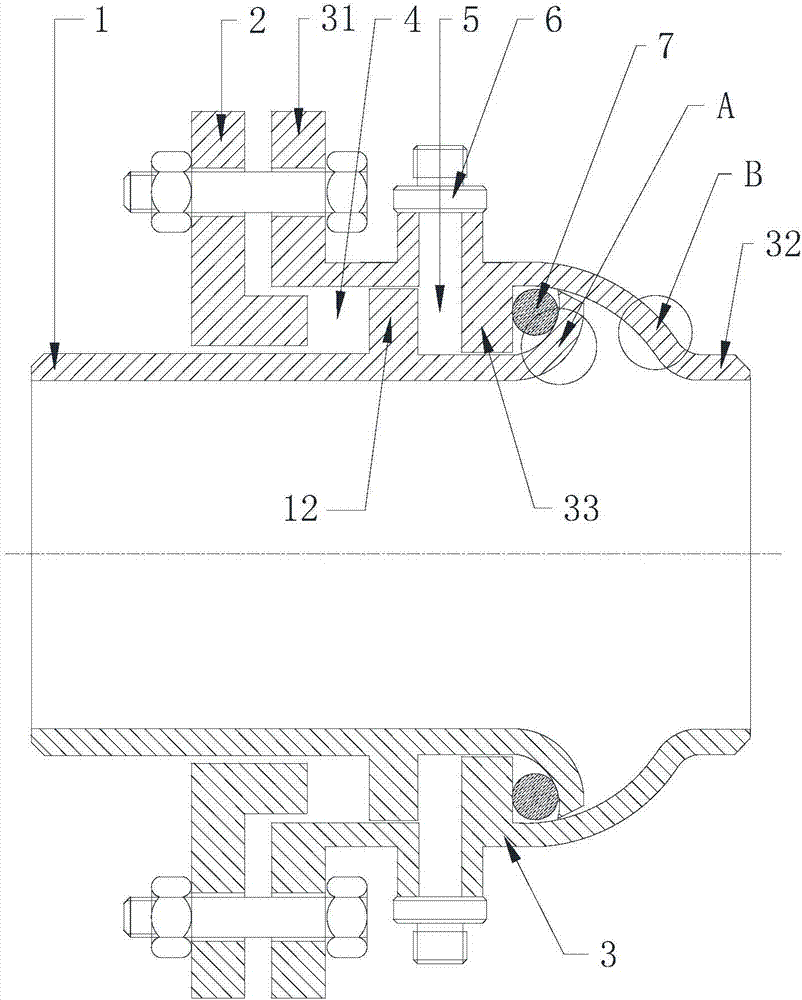

Crystal curing press head of radio frequency identification back-off packaging device

InactiveCN102903648AImprove hot pressing accuracySimple structureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a crystal curing press head of a radio frequency identification back-off packaging device. An air cylinder barrel of the press head is connected with an upper hot-press head template through a connecting assembly. A spring is installed in an adjusting ring, the adjusting ring and the spring are sleeved on a piston rod of an air cylinder, and the upper end of the adjusting ring is in threaded connection with the air cylinder barrel. The press head is connected with the lower portion of the piston rod through a heat insulating and dissipating device. The air cylinder is a gap sealing air cylinder. The crystal curing press head of the radio frequency identification back-off packaging device adopts the gap sealing air cylinder to replace a low-friction air cylinder, and the gap sealing air cylinder is simple in structure, good in low-friction performance and sealing performance, small in guiding gap and capable of avoiding shake of the piston rod in the moving process, so that the hot-press precision is high. Due to the fact that the gap sealing air cylinder is not provided with a sealing part made of a heat-intolerant material, the heat insulation is not strict, and a structure of the heat insulating and dissipating device is simplified.

Owner:CHANGSHUN GUANGHUA MICRO ELECTRONICS EQUIP ENG CENT

Environment-friendly corrosion-resistant and wear-resistant coating for ship waterline area and preparation method of environment-friendly corrosion-resistant and wear-resistant coating

ActiveCN109181475AReduce coefficient of frictionNo pollution in the processAnti-corrosive paintsEpoxy resin coatingsEpoxyThermal spraying

The invention discloses an environment-friendly corrosion-resistant and wear-resistant coating for a ship waterline area and a preparation method of the environment-friendly corrosion-resistant and wear-resistant coating. The environment-friendly corrosion-resistant and wear-resistant coating for the ship waterline area comprises a component A and a component B which are in the mass ratio of 1:1,wherein the component A contains the following components in parts by mass: 50-60 parts of epoxy curing agent, 0.2-0.5 part of defoaming agent, 70-90 parts of deionized water, 2-4 parts of rheologicalagent, 20-30 parts of titanium dioxide, 20-30 parts of antifriction agent and 40-50 parts of modified zinc-rich shell powder; and the component B contains the following component in parts by mass: 200-240 parts of epoxy resin. The environment-friendly corrosion-resistant and wear-resistant coating is used as a primer for the waterline area, is capable of effectively avoiding electrochemical corrosion under the environments of seawater scouring, solarization radiation and dry and wet alternation, omitting an aluminum hot-spraying process, simplifying a process and reducing the cost and has theservice life of more than 10 years if being used for the ship waterline area.

Owner:常州市天安特种涂料有限公司

Preparation method of nonferrous alloy anti-corrosion layer

ActiveCN111041538AHigh bonding strengthEnhance coverage and wettabilityAnodisationLiquid/solution decomposition chemical coatingAlloySol-gel

The invention provides a preparation method of a nonferrous alloy anti-corrosion layer. The preparation method comprises the following steps of raw material proportioning of a sol-gel solution, sol preparing, preparing of the sol-gel solution, film layer dipping and film layer drying. According to the method, sol-gel solution hole sealing is carried out on the porous microarc oxidization film, aneven film layer is obtained, surface clearances are reduced, binding force and smoothness are better, the coverage rate of a ceramic layer after nonferrous alloy oxidization is improved, the functionof hole sealing is achieved, the anti-friction function is also achieved, and the defects of surface needle holes, cracks and the like are overcome.

Owner:八龙应用材料科技(海南)有限公司

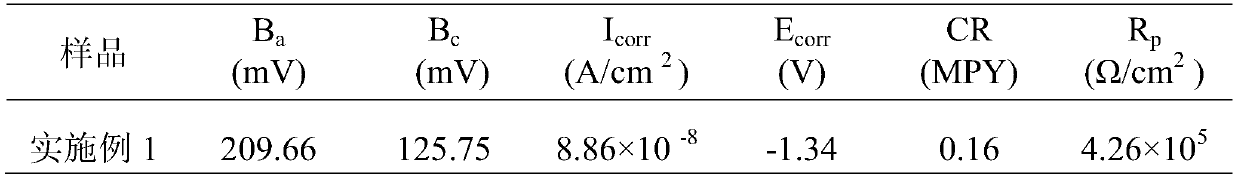

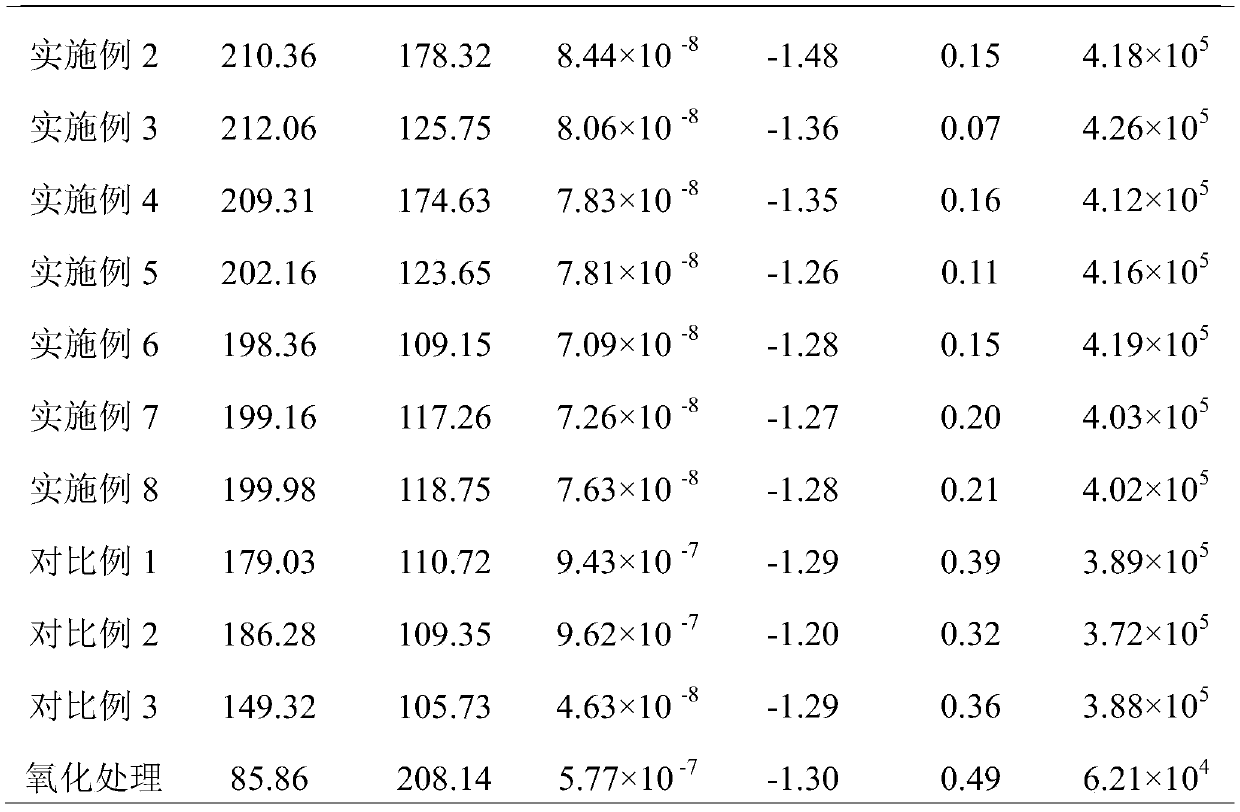

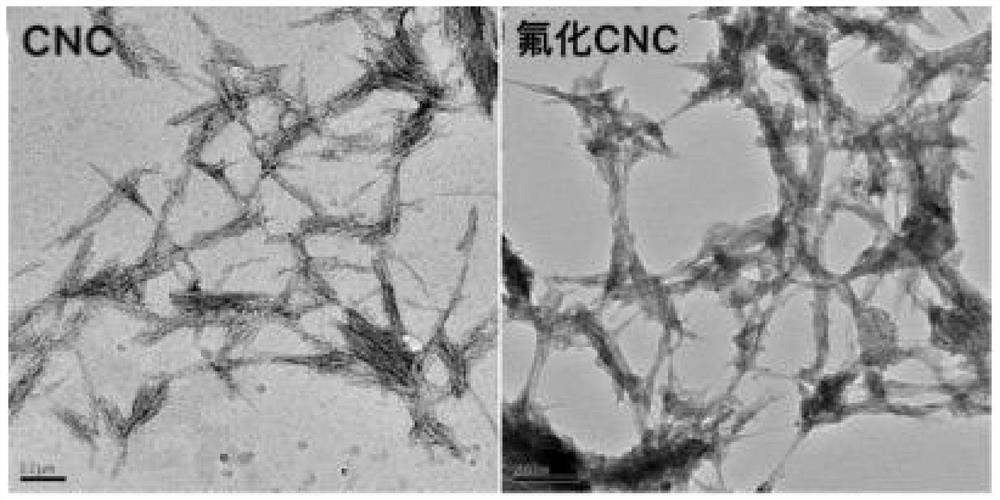

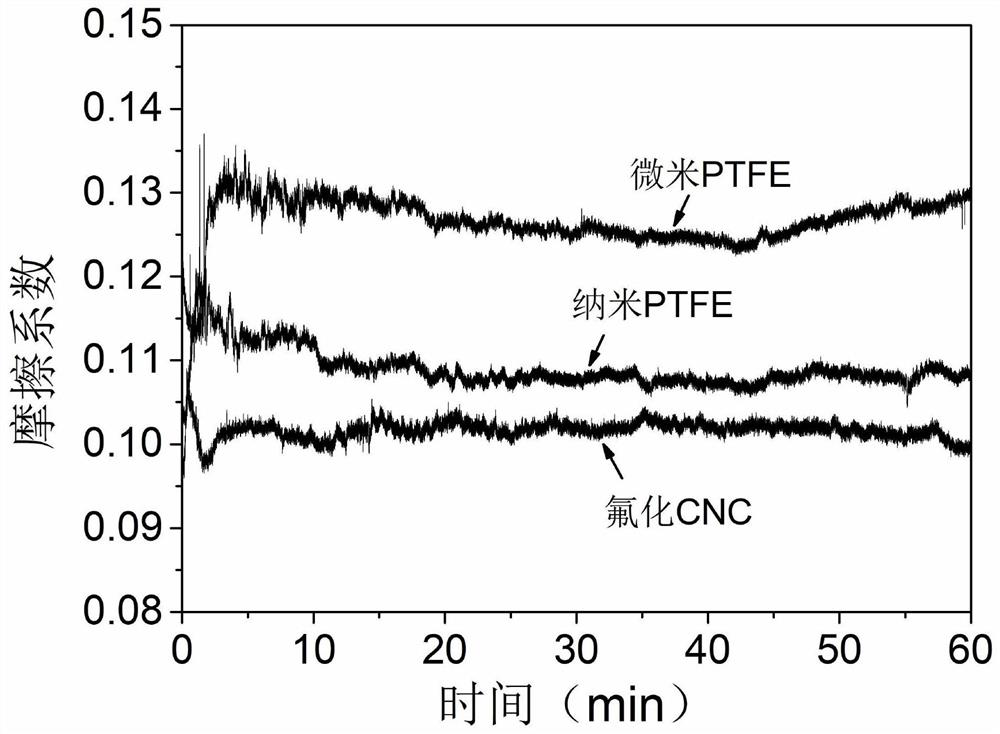

Preparation method of fluorinated cellulose nanocrystalline lubricating grease thickening agent

ActiveCN113563518AStrong thickening abilityHigh oil contentChemical industryAdditivesMeth-Atom-transfer radical-polymerization

The invention discloses a preparation method of a fluorinated cellulose nanocrystal lubricating grease thickening agent. The method comprises the following steps: dispersing cellulose nanocrystal into N, N-dimethylformamide, adding 4-dimethylaminopyridine and triethylamine, and carrying out ultrasonic dispersion to obtain a suspension; slowly dropwise adding a 2-bromoisobutyryl bromide solution into the obtained suspension in an inert atmosphere, heating to 70-90 DEG C after dropwise adding, reacting for 24-36 hours, centrifuging, washing and dialyzing to obtain CNC-Br powder; dispersing the CNC-Br powder into N, N-dimethylformamide, adding copper bromide, N, N, N, N, N-pentamethyldiethylenetriamine, cuprous chloride and a monomer with a fluorine-containing group, removing oxygen in a reaction system, and carrying out an atom transfer radical polymerization reaction in an inert atmosphere; and removing impurities, and drying the extracted product to obtain the product. According to the preparation method, surface hydroxyl groups of the cellulose nanocrystals are replaced by Br-containing ester groups, and then monomers with fluorine-containing groups are added, so that fluorinated chains grow on the surfaces of the cellulose nanocrystals for grafting, and the lubricating grease thickening agent with excellent performance is obtained.

Owner:WUHAN UNIV OF TECH +1

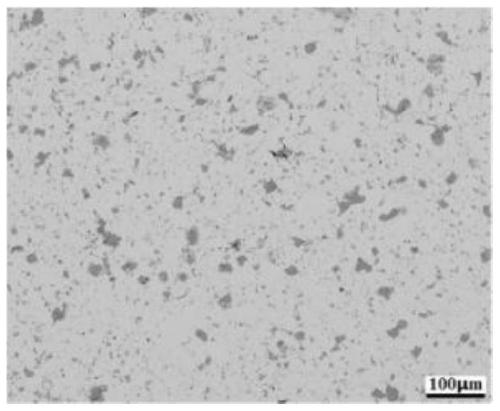

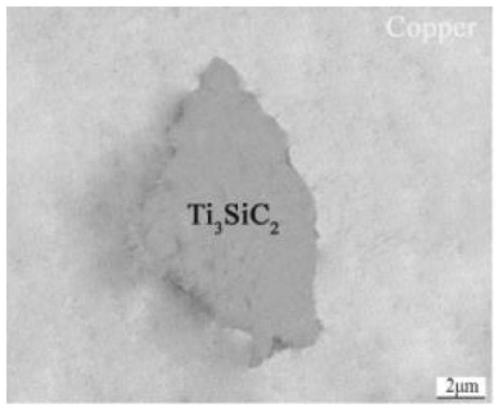

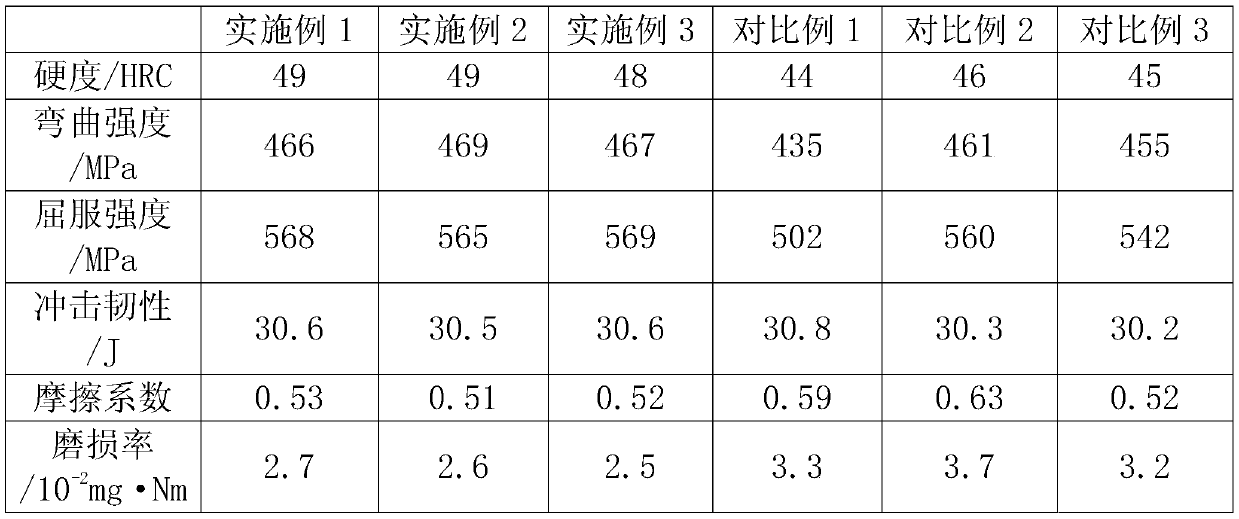

Preparation method of titanium element modified Ti3SiC2 enhanced Cu-base pantograph sliding plate

ActiveCN109852829AEnhanced interface bindingImprove mechanical propertiesVacuum evaporation coatingSputtering coatingDecompositionTin plating

The invention discloses a preparation method of a titanium element modified Ti3SiC2 enhanced Cu-base pantograph sliding plate. The preparation method comprises the steps that Ti3SiC2 ceramics are cleaned; the Ti3SiC2 ceramics are subjected to titanizing treatment by adopting a multi-arc ion plating technology, and a TiN plating layer generated in situ is obtained on the surface of the Ti3SiC2 ceramics; and then the proportioned Ti3SiC2 ceramics and metal powder are poured into a mould for cold pressing, sintering, re-pressing and resintering treatment, and after cooling and demoulding are carried out, the Ti3SiC2 enhanced Cu-base pantograph sliding plate is obtained. Introduced titanium elements can form TiN phases at the interface of a Cu-Ti3SiC2 composite in situ, so that a Cu base and Ti3SiC2 form metallurgical bonding, the interface bonding property of the composite is improved; and decomposition of the Ti3SiC2 can be inhibited through TiN, and it is guaranteed that the structure of the Ti3SiC2 is complete, so that the mechanical property and the wear resistance of the composite are improved, and the service life of the pantograph sliding plate is prolonged.

Owner:XI AN JIAOTONG UNIV +1

Alloy material for bearing rolling body and preparation method thereof

ActiveCN110066934AUniform stressHigh strengthTransportation and packagingMetal-working apparatusAlloyHardness

The invention discloses an alloy material for a bearing rolling body. The alloy material is prepared from the following raw materials in parts by weight: 80-100 parts of a base material, 9-11 parts ofa lubricant and 6-7 parts of modified graphene oxide, wherein the base material comprises Ti powder, Al powder, Cr powder, Nb powder and Al2O3 powder. The invention also discloses a preparation method of the alloy material. The preparation method comprises the following steps: two-step grinding, plasma sintering and the like. By taking the Ti powder, Al powder, Cr powder, Nb powder and Al2O3 powder as the base material of the alloy, the alloy material is prepared by means of two-step grinding and plasma sintering by adding the lubricant and the modified graphene oxide. By adding the stretchedlaminar graphene oxide, the mechanical properties of hardness, strength and the like of the alloy material can be improved. The self-lubricating effect of the alloy material can be improved by meansof a synergistic effect of the lubricant and a graphene lubricating film. The alloy material is prepared into the bearing rolling body which is excellent in comprehensive performance.

Owner:NINGBO DAER MACHINERY TECH CO LTD

Wear-resistant material, preparation method and application

ActiveCN111961942ASmall particlesNarrow particle size distributionMolten spray coatingMetal powderUltimate tensile strength

The invention provides a wear-resistant material, a preparation method and an application. The material comprises the following components in percentage by mass: 20%-25% of ceramic tungsten carbide powder, 40%-60% of Mo-B powder, 5%-10% of metal Co powder, 4% of large tungsten carbide particles and the balance of Fe. A nano-cermet coating is prepared from a novel ceramic wear-resistant powder material, the problems of poor wear resistance of current hob rings, and failure of frequent tipping, edge rolling, abnormal wear and the like and the problems of short service life, frequent replacementand the like due to lack of wearability are solved, the nano-cermet coating is prepared from the novel ceramic wear-resistant powder material, the binding strength between the coating and a ring matrix is high, the material has good compactness, low porosity, high hardness and good wear resistance, frequent stop and hob change caused by lack of wear resistance are reduced, and powerful support andguarantee are provided for efficient tunnel construction and excavation.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material and preparation method thereof

InactiveCN112159242AImprove fracture toughnessImprove anti-friction and anti-wear propertiesCeramic compositeComposite ceramic

The invention discloses a graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material and a preparation method thereof, belongs to the field of cutter materials, and aims to solve the technical problem of how to further improve the fracture toughness and antifriction and antiwear properties of a ceramic composite material in a high-speed cutting process. Accordingto the technical scheme, the graphene nanosheet-based toughened aluminum oxide titanium boride composite ceramic material is mainly prepared from, by weight, 70-80 parts of submicron aluminum oxide, 20-30 parts of titanium boride, 0-0.6 part of graphene and 0.4-1.5 parts of a sintering aid. The graphene nanosheet-based toughened aluminum oxide titanium boride composite ceramic material is used forpreparing cutters. The invention also discloses a preparation method of the graphene nanosheet-based toughened aluminum oxide-titanium boride composite ceramic material.

Owner:QILU UNIV OF TECH

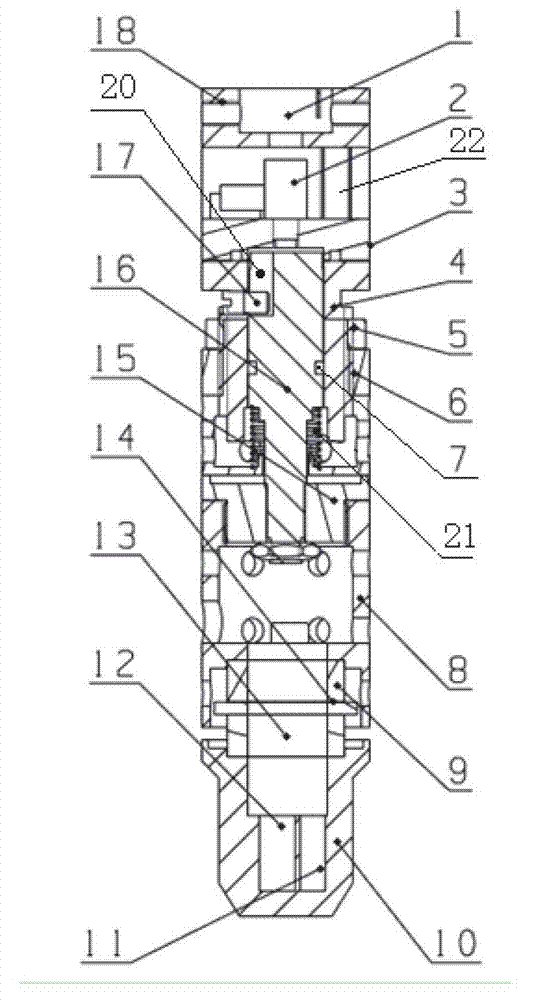

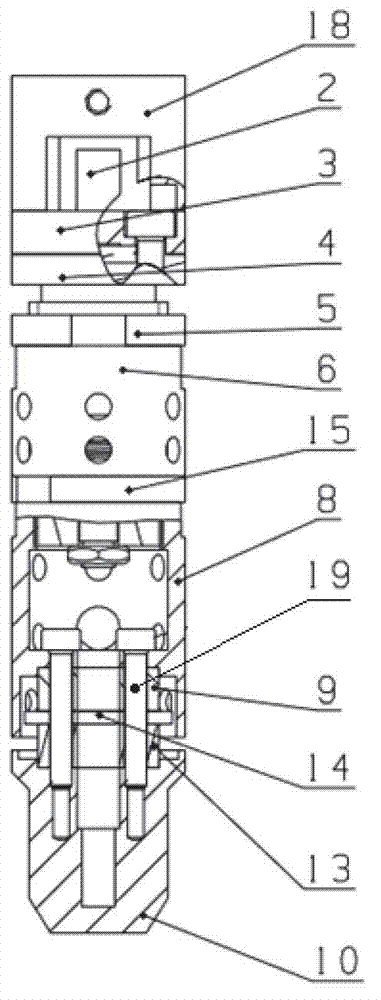

Zero-thrust multifunctional rotating compensator and manufacturing method thereof

PendingCN107270013AFlexible operationReduce frictionPipeline expansion-compensationAdjustable jointsHigh pressureUltimate tensile strength

The invention relates to a zero-thrust multifunctional rotating compensator and a manufacturing method thereof. The compensator comprises a rotating pipe and a rotating seat; one end of the rotating seat is provided with a rotating seat flange, and the other end of the rotating seat is provided with an arc-shaped shrinkage pipe; one side of the rotating seat flange is provided with a gland flange; the outer circumference of the rotating pipe is provided with a convex ring; the inner wall of the rotating seat is provided with a packing ring; the gland flange and the convex ring of the rotating pipe form a first packing cabin; the convex ring of the rotating pipe and the packing ring of the rotating seat form a second packing cabin; the end, close to the arc-shaped shrinkage pipe of the rotating seat, of the rotating pipe is provided with a port which is outwards turned; and an end surface sealing ring is arranged between the outwards-turned port of the rotating pipe and the packing ring of the rotating seat. The manufacturing method comprises the steps: (1) outwards turning the end of the rotating pipe; (2) arranging a metal end surface sealing ring; and (3) stretching the end of the rotating seat to form an arc-shaped pipe which is inwards shrunk. The zero-thrust multifunctional rotating compensator is suitable for a high-pressure heat pipe network, free of welding in whole, high in bearing strength, free of eccentricity, good in sealing performance, safe and reliable in use and long in product life.

Owner:JIANGSU YONGLI PIPELINE CO LTD

A kind of alloy material for bearing rolling body and preparation method thereof

ActiveCN110066934BIncrease room temperature shapingHigh strengthTransportation and packagingMetal-working apparatusAl powderUltimate tensile strength

The invention discloses an alloy material for a bearing rolling body, which is made of the following raw materials in parts by weight: 80-100 parts of base material, 9-11 parts of lubricant, 6-7 parts of modified graphene oxide, and the base material includes Ti powder, Al powder, Cr powder, Nb powder, Al 2 o 3 powder; the invention also discloses the preparation method of the alloy material, including two steps of ball milling and plasma sintering. The present invention adopts Ti powder, Al powder, Cr powder, Nb powder, Al 2 o 3 The powder is used as the matrix material of the alloy, and lubricant and modified graphene oxide are added, and the alloy material is prepared by two-step ball milling method and plasma sintering method. The addition of stretched lamellar graphene oxide can improve the hardness and strength of the alloy material And other mechanical properties, the synergistic effect of the lubricant and the graphene lubricating film can improve the self-lubricating effect of the alloy material, and the alloy material can be made into a bearing rolling body with excellent comprehensive performance.

Owner:NINGBO DAER MACHINERY TECH CO LTD

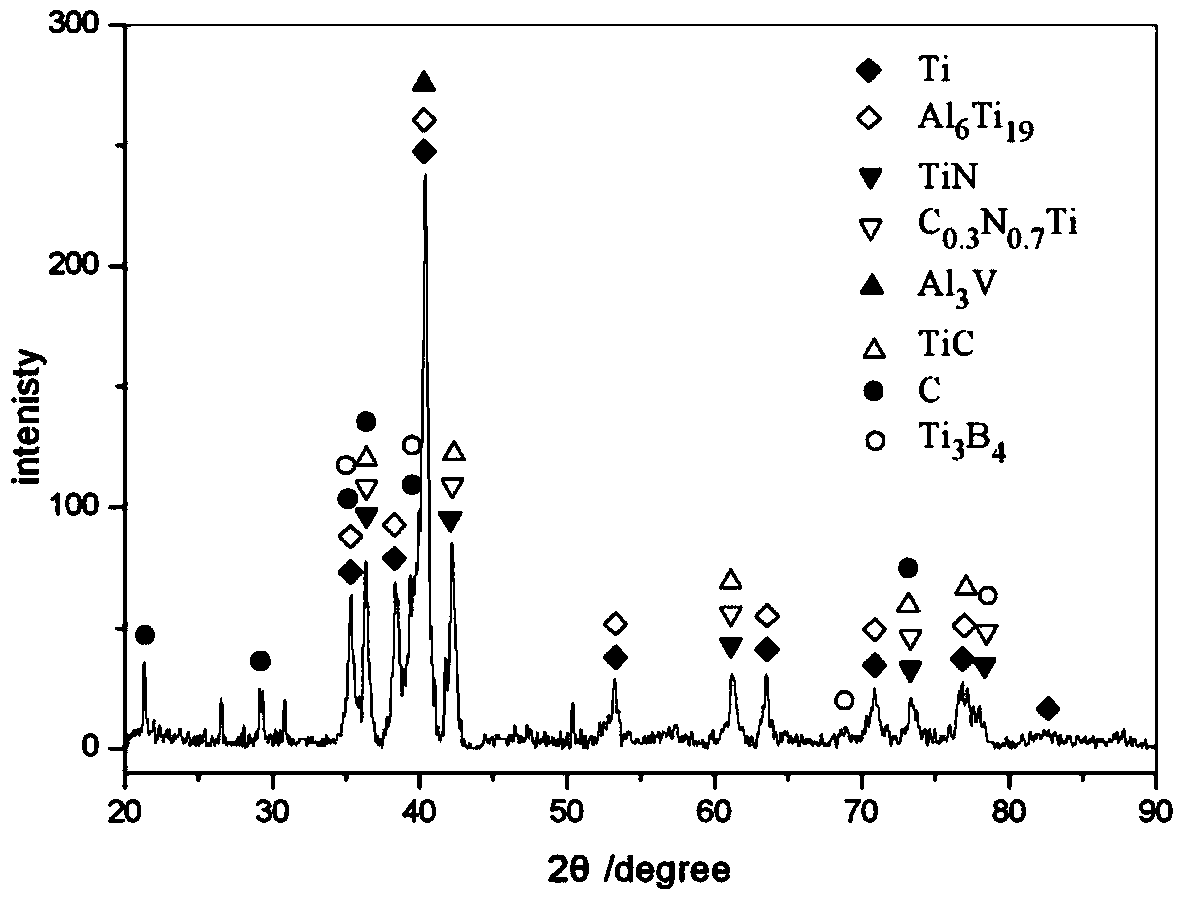

A kind of multi-element laser alloying layer on the surface of titanium alloy and its preparation method

ActiveCN103966598BGood metallurgical bondIncrease contentMetallic material coating processesWear resistantComposite ceramic

The invention relates to a titanium alloy surface multi-element laser alloyed layer and a preparation method thereof. The preparation method comprises the following steps: by using titanium alloy as a base material, applying mixed powder of B4C, graphite, Ti powder and rare-earth oxides Y2O3 used as a coating material onto the titanium alloy surface, and carrying out laser scanning while blowing nitrogen gas to perform alloying, wherein the coating material comprises the following components in percentage by mass: 10-90% of B4C, 10-90% of graphite powder, 0-50% of Ti powder and 0-4% of Y2O3.In an open N2 environment, the B4C and graphite powder are subjected to boron-carbon-nitrogen multi-element composite laser alloying on the titanium alloy surface to prepare the high-hardness wear-resistant composite ceramic coating. The simultaneous addition of the Ti powder and rare-earth oxides Y2O3 is beneficial to enhancing the microhardness and wear resistance of the alloyed layer; and the proper amount of Ti can promote the in-situ reaction in the alloyed layer, and the Y2O3 can refine the structure, thereby enhancing the comprehensive mechanical properties of the coating.

Owner:SHANDONG UNIV

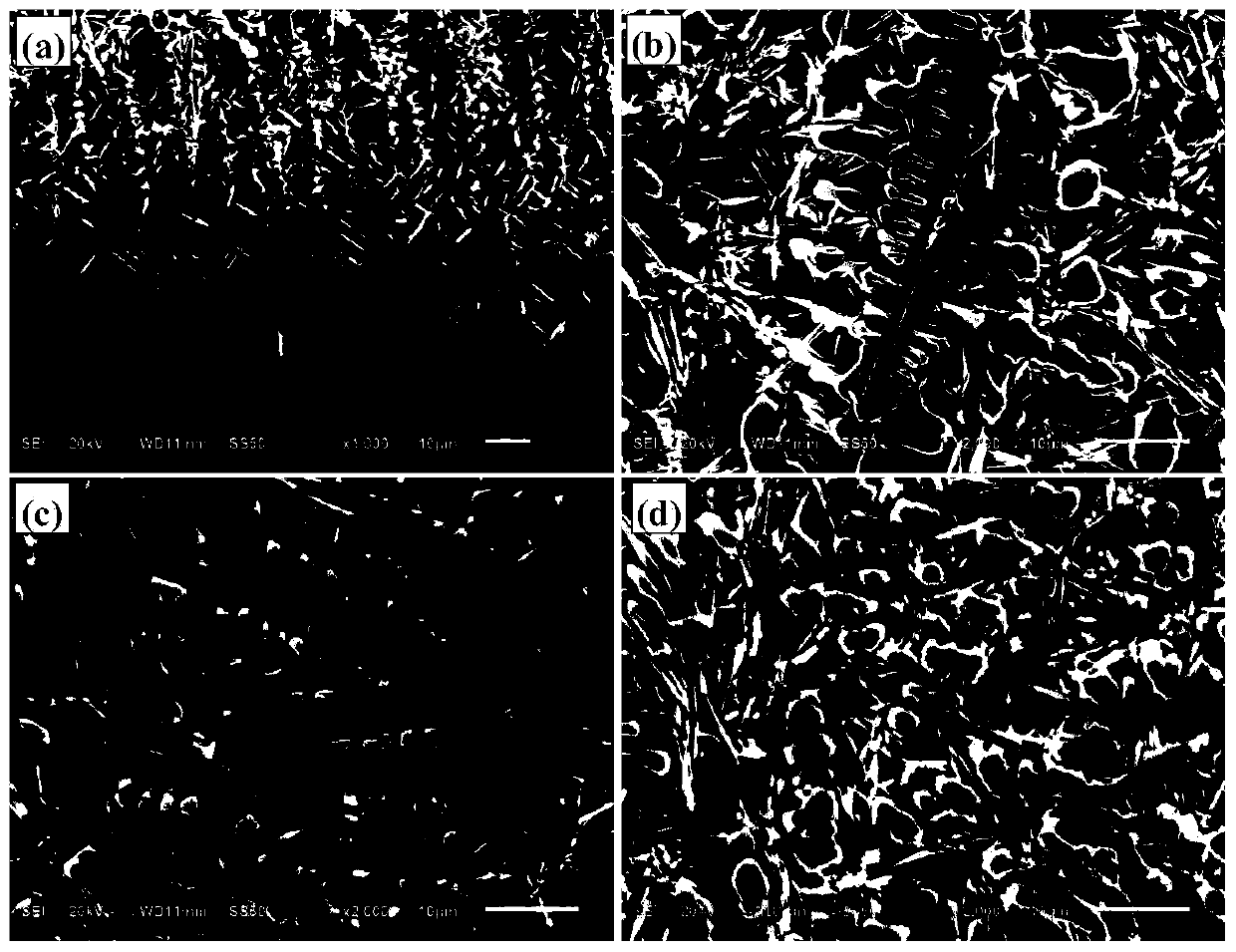

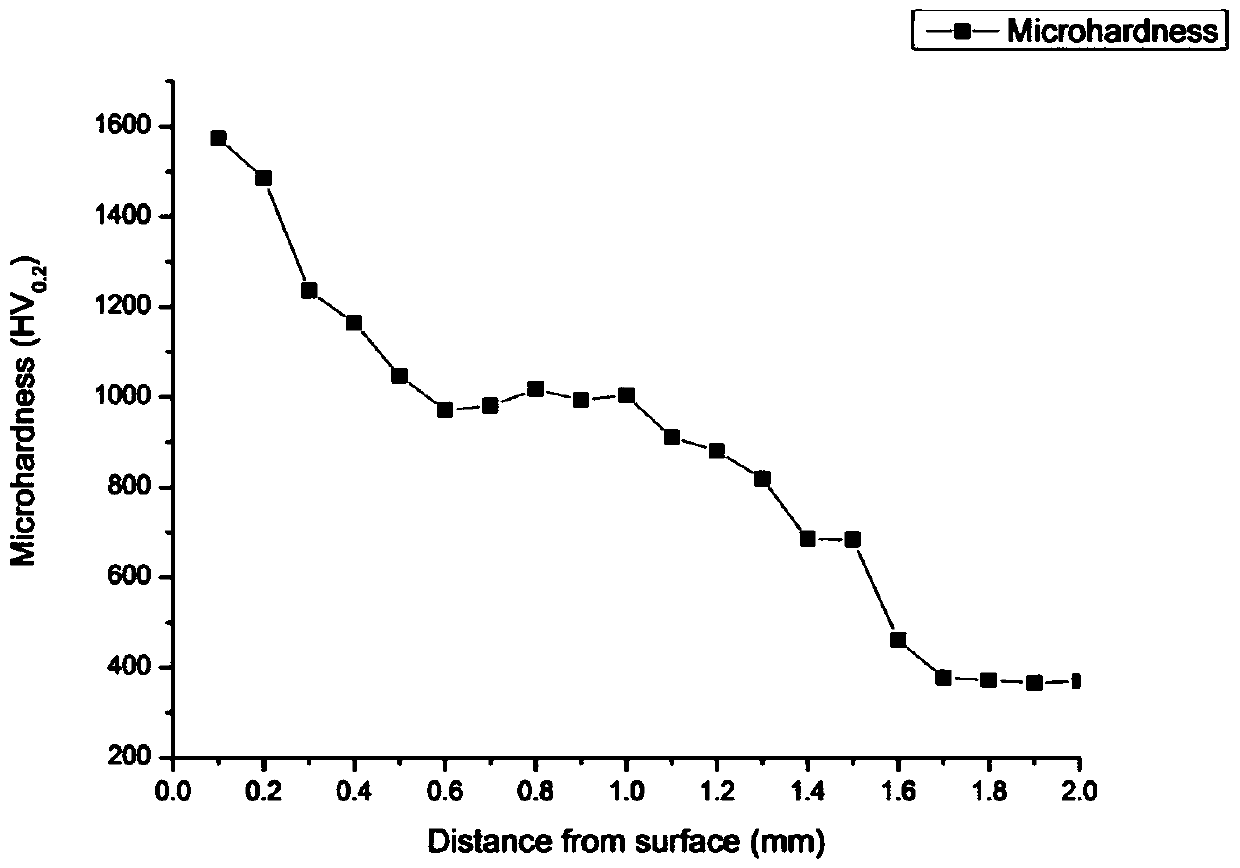

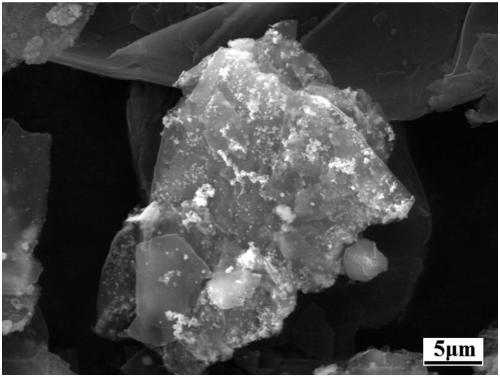

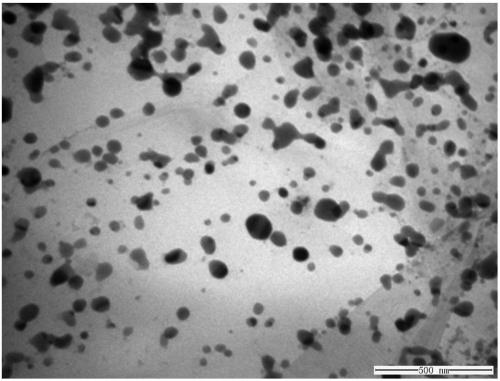

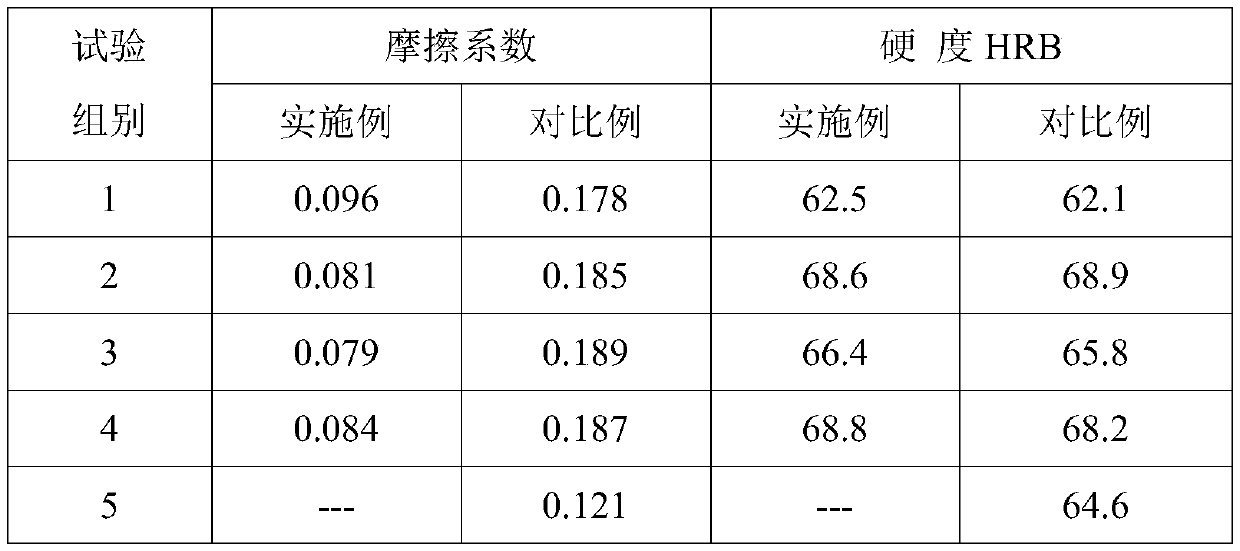

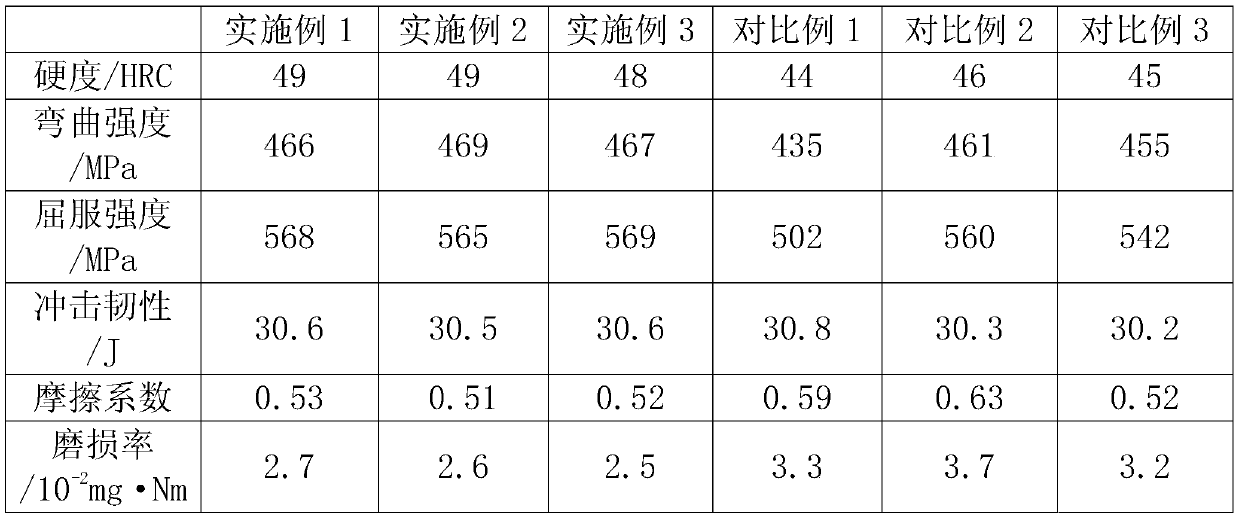

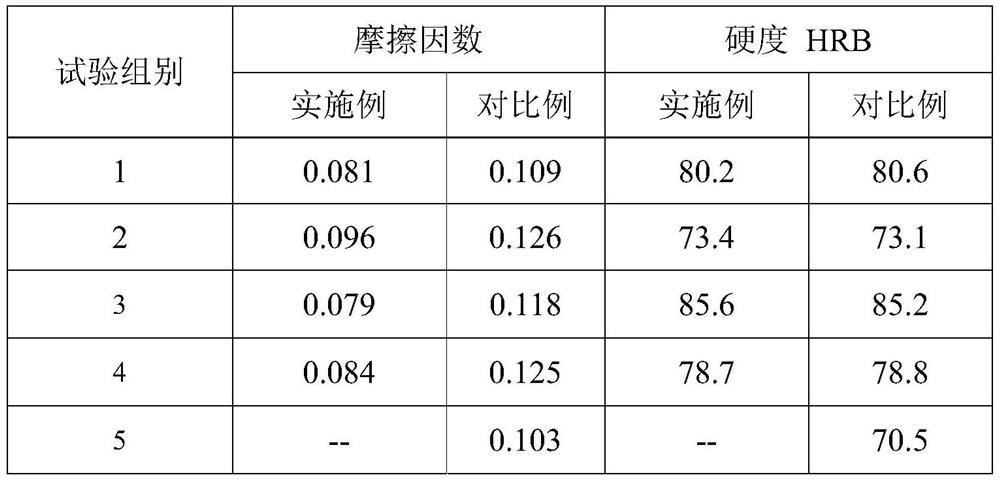

a nano b 4 C modified anti-friction and wear-resistant laser cladding layer and preparation method thereof

ActiveCN107201515BReduce coefficient of frictionPlay a role in reducing frictionMetallic material coating processesWear resistantHardness

Owner:SHANDONG UNIV

Carbon-based composite material for sliding block of current collector and preparation method thereof

ActiveCN102002621BImprove conductivityImprove mechanical propertiesNon-metal conductorsCobaltMechanical property

The invention relates to a carbon-based composite material for a sliding block of a current collector. The carbon-based composite material is characterized by using a mixture of 15 to 30 mass percent of graphite and 20 to 30 mass percent of active carbon as a matrix, using 15 to 35 mass percent of copper powder as a conductive component, using 10 to 20 mass percent of solid phenolic resin as a binder and using a mixture of 1 to 6 mass percent of silicon powder, 1 to 6 mass percent of glass powder, 1 to 6 mass percent of aluminium oxide powder, 2 to 8 mass percent of aluminium powder, 2 to 8 mass percent of tin powder, 1 to 2 mass percent of cobalt powder and 1 to 2 mass percent of molybdenum disulfide as a modifier. The carbon-based composite material has a metal conductive network structure and can effectively improve conductivity; the graphite serves as the matrix and has antifriction effect, so the prepared sliding block material has small friction coefficient; and the modified components can improve the interface combination of a metal matrix and a carbon matrix and improve the mechanical property of the carbon-based sliding block material.

Owner:BEIHANG UNIV

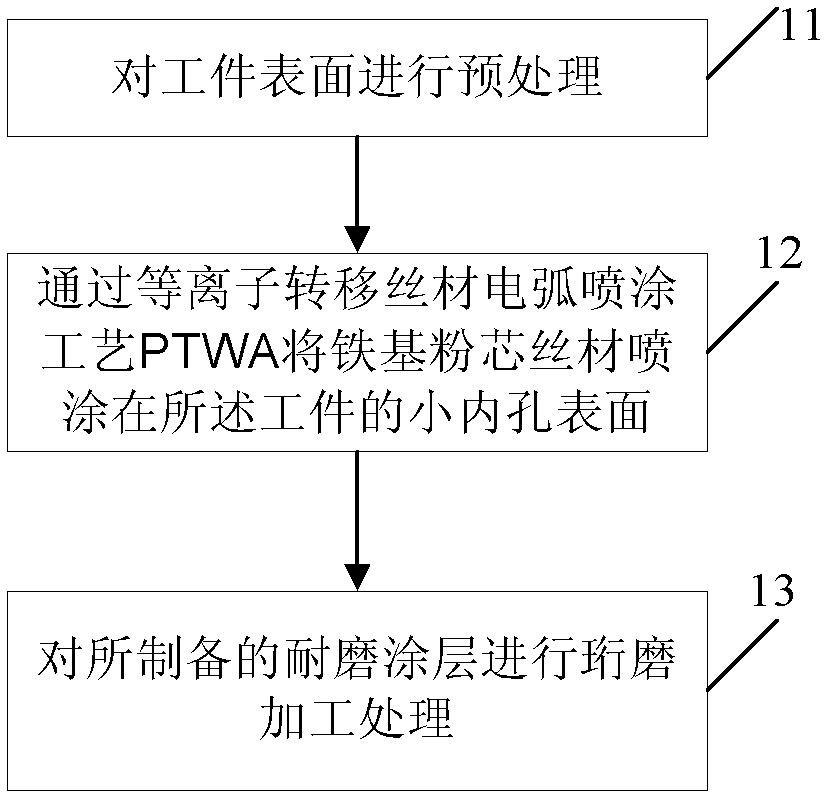

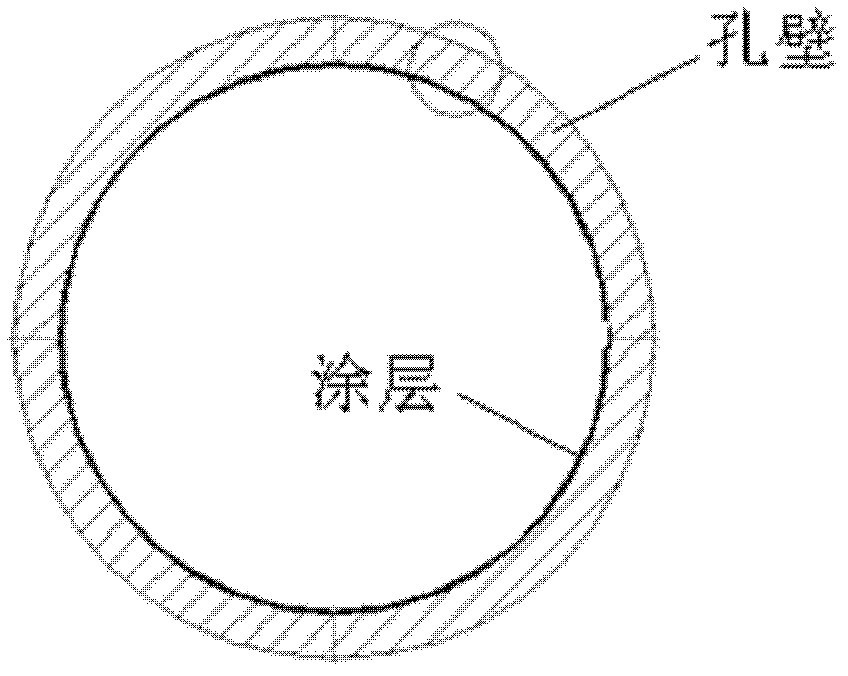

Method for spraying inner wall with novel plasma cored wire

ActiveCN102517536BNot easy to fall offHigh hardnessMolten spray coatingWear resistantThermal expansion

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

A high-strength anti-friction aluminum alloy

ActiveCN104561706BHigh strengthInhibition of recrystallizationRare-earth elementChemical composition

The invention discloses a high-strength antifriction aluminum alloy which comprises the following chemical components in percentage by weight: 1.0-7.0% of tin, 3.0-7.0% of copper, 0.20-1.60% of manganese, 0.40-1.60% of silicon, 0.40-2.0% of magnesium, 0.01-1.0% of rare earth element scandium, at most 0.70% of impurities and the balance of aluminum. The aluminum alloy has the advantages of uniform and segregation-free components, fine structure and high tensile strength (up to 320-350 MPa). The friction factor is less than 0.02, and the aluminum alloy has excellent antifriction property and wear resistance. The aluminum alloy has the advantages of favorable processability and low cost.

Owner:安徽熠辉新材料有限公司

In situ friction polymer , and preparation method

This invention discloses a method for preparing in situ friction polymer, which comprises: polymer of acrylate monomer 1.0-10.0 wt. %, and base oil 90.0-99.0 wt. %. The method comprises: adding acrylate monomer into base oil, performing interfacial friction to initiate polymerization of acrylate monomer on the friction surface and obtain a protective film. The friction conditions are: loading is 10-100 N, temperature is 20-50 deg.C, rotational speed is 195-585 rpm, and time is above 30 min. The in situ friction polymer has such advantages as simple process, good compatibility with friction medium, and few influences on oil quality. The in situ friction polymer has friction-reducing and coagulation-decreasing functions, and can improve oil quality.

Owner:BEIJING UNIV OF CHEM TECH

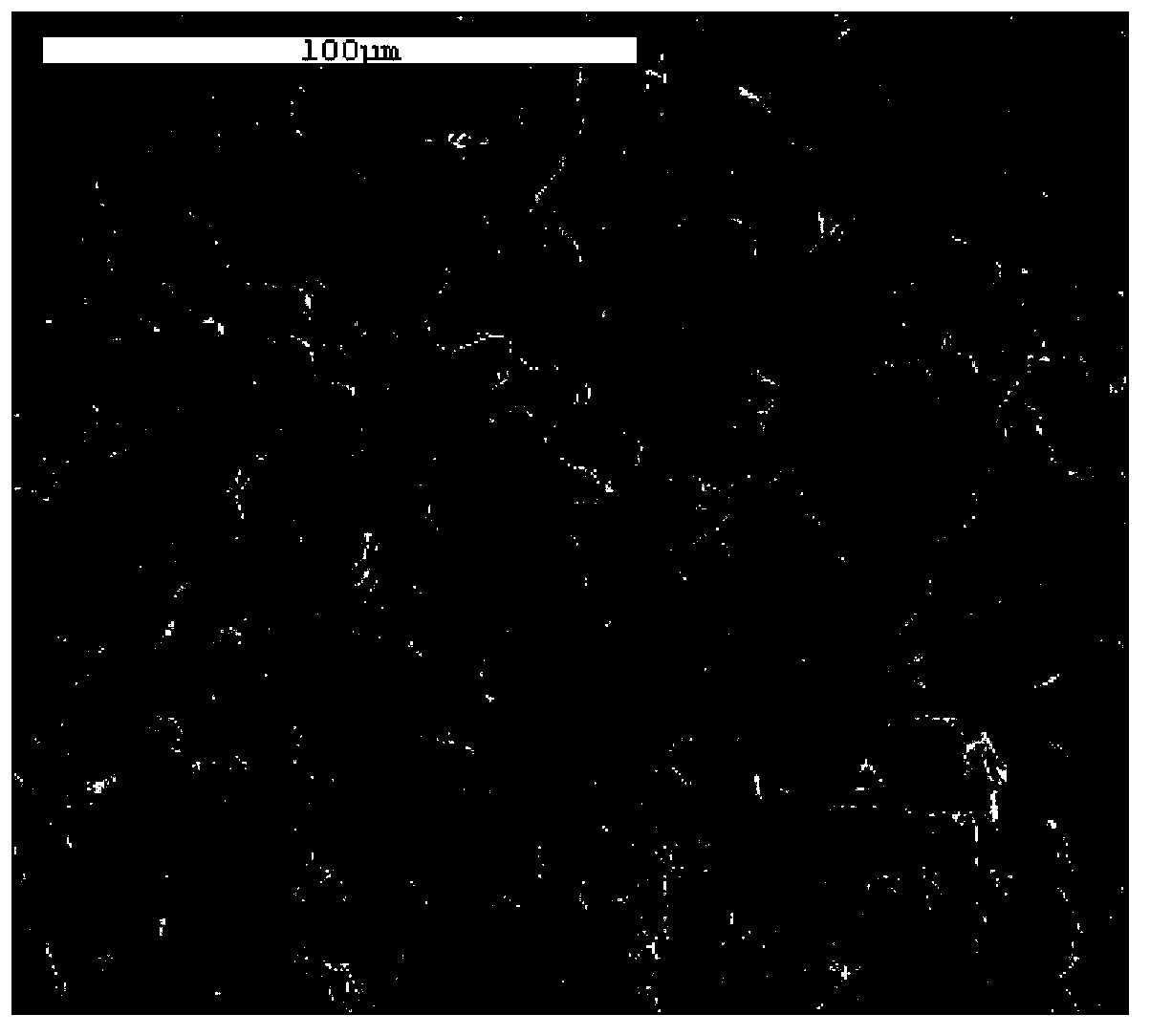

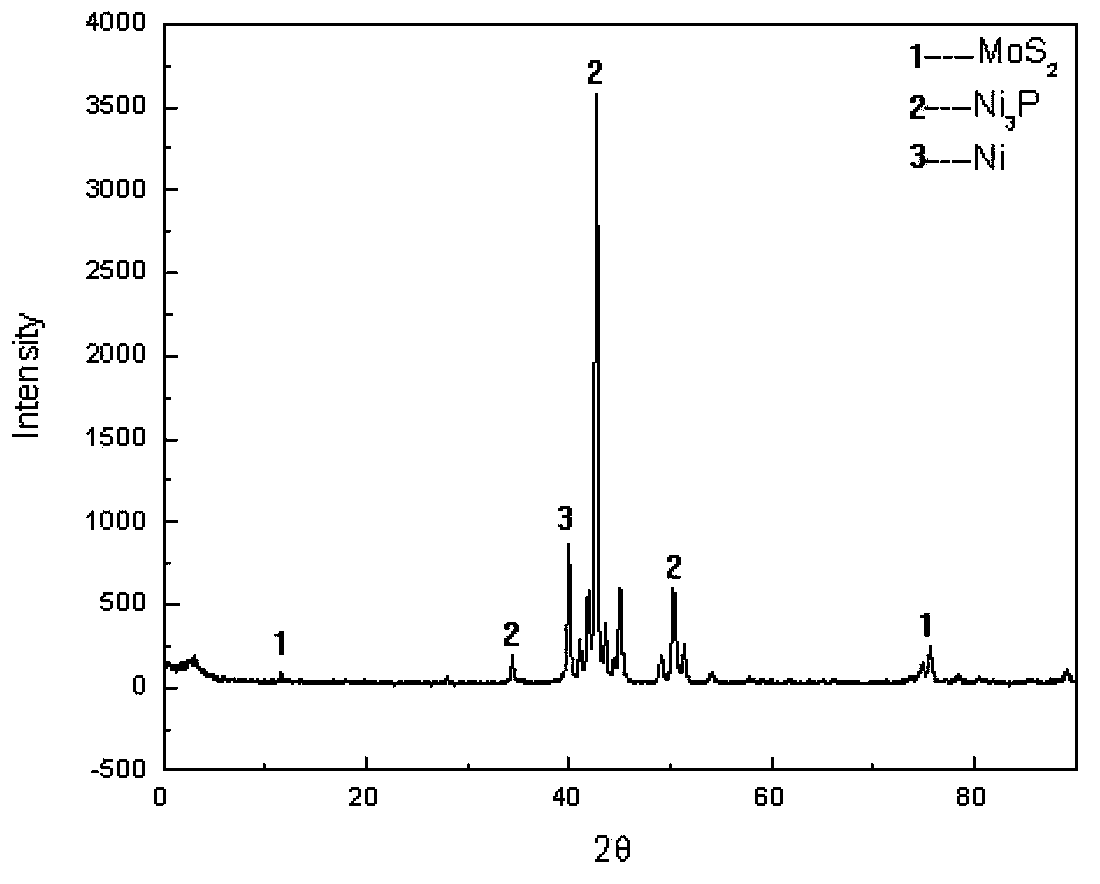

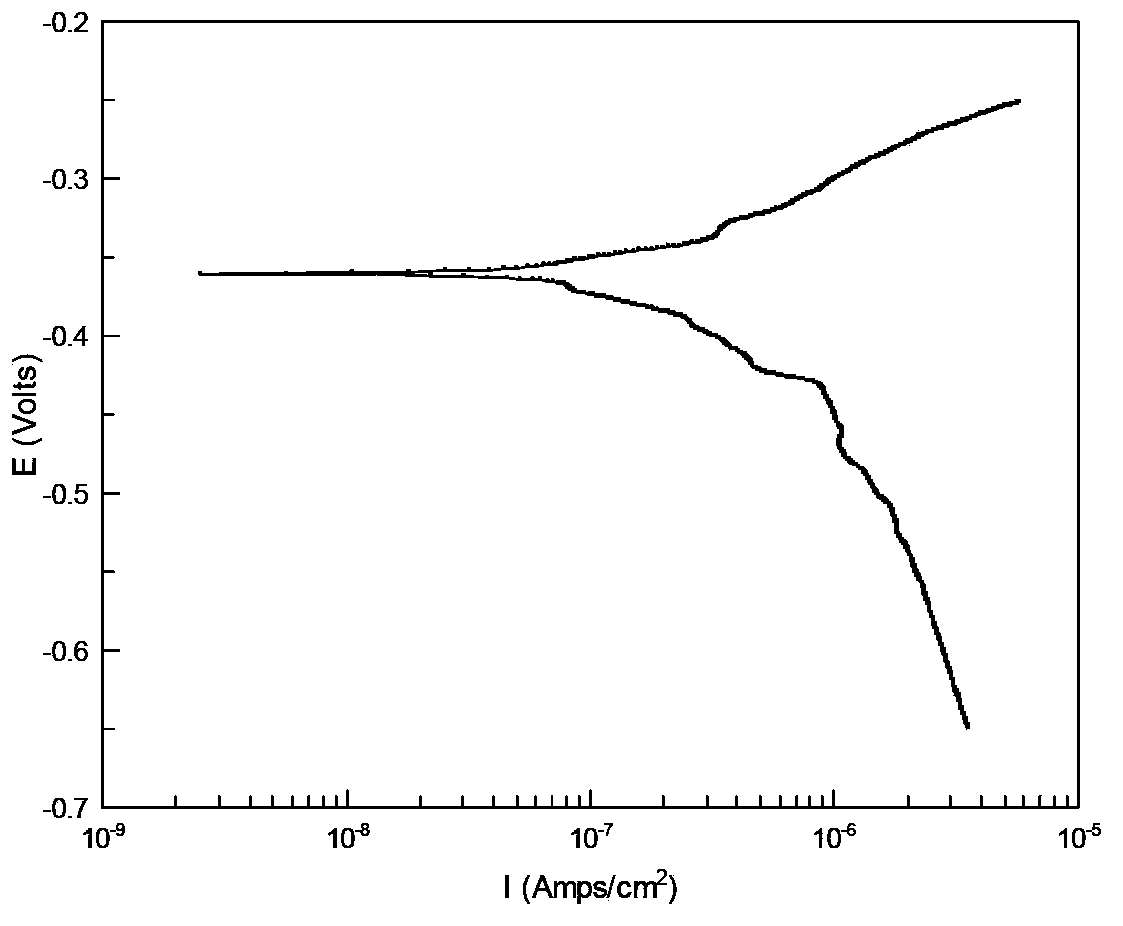

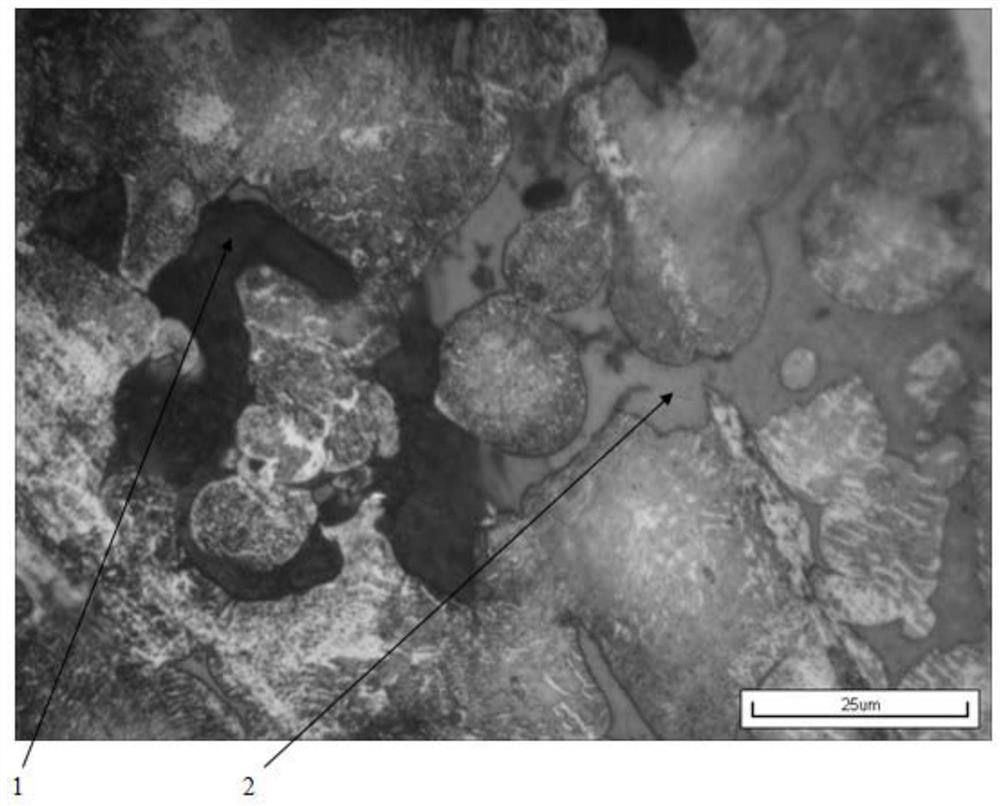

Preparation method of self-lubricating coating of traveller for textile

InactiveCN102747346BImprove wear resistanceHigh hardnessLiquid/solution decomposition chemical coatingHardnessPre treatment

The invention provides a preparation method of a self-lubricating coating of a traveller for textile. The preparation method comprises the following steps: 1, carrying out surface pre-treatment on the traveller for textile; 2, dipping into plating liquid to plate to obtain an Ni-P-MoS2 self-lubricating coating on the surface of the traveller for the textile. The preparation method, provided by the invention, is simple, easy to control and short in process flow; the self-lubricating coating of the traveller for the textile, prepared by the invention, is compact, uniform and firmly combined with the traveller for the textile, and has the advantages of high hardness, good wear resistance and good anti-corrosion protection performance.

Owner:XIAN UNIV OF SCI & TECH

Iron-based sintered vulcanized material and its preparation method, iron-based side plate and oil distribution plate

ActiveCN110735106BGood anti-frictionLow friction factorSolid state diffusion coatingGear pumpSulfidation

The invention provides an iron-based sintered vulcanized material, the material composition of which includes Fe, Cu, S, and Cu exists in the microstructure 2 S. It also provides a preparation method for iron-based sintered vulcanized materials. The raw materials are mixed, pressed, and sintered, and sulfur is coated on the surface of the sintered material by coating, and placed at a temperature higher than the melting point of sulfur. Into the pores of the sintered material, the sintered vulcanized material is obtained. In the vulcanization process, the sulfur coated on the surface of the sintered material enters the pores of the sintered material after heat preservation, and reacts with Cu around the pores to form Cu 2 S. while Cu 2 S is an anti-friction component, which can improve the anti-friction effect of the sintered material and reduce the friction factor. At the same time, it also discloses a gear pump side plate, a vane pump or a plunger pump oil distribution plate made of iron-based sintered vulcanized material.

Owner:合肥波林新材料股份有限公司

A kind of laser alloying layer on titanium alloy surface and preparation process thereof

ActiveCN103614722BFlat surfaceDense microstructureMetallic material coating processesOptoelectronicsTitanium alloy

The invention relates to a laser alloying layer on a titanium alloy surface and a preparation process thereof. Titanium or titanium alloy is used as a matrix material, and BN or BN and graphite powder are used as a coating material which is applied to the matrix material; a continuous laser is used for scanning a sample, wherein the service power is 800-1,200W, the diameter of a light spot is kept at 4mm, and the scanning speed is 2-10mm / s; in a scanning process of a laser beam, argon is blown to protect a molten pool and a laser lens barrel, and the argon pressure is kept at 0.2-0.4MPa. In the invention, the BN and graphite powder have similar structure and relatively good compatibility; after laser treatment, possible residual BN and graphite particles on the alloying layer can realize an antifriction effect to a certain degree; the surface of the alloying layer is relatively flat, the microstructure is dense, and the hardness is remarkably improved over the matrix.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com