Preparation method of self-lubricating coating of traveller for textile

A technology of self-lubricating coating and traveler, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problems that the self-lubricating coating of textile traveler has not been found in the report, and achieve the combination The effect of strong strength, no cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

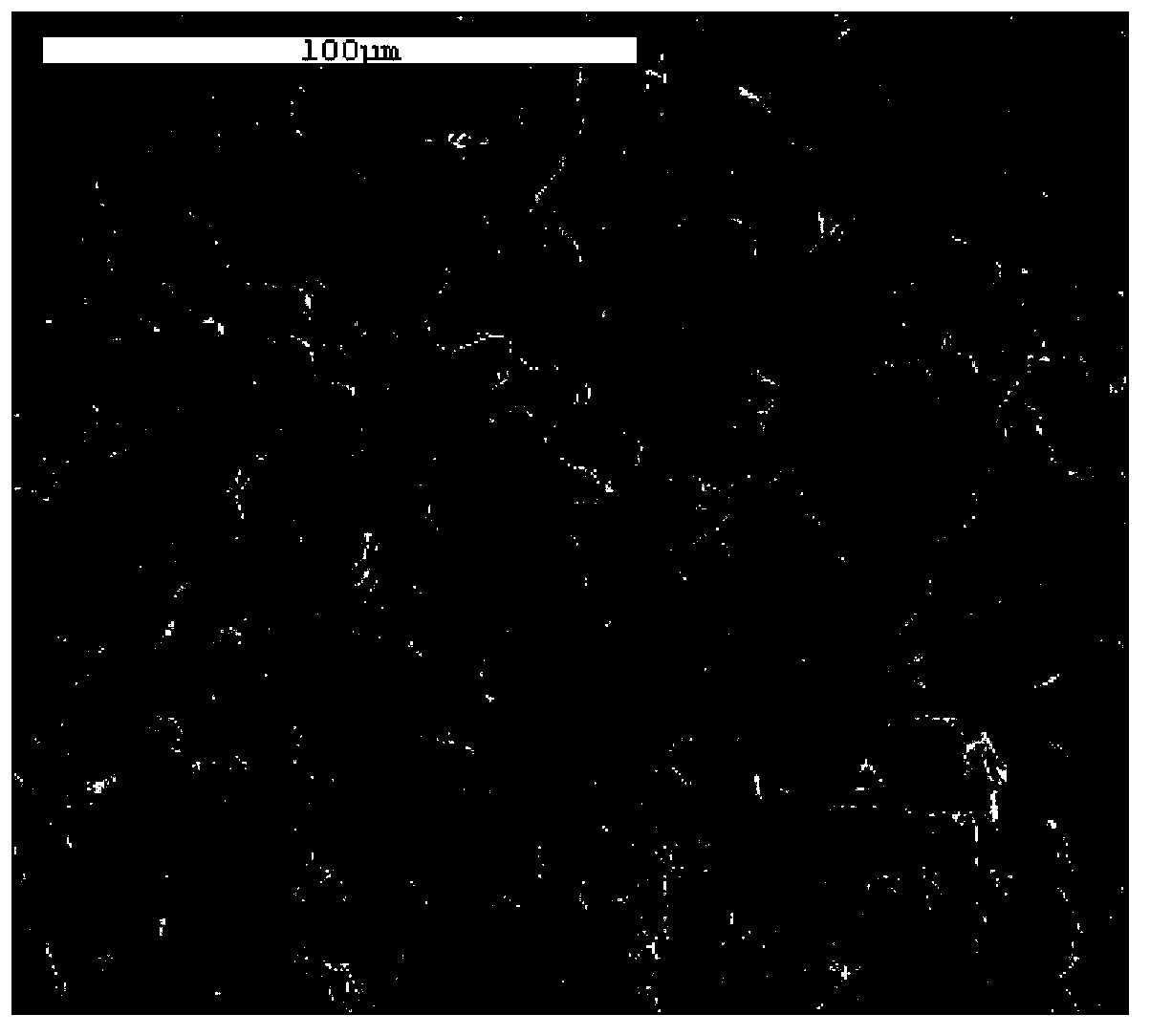

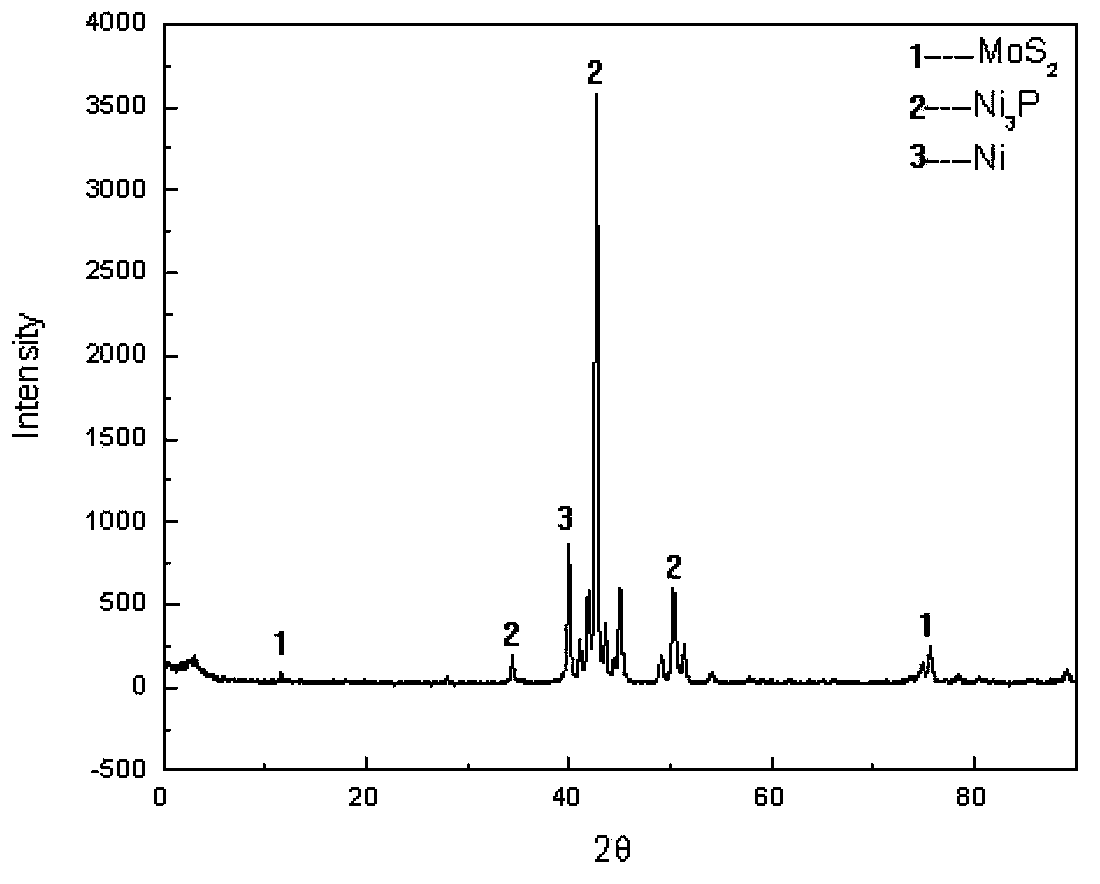

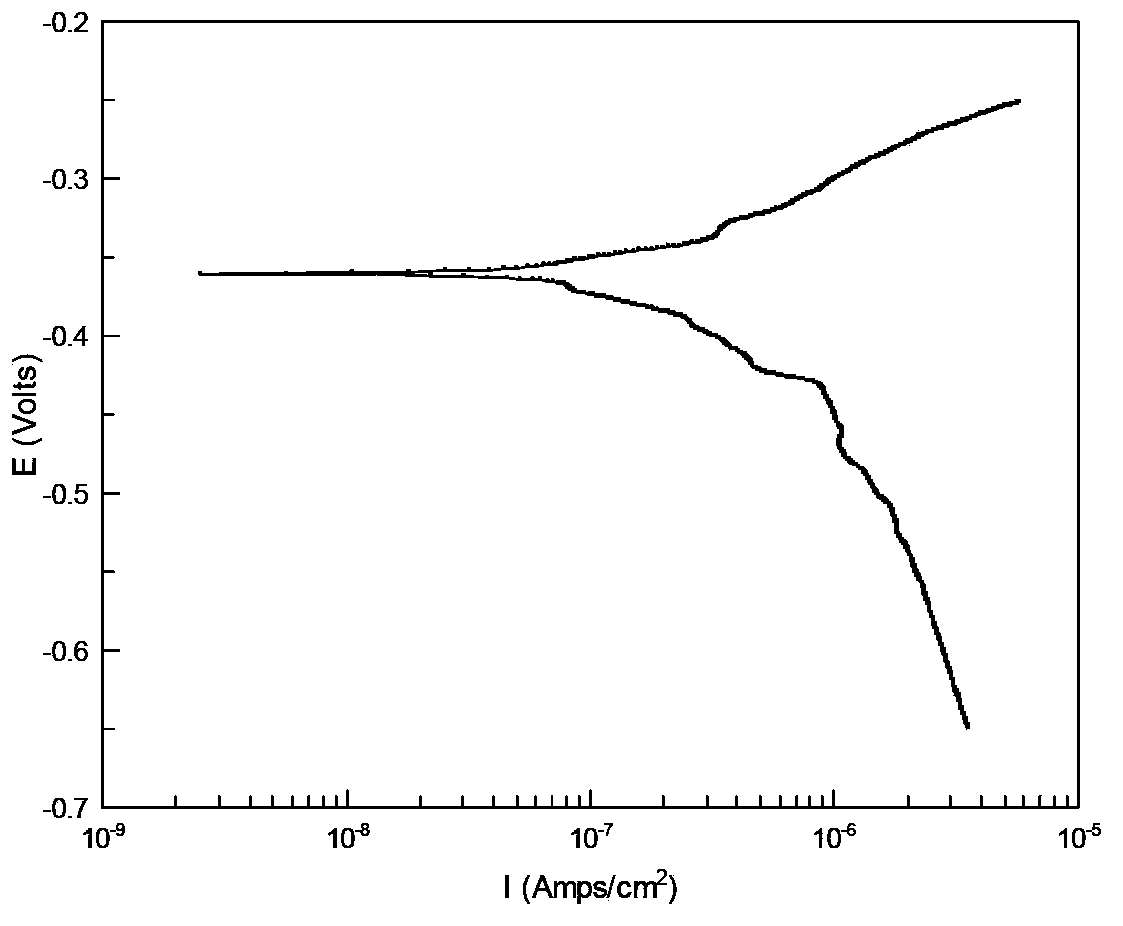

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the textile traveler self-lubricating coating of the present embodiment comprises the following steps:

[0034] Step 1. Surface pretreatment of the textile traveler:

[0035]Step 101, immerse the textile traveler in a degreasing solution for degreasing for 15 minutes; the degreasing solution is preferably a mixed solution made of sodium hydroxide, sodium acetate, trisodium phosphate, sodium silicate and deionized water, Wherein the concentration of the sodium hydroxide is preferably 25g / L, the concentration of the sodium acetate is preferably 12g / L, the concentration of the trisodium phosphate is preferably 25g / L, and the concentration of the sodium silicate is preferably 0.7g / L;

[0036] Step 102, ultrasonically clean the textile traveler after degreasing in step 101; the ultrasonic cleaning process is preferably: first place the degreasing textile traveler in acetone for 30 seconds, and then place it in anhydrous Ultrasonic cleaning in eth...

Embodiment 2

[0041] The preparation method of the textile traveler self-lubricating coating of the present embodiment comprises the following steps:

[0042] Step 1. Surface pretreatment of the textile traveler:

[0043] Step 101, immersing the textile traveler in a degreasing solution for 10 minutes; the degreasing solution is preferably a mixed solution made of sodium hydroxide, sodium acetate, trisodium phosphate, sodium silicate and deionized water, Wherein the concentration of the sodium hydroxide is preferably 30g / L, the concentration of the sodium acetate is preferably 10g / L, the concentration of the trisodium phosphate is preferably 20g / L, and the concentration of the sodium silicate is preferably 0.8g / L;

[0044] Step 102, ultrasonically clean the textile traveler after degreasing in step 101; the ultrasonic cleaning process is preferably: first place the degreasing textile traveler in acetone for 60 seconds, and then place it in anhydrous Ultrasonic cleaning in ethanol for 20s...

Embodiment 3

[0049] The preparation method of the textile traveler self-lubricating coating of the present embodiment comprises the following steps:

[0050] Step 1. Surface pretreatment of the textile traveler:

[0051] Step 101, immerse the textile traveler in a degreasing solution to remove oil for 30 minutes; the degreasing solution is preferably a mixed solution made of sodium hydroxide, sodium acetate, trisodium phosphate, sodium silicate and deionized water, Wherein the concentration of the sodium hydroxide is preferably 20g / L, the concentration of the sodium acetate is preferably 15g / L, the concentration of the trisodium phosphate is preferably 30g / L, and the concentration of the sodium silicate is preferably 0.6g / L;

[0052] Step 102, ultrasonically cleaning the textile traveler after degreasing in step 101; the ultrasonic cleaning process is preferably: first place the degreasing textile traveler in acetone for 10 seconds, and then place it in anhydrous Ultrasonic cleaning in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com