Preparation method of titanium element modified Ti3SiC2 enhanced Cu-base pantograph sliding plate

A technology for pantograph slides and elements, which is applied in the field of preparation of titanium-modified Ti3SiC2 reinforced copper-based pantograph slides, which can solve the problems of poor wear resistance, impact resistance, and low interface bonding strength, etc. Performance and anti-wear performance, guarantee service life, and improve the effect of interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

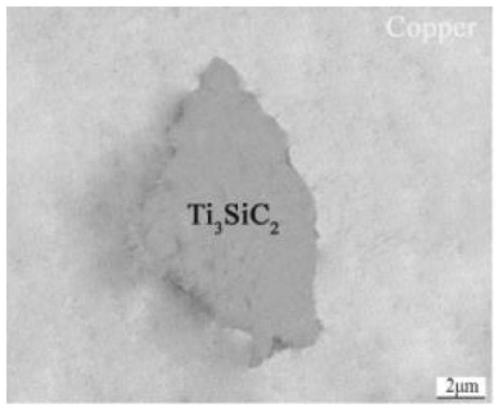

[0037] Titanium element modified Ti of the present invention 3 SiC 2 The specific steps of the preparation method of the reinforced copper-based pantograph sliding plate are as follows:

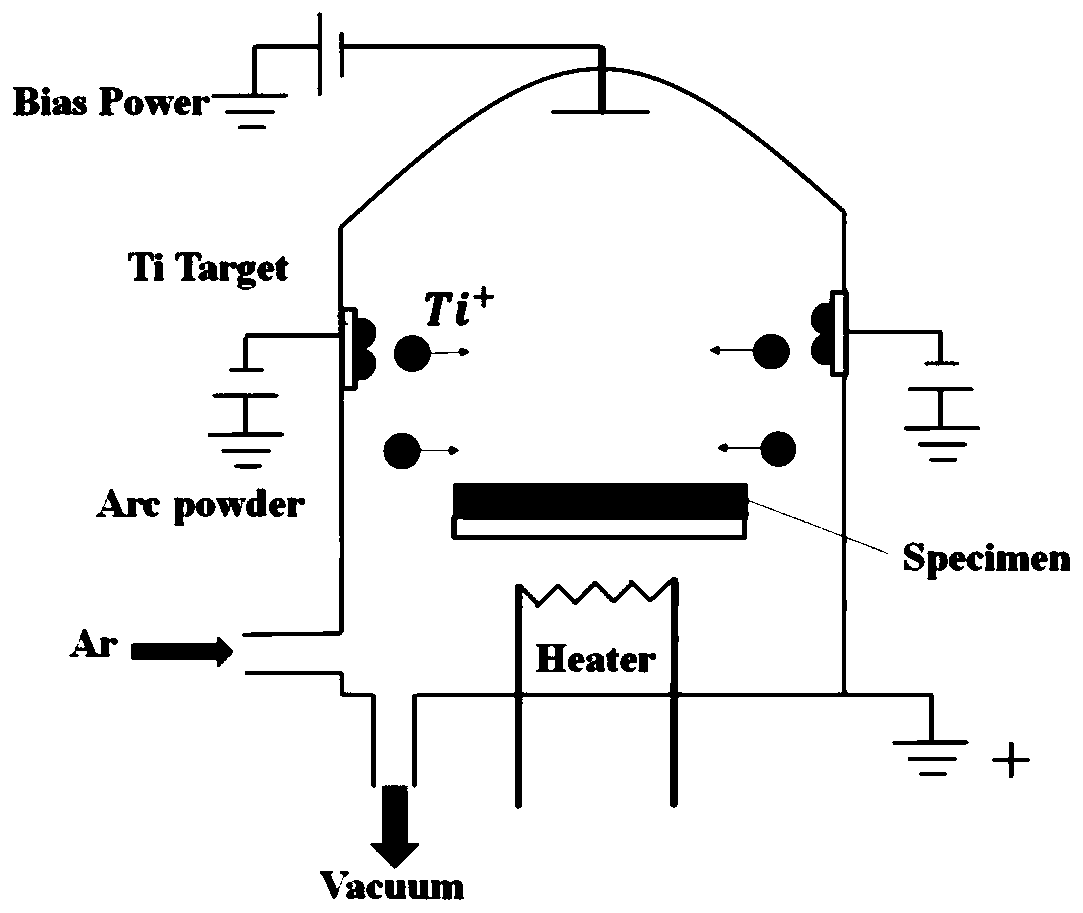

[0038] S1, first fully wash Ti with distilled water 3 SiC 2 powder, and then evaporated to dryness, the dried Ti 3 SiC 2 The powder is subjected to multi-arc ion plating treatment;

[0039] The temperature of evaporative drying is 80-90°C, and the time is 0.5-1 hour.

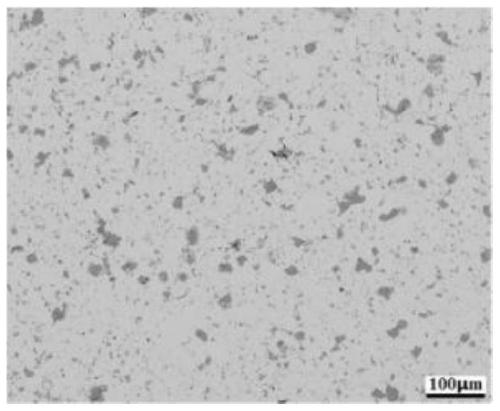

[0040] Ti 3 SiC 2 The powder is irregular Ti with a particle size of 200-300 mesh and a purity of 97.5-99.5%. 3 SiC 2 Powder; multi-arc ion plating means that the plating time is 0.5 to 1 hour, the plating atmosphere is argon, and the atmosphere pressure is 2 to 3×10 -1 Pa, the coating process with a coating temperature of 250-270°C, a duty ratio of 50-60%, and a bias voltage of 25-35V.

[0041] S2, the Ti after plating 3 SiC 2 The powder and metal powder are ball milled for 2 to 3 hours, and then poured into a mol...

Embodiment 1

[0047] High-speed railway pantograph skateboard

[0048] 1) First, fully wash Ti with distilled water 3 SiC 2 powder, then evaporated to dryness at 80°C for 1 hour. The dried Ti 3 SiC 2 The powder is subjected to multi-arc ion plating treatment. The specific plating parameters are that the plating time is 1 hour, the plating atmosphere is argon, and the atmosphere pressure is 3×10 -1 Pa, the plating temperature is 270°C, the duty cycle is 60%, and the bias voltage is 35V.

[0049] 2) The plated Ti 3 SiC 2 The powder and metal powder are ball milled for 2 hours, and then poured into a mold for cold pressing at a pressure of 700MPa.

[0050] 3) For sintering the cold-pressed green body, evacuate the sintering furnace to vacuum, raise the temperature from room temperature to 400°C at a heating rate of 10°C / min, and then raise the temperature to 820°C at a heating rate of 5°C / min, at 820°C Keep warm for 1 hour, then cool with the furnace.

[0051] 4) Put the sintered gre...

Embodiment 2

[0053] Heavy-duty freight railway pantograph slide

[0054] 1) First, fully wash Ti with distilled water 3 SiC 2 powder, then evaporated to dryness at 90°C for 0.5 hours. The dried Ti 3 SiC 2 The powder is subjected to multi-arc ion plating treatment. The specific plating parameters are that the plating time is 0.5 hours, the plating atmosphere is argon, and the atmosphere pressure is 2×10 -1 Pa, the plating temperature is 250°C, the duty cycle is 50%, and the bias voltage is 25V.

[0055] 2) The plated Ti 3 SiC 2 The powder and metal powder are ball milled for 3 hours, and then poured into a mold for cold pressing at a pressure of 500MPa.

[0056] 3) To sinter the cold-pressed body, evacuate the sintering furnace to vacuum, raise the temperature from room temperature to 450°C at a rate of 20°C / min, and then to 850°C at a rate of 8°C / min. Hold at 850°C for 1.5 hours, then cool in the furnace.

[0057] 4) Put the sintered green body into the mold and carry out repress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com