Preparation method of fluorinated cellulose nanocrystalline lubricating grease thickening agent

A cellulose and nanocrystalline technology, applied in the field of materials, can solve the problems of weak fluorine base oil affinity, limited lubricating performance, and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation process of fluorinated cellulose nanocrystals of the present invention is as follows:

[0028]

[0029] Concrete preparation process is as follows:

[0030] 1) Disperse cellulose nanocrystals in N,N-dimethylformamide (DMF), add 4-dimethylaminopyridine (DMAP) and triethylamine (TEA), and ultrasonically disperse to obtain a suspension; the fiber The purity of the plain nanocrystal is higher than 97wt%, the crystallinity is 54%~88%, the length is 100~300nm, and the diameter is 10~20nm; the mass ratio of the amount of cellulose nanocrystal, 4-dimethylaminopyridine and triethylamine is 1:( 2~3): (1~2);

[0031] 2) Slowly add 2-bromoisobutyryl bromide (BiBB) solution dropwise to the obtained suspension under an inert atmosphere, heat up to 70-90°C for 24-36 hours after dropping, and centrifuge, wash and dialyze to obtain CNC-Br powder; The amount of 2-bromoisobutyryl bromide is 13 to 17 times the mass of cellulose nanocrystals;

[0032] 3) The obtained C...

Embodiment 1

[0037] A preparation method of a fluorinated cellulose nanocrystalline grease thickener and its application in fluorine grease, comprising the following steps:

[0038] (1) Weigh 1g of cellulose nanocrystal (CNC) and disperse it into a 250ml flask equipped with 120ml N,N-dimethylformamide (DMF), add 2.4g 4-dimethylaminopyridine (DMAP) and 1.32g Triethylamine (TEA) was ultrasonically dispersed in a cell pulverizer with 200W power for 10min to obtain a suspension;

[0039] (2) Under an inert atmosphere, 15 g of 2-bromoisobutyryl bromide (BiBB) was slowly added dropwise to the obtained suspension, and the temperature was raised to 70° C. for 24 h. After the reaction, it was centrifuged and washed twice with ethanol and deionized water, put into a dialysis bag and dialyzed for 3 days to obtain about 0.8 g of CNC-Br powder;

[0040] (3) Disperse 0.8g of CNC-Br powder into a 250ml flask containing 120ml of DMF, add 0.2g of copper bromide, 0.7g of N,N,N,N,N-pentamethyldiethylenetria...

Embodiment 2

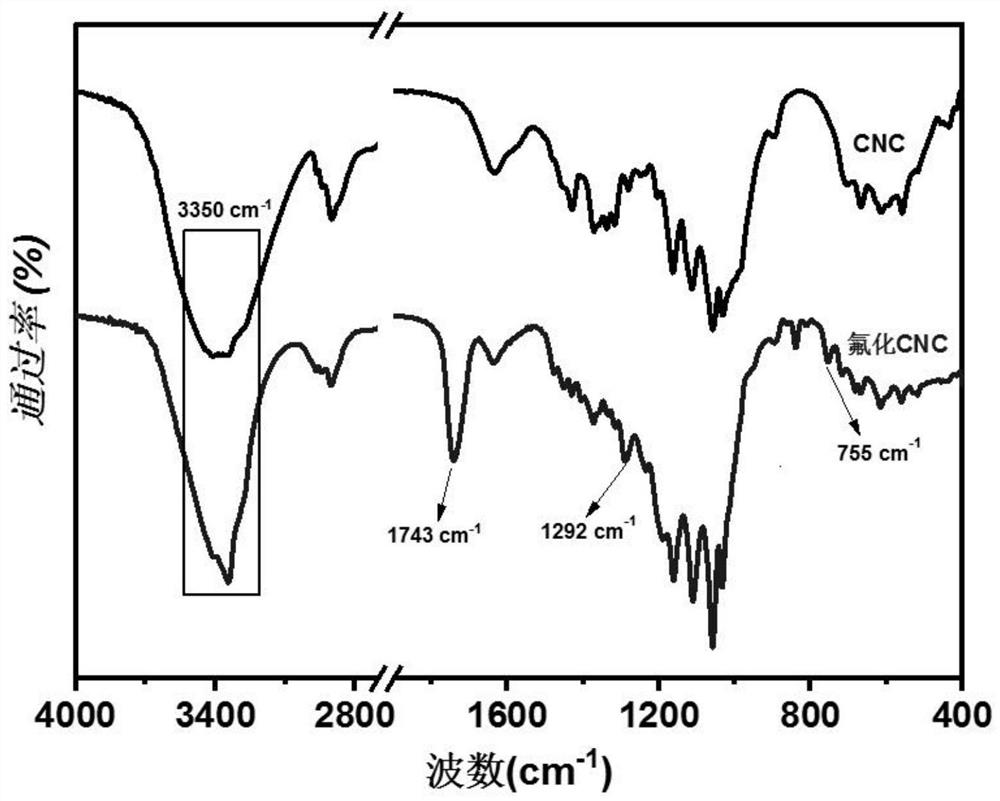

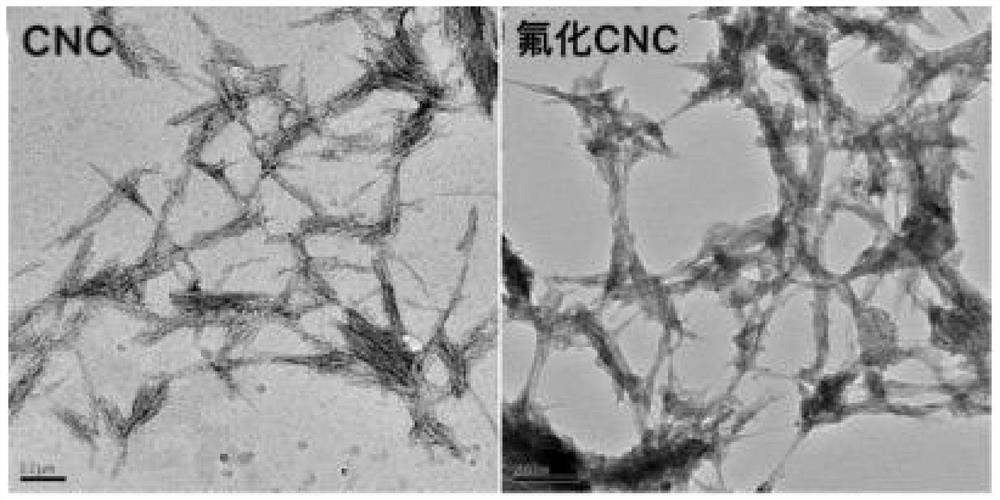

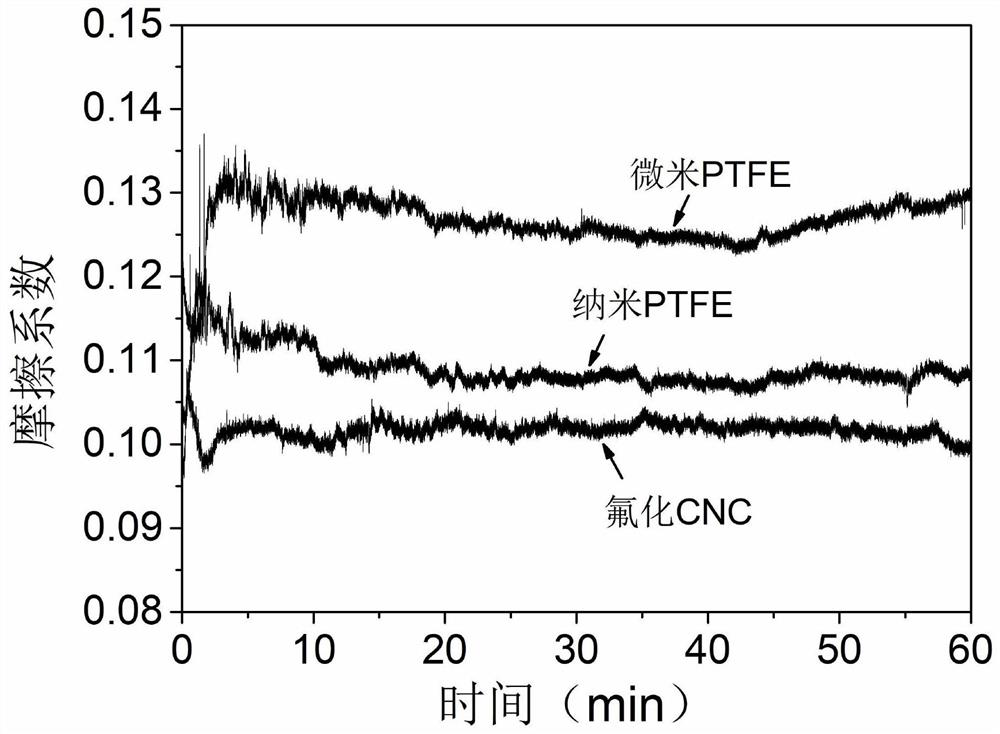

[0047] The difference between this example and Example 1 is that the doping amount of fluorinated cellulose nanocrystals in step (5) is 20 wt%, and other steps, reagents and parameters are the same as in Example 1. In this embodiment, fluorine grease with higher viscosity can be obtained, which is used in heavy-load or low-speed working conditions. The fluorinated grafting of cellulose nanocrystals in this implementation case was confirmed by infrared spectroscopy and transmission electron microscope analysis; the friction and wear properties of the obtained grease were confirmed by a four-ball friction test (ASTMD266).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com