Crystal curing press head of radio frequency identification back-off packaging device

A technology for packaging equipment and electronic labels, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., and can solve the problems of irregular shape and structure of the indenter, complex thermal insulation structure of the indenter, and influence of hot-pressing accuracy, etc. The effect of good friction performance, simple structure and high precision of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

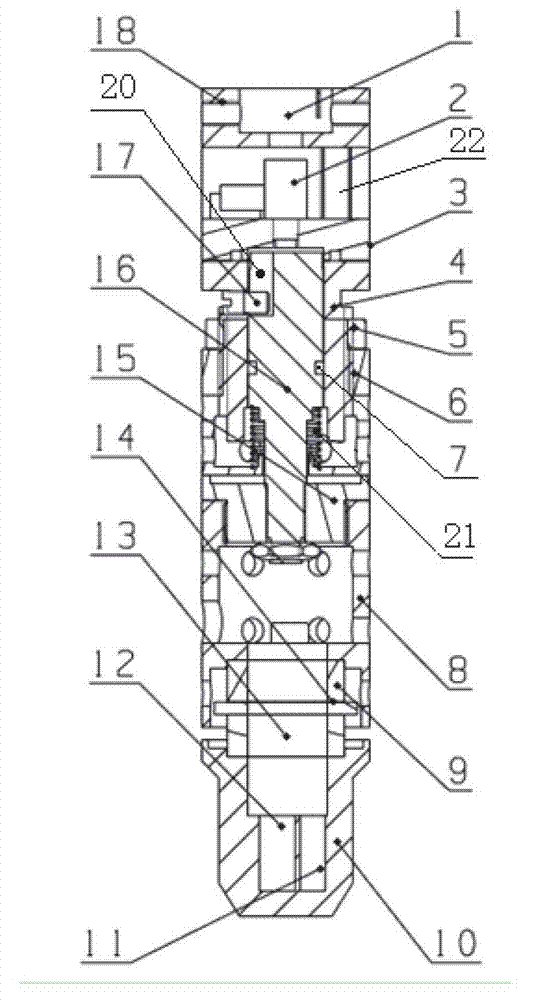

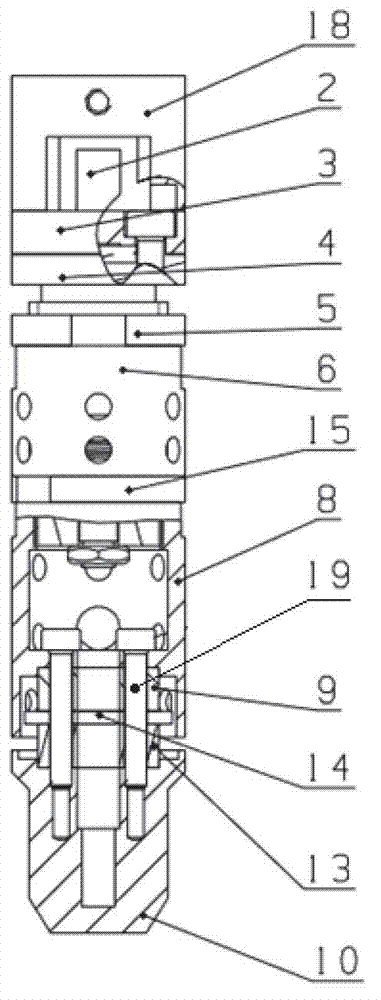

[0025] like figure 1 , 2 As shown, the die-bonding indenter of the electronic label upside-down packaging device of the present invention includes a cylinder, a connecting component, a spring 21, an adjustment ring 6, a heat insulation and heat dissipation device, and an indenter.

[0026] The cylinder adopts a gap-sealed cylinder; the connecting assembly includes a connecting seat 18 and a connecting screw 22; the connecting seat 18 is fixedly connected to the upper end of the connecting column 22; the concave hole at the upper end of the connecting seat 18 is embedded with a magnetic block 1. The upper indenter connecting plate is made of magnetic material, and the upper thermal indenter template is attached and connected to the upper indenter connecting plate. The connecting seat 18 is embedded in the corresponding opening of the upper indenter template, and the entire die-bonding is made by the magnetic force of the magnetic block 1. The pressure head is connected on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com