Hot press molding method of palm mattress and device

A technology of hot-pressing forming and hot-pressing method, which is applied in the field of hot-pressing forming and devices of brown mattresses, can solve the problems of low production efficiency, energy consumption and high scrap rate, and achieves the improvement of production efficiency and quality, and the improvement of production efficiency and heat. The effect of high pressure precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

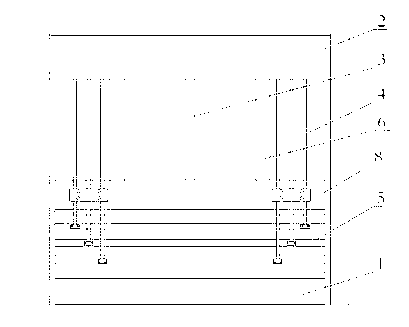

[0029] look first figure 1 , figure 1 It shows the front elevation view of the heat press machine used for palm mattress production of the present invention, which is provided with a base 1 and a top frame 2, and between the base 1 and the top frame 2, there are more than three layers for brown silk The hot pressing plate 5 formed by hot pressing is provided with a pressurizing seat 8 that can pressurize the hot pressing plate 5 above the hot pressing plate 5. The pressurizing seat 8 is supported by the top frame 2 and passed through the lifting rail 3 and hydraulic pressure Oil cylinder 6 controls its up and down movement; each layer of hot pressing plate 5 is provided with at least one hot pressing oil pipe 7 that can deliver hot oil to its interior; combine figure 2 , as can be seen from the figure, the top of the separation rod 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com