Environment-friendly corrosion-resistant and wear-resistant coating for ship waterline area and preparation method of environment-friendly corrosion-resistant and wear-resistant coating

An environmentally friendly, anti-corrosion and wear-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as high process costs, polluting the environment, and reducing the strength of ship steel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

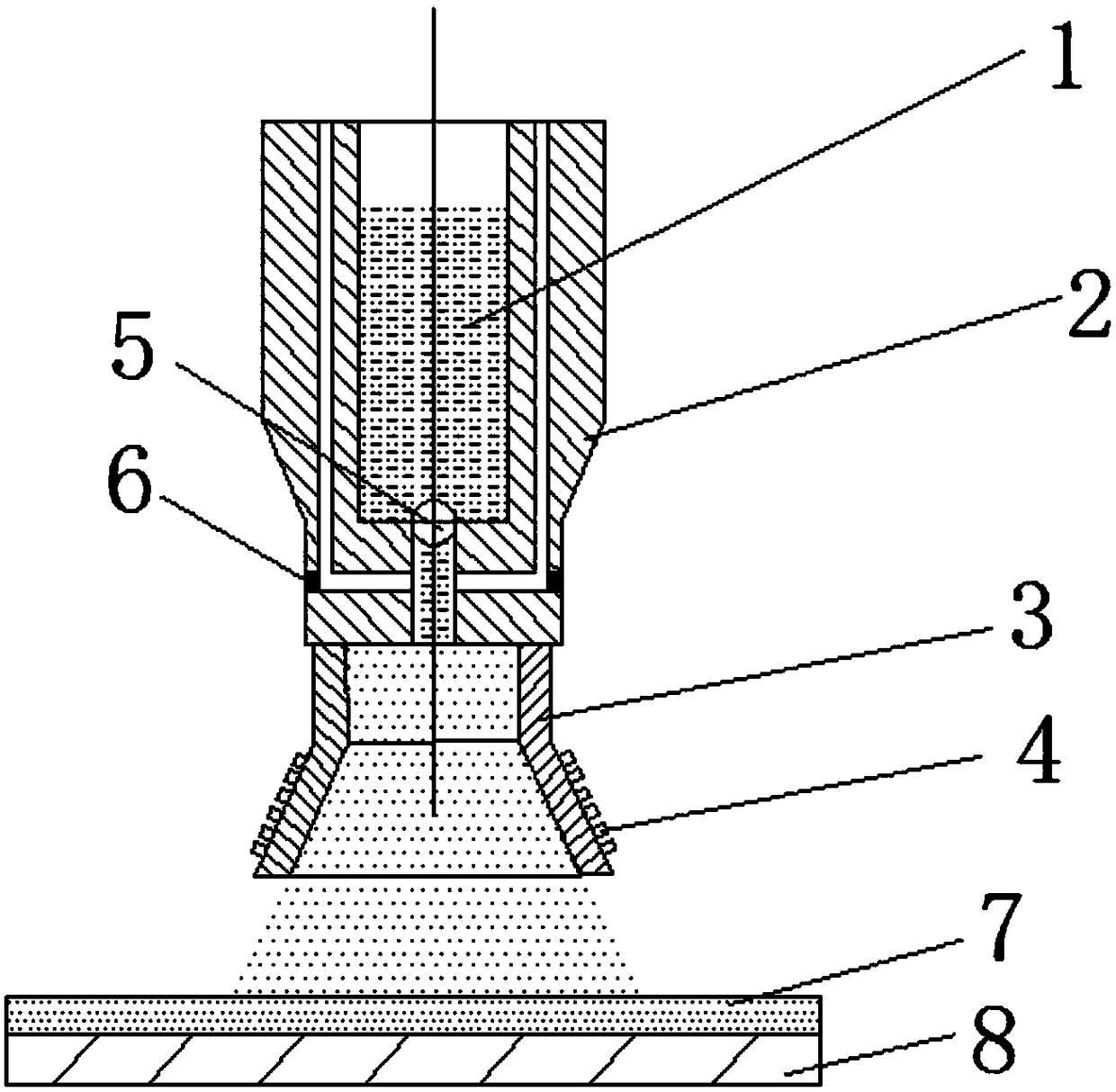

Image

Examples

Embodiment 1

[0035] Environmentally friendly anti-corrosion and wear-resistant coatings for the waterline area of ships, which include component A and component B with a mass ratio of 1:1, of which,

[0036] The components contained in component A and the parts by mass of each component are as follows:

[0037] 50 parts of epoxy curing agent;

[0038] 0.2 parts of defoamer;

[0039] 70 parts of deionized water;

[0040] 2 parts rheological agent;

[0041] 20 parts of titanium dioxide;

[0042] 20 parts of anti-friction agent;

[0043] 40 parts of modified zinc-rich shell powder;

[0044] The components contained in component B and the parts by mass of each component are as follows:

[0045] 200 parts of epoxy resin.

[0046] Wherein, the epoxy resin can be Araldite ® 3961-1.

[0047] The epoxy curing agent can be Aradur ® 3986;

[0048] The defoamer can be defoamer BYK-024.

[0049] The dispersant may be BYK-190.

[0050] The rheological agent may be rheological agent 1010...

Embodiment 2

[0064] Environmentally friendly anti-corrosion and wear-resistant coatings for the waterline area of ships, which include component A and component B with a mass ratio of 1:1, of which,

[0065] The components contained in component A and the parts by mass of each component are as follows:

[0066] 55 parts of epoxy curing agent;

[0067] 0.4 parts of defoamer;

[0068] 80 parts of deionized water;

[0069] 3 parts rheological agent;

[0070] 25 parts of titanium dioxide;

[0071] 25 parts of anti-friction agent;

[0072] 45 parts of modified zinc-rich shell powder;

[0073] The components contained in component B and the parts by mass of each component are as follows:

[0074] 220 parts of epoxy resin.

[0075] Wherein, the epoxy resin can be Araldite ® 3961-1.

[0076] The epoxy curing agent can be Aradur ® 3986;

[0077] The defoamer can be defoamer BYK-024.

[0078] The dispersant may be BYK-190.

[0079] The rheological agent may be rheological agent 1010...

Embodiment 3

[0093] Environmentally friendly anti-corrosion and wear-resistant coatings for the waterline area of ships, which include component A and component B with a mass ratio of 1:1, of which,

[0094] The components contained in component A and the parts by mass of each component are as follows:

[0095] 60 parts of epoxy curing agent;

[0096] 0.5 part of defoamer;

[0097] 90 parts of deionized water;

[0098] 4 parts of rheology agent;

[0099] 30 parts of titanium dioxide;

[0100] 30 parts of anti-friction agent;

[0101] 50 parts of modified zinc-rich shell powder;

[0102] The components contained in component B and the parts by mass of each component are as follows:

[0103] 240 parts of epoxy resin.

[0104] Wherein, the epoxy resin can be Araldite ® 3961-1.

[0105] The epoxy curing agent can be Aradur ® 3986;

[0106] The defoamer can be defoamer BYK-024.

[0107] The dispersant may be BYK-190.

[0108] The rheological agent may be rheological agent 1010....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com