Novel antifriction lubricant additive containing nano ferrous sulphide

A lubricating oil additive, ferrous sulfide technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., to achieve the effect of improving anti-scratch performance, good dispersibility and stability, and improving friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

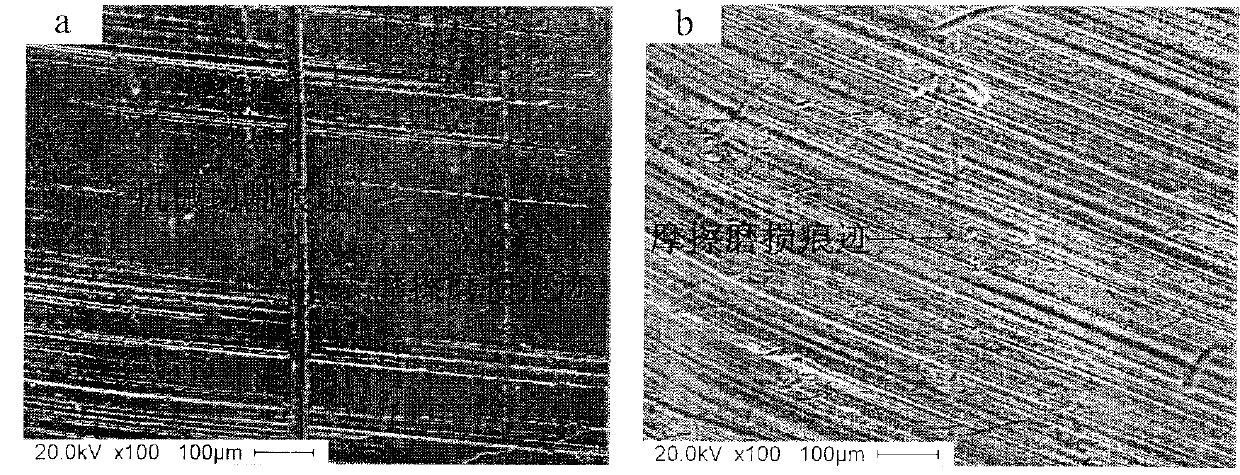

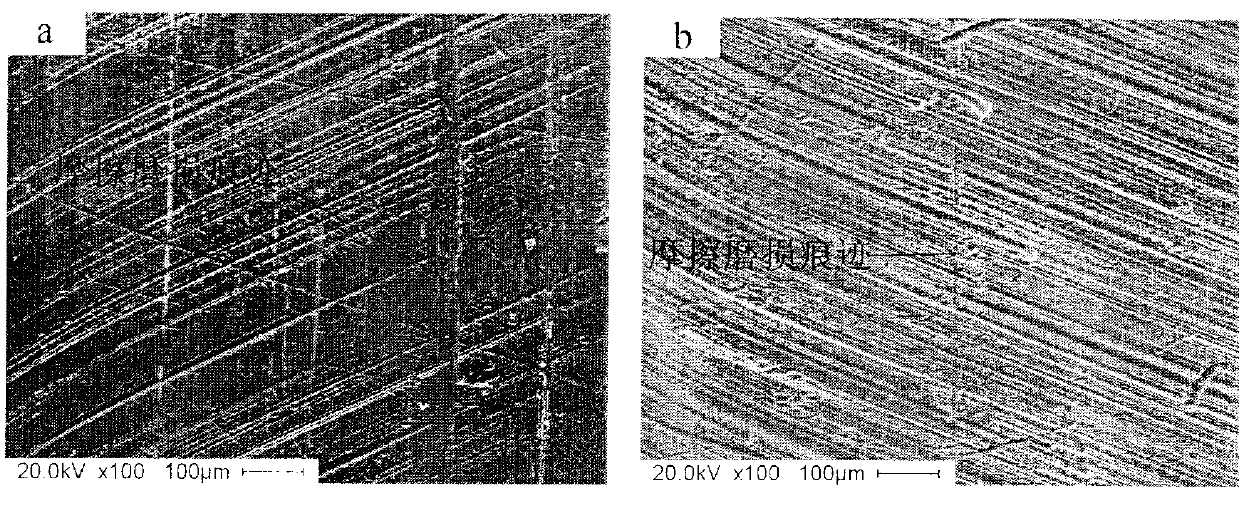

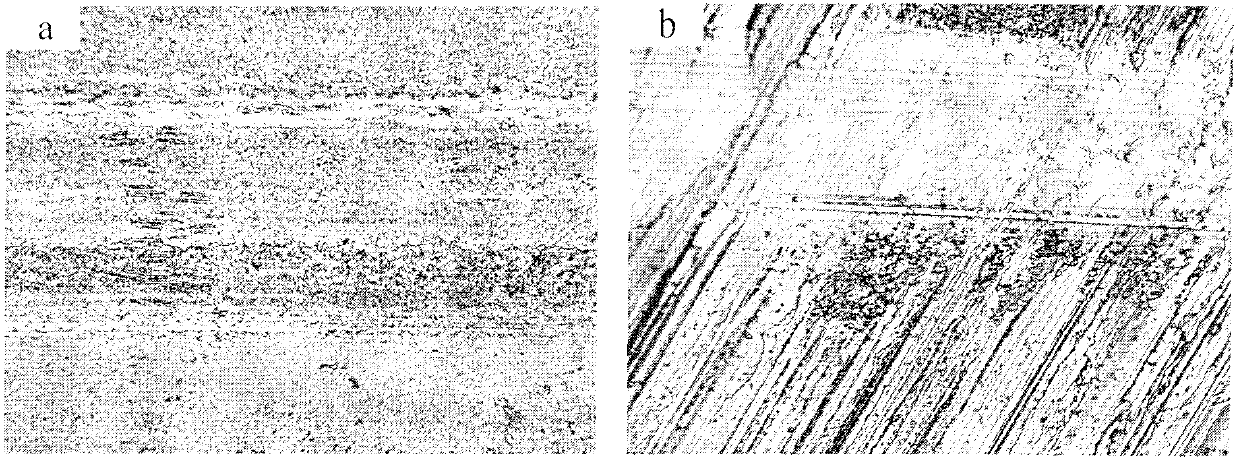

[0028] First, SEM, ultra-depth of field and secondary particle mass spectrometry were used to characterize the wear surface to study the mechanism of action of lubricating oil additives containing nano-ferrous sulfide (lubrication friction test):

[0029] Under the condition of load of 100N and rotating speed of 200rpm, lubricating oil with 2%, 5% and 10% of lubricating oil without adding and adding nano-ferrous sulfide was used in the experiment after the friction test. The parts of the wear marks were cut with a cutting machine to make observation samples, and observed under SEM: the upper sample was cut with a length of 8 mm and a width of 5 mm, and the lower sample was cut with the claws of the lower three-claw pin. At the same time, SEM is used for surface scanning analysis of micro-area element distribution analysis, and EDX is used for phase composition analysis. The cut samples were wiped with acetone and cleaned in an ultrasonic cleaner until there was no oil stain. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com