Vanadium oxide nanosheet and preparation method of two-dimensional composite material of vanadium oxide nanosheet and MXene

A technology of vanadium oxide and composite materials, applied in chemical instruments and methods, vanadium oxide, carbide, etc., can solve the problems of low yield, unsatisfactory product shape, limited energy storage capacity of composite materials, etc., and achieve wide layer spacing , good universality and high yield, good shape characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

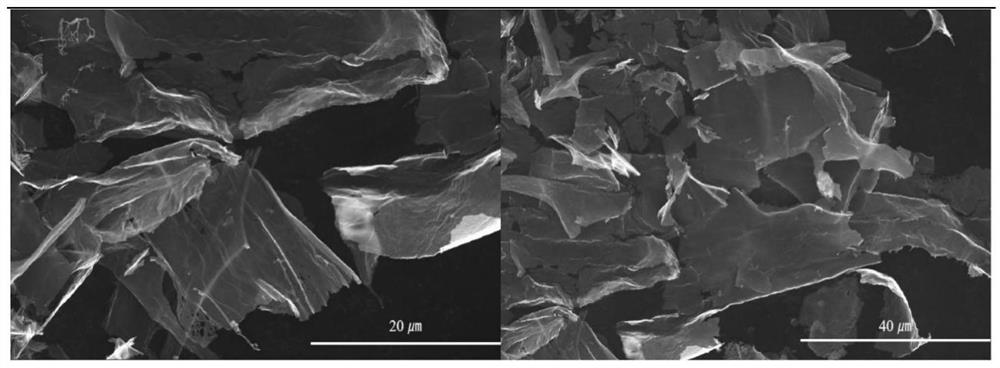

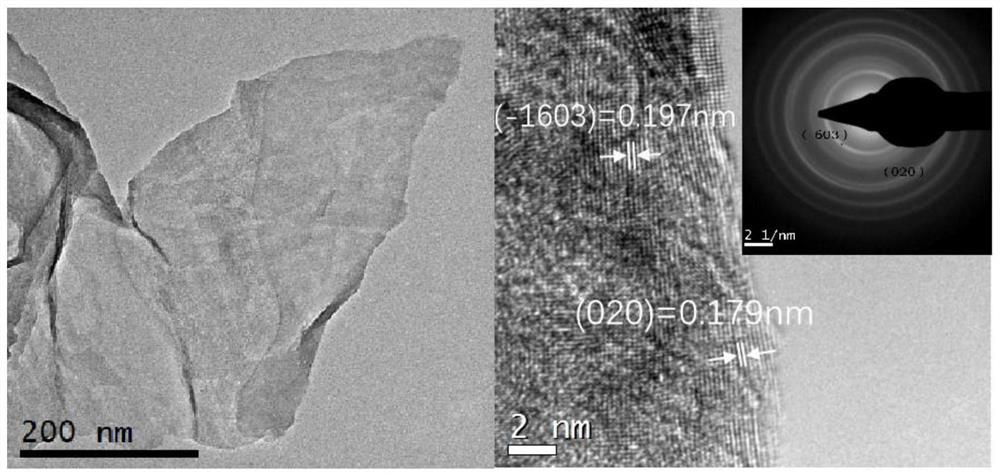

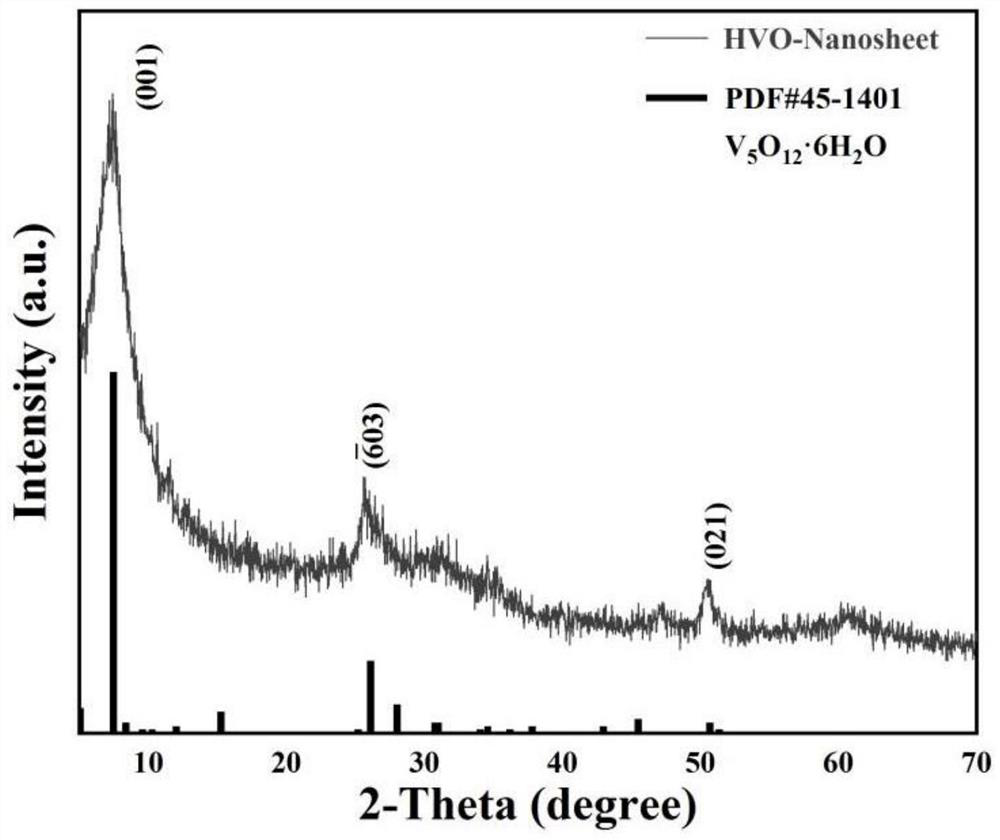

[0052] Step A-Step D of this embodiment is the process of preparing vanadium oxide nanosheets (HVO-NS).

[0053] Step E-step G is to prepare the two-dimensional composite material (V 5 o 12 ·nH 2 O@MXene) process, because the raw material of the latter is prepared by the aforementioned steps, so it is carried out as a whole test in the embodiment.

[0054] A preparation method of vanadium oxide nanosheets, prepared according to the following steps:

[0055] Step A, vanadium source dispersion;

[0056] Weigh 2g of V as the source of vanadium 2 o 5 ·H 2 O was added to 450 mL of deionized water to form 0.022 mol / L of V 2 o 5 Suspension, then add 45mL of 30% hydrogen peroxide solution and 8 drops of ethylene glycol (measured to be about 0.4mL), then transfer the mixture into a water bath, and carry out constant temperature magnetic stirring at 60 °C For 2 hours, the vanadium source was evenly dispersed.

[0057] Step B, nucleation and growth of vanadium oxide;

[0058] ...

Embodiment 2

[0073] The difference with Example 1 is:

[0074] The vanadium source that weighs in the step A is the V of 2.133g 2 o 5 , the added deionized water is 250mL, finally forming V with a molar concentration of 0.047mol / L 2 o 5 Suspension; add hydrogen peroxide to a volume of 190mL; add 12 drops of ethylene glycol (measured to be about 0.6mL); in a water bath, carry out constant temperature magnetic stirring at 50°C for 3 hours to uniformly disperse the vanadium source.

[0075] In step B, the temperature of the water bath heating is 50° C., and the temperature is kept for 20 hours.

[0076] In step C, the temperature for heat preservation is 50° C.; the time for constant temperature ultrasonication is 1 hour; the centrifugation index of the suspension is: the rotating speed is 3000 r / min, and the time is 0.5 hour.

[0077] Similarly, the obtained upper layer suspension is the successfully exfoliated vanadium oxide nanosheets (HVO-NS), accounting for about 75%-85% of the total...

Embodiment 3

[0084] The difference with Example 1 is:

[0085] The vanadium source that weighs in the step A is the V of 2.133g 2 o 5 , the added deionized water is 450mL, finally forming a molar concentration of 0.026mol / L V 2 o 5 Suspension; add hydrogen peroxide to a volume of 90mL; add 9 drops of ethylene glycol (measured to be about 0.5mL); in a water bath, perform constant temperature magnetic stirring at 50°C for 3.5 hours to disperse the vanadium source evenly.

[0086] In step B, the temperature of the water bath heating is 50° C., and the temperature is kept for 30 hours.

[0087] In step C, the temperature for heat preservation is 50° C.; the time for constant temperature ultrasonication is 3 hours; the centrifugation index of the suspension is: rotation speed 1500 r / min, time 1 hour.

[0088] Similarly, the obtained upper layer suspension is the successfully exfoliated vanadium oxide nanosheets (HVO-NS), accounting for about 75%-85% of the total mass of vanadium oxide. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com