Laser alloying layer on titanium alloy surface and preparation process thereof

A technology of laser alloying and preparation process, which is applied in the direction of metal material coating process and coating, which can solve the problem of decreased toughness of the alloyed layer, failure to meet performance requirements, and reduced wear resistance and corrosion resistance of the alloyed layer and other issues to achieve the effect of low cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

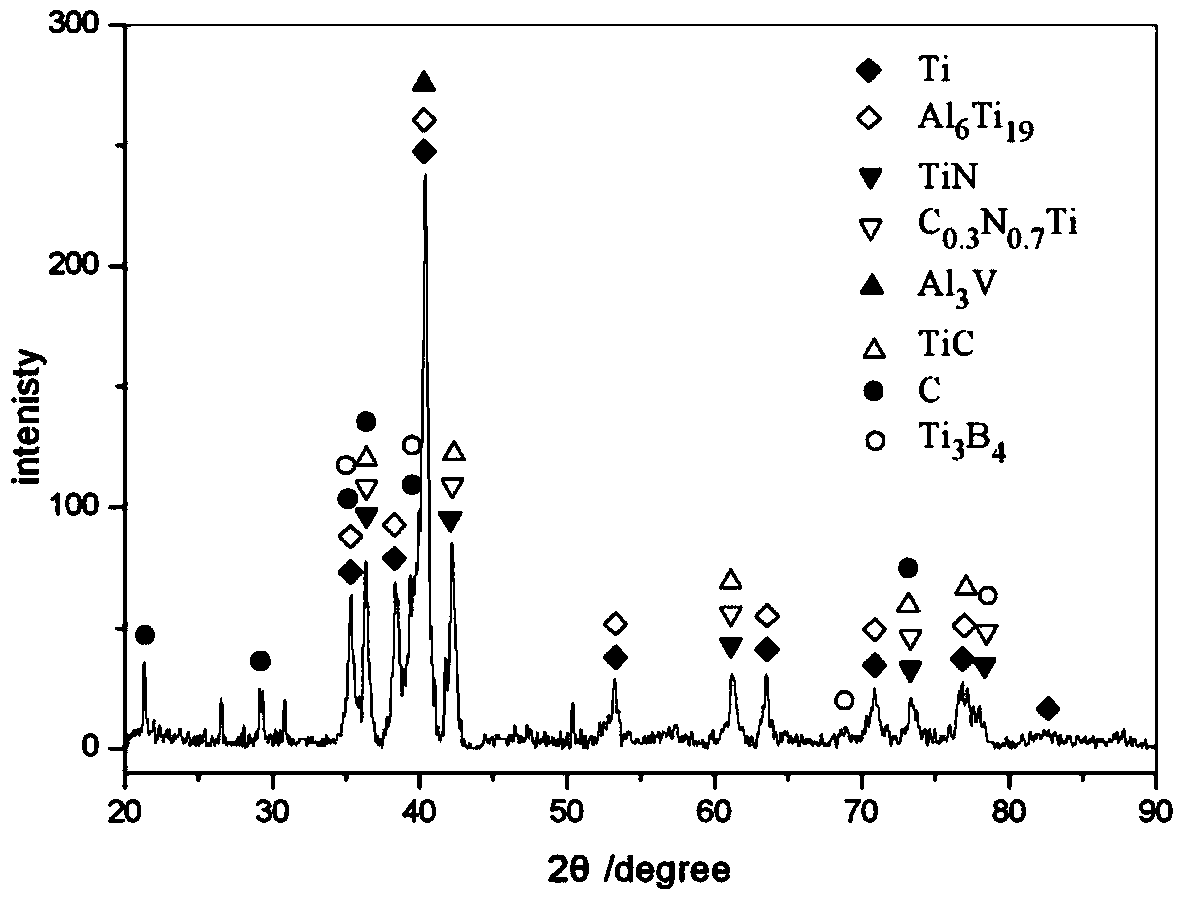

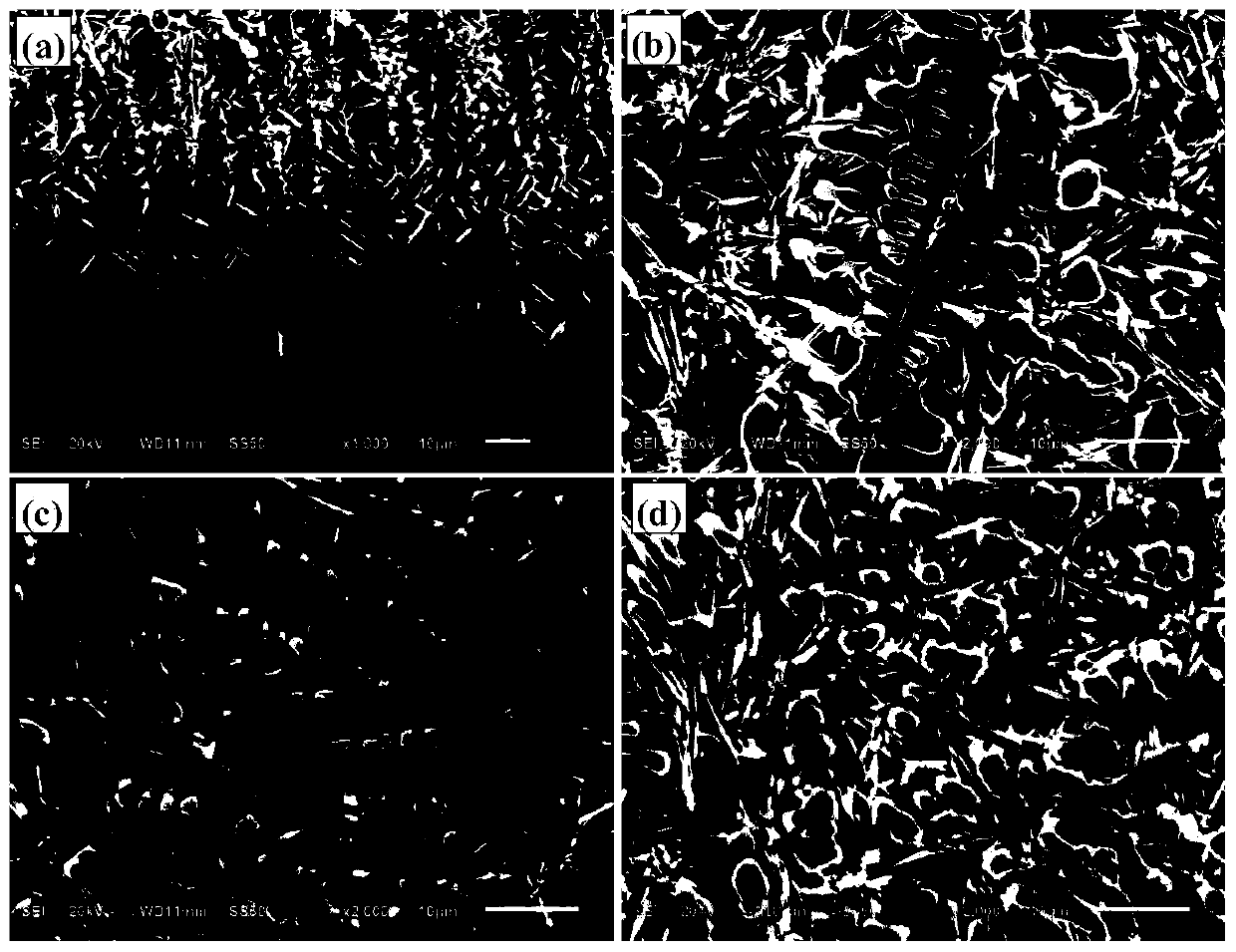

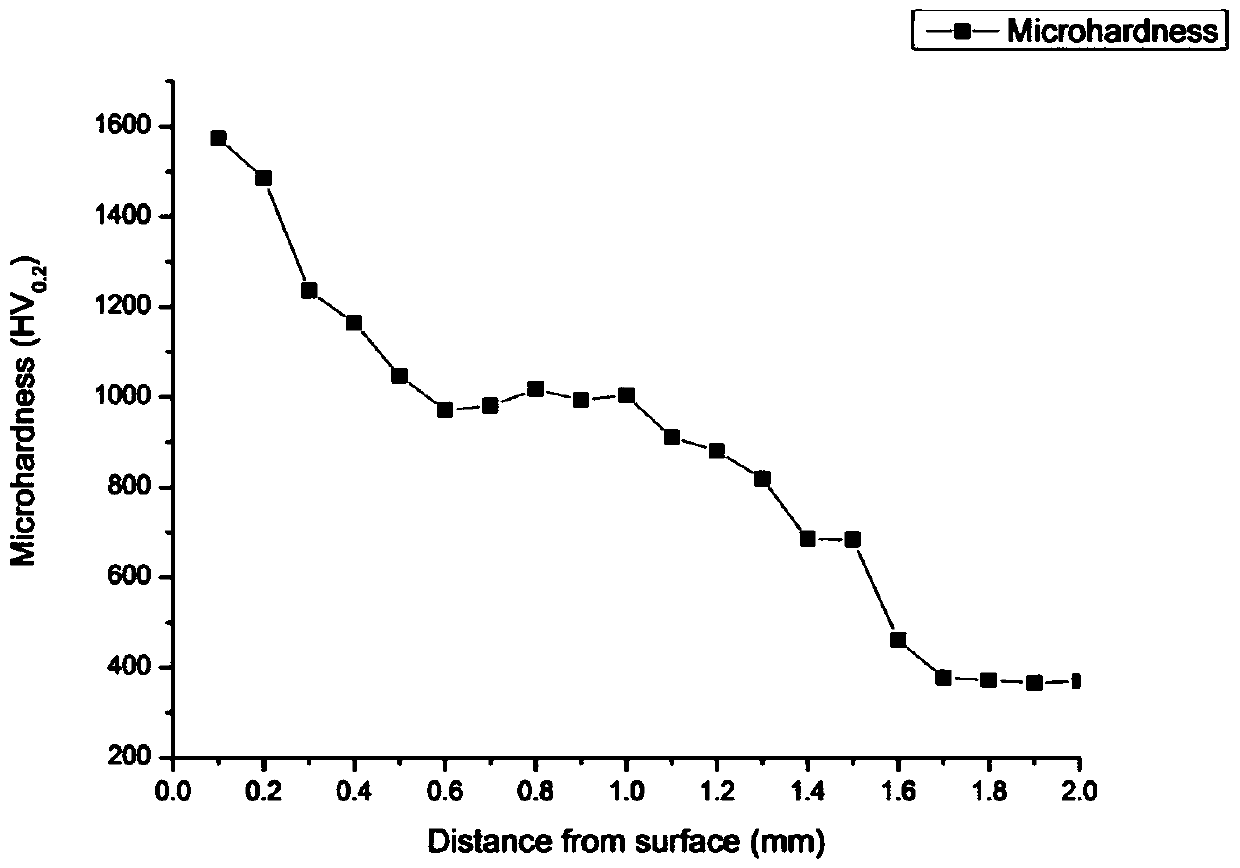

[0061] With Ti-6Al-4V as the base material, the mass composition of the coating material used is 67.4% of BN powder and 32.6% of graphite powder.

[0062] (1) Cut the base material into a size of 10×10×12mm with a wire cutting machine 3 For the block sample, a groove of 8mm×10mm and 0.5mm deep is milled along the width direction on the 12mm×10mm surface. The bottom surface of the groove is polished with sandpaper to remove impurities such as scale, cleaned with gasoline and absolute ethanol respectively, dried and set aside.

[0063] (2) mix the BN and the graphite powder of the above-mentioned mass percentage with a ball mill, adjust the mixed powder into a uniform paste with a water glass solution, and evenly apply it to the base metal surface, that is, in the groove described in the above-mentioned step (1), Keep the thickness even and dry before use.

[0064] (3) Use a continuous laser to scan the sample (the instrument HJ-4 cross-flow CO 2 Gas laser, rated power 1500W)...

Embodiment 2

[0072] With Ti-6Al-4V as the base material, the mass composition of the coating material used is 50.8% of BN powder and 49.2% of graphite powder.

[0073] (1) Cut the base material into a size of 10×10×12mm with a wire cutting machine 3 For the block sample, a groove of 8mm×10mm and 0.5mm deep is milled along the width direction on the 12mm×10mm surface. The bottom surface of the groove is polished with sandpaper to remove impurities such as scale, cleaned with gasoline and absolute ethanol respectively, dried and set aside.

[0074] (2) mix the BN and the graphite powder of the above-mentioned mass percentage with a ball mill, adjust the mixed powder into a uniform paste with a water glass solution, and evenly apply it to the base metal surface, that is, in the groove described in the above-mentioned step (1), Keep the thickness even and dry before use.

[0075] (3) Use a continuous laser to scan the sample, use a power of 1000W, keep the spot diameter at 4mm, and scan at a...

Embodiment 3

[0080] With Ti-6Al-4V as the base material, the mass composition of the coating material used is 80.5% of BN powder and 19.5% of graphite powder.

[0081] (1) Cut the base material into a size of 10×10×12mm with a wire cutting machine 3 For the block sample, a groove of 8mm×10mm and 0.5mm deep is milled along the width direction on the 12mm×10mm surface. The bottom surface of the groove is polished with sandpaper to remove impurities such as scale, cleaned with gasoline and absolute ethanol respectively, dried and set aside.

[0082] (2) mix the BN and the graphite powder of the above-mentioned mass percentage with a ball mill, adjust the mixed powder into a uniform paste with a water glass solution, and evenly apply it to the base metal surface, that is, in the groove described in the above-mentioned step (1), Keep the thickness even and dry before use.

[0083] (3) Use a continuous laser to scan the sample, use a power of 1000W, keep the spot diameter at 4mm, and scan at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com