Wear-resistant material, preparation method and application

A wear-resistant material, stirring grinding technology, applied in the direction of metal material coating process, coating, melting spray plating, etc., can solve the problems of poor toughness and easy chipping, the hob is not wear-resistant, fractured, etc., and achieves low porosity. , uniform thickness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

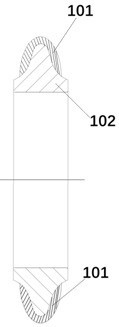

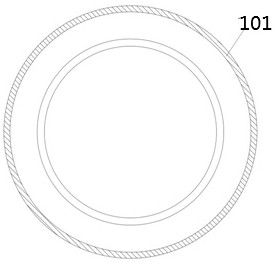

Image

Examples

Embodiment 1

[0040] A wear-resistant material powder, including the following components in mass percentage: ceramic tungsten carbide powder 20%, Mo-B powder 60%, metal Co powder 5%, large tungsten carbide particles 4%, and the balance is Fe. The particle size of the ceramic tungsten carbide powder is 30 μm, and that of the Mo-B powder is 35 μm.

[0041] Wherein the preparation of Mo-B powder is as follows:

[0042] Step 1: Put Mo powder and B powder in a hydrogen reduction furnace for reduction respectively to obtain reduced Mo powder and reduced B powder; the reduction temperature of Mo powder is 1100°C, and the reduction temperature of B powder is 1200°C;

[0043] Step 2: Add the reduced Mo powder and the reduced B powder into the stirring mill tank according to the molar ratio of 2:1 to stir the abrasive to obtain the Mo-B mixed powder; the time for stirring the abrasive is 100h, and the rotating speed is 800r / min;

[0044] Step 3: put the Mo-B mixed powder into a vacuum drying oven f...

Embodiment 2

[0058] A wear-resistant material powder, including the following components in mass percentage: ceramic tungsten carbide powder 22%, Mo-B powder 50%, metal Co powder 8%, large tungsten carbide particles 4%, and the balance is Fe. The particle size of the ceramic tungsten carbide powder is 35 μm, and that of the Mo-B powder is 40 μm.

[0059] Wherein the preparation of Mo-B powder is as follows:

[0060] Step 1: Put Mo powder and B powder in a hydrogen reduction furnace for reduction respectively to obtain reduced Mo powder and reduced B powder; the reduction temperature of Mo powder is 1300°C, and the reduction temperature of B powder is 1400°C;

[0061] Step 2: Add the reduced Mo powder and the reduced B powder into the stirring mill tank according to the molar ratio of 2:1 to stir the abrasive to obtain the Mo-B mixed powder; the time for stirring the abrasive is 110 hours, and the rotation speed is 600r / min;

[0062] Step 3: Put the Mo-B mixed powder into a vacuum drying o...

Embodiment 3

[0076] A wear-resistant material powder, including the following components in mass percentage: ceramic tungsten carbide powder 25%, Mo-B powder 40%, metal Co powder 10%, large tungsten carbide particles 4%, and the balance is Fe. The particle size of the ceramic tungsten carbide powder is 40 μm, and that of the Mo-B powder is 50 μm.

[0077] Wherein the preparation of Mo-B powder is as follows:

[0078] Step 1: Put Mo powder and B powder in a hydrogen reduction furnace for reduction respectively to obtain reduced Mo powder and reduced B powder; the reduction temperature of Mo powder is 800°C, and the reduction temperature of B powder is 900°C;

[0079] Step 2: Add the reduced Mo powder and the reduced B powder into the stirring mill tank according to the molar ratio of 2:1 to stir the abrasive to obtain the Mo-B mixed powder; the time for stirring the abrasive is 120h, and the rotating speed is 400r / min;

[0080] Step 3: Put the Mo-B mixed powder into a vacuum drying oven fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com