Reverse gravel throwing device

A kind of gravel throwing and reverse technology, which is applied in the direction of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of loss, easy collapse, insufficient circulating gravel throwing and filling, etc., and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

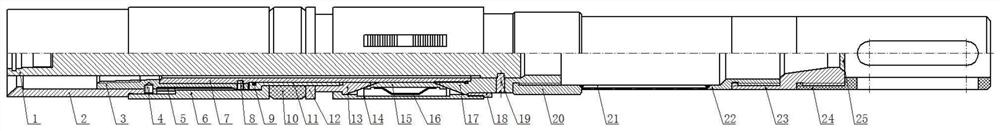

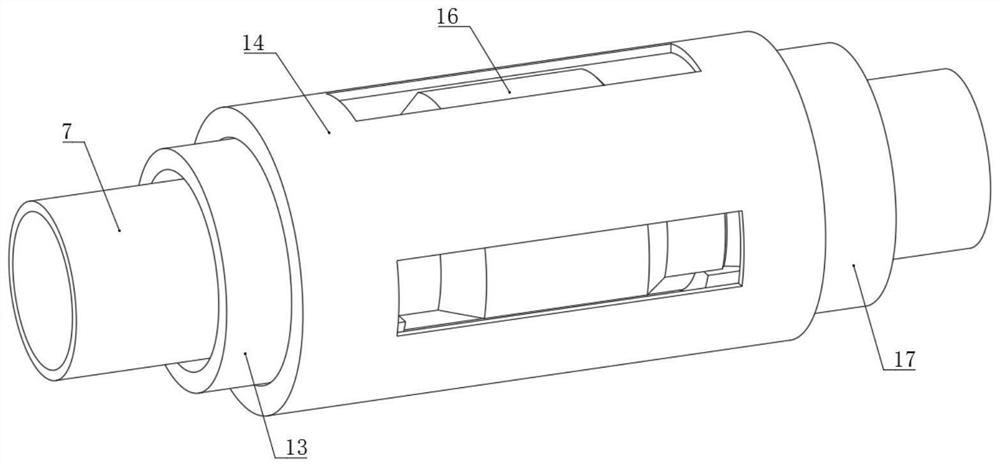

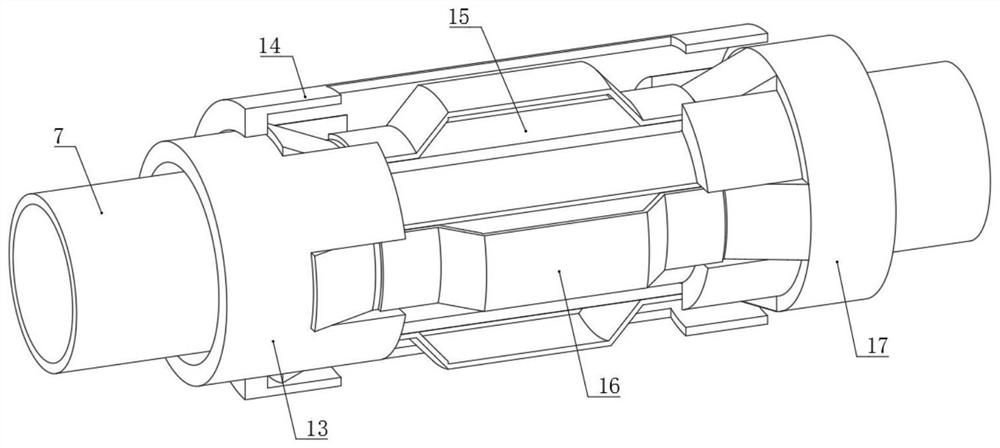

[0028] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a reverse gravel throwing device, including a pull rod 1, an unsealing joint 3, a rubber sleeve bushing 11, an upper cone 13, a slip cylinder 14, a limit ring 18, a screen tube 21. The upper part of the tie rod 1 is connected with the setting tool through threads; the lower part of the tie rod 1 is riveted with the lower cone 17 through the hand shear nail 19; the unsealing joint 3 is fixed and installed in the inner hole of the setting joint 2 through the setting pin 4; The setting joint 2 can slide up and down on the outside of the unsealing joint 3, and when the setting joint 2 sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com