A self-positioning multi-layer laminating machine

A laminating machine and self-positioning technology, applied in the field of foam production, can solve the problems of reducing glue stickiness, unqualified foam, glue exposure, etc., to avoid offset and reduce defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

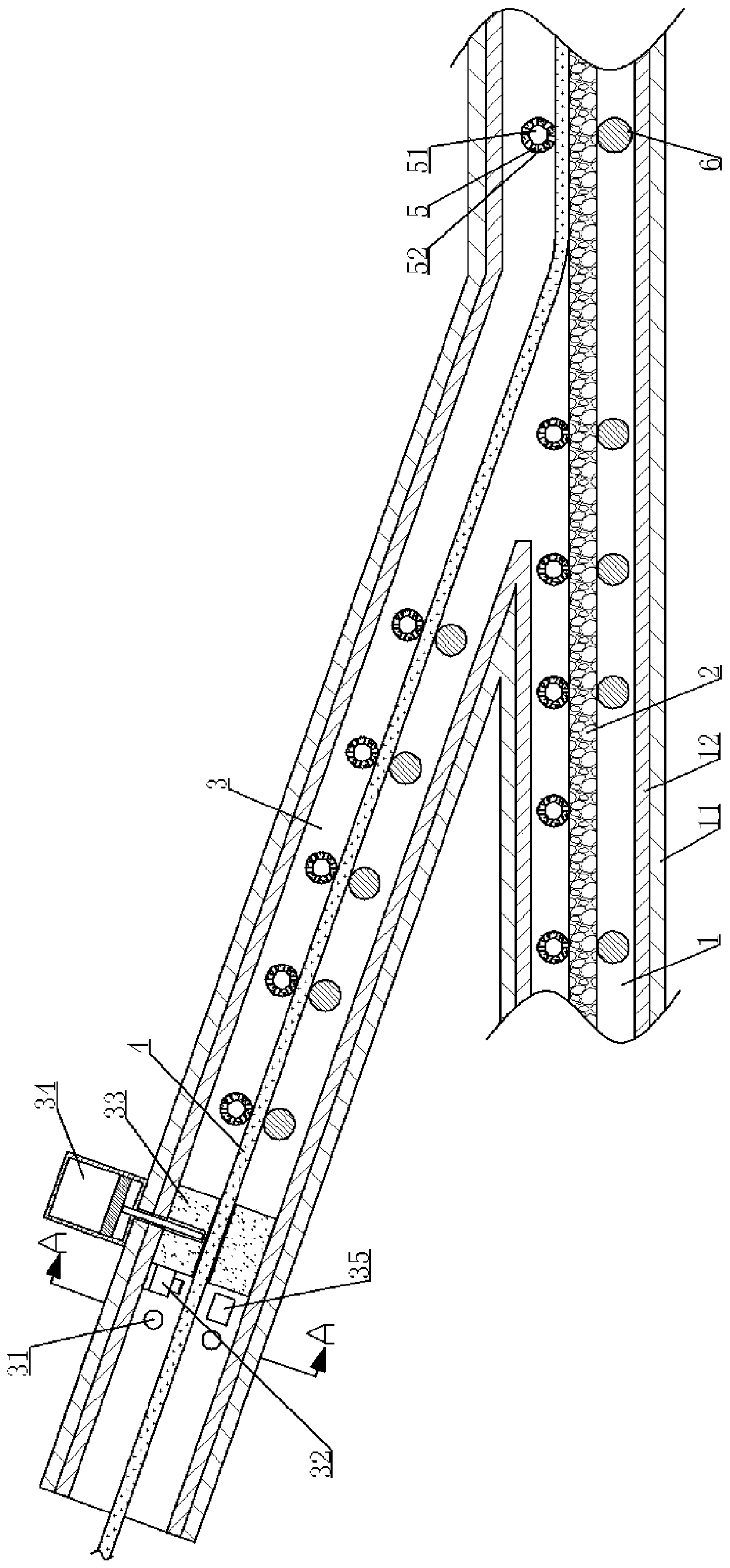

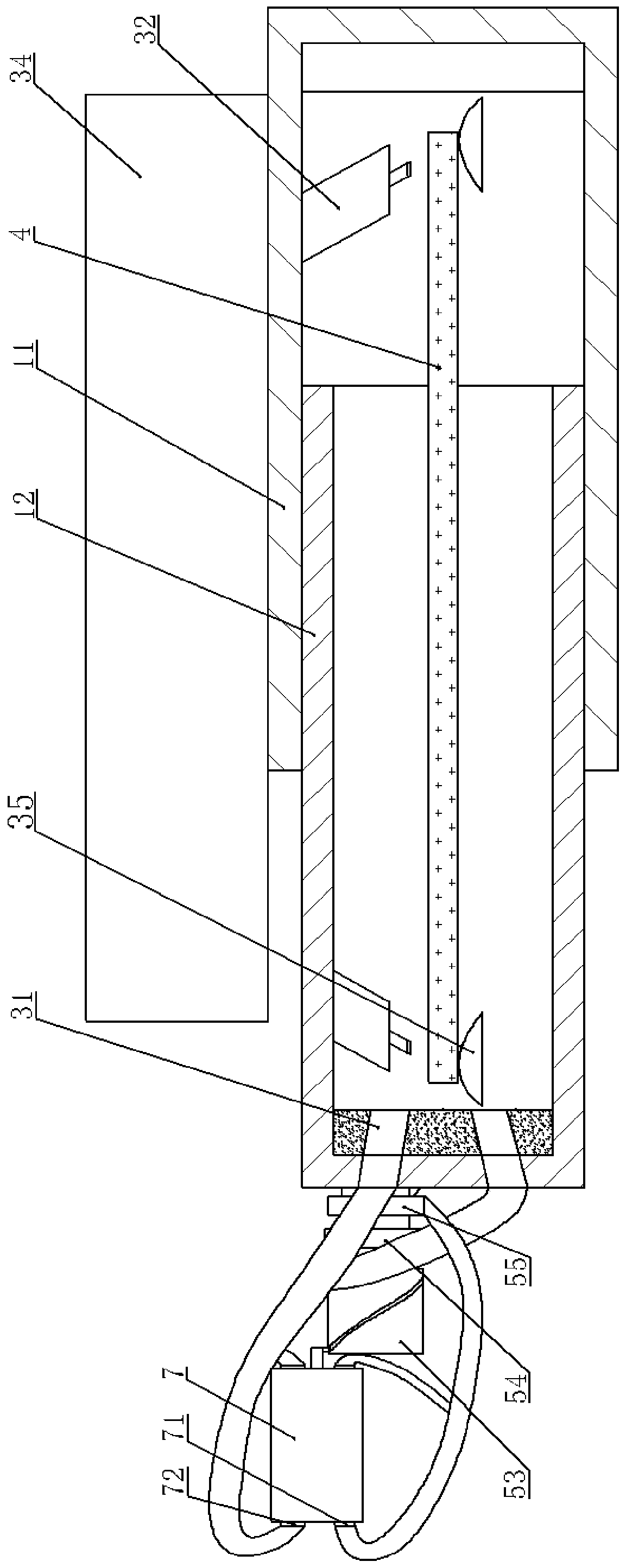

[0026] The following will be further described in detail through specific embodiments: horizontal section 1, first side 11, second side 12, foam 2, inclined section 3, air inlet 31, stretching cylinder 32, cleaning block 33, inflation cylinder 34, arc Shaped plate 35, paper 4, upper roller 5, negative pressure chamber 51, negative pressure hole 52, cylindrical cam 53, upper roller sprocket 54, connection block 55, lower roller 6, blowing cylinder 7, air intake check valve 71, Air outlet one-way valve 72.

[0027] The reference signs in the accompanying drawings of the specification include:

[0028] A self-positioning multilayer laminating machine such as figure 1 , figure 2 As shown, it includes a frame, a motor, a negative pressure mechanism, a positioning channel and several conveying rollers distributed along the positioning channel. Conveying pair of rollers includes upper roller 5 and lower roller 6, upper roller 5 and lower roller 6 all pass through frame, and coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com