Patents

Literature

31results about How to "Increase the maximum static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

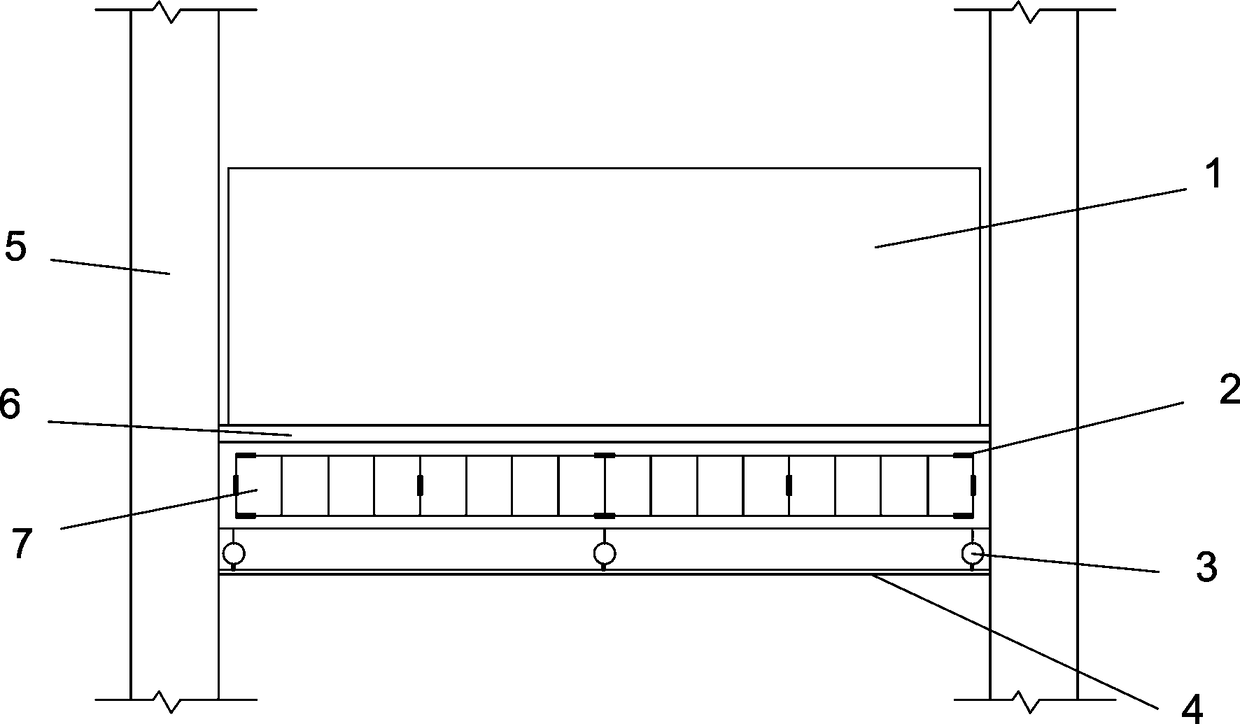

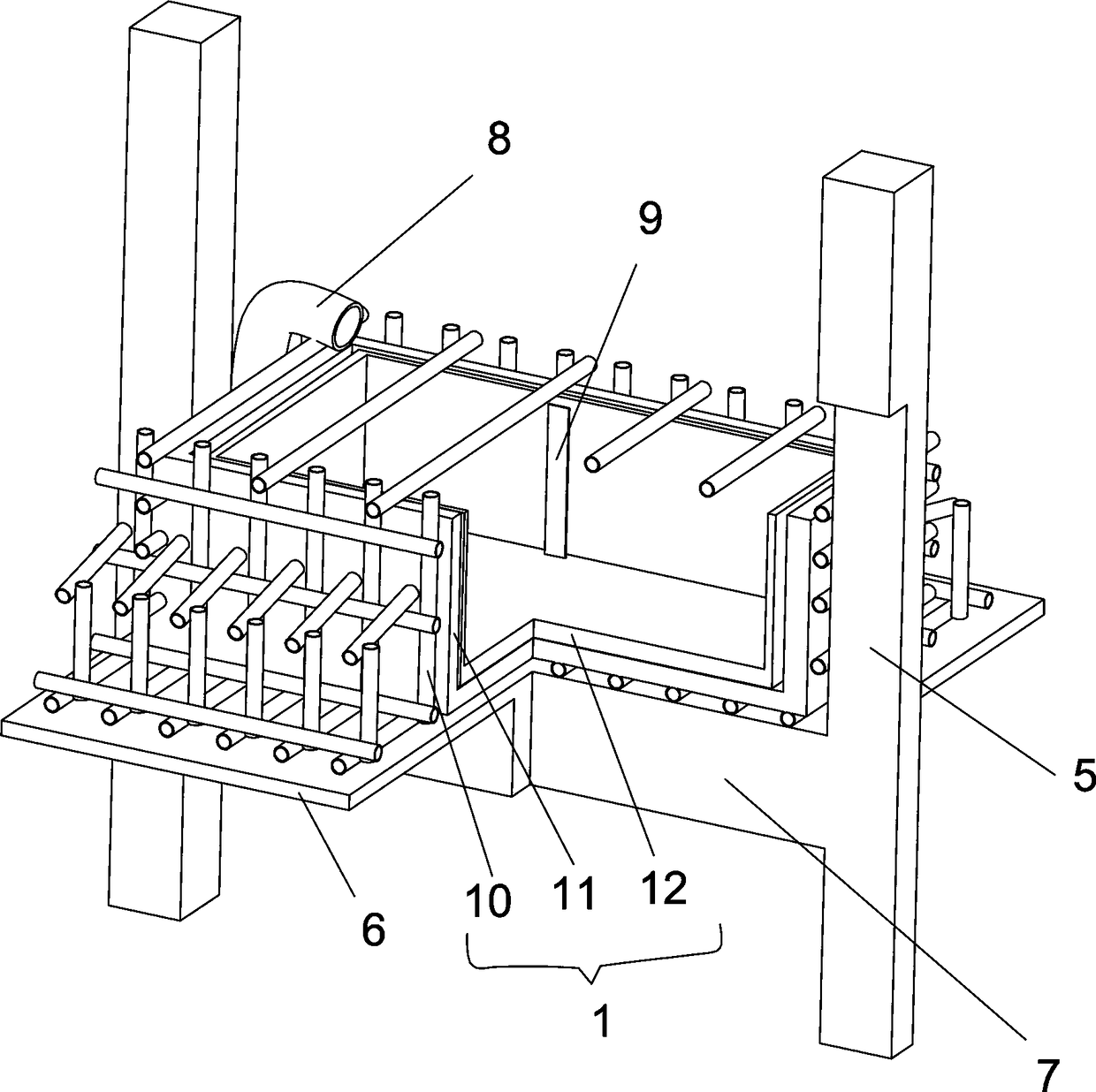

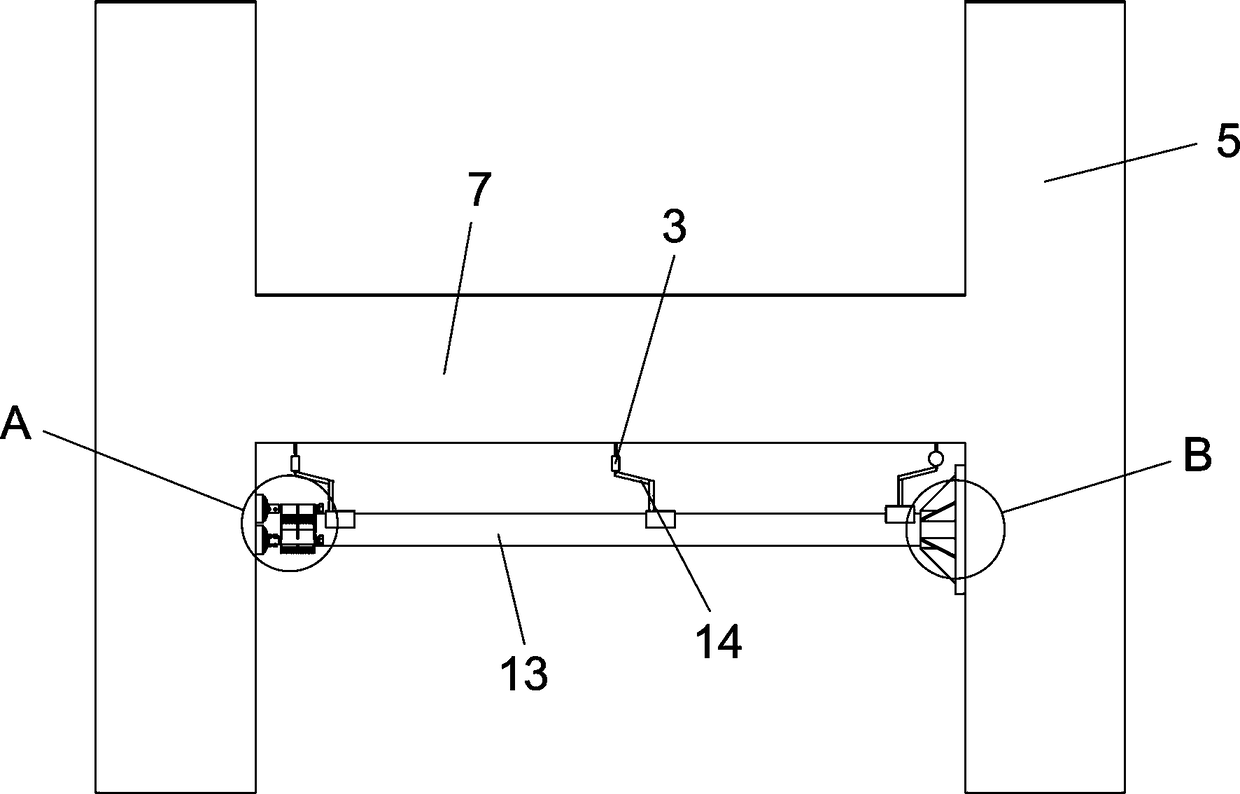

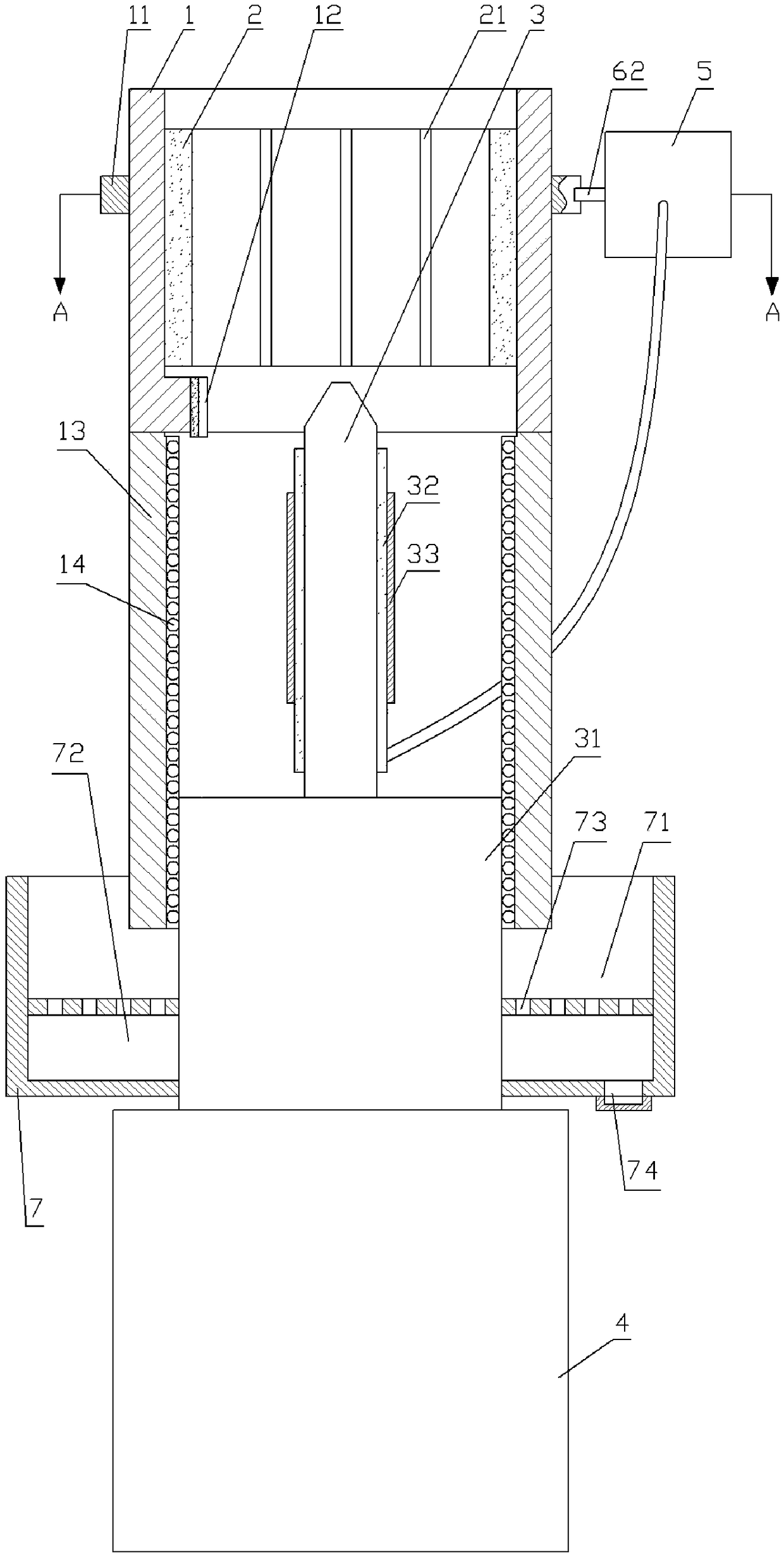

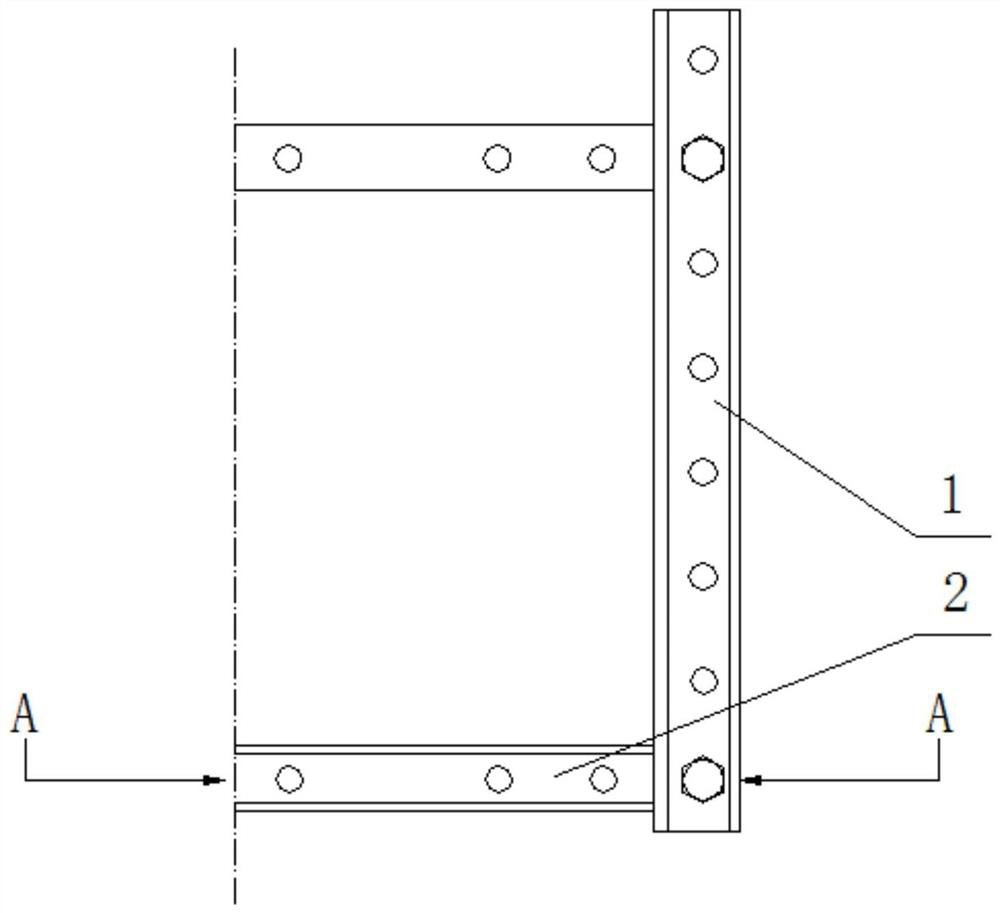

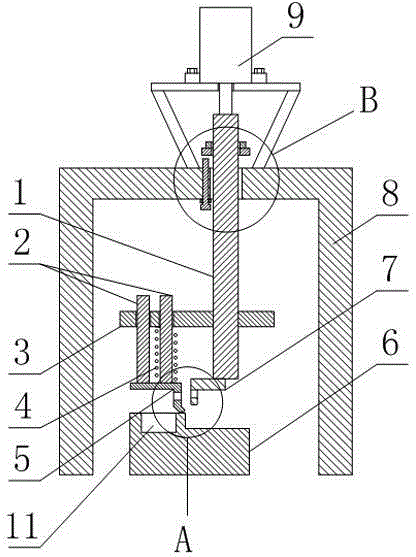

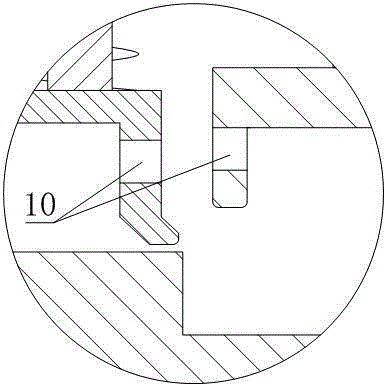

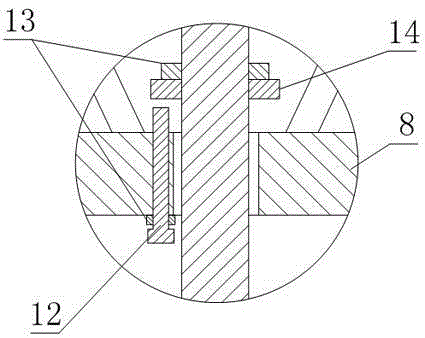

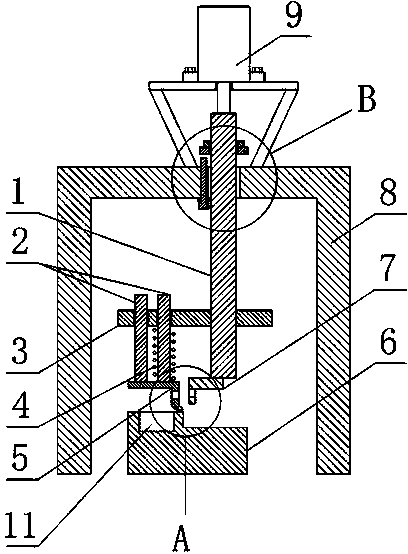

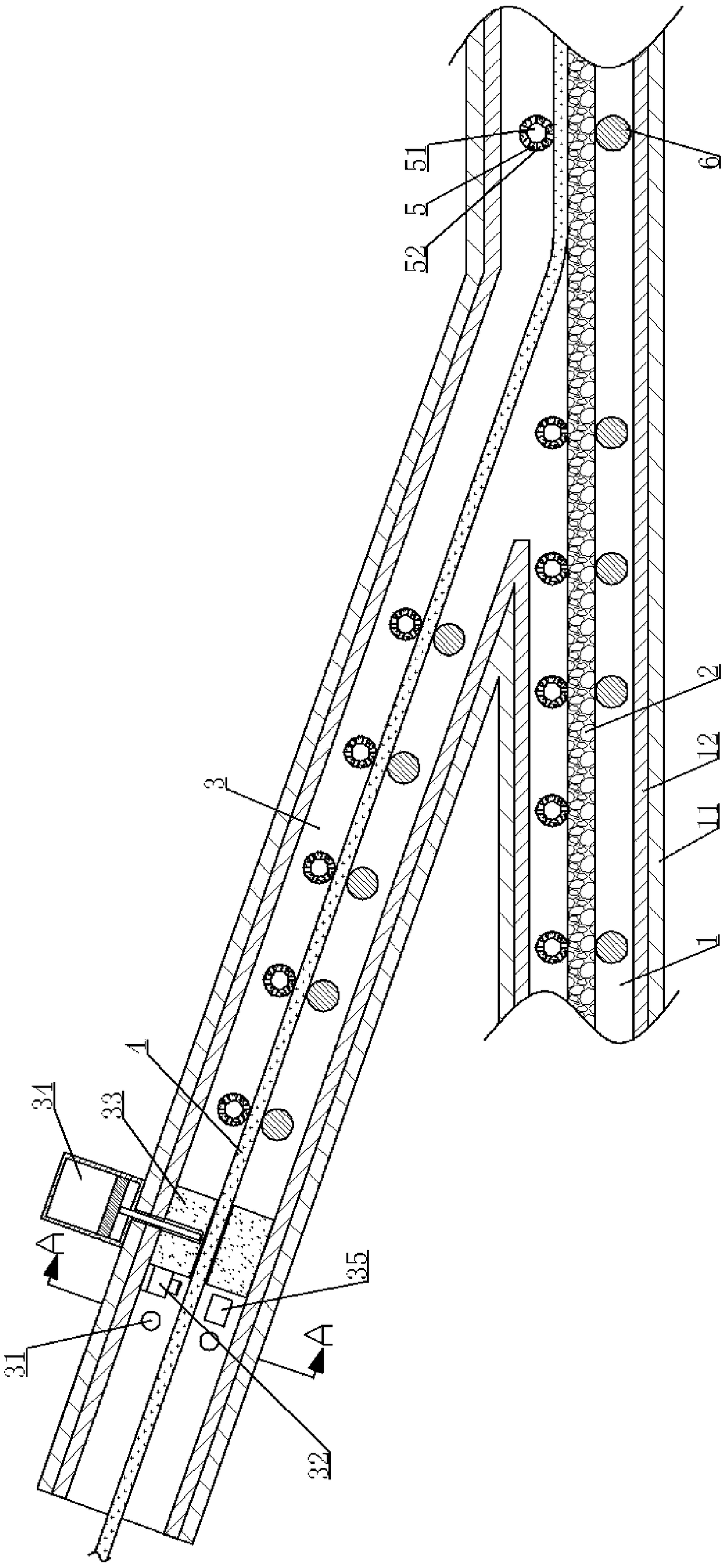

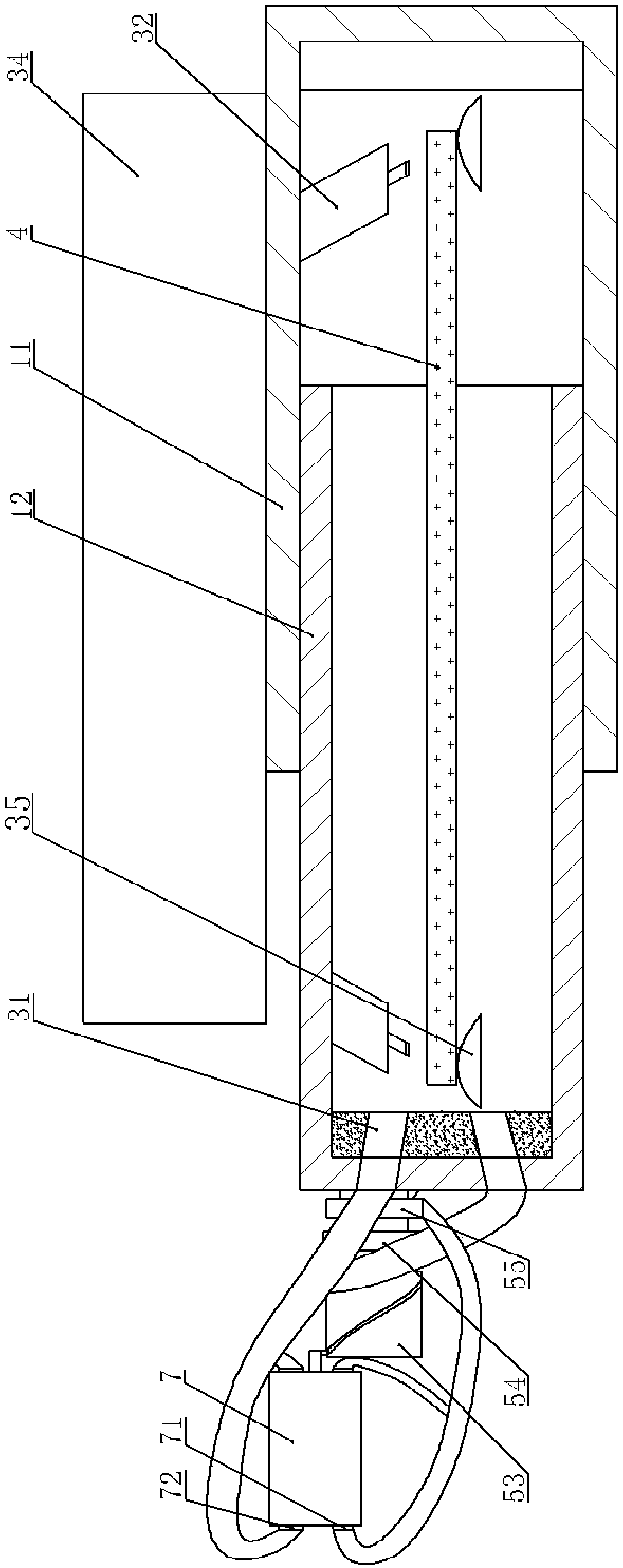

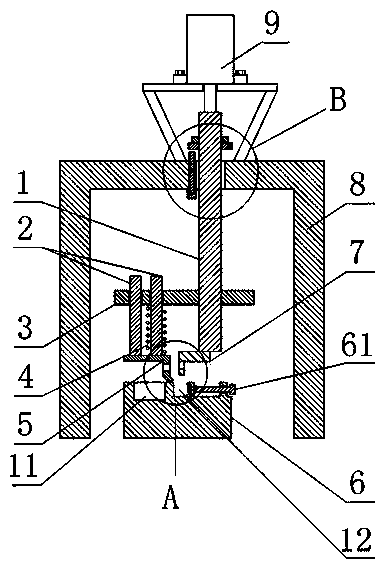

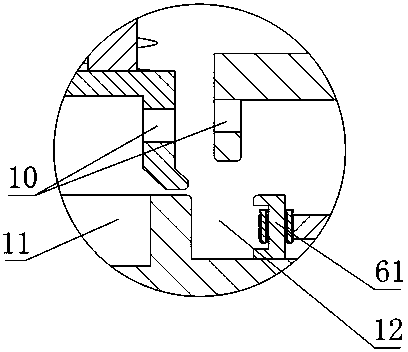

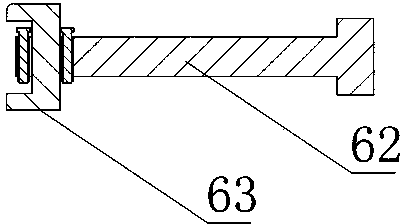

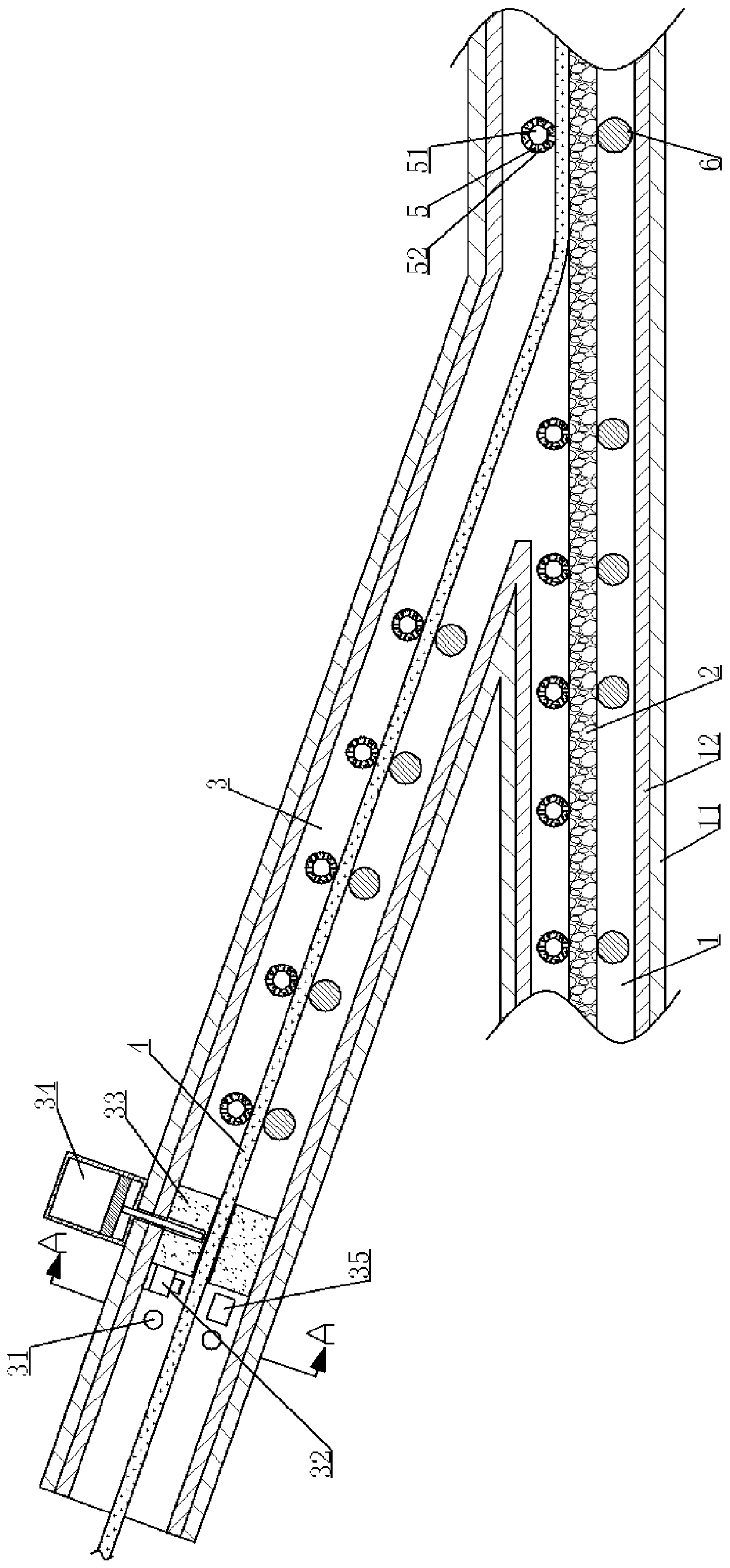

Field detection device suitable for bearing capacity of reinforced concrete beams and arranging method

PendingCN109374413AHigh precisionReduce distractionsMaterial strength using tensile/compressive forcesGirdersFloor slabReinforced concrete

The invention relates to the technical field of field detection of the bearing capacity of reinforced concrete beams, in particular to a field detection device suitable for the bearing capacity of reinforced concrete beams and an arranging method. The field detection device comprises a detected beam, a floor slab arranged at the upper end of the detected beam and load-bearing columns arranged on the two sides of the detected beam; a displacement meter bracket is horizontally arranged on the lower side of the detected beam, and the two sides of the displacement meter brackets are detachably fixed between the two load-bearing columns; displacement meters are arranged between the detected beam and the displacement meter brackets; a loading water tank is arranged at the upper end of the detected beam, and a water delivering pipeline is arranged on one side of the loading tank; and a plurality of strain gauges are attached to a steel bar key stress point of the detected beam. The structureof the displacement meter bracket is simplified, the bracket is only composed of a longitudinal steel pipe and fixing devices at the two ends, and mounting is convenient and quick.

Owner:NANCHANG UNIV

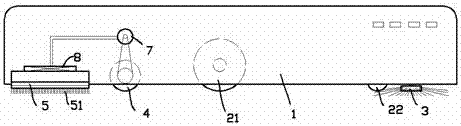

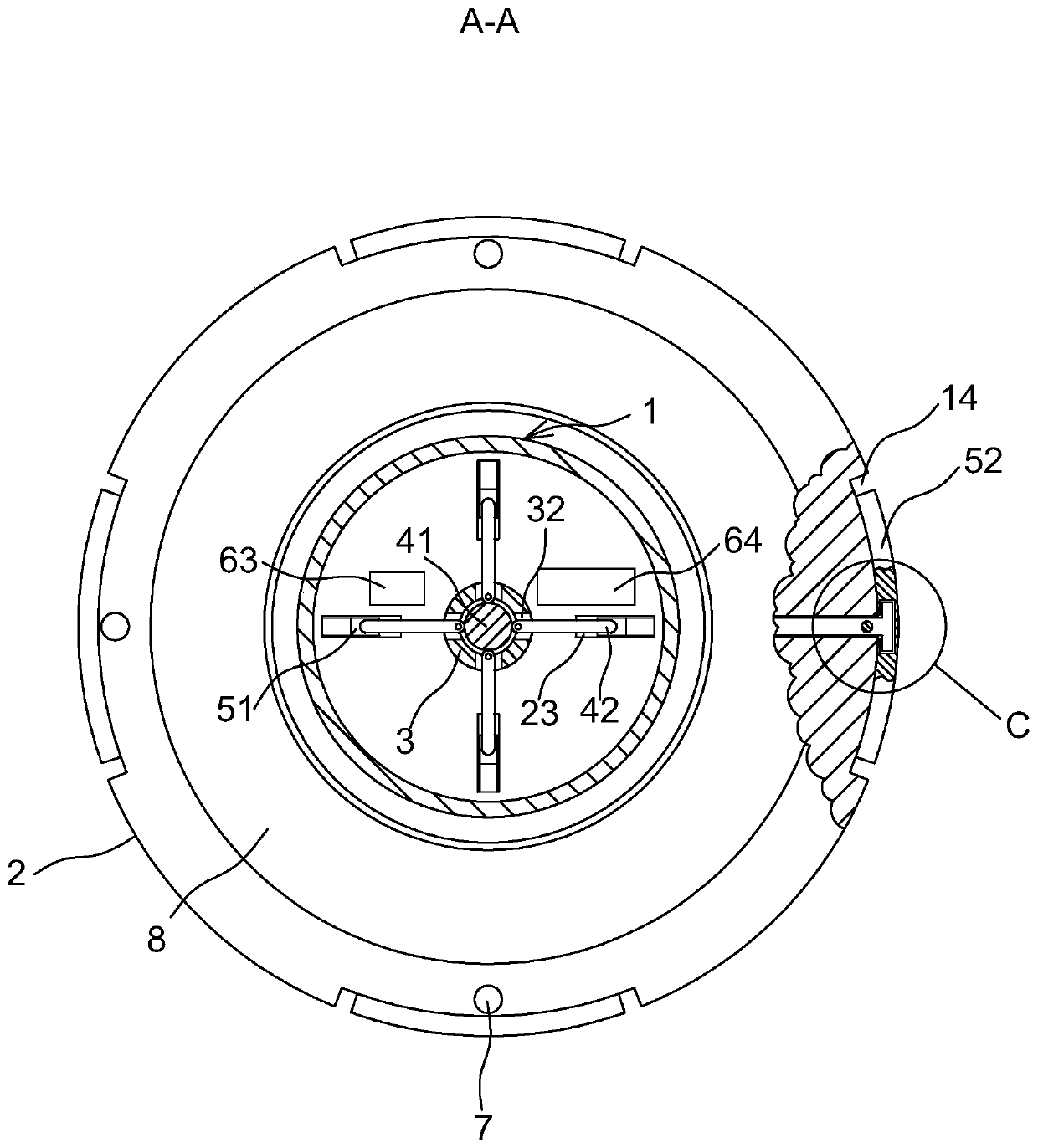

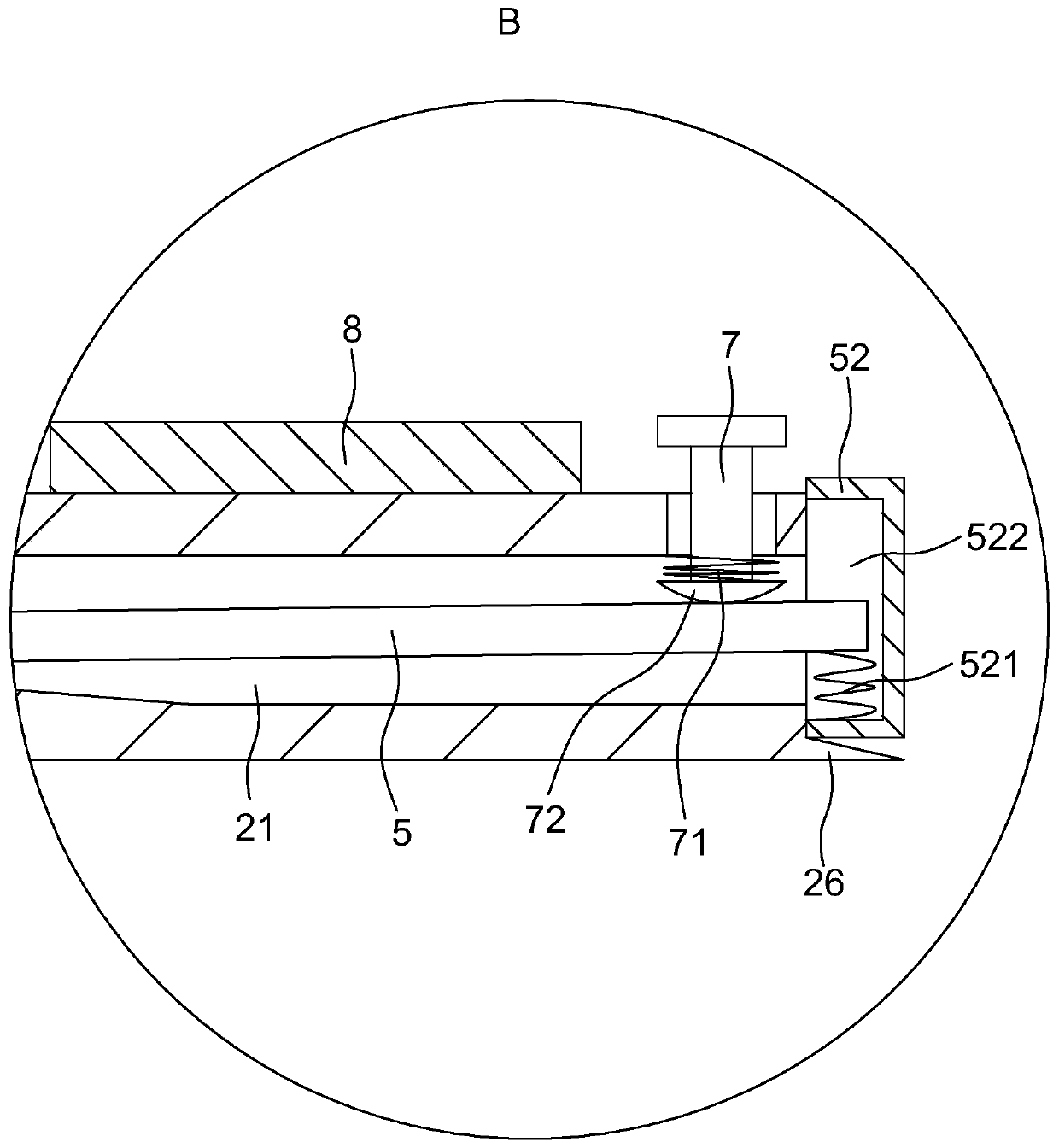

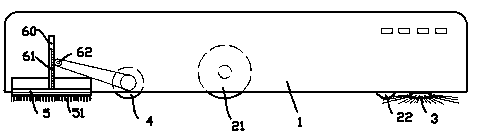

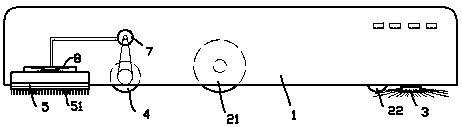

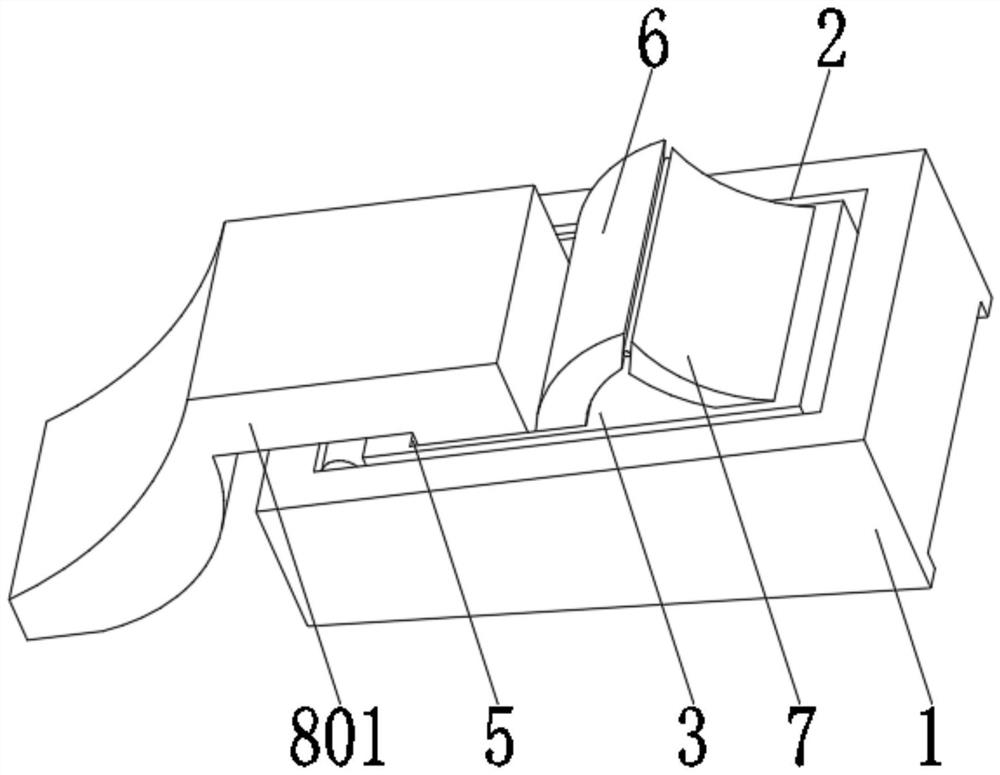

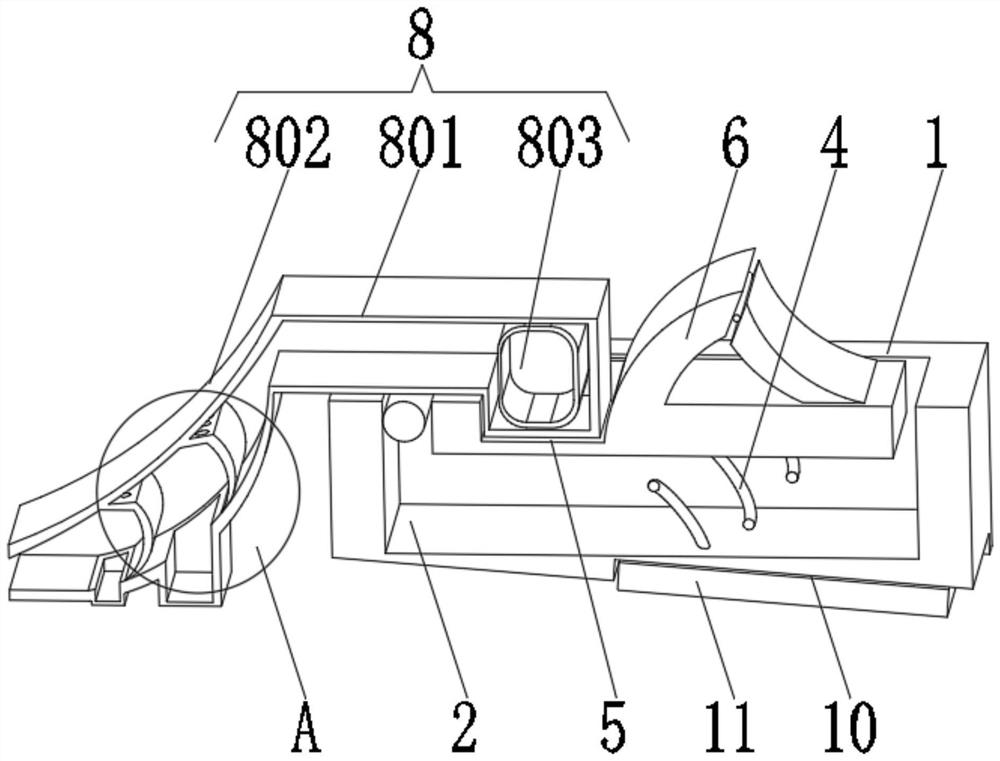

Automatic floor sweeping robot

ActiveCN107242837AAvoid damageIncrease the maximum static frictionMachine detailsFloor sweeping machinesSteering wheelRolling resistance

The invention provides an automatic floor sweeping robot. The robot comprises a robot body, a dust suction inlet is formed in the bottom of the robot body, a walking wheel, a steering wheel and a dusting brush are arranged on the bottom of the robot body, and a driven roller is further arranged on the back at the rear of the walking wheel; the driven roller, the walking wheel and the steering wheel land together; a movable plate which can move up and down is arranged at the rear of the driven roller, and a duster cloth is horizontally fixed to the lower side of the movable plate; a drive mechanism which is coupled with the driven roller is connected to the upper side of the movable plate, and when the drive mechanism drives the driven roller to move forward, the movable plate lifts upward; the requirements for the surface roughness of the driven roller are as follows, when the robot body walks on the floor and the ground of floor tiles, sliding friction is kept between the driven roller and the ground; however, when the robot body walks on a carpet, rolling friction is kept between the driven roller and the ground. The robot can automatically adjust the floor sweeping function in a room paved with the carpet, and thus the damage on the carpet is avoided.

Owner:江苏蒂森智能科技有限公司

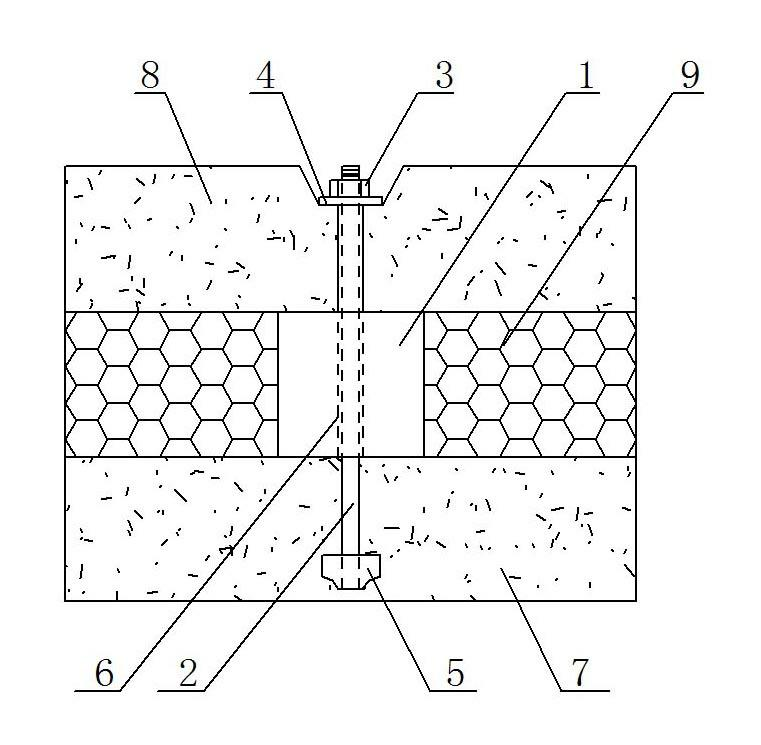

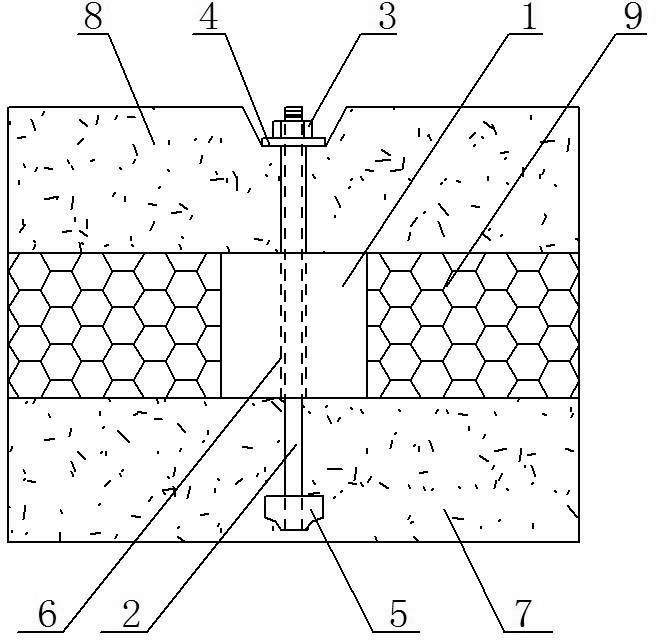

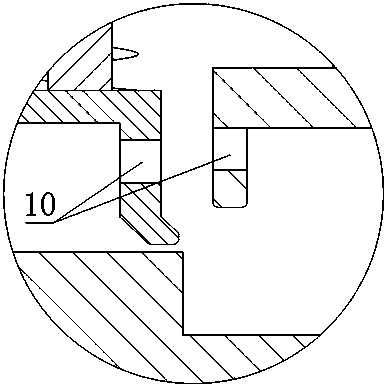

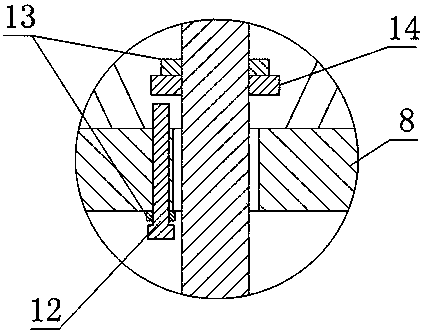

Novel method for installing prestress connecting piece of concrete heat-insulating sandwich board

InactiveCN102168491AIncrease the maximum static frictionGuaranteed pressureBuilding material handlingBlade platePre stress

The invention relates to a novel method for installing a prestress connecting piece of a concrete heat-insulating sandwich board, which comprises the following steps of: connecting an anchoring end socket and a bolt, and pre-burying into a concrete outer blade board; sleeving a casing pipe on the bolt which exposes from the concrete outer blade board, and allowing a cushion block to pass through the bolt and the casing pipe, and jointing the cushion block and the concrete outer blade board; paving an insulating layer; pouring a concrete inner blade plate on the insulating layer and the cushion block, and reserving a groove, so that one end of the bolt passes through the groove of the concrete inner blade plate; and after concrete reaches the anticipated strength, installing a gasket in the groove, and stretching the bolt to be fixed by an anchorage device. By the method, the prestress connecting piece is easy to install, reasonable in structure, low in cost, safe and reliable.

Owner:李爱国

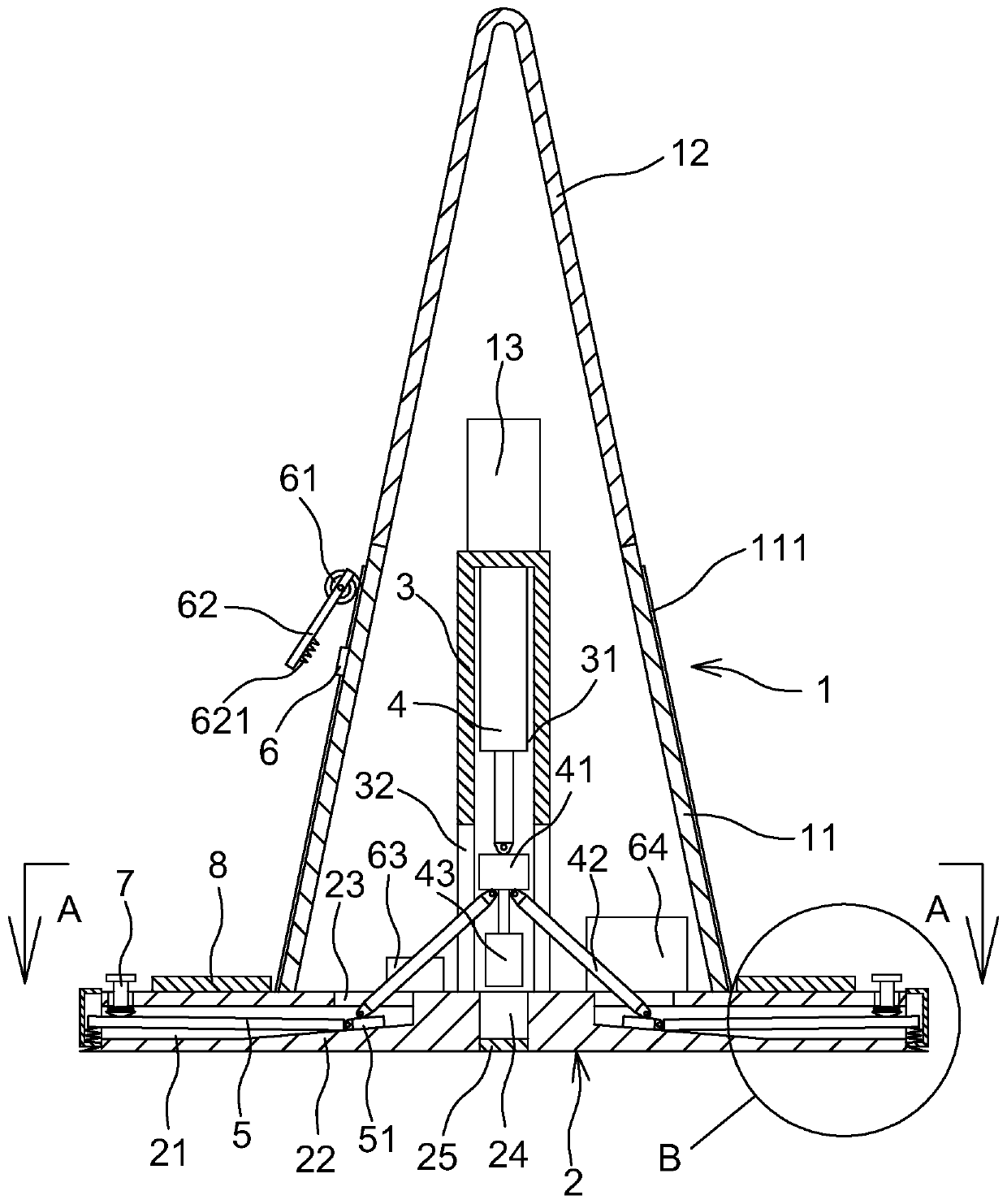

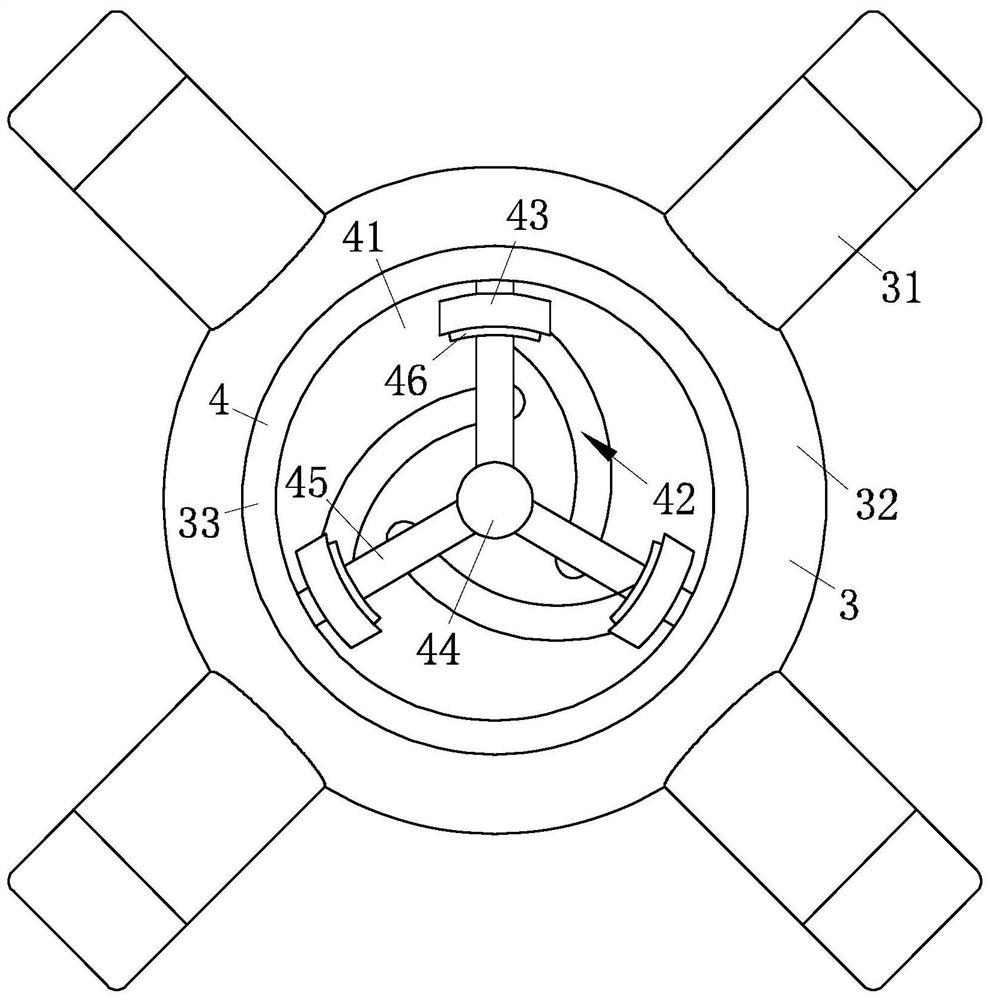

Traffic cone

PendingCN110409333AEasy to stick outConvenient indentationBatteries circuit arrangementsTraffic signalsEngineeringConical shell

The invention belongs to the technical field of traffic safety, and relates to a traffic cone which comprises a base and a conical shell arranged on the base, wherein four guide grooves are formed inthe base; a plurality of telescopic rods are slidably arranged in all the guide grooves correspondingly; the outer ends of the telescopic rods extend out of the guide grooves; propping blocks are arranged at the end parts of the telescopic rods; four guide sheets are arranged on the edge of the lower side of the base and positioned below the propping blocks correspondingly; four bolt rods are arranged on the base in an inserting manner; the lower ends of all the bolt rods extend into the guide grooves correspondingly; compressing sheets are fixedly connected with the bolt rods; compressing springs are arranged on all the bolt rods; under the action of the compressing springs, the compressing sheets are always propped against the telescopic rods; a driving mechanism is arranged at the middle of the base; and when the driving mechanism is started, the telescopic rods can be driven by the driving mechanism to extend out of and retract into the guide grooves simultaneously. The traffic cone provided by the invention has the advantage that the stability can be effectively improved.

Owner:ZHEJIANG OCEAN UNIV

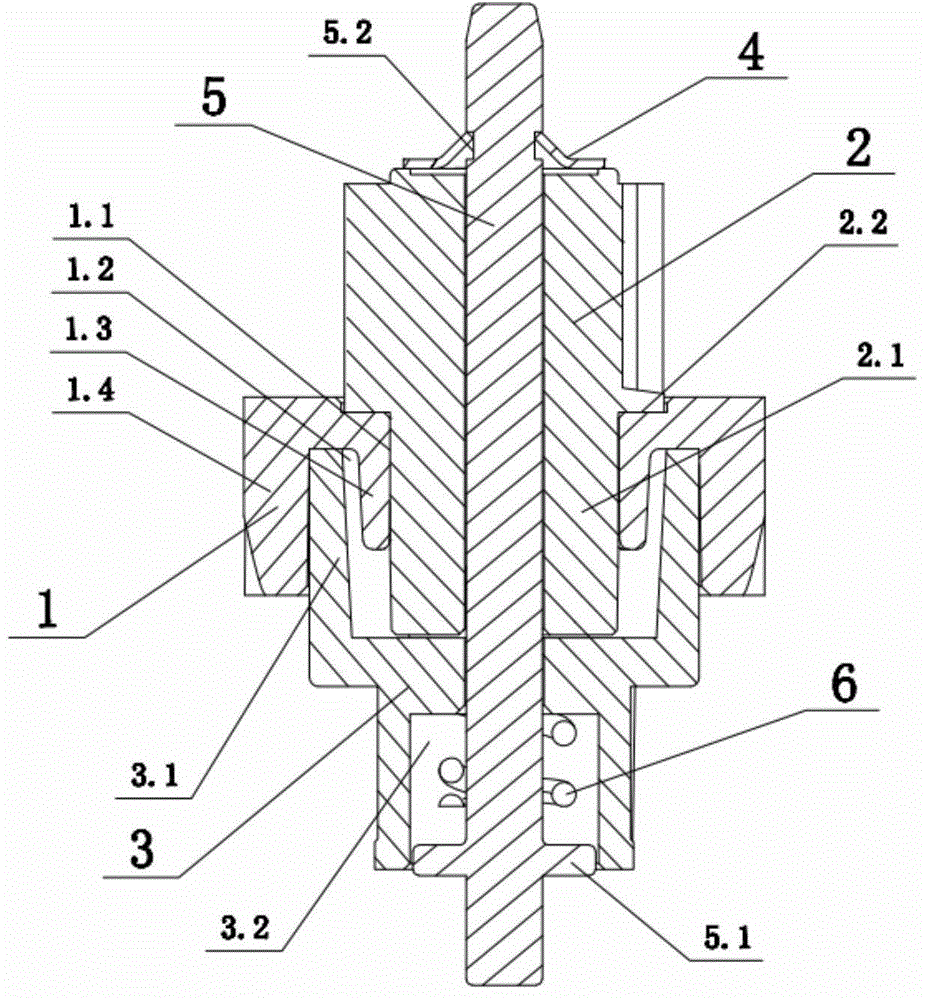

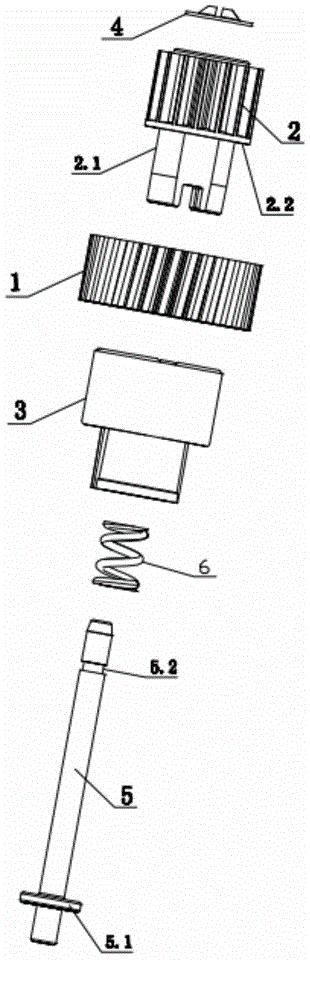

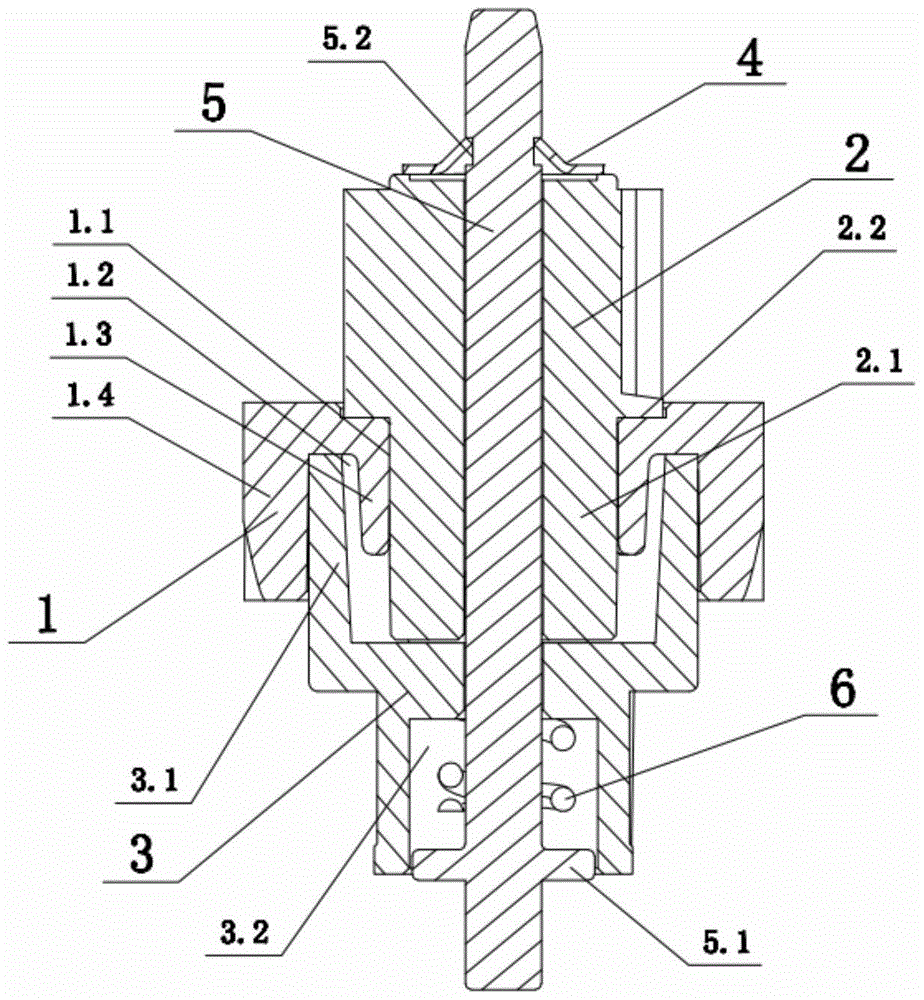

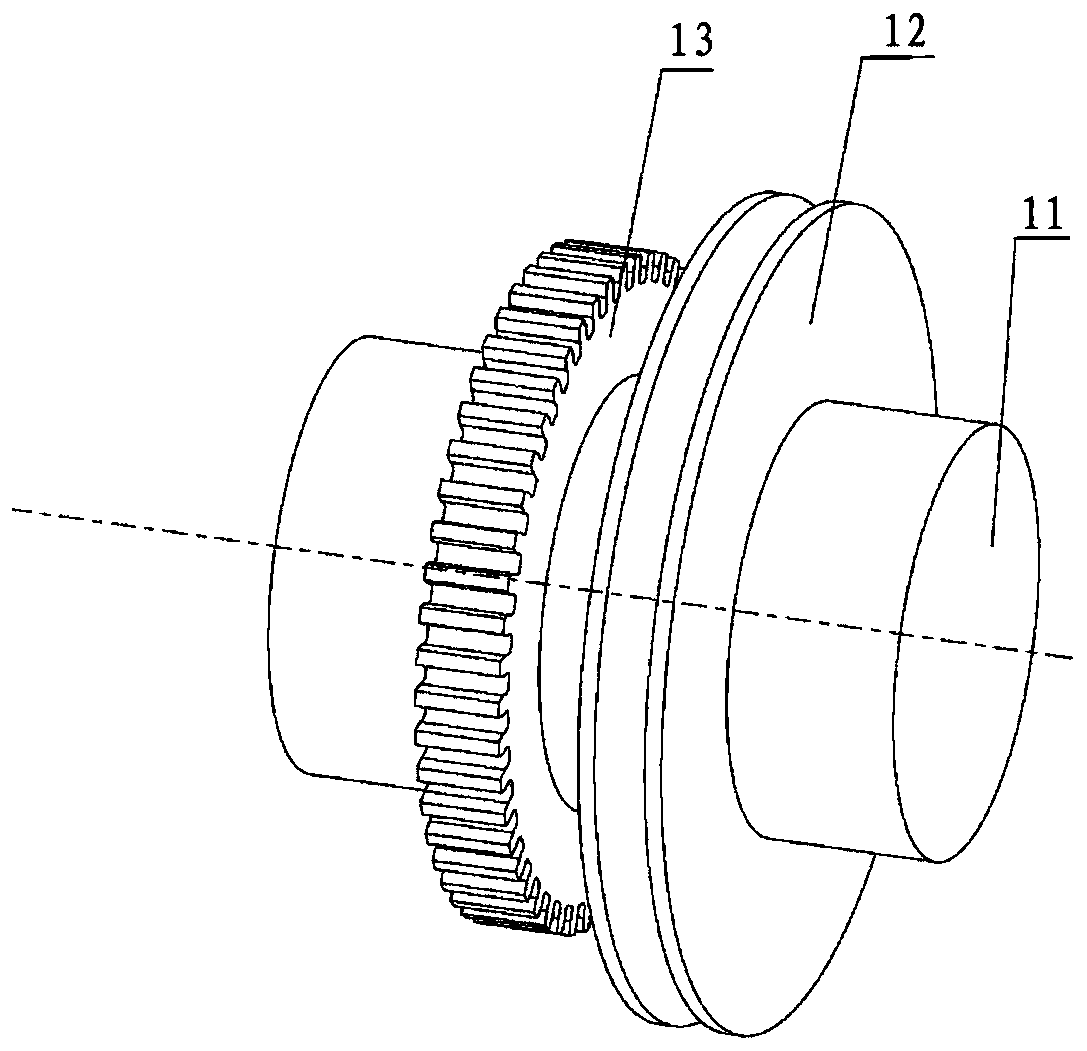

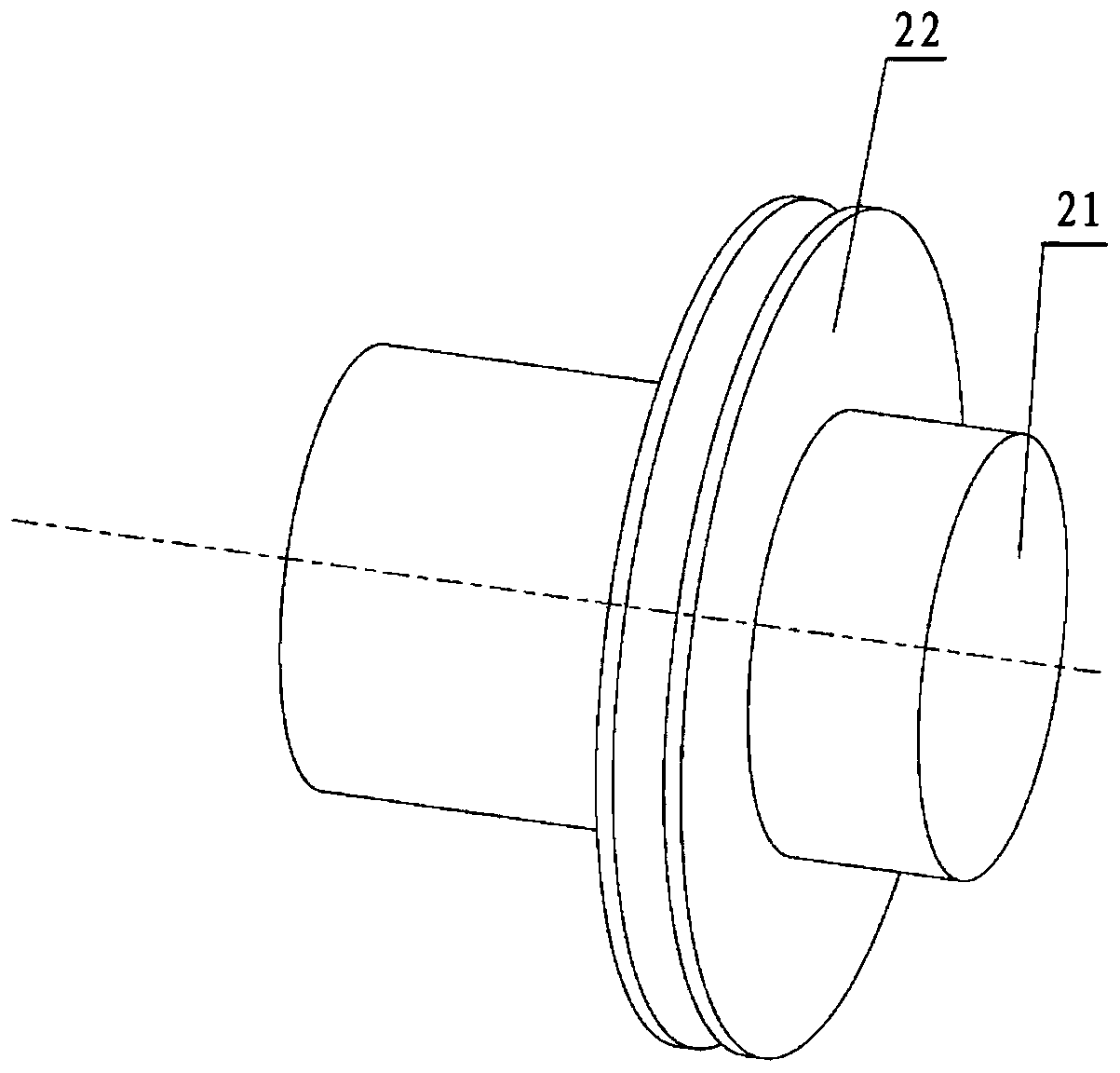

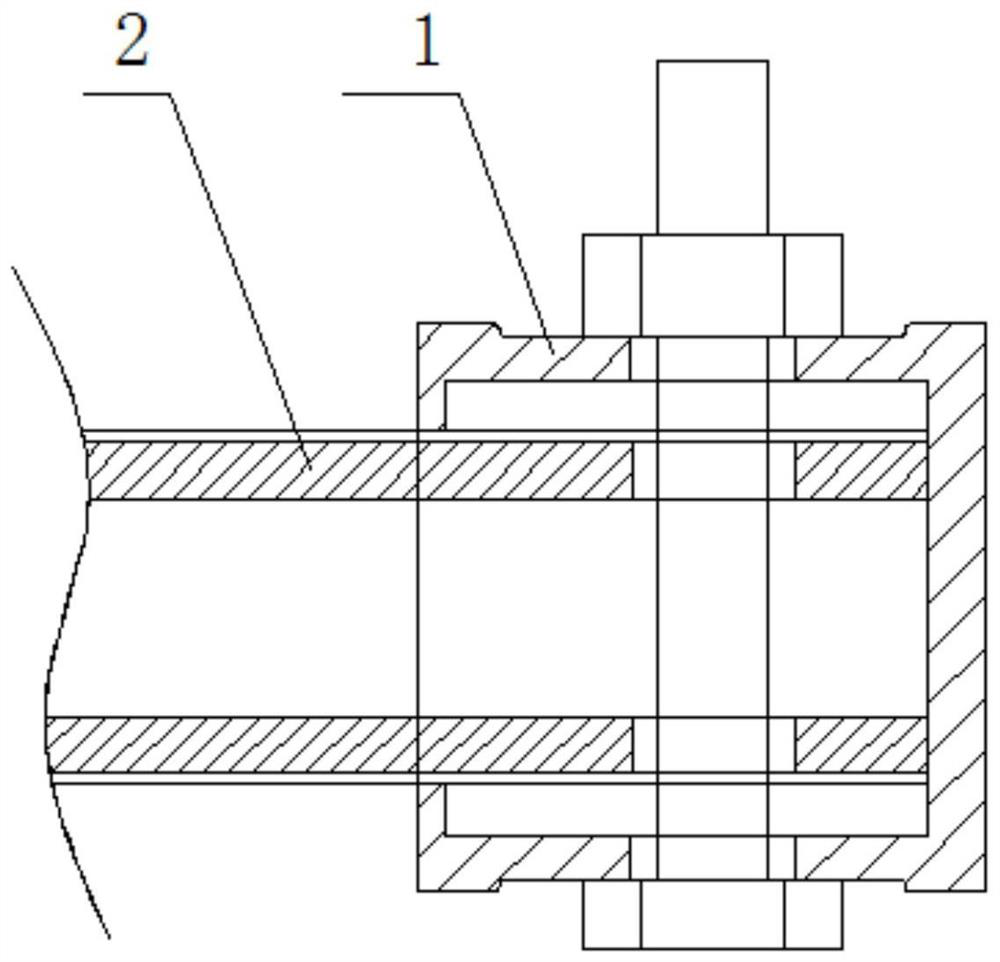

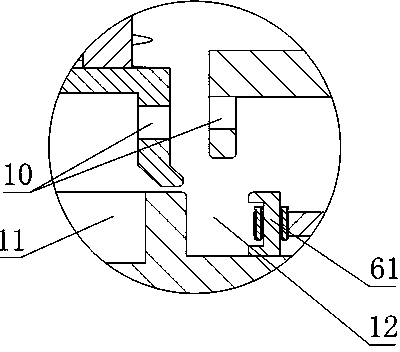

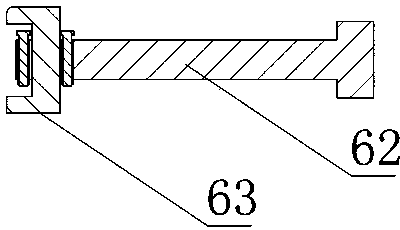

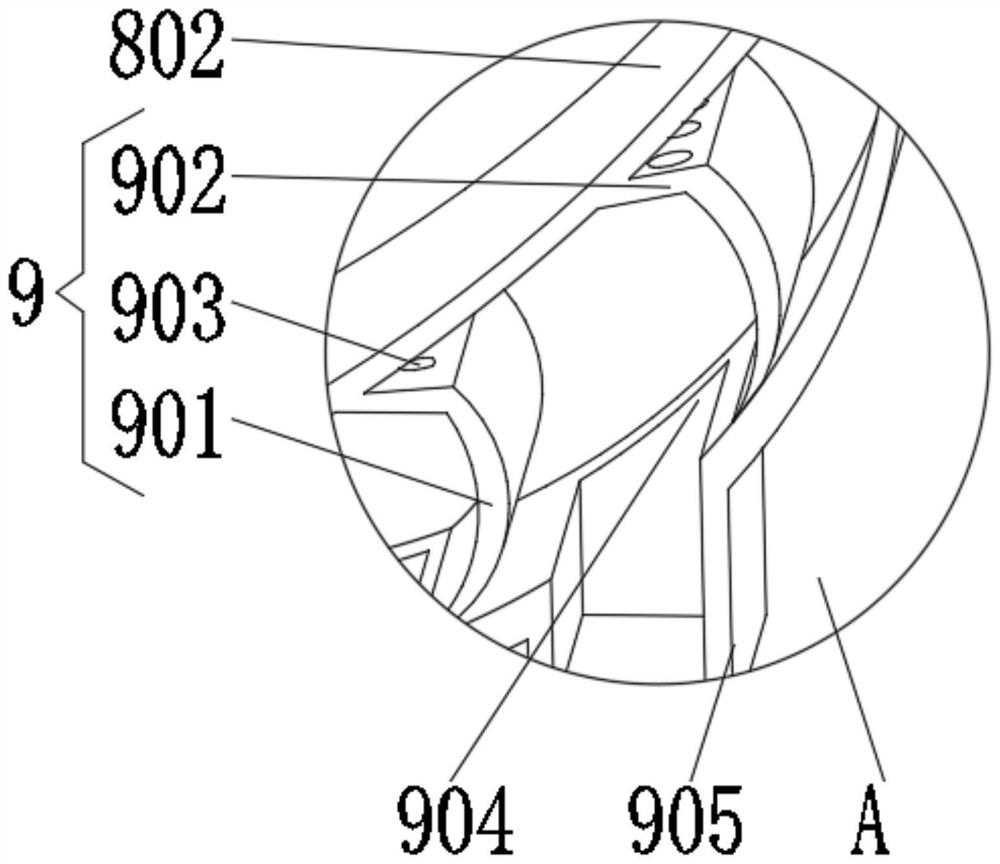

Slipping mechanism for mirror surface driver of automotive rearview mirror

The invention discloses a slipping mechanism for a mirror surface driver of an automotive rearview mirror. The slipping mechanism comprises a rotation shaft (5), a straight-tooth wheel column (2) and an oblique-tooth disc (1) which sequentially sleeves the rotation shaft (5), as well as a limiting mechanism arranged on the rotation shaft (5) and used for limiting axial movement between the straight-tooth wheel column (2) and the oblique-tooth disc (1). The slipping mechanism is characterized in that a driving friction surface is arranged on the oblique-tooth disc (1); a driven friction surface matched with the driving friction surface is arranged on the straight-tooth wheel column (2); a friction force used for driving linkage of the straight-tooth wheel column (2) and the oblique-tooth disc (1) is formed between the driving friction surface and the driven friction surface; the maximum value of the friction force is smaller than the resistance generated by rotating the straight-tooth wheel column (2) to an extreme position. The slipping mechanism for the mirror surface driver of the automotive rearview mirror is simple in structure and can be used for effectively preventing the mirror surface from being broken by rotating out of travel when the mirror surface rotates to the extreme position.

Owner:NINGBO JINGCHENG CAR IND

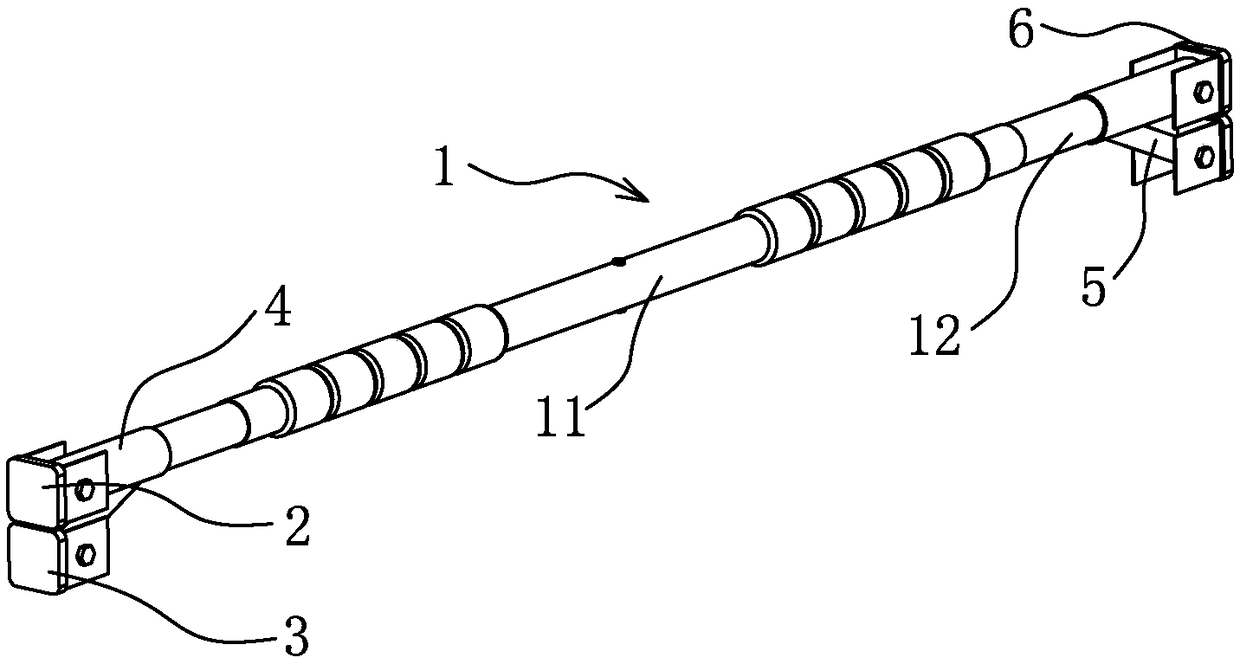

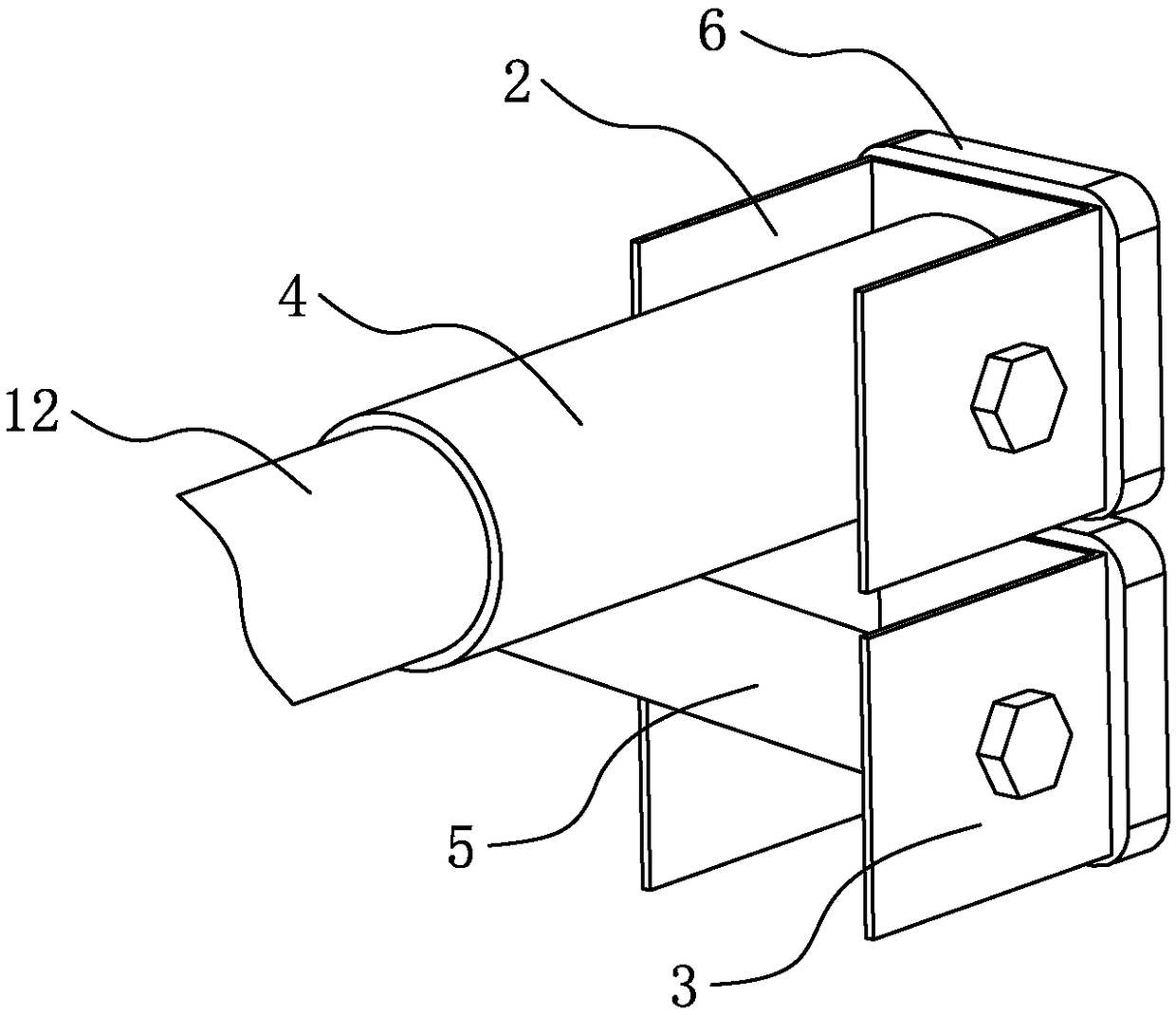

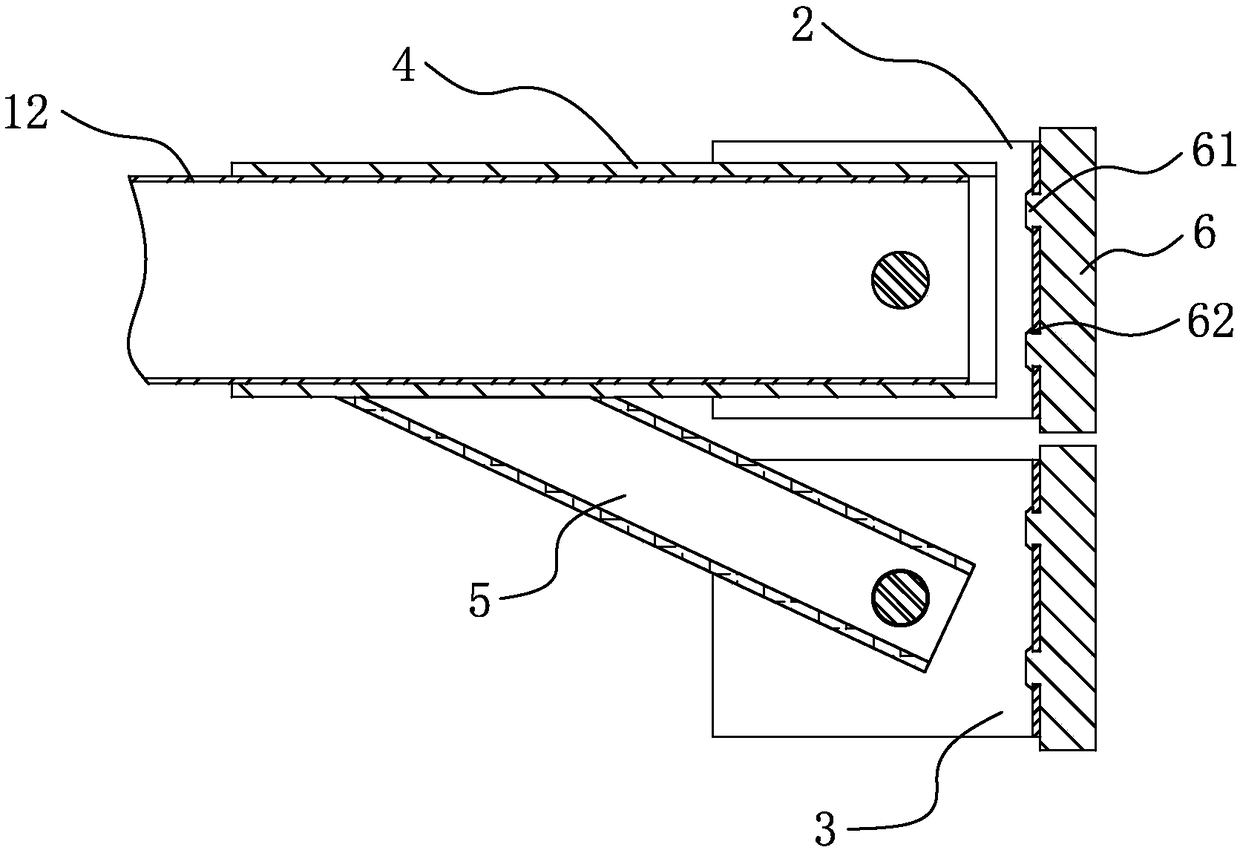

Reinforced door frame horizontal bar

PendingCN109011321AReduced material toughness requirementsStable supportHorizontal barsJambHorizontal bar

The invention relates to the technical field of horizontal bars, in particular to a reinforced door frame horizontal bar. The reinforced door frame horizontal bar comprises a telescopic rod and is characterized in that supporting base assemblies are arranged at the two ends of the telescopic rod and comprise first supporting base, second supporting bases, supporting sleeves and supporting rods, the telescopic rod is sleeved with the supporting sleeves, the supporting sleeves are rotatably arranged on the first supporting bases, one end of each supporting rod is connected with the lower portionof the corresponding supporting sleeve, and the other end of each supporting rod is connected with the corresponding second supporting base. The supporting base assemblies of the door frame horizontal bar have a good supporting effect and are each provided with a good structure, the maximum supporting force capable of being provided by the supporting base assemblies can be synchronously increasedalong with increase of the stress of the telescopic rod, and installing is firmer.

Owner:QUANZHOU FENGDONG SPORTS GOODS CO LTD

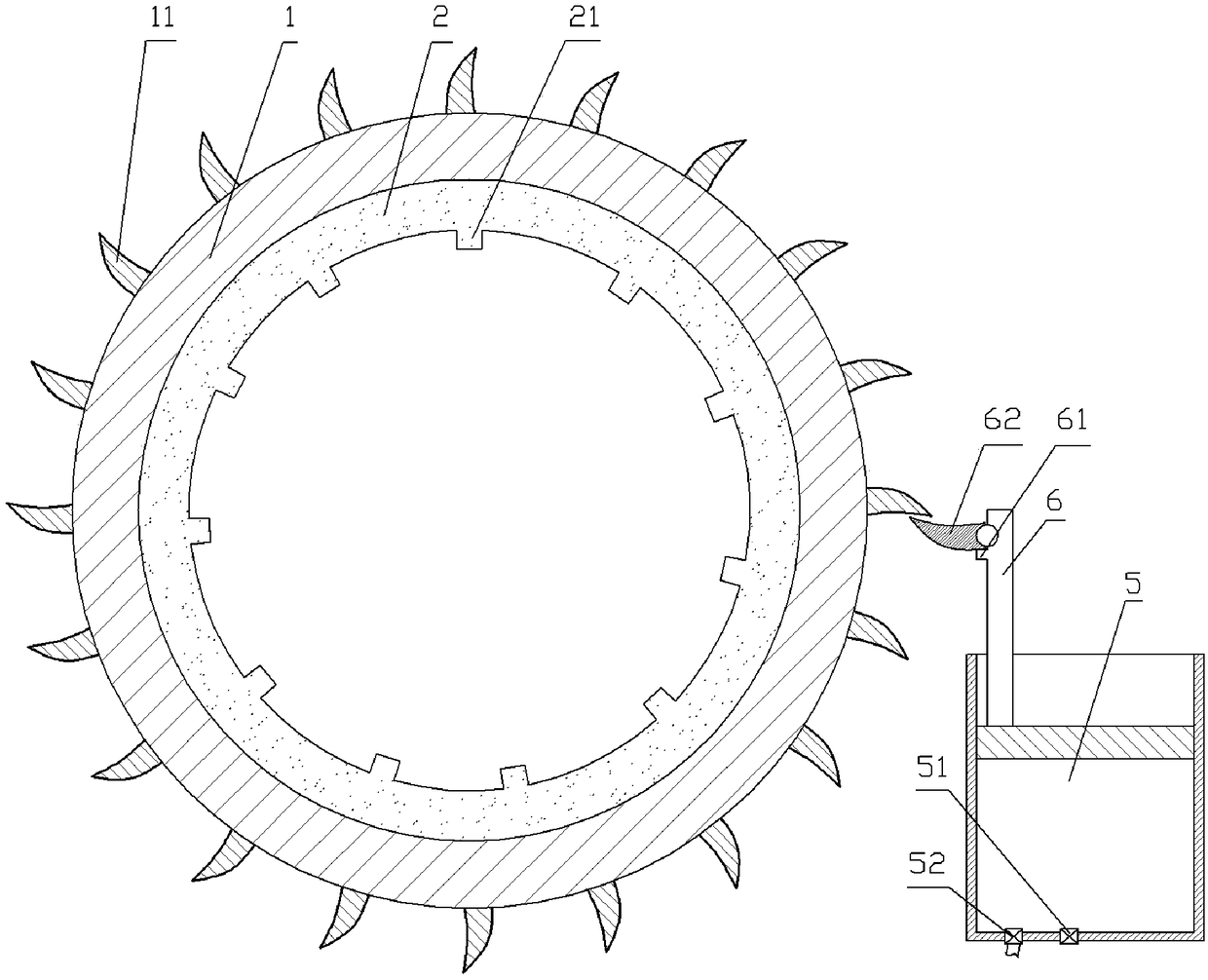

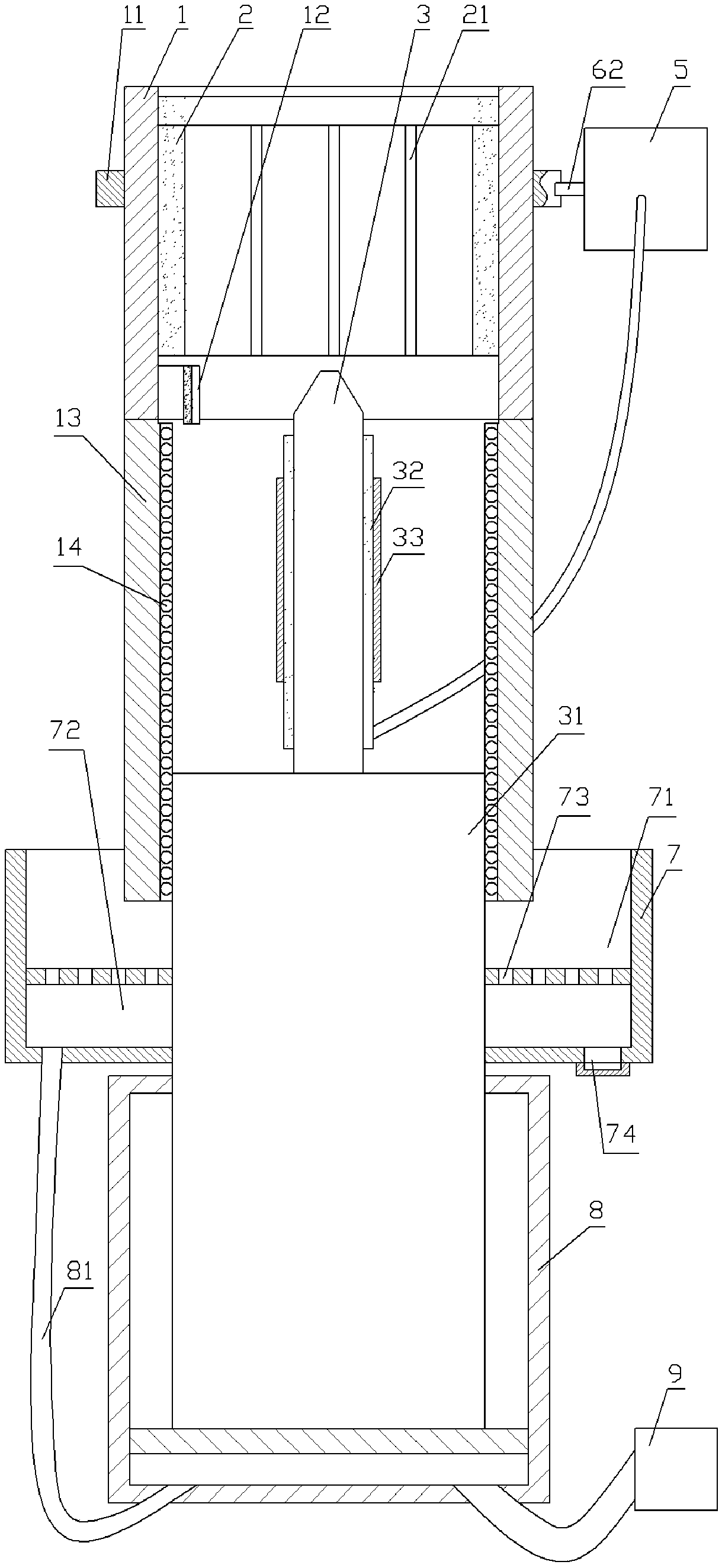

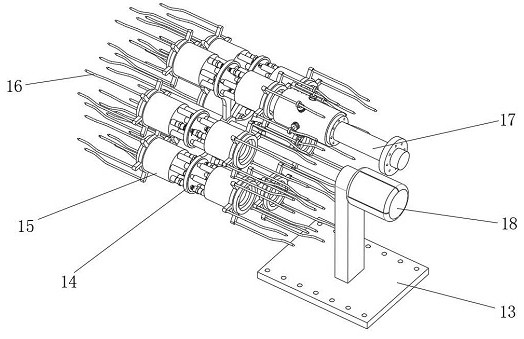

Corn threshing device

ActiveCN108617278AIncrease pressureGuaranteed threshing effectMowersThreshersMechanical engineeringPiston rod

The invention relates to the field of planting, and particularly discloses a corn threshing device. The corn threshing device comprises a rack, a threshing mechanism and a moving mechanism, wherein the threshing mechanism comprises a rotary cylinder, a slotting knife, a threaded piece and a threshing piece, and protruding ribs are arranged on the threshing piece; the moving mechanism and the slotting knife are located on the same side of the rotary cylinder. The moving mechanism comprises a propelling assembly, a threaded rod and an air bag, wherein the threaded rod is coaxial with the rotarycylinder, balls are arranged between the threaded piece and the threaded rod, an air outlet capable of being closed is formed in the air bag, and a plurality of cutting knives are fixed to the periphery of the air bag. The rack is fixedly provided with an air-filled cylinder, a piston rod is fixed to a piston of the air-filled cylinder, a spring is arranged in a rodless cavity of the air-filled cylinder, poke pieces are fixed to the outer wall of the rotary cylinder, the side wall of the rodless cavity of the air-filled cylinder is fixedly provided with an air-inlet one-way valve and an air-filled one-way valve, and the air-filled one-way valve is communicated with the air bag. The threshing device can dispose corn cobs.

Owner:贵州务川八爷农场有限公司

Network transformer pin bending device

InactiveCN104190817APrevent opposite motionIncrease the maximum static frictionTransformerEngineering

The invention discloses a network transformer pin bending device which comprises a machine frame, a press rod arranged on the machine frame, a deformation press block fixed to the lower end of the press rod and a material table located under the deformation press block. The press rod can move in the axial direction, and a pin tightening device is further fixed to the press rod. The pin tightening device comprises a spring seat, a spring and a positioning press block, wherein the spring seat is fixed to the press rod, two ends of the spring are respectively and fixedly connected with the spring seat and the positioning press block, the axis of the spring is parallel to the axis of the press rod, and the lower-end position of the positioning press block is lower than the lower-end position of the deformation press block. Accommodating holes are formed in the positioning press block and deformation press block. The network transformer pin bending device is simple in structure, and the situation that the matching accuracy of pin holes are not high due to the fact that a separation distance between pins is changed through bending machining can be prevented.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

A skid mechanism for mirror driver of automobile rearview mirror

The invention discloses a slipping mechanism for a mirror surface driver of an automotive rearview mirror. The slipping mechanism comprises a rotation shaft (5), a straight-tooth wheel column (2) and an oblique-tooth disc (1) which sequentially sleeves the rotation shaft (5), as well as a limiting mechanism arranged on the rotation shaft (5) and used for limiting axial movement between the straight-tooth wheel column (2) and the oblique-tooth disc (1). The slipping mechanism is characterized in that a driving friction surface is arranged on the oblique-tooth disc (1); a driven friction surface matched with the driving friction surface is arranged on the straight-tooth wheel column (2); a friction force used for driving linkage of the straight-tooth wheel column (2) and the oblique-tooth disc (1) is formed between the driving friction surface and the driven friction surface; the maximum value of the friction force is smaller than the resistance generated by rotating the straight-tooth wheel column (2) to an extreme position. The slipping mechanism for the mirror surface driver of the automotive rearview mirror is simple in structure and can be used for effectively preventing the mirror surface from being broken by rotating out of travel when the mirror surface rotates to the extreme position.

Owner:NINGBO JINGCHENG CAR IND

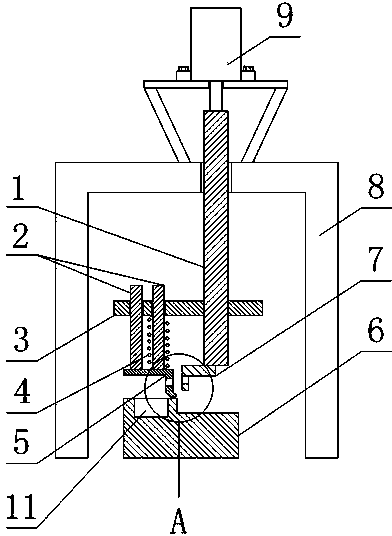

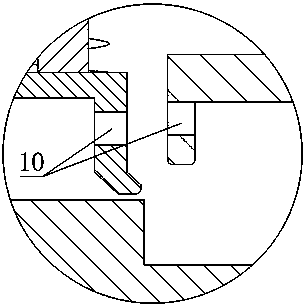

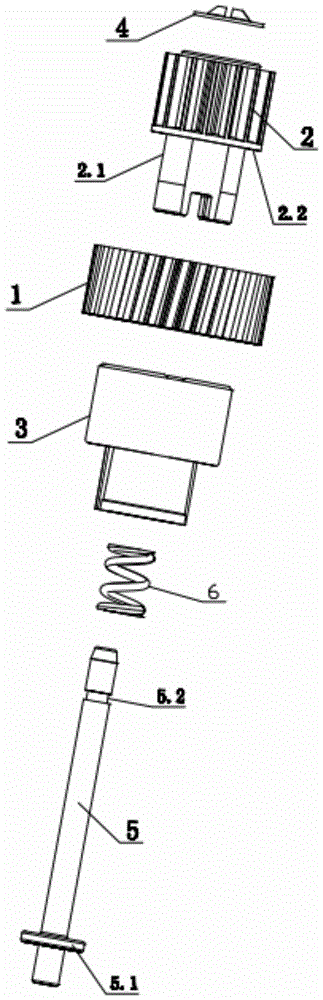

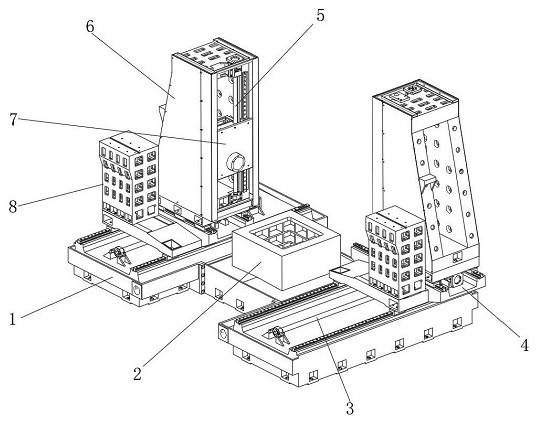

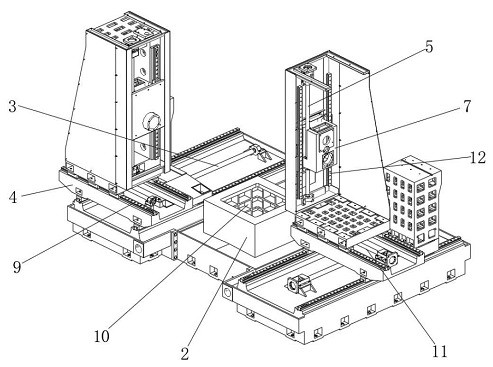

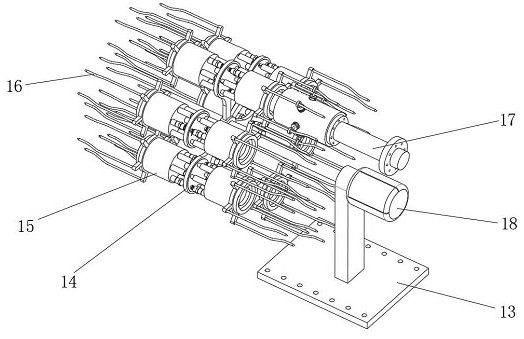

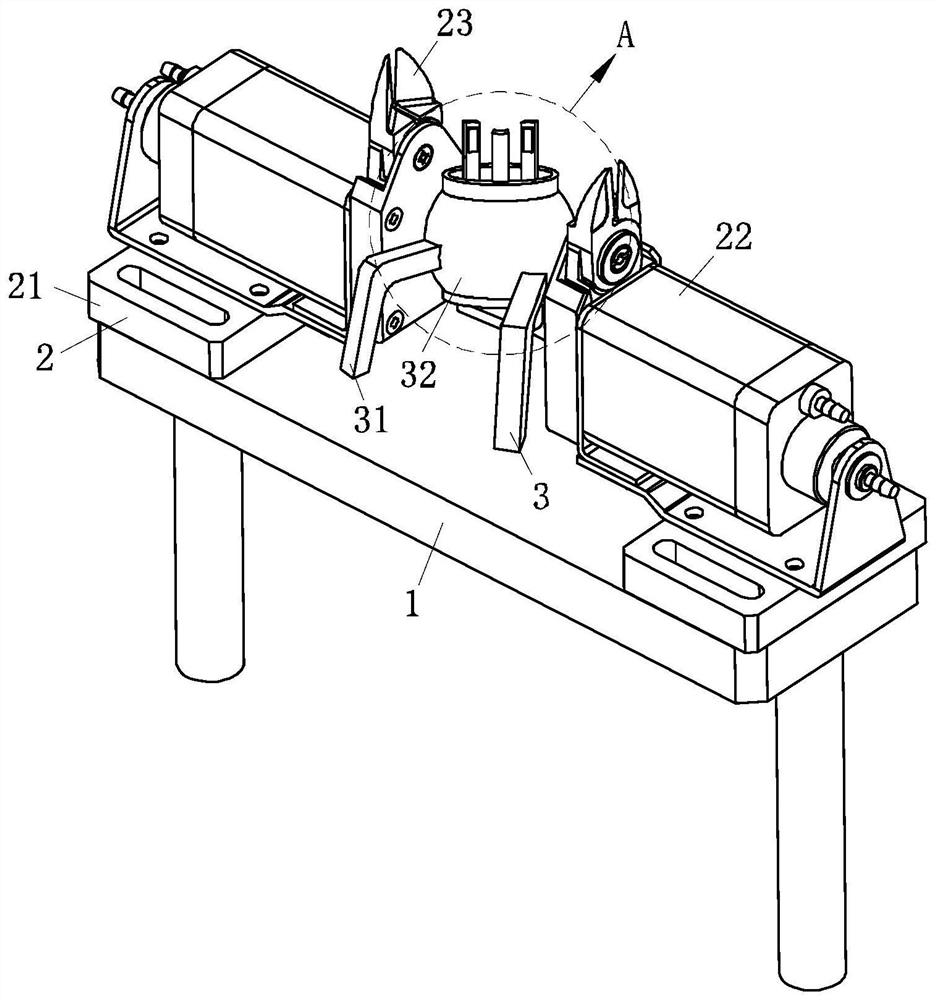

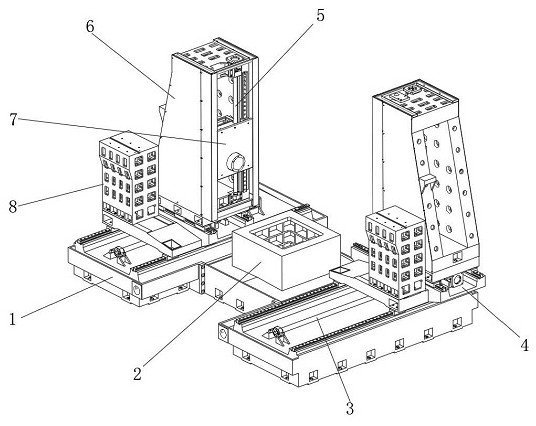

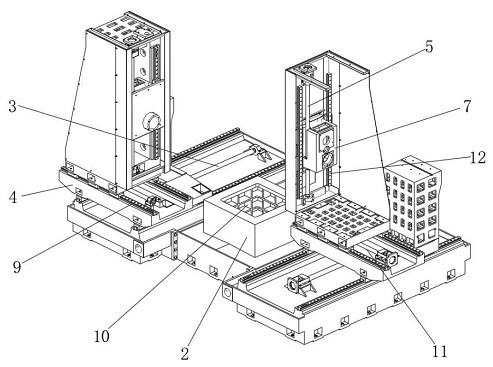

Automatic tool changing numerical control machine tool for graphite processing

ActiveCN114474432ASave human effortImprove practicalityWorking accessoriesStone-like material working toolsElectric machineryEngineering

The invention discloses an automatic tool changing numerical control machine tool for graphite machining, and relates to the technical field of automatic tool changing numerical control machine tools. The automatic tool changing function is achieved. The automatic tool changing device specifically comprises an automatic tool changing mechanism and a multi-directional movable supporting frame, the automatic tool changing mechanism comprises a mounting frame and a motor, the motor is fixed to the outer wall of one side of the mounting frame, the output end of the motor is in transmission connection with a rotating frame, containing bases which are evenly and circumferentially distributed are mounted on the outer walls of the two sides of the rotating frame, and tools are contained in the containing bases; the cutter is used in cooperation with a cutter fixing cylinder, an installation rod is fixed to the outer wall of one side of the cutter fixing cylinder, a fixing pin is movably installed on the outer wall of the circumference of the cutter fixing cylinder through a first spring, and the fixing pin is in sliding connection with the cutter fixing cylinder. By arranging the tool fixing cylinder, the fixing pin, the guide rod, the tool with the pin hole and other structures, the tool is fixed, the automatic tool changing function can be achieved in the mode, manpower is effectively saved, and practicability is improved.

Owner:南通固邦数控机床有限公司

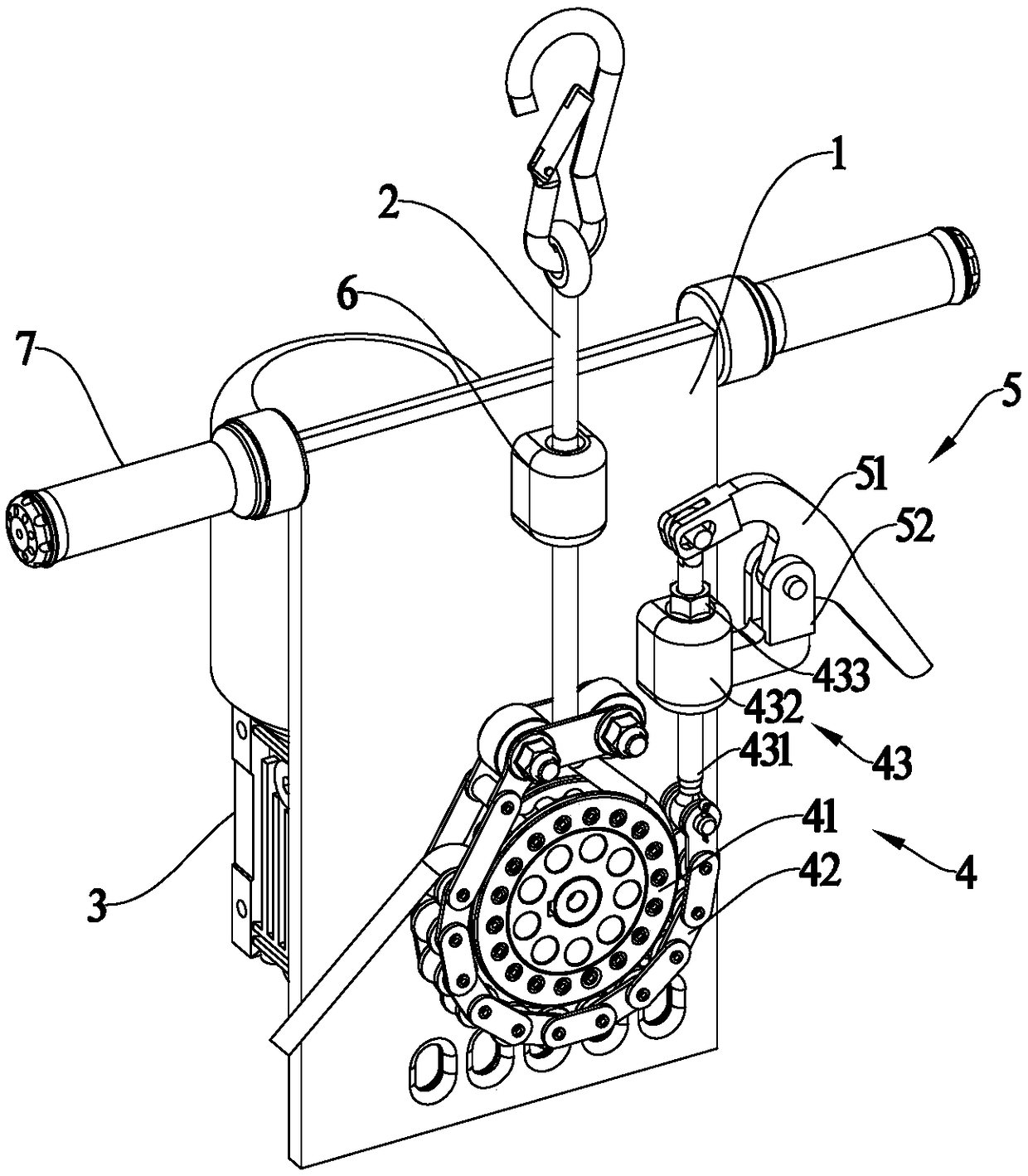

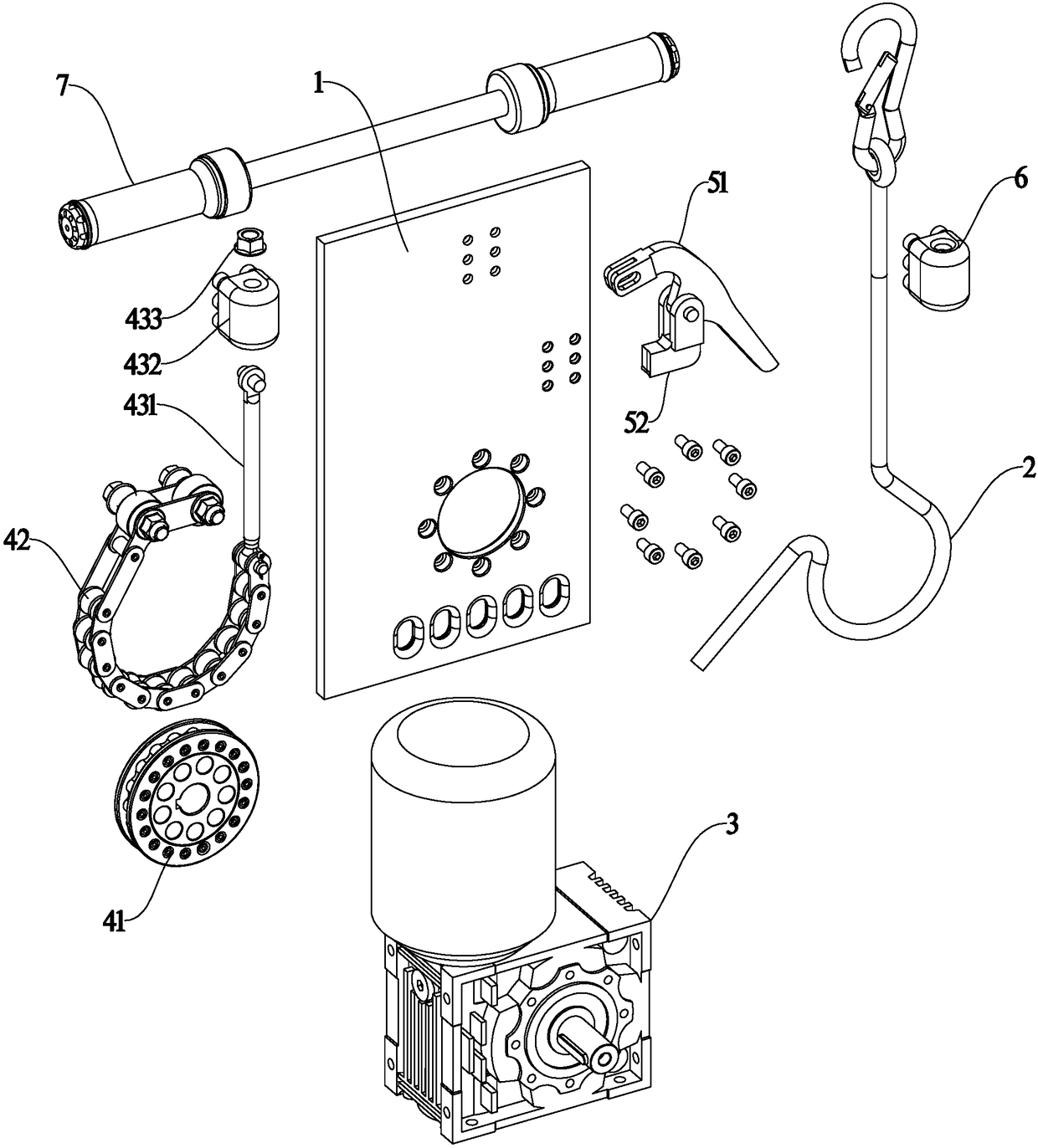

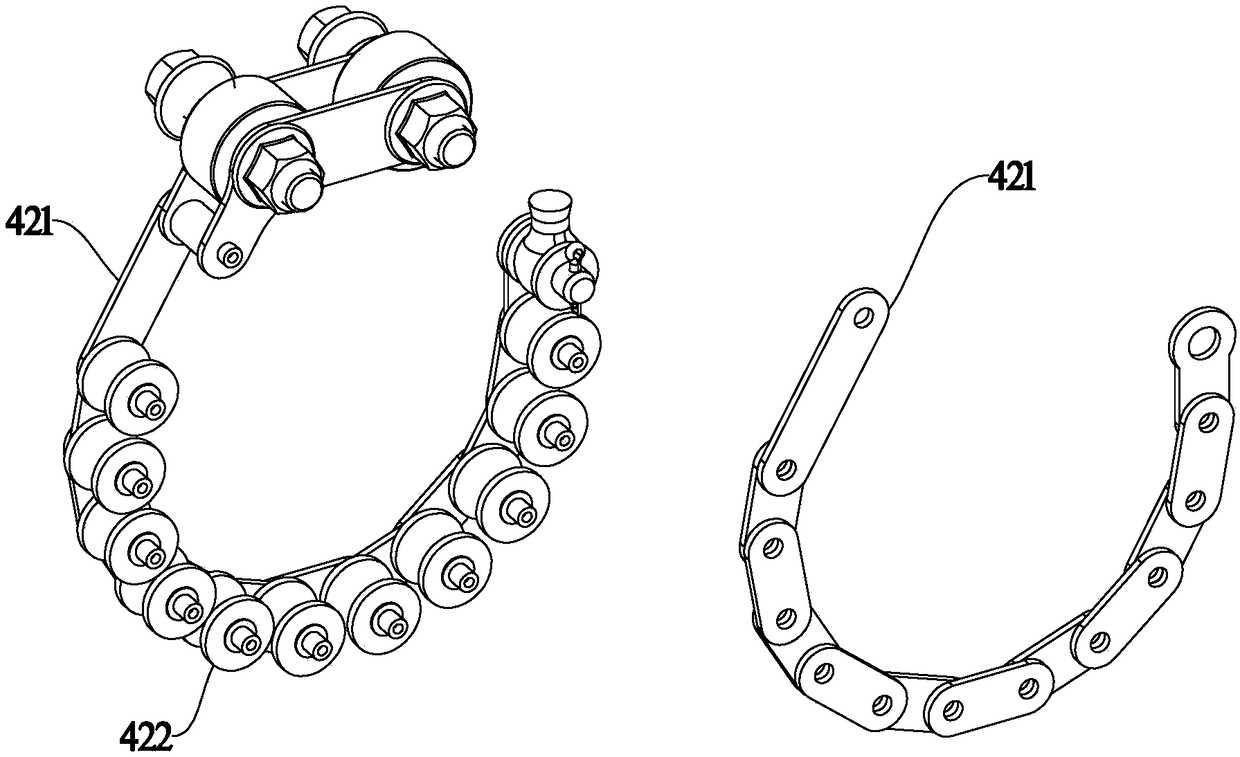

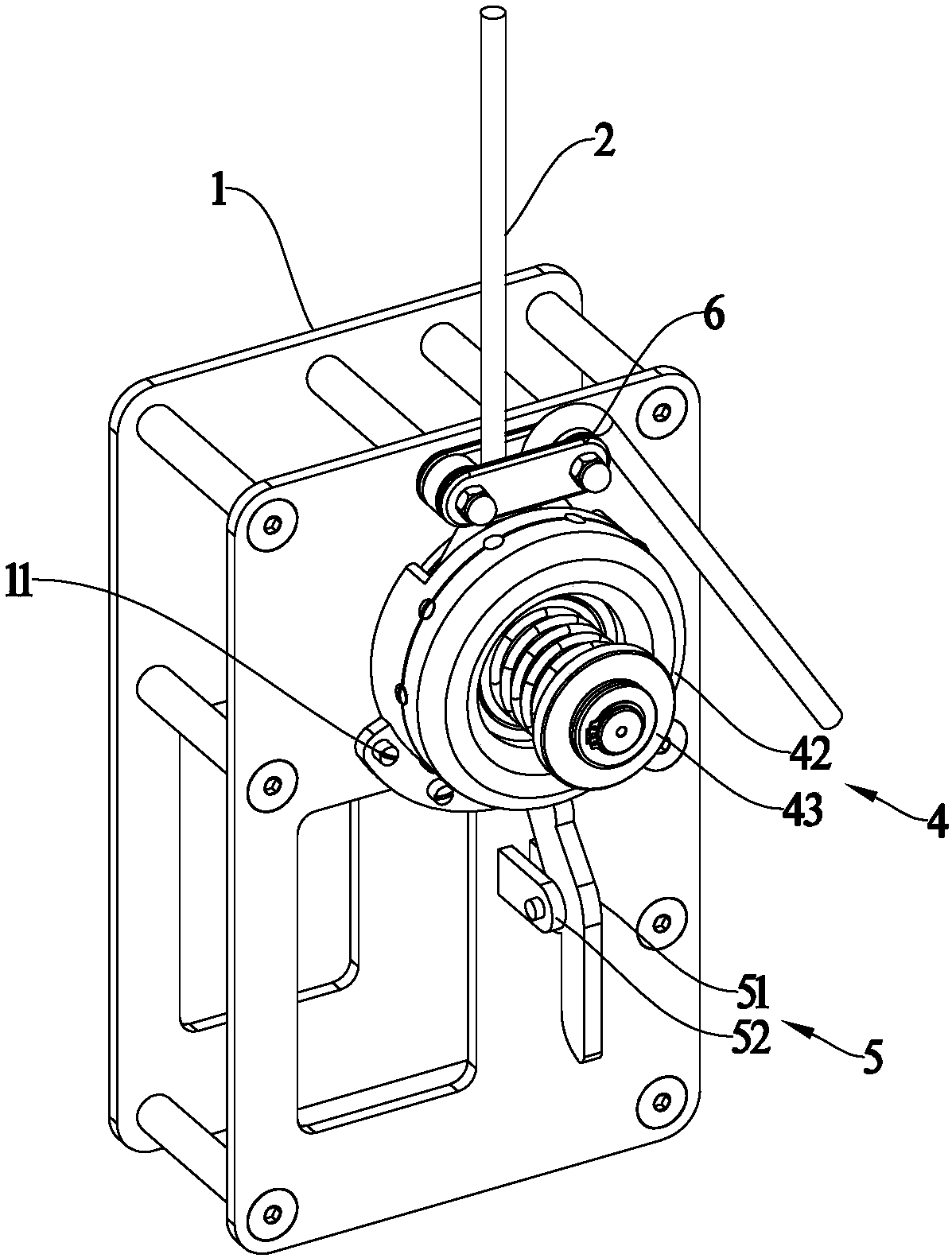

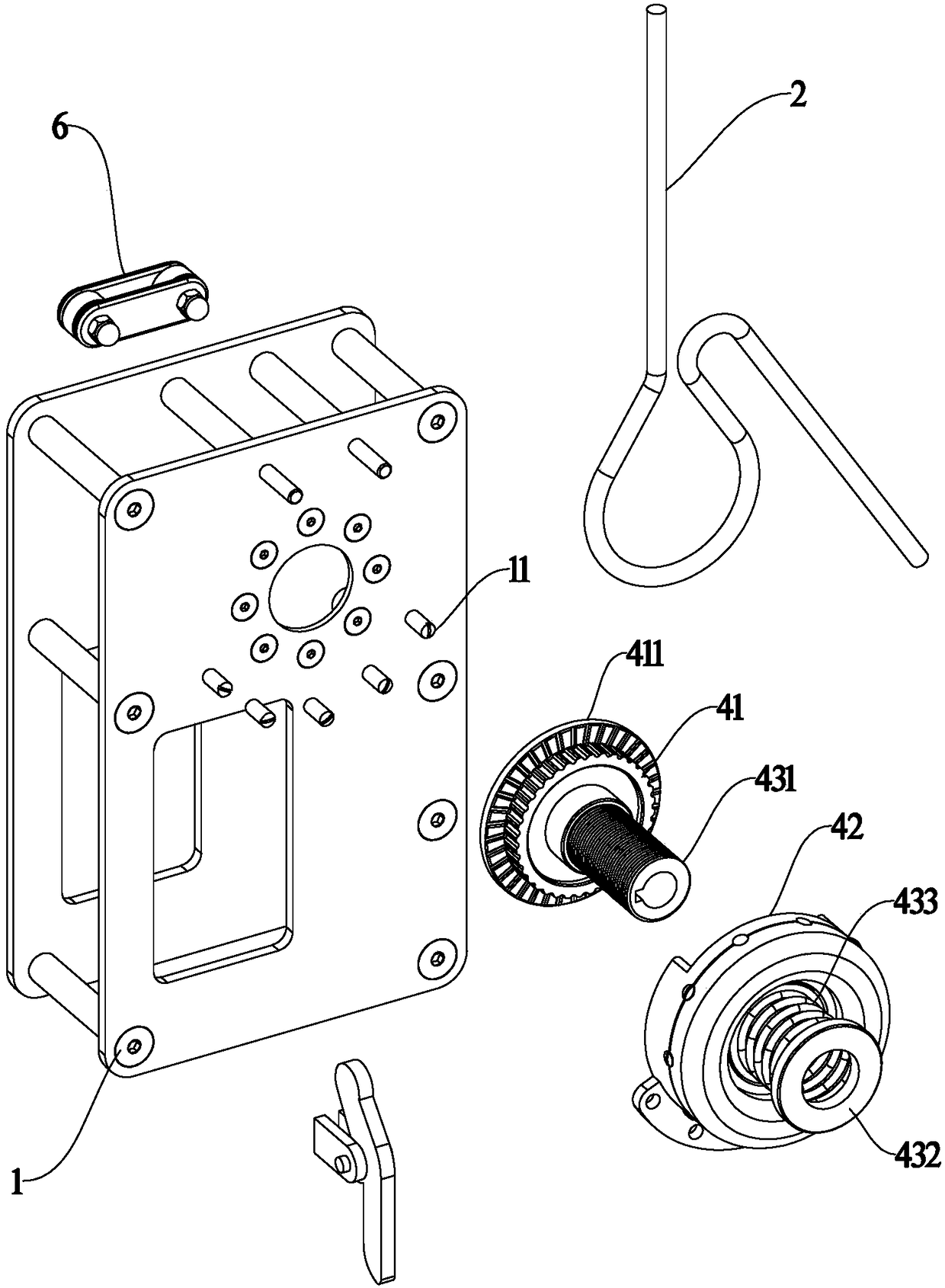

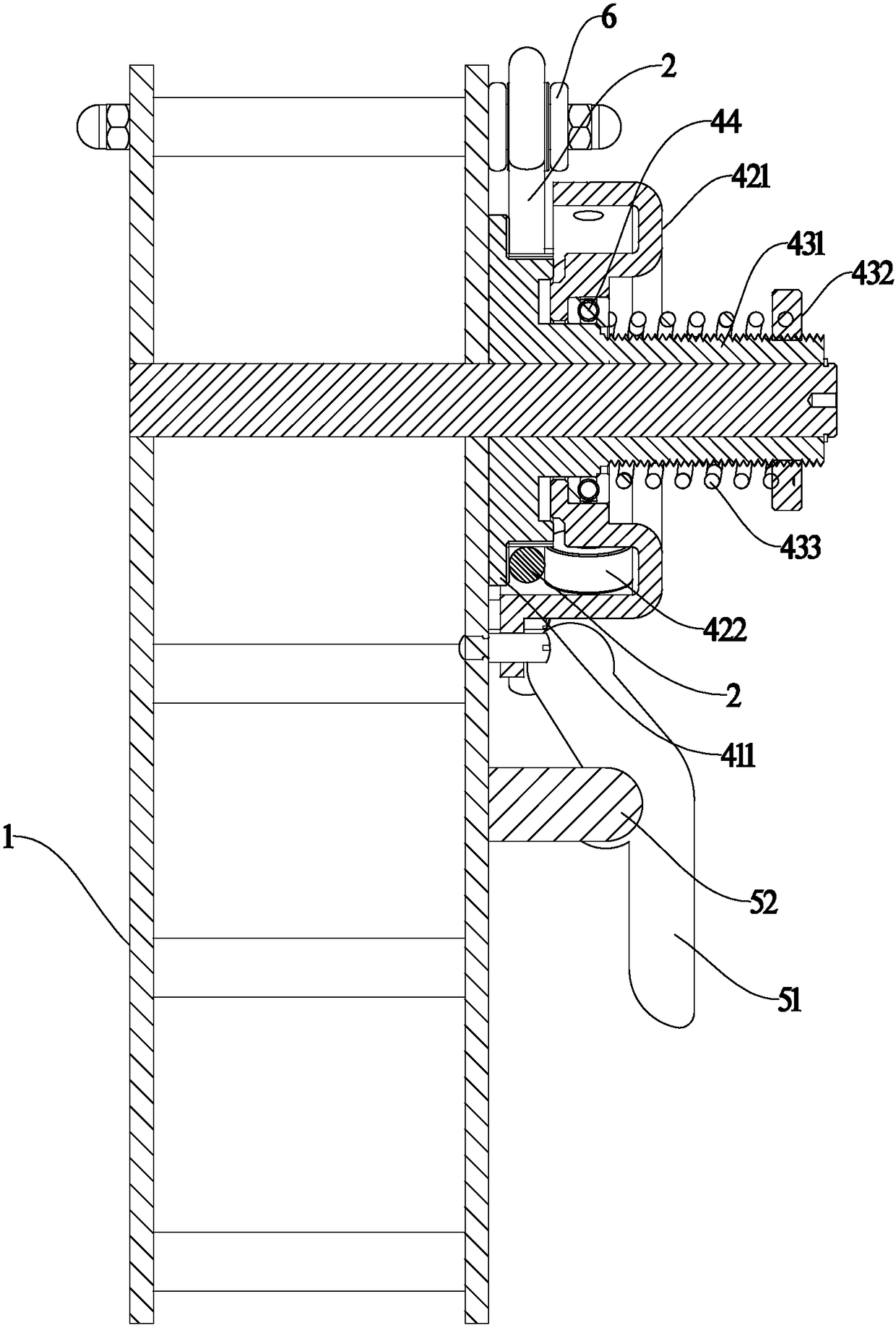

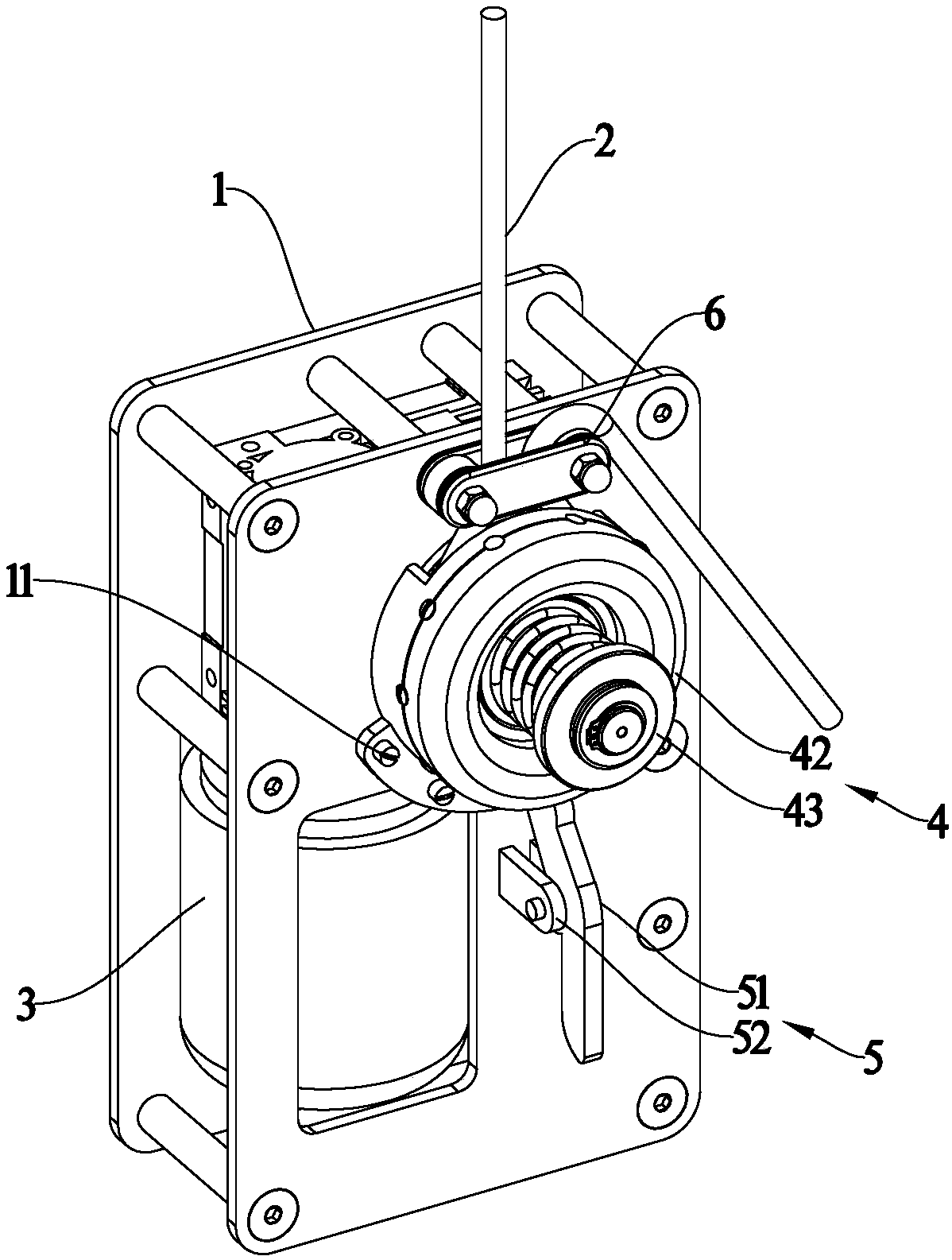

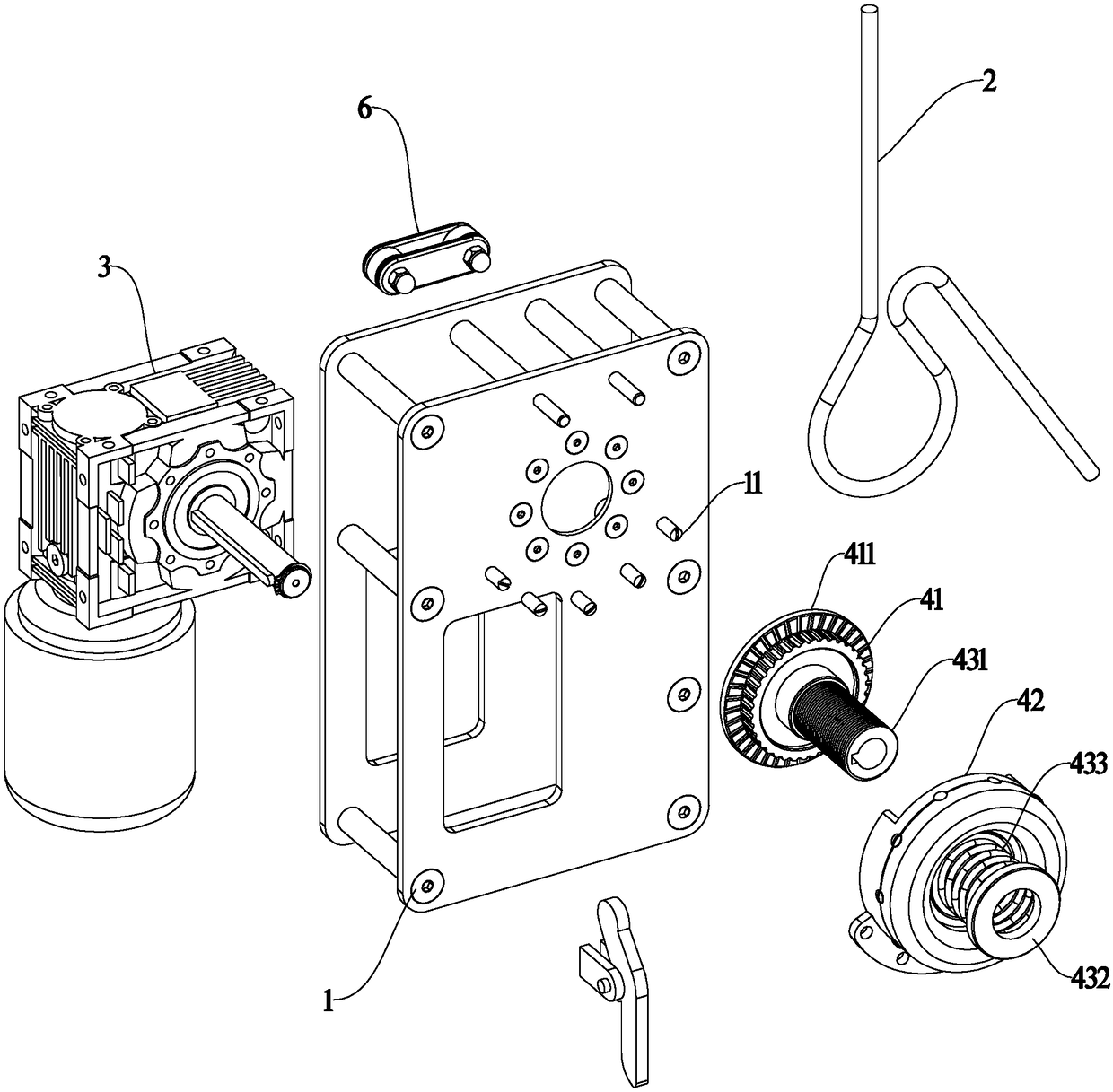

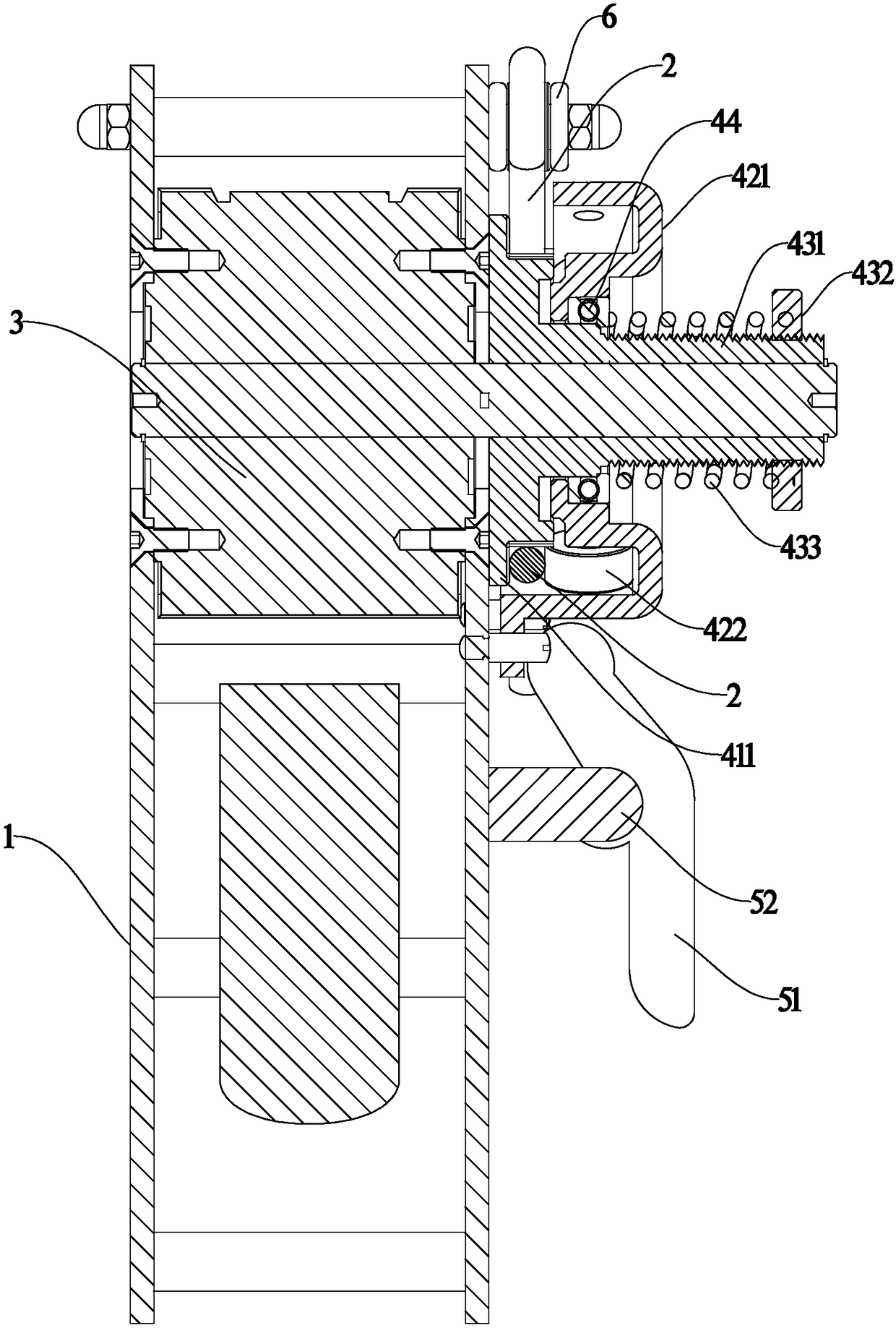

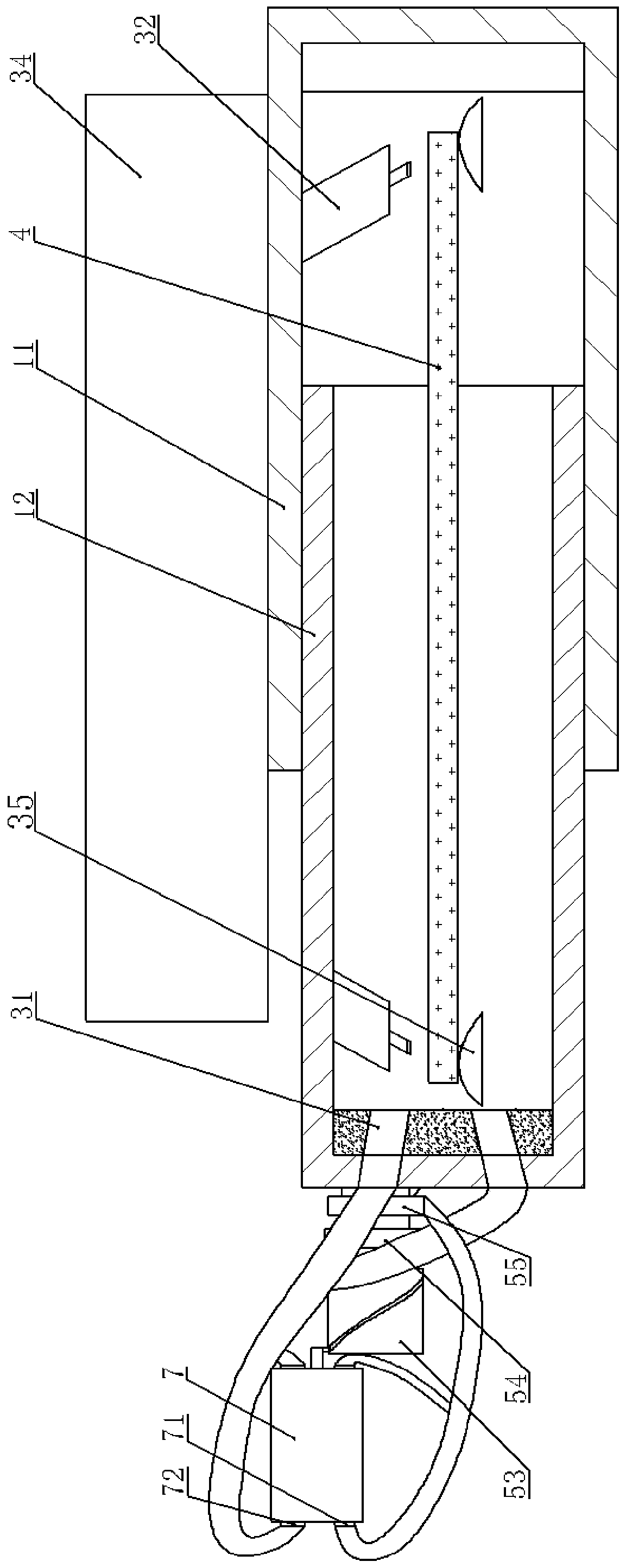

Radial pressing mechanism and lifting device comprising same

The invention provides a radial pressing mechanism. The radial pressing mechanism comprises a rotating disc and a pressing part; the pressing part is of a chain structure and comprises chain plates and idler wheels; the chain plates are sequentially articulated; the idler wheels are articulated between the chain plates positioned at the two sides; the two ends of the pressing part are fixed and are arranged at the periphery of the rotating disc; a rope penetrates through the position between the rotating disc and the pressing part; the rope is pressed by the idler wheels so as to make contactwith the rotating disc; when the rotating disc runs on the rope, the rope is used for driving the idler wheels to rotate; the invention also provides a lifting device; the lifting device comprises a frame, the rope, a power mechanism and the radial pressing mechanism; the radial pressing mechanism has the advantages of simple structure, small abrasion, little generated heat, long service life andreliable pressing; and the lifting device comprising the radial pressing mechanism has the advantages of being simple in structure, safe, reliable and long in service life.

Owner:浙江弘安智能科技有限公司

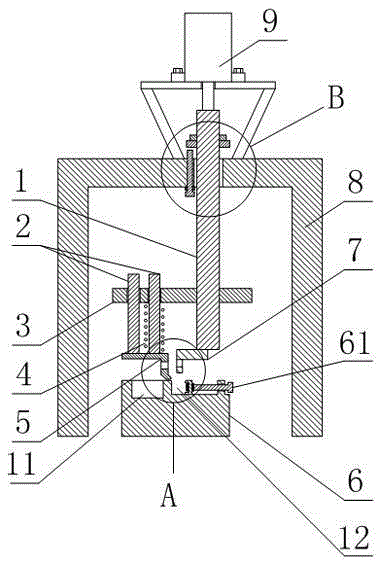

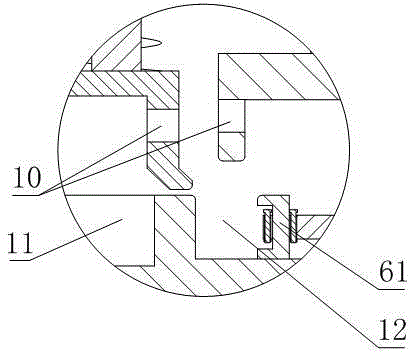

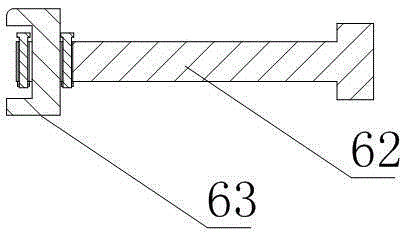

Axial compression slow descending device

The invention relates to an axial compression slow descending device which is characterized by comprising a rack, a rope and an axial compression mechanism. The rope penetrates the axial compression mechanism, the axial compression mechanism comprises a rotary disc and a compression piece, the rotary disc is rotationally arranged on the rack, the peripheral side of the bottom of the rotary disc extends out of a supporting table, the rope surrounds the periphery of the rotary disc in the peripheral direction of the rotary disc and is arranged on the supporting table, the compression piece comprises a compression shell and a compression roller, the compression roller is rotationally arranged on the compression shell, the compression shell can be fixed in the axial direction of the rotary disc, and the compression roller presses the rope to be in contact with the supporting table in the axial direction of the rotary disc; and when the rotary disc rolls on the rope, the rope drives the compression roller to rotate. The axial compression slow descending device has the beneficial effects of being simple in structure, small in abrasion, less in generated heat, safe, reliable and long in service life.

Owner:浙江弘安智能科技有限公司

automatic sweeping robot

ActiveCN107242837BAvoid damageIncrease the maximum static frictionMachine detailsFloor sweeping machinesSteering wheelRolling resistance

The invention provides an automatic floor sweeping robot. The robot comprises a robot body, a dust suction inlet is formed in the bottom of the robot body, a walking wheel, a steering wheel and a dusting brush are arranged on the bottom of the robot body, and a driven roller is further arranged on the back at the rear of the walking wheel; the driven roller, the walking wheel and the steering wheel land together; a movable plate which can move up and down is arranged at the rear of the driven roller, and a duster cloth is horizontally fixed to the lower side of the movable plate; a drive mechanism which is coupled with the driven roller is connected to the upper side of the movable plate, and when the drive mechanism drives the driven roller to move forward, the movable plate lifts upward; the requirements for the surface roughness of the driven roller are as follows, when the robot body walks on the floor and the ground of floor tiles, sliding friction is kept between the driven roller and the ground; however, when the robot body walks on a carpet, rolling friction is kept between the driven roller and the ground. The robot can automatically adjust the floor sweeping function in a room paved with the carpet, and thus the damage on the carpet is avoided.

Owner:江苏蒂森智能科技有限公司

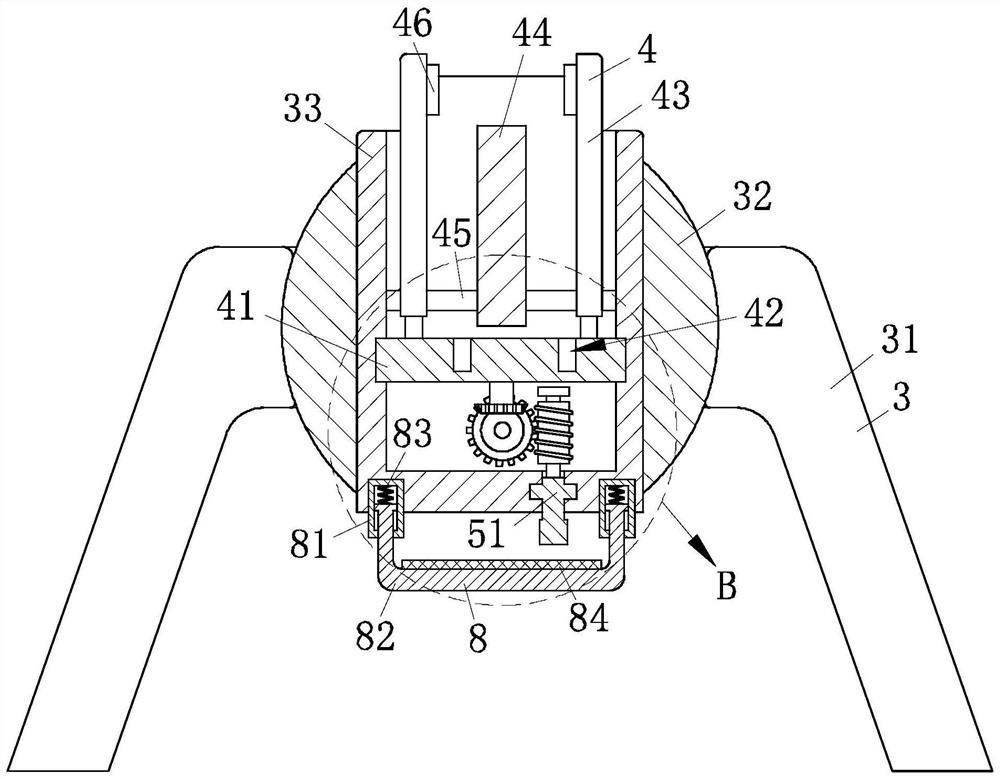

Shearing mechanism for assembly of cup lid

PendingCN112372929AAchieve grindingIncrease the maximum static frictionDomestic articlesMetal working apparatusPhysicsManufacturing sector

The invention relates to the field of manufacturing industries of articles for daily use, in particular to a shearing mechanism for assembly of a cup lid. The shearing mechanism comprises a base, a shearing structure, a supporting structure, a clamping structure, an adjusting structure and a controlling structure, wherein through arrangement of the shearing structure, the cup lid can be sheared and ground; through arrangement of the supporting structure, a cup lid blank body can be moved at any angles, so that the cup lid blank body can be cooperated with the shearing structure to perform theprocedures of shearing and grinding; through arrangement of the clamping structure, the cup lid blank body can be clamped, and cup lid blank bodies with different diameters can be clamped; through arrangement of the adjusting structure, the adjusting structure is controlled so as to drive the clamping structure to clamp the cup lid blank body, and due to the adjusting structure, the phenomenon that the cup lid blank body cannot be easily loosened even if vibration occurs in shearing and grinding processes also can be ensured, and the stability of the clamping structure is ensured; and througharrangement of the controlling structure, the adjusting structure and the supporting structure can be controlled more conveniently through hands, and thus, convenience for operation is improved.

Owner:浙江致一智能机器人有限公司

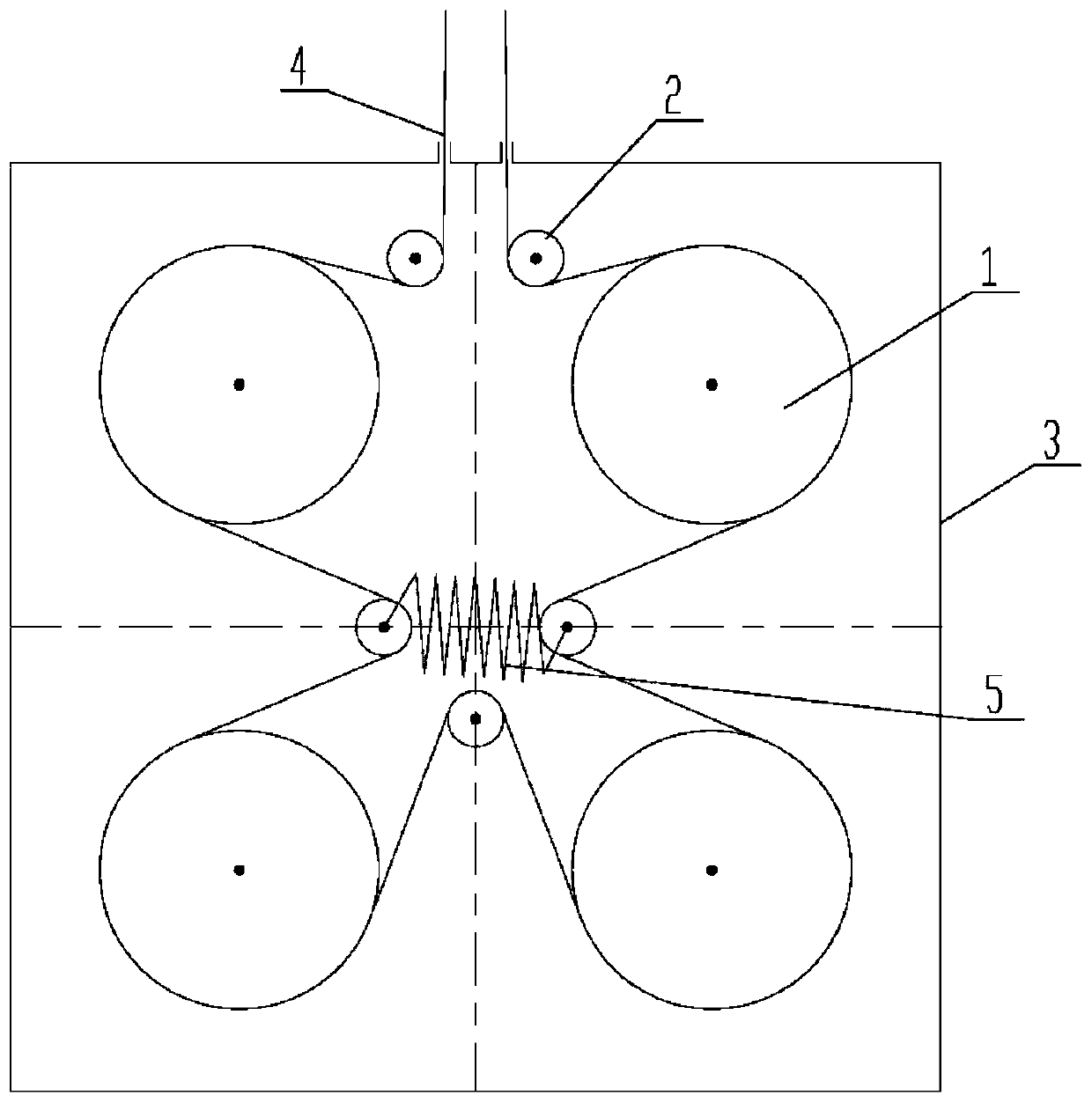

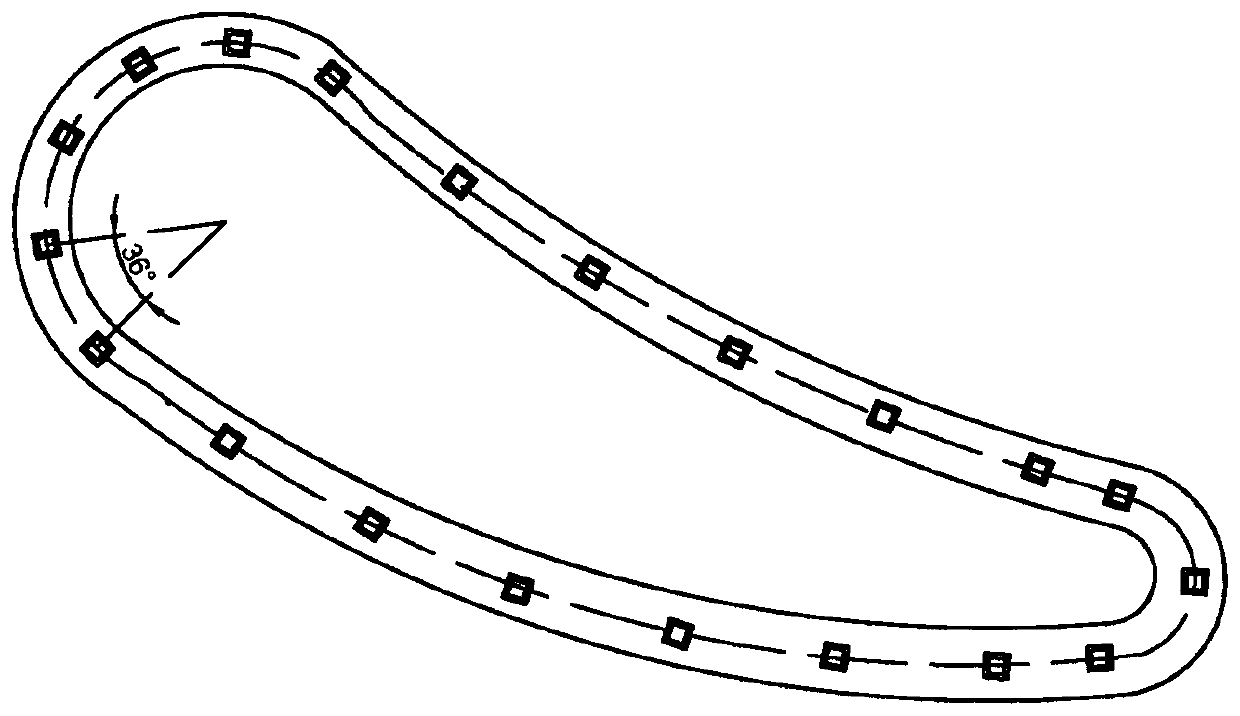

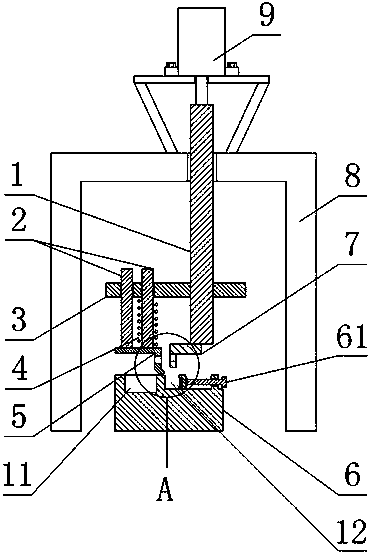

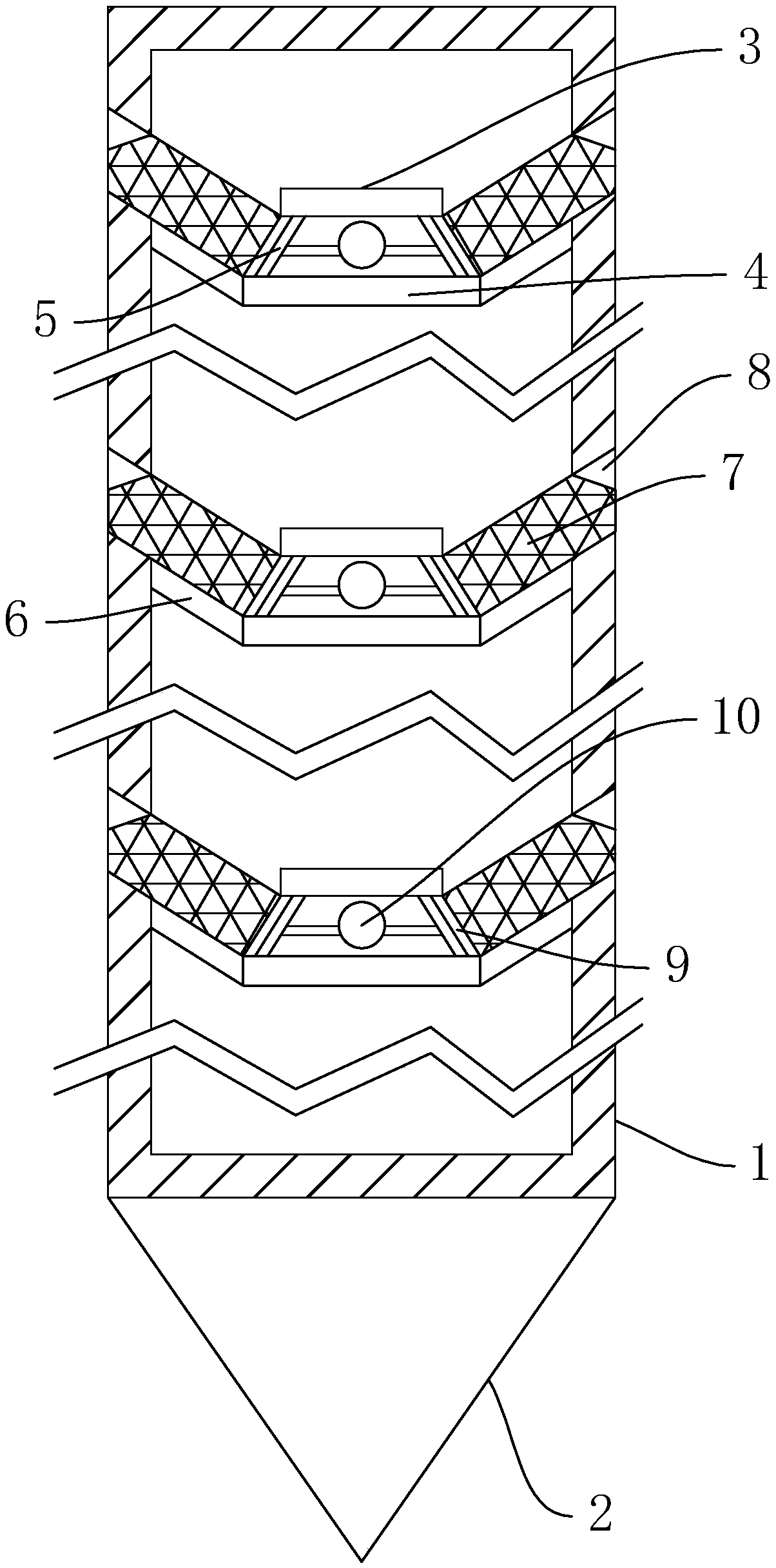

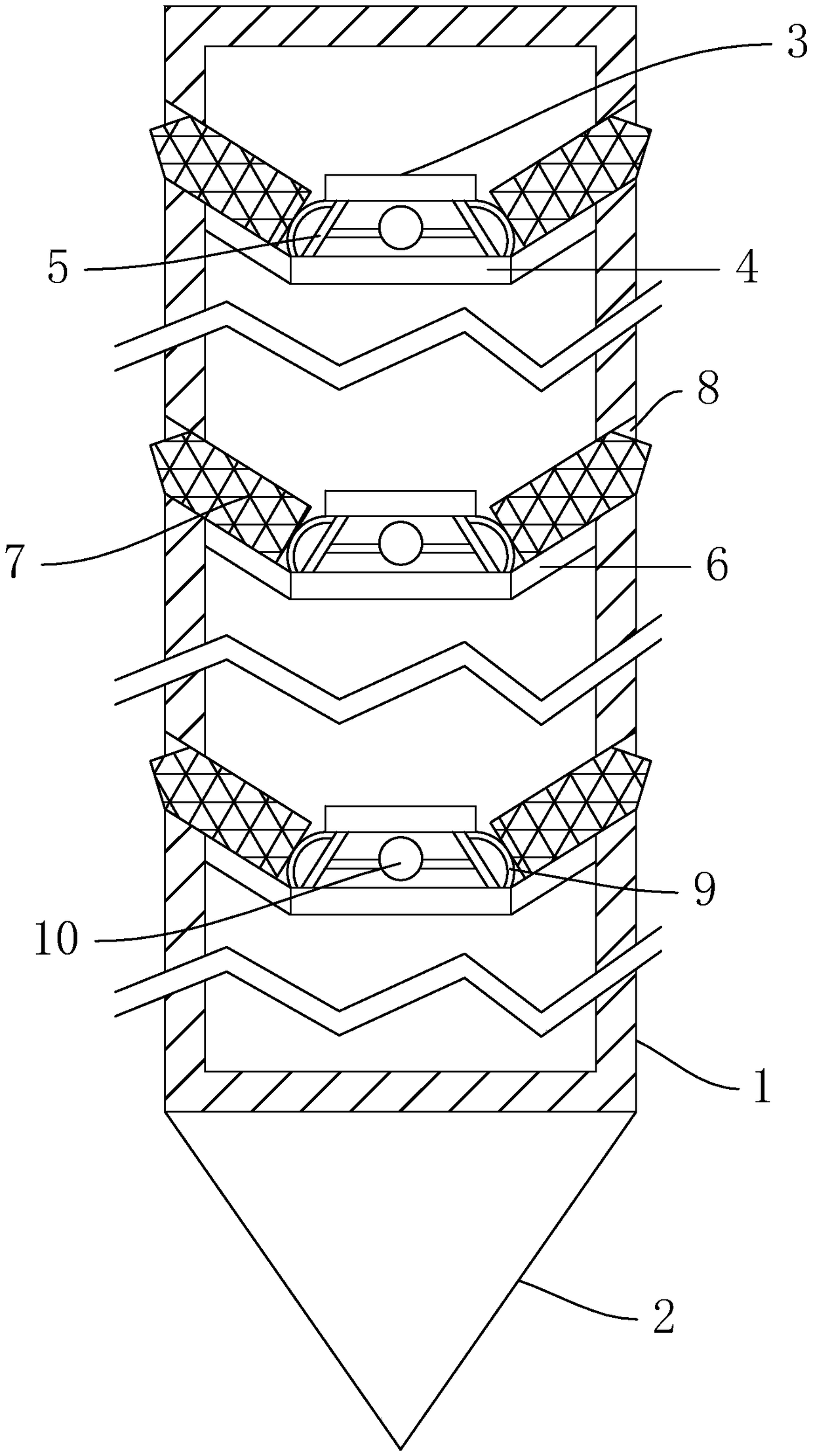

Anti-skid device for climbing-free device for wind turbine generator and design method thereof

PendingCN111591935AImprove the delivery effectImprove skid resistanceSafety devices for lifting equipmentsPortable liftingDrive wheelMarine engineering

The invention discloses an anti-skid device for a climbing-free device for a wind turbine generator and a design method thereof. The anti-skid device for the climbing-free device for the wind turbinegenerator comprises a power box, driving wheels, driven wheels, a steel rope and a pre-tightening spring; the driving wheels and the driven wheels are installed in the power box; at least two drivingwheels are arranged; the steel rope passes through the power box and sequentially bypasses the driving wheels and the driven wheels; the power box is internally provided with a guide groove; at leasttwo driven wheels are floating wheels; a wheel shaft of each floating wheel is installed inside the guide groove; and the wheel shafts of the floating wheels are connected through the pre-tightening spring. According to the anti-skid device disclosed by the invention, a plurality of small-diameter driving wheels are used to replace a single large-diameter driving wheel in the existing design; thecontact length between the driving wheels and the steel rope is increased; reliable running of a transmission system is guaranteed; the transmission capability of the driving wheels is also improved;and the skid resistance of the climbing-free device under extremely severe working conditions is improved.

Owner:GUODIAN UNITED POWER TECH

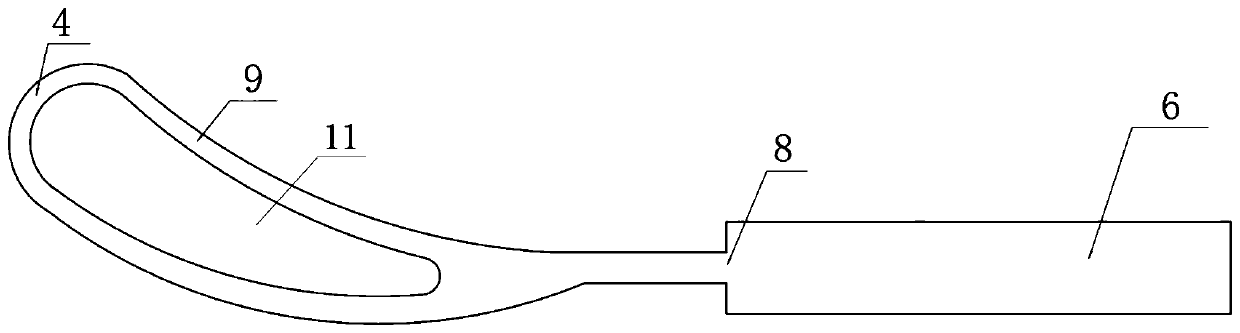

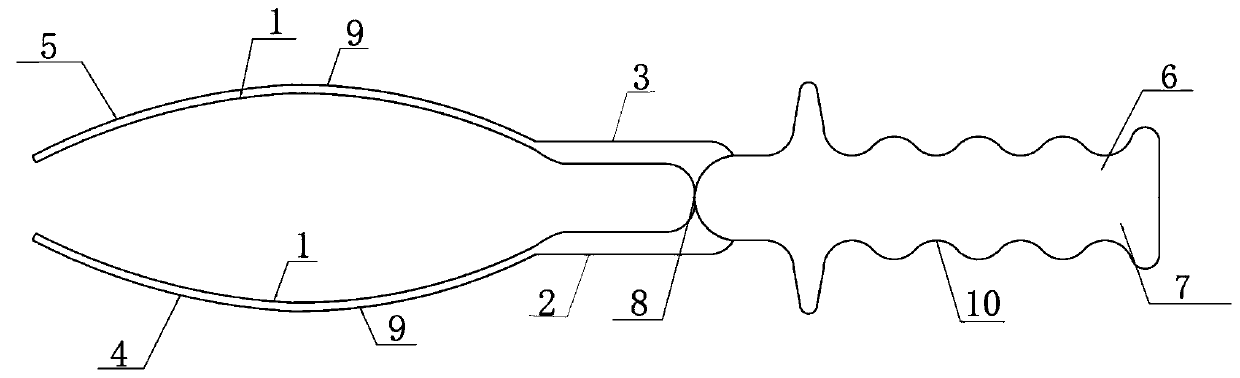

Delivery forceps for obstetrics department and preparation method of coating layer for delivery forceps for obstetrics department

PendingCN110051413AChemically stableBiocompatiblePharmaceutical delivery mechanismCoatingsCompression moldingCompression injury

The invention discloses a pair of delivery forceps for the obstetrics department and a preparation method of a coating layer for the delivery forceps for the obstetrics department. The pair of delivery forceps for the obstetrics department comprises a forceps body, forceps blades arranged at the front end of the forceps body and used for including a fetal head, and forceps handles arranged at therear end of the forceps body, and the inner side surfaces of the forceps blade are provided with coating layers prepared from polydimethylsiloxane / hydrophilic silica polymer nanocomposite material, wherein the coating layer is prepared through solution preparation, internal mold processing and compression molding. The pair of delivery forceps for the obstetrics department is used for solving the problems of fetal head slippery caused by poor control over delivery forceps clamping force or too large tensile force, reduction of fetal head compression injury due to too large clamping force and the like, and the pair of delivery forceps for the obstetrics department has the advantages of moderate compliance, simple structure, convenient use, safety, sanitation and the like.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

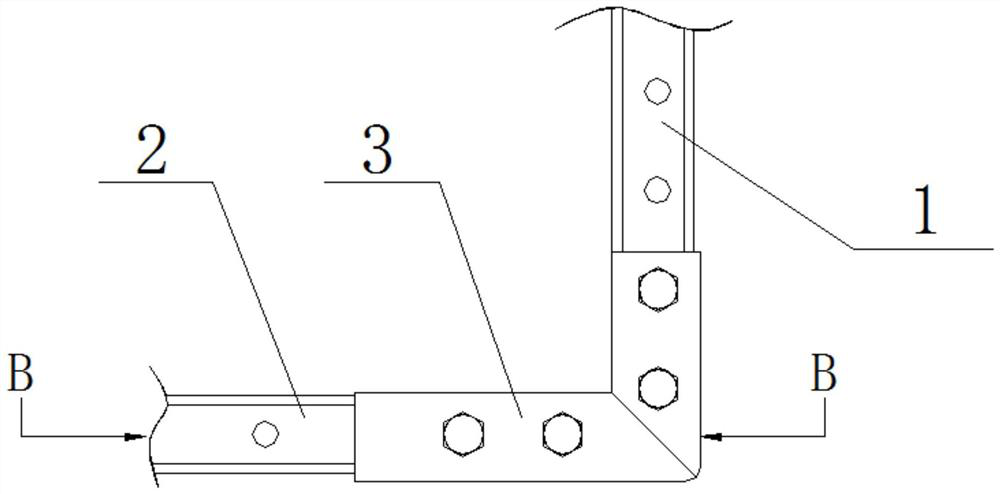

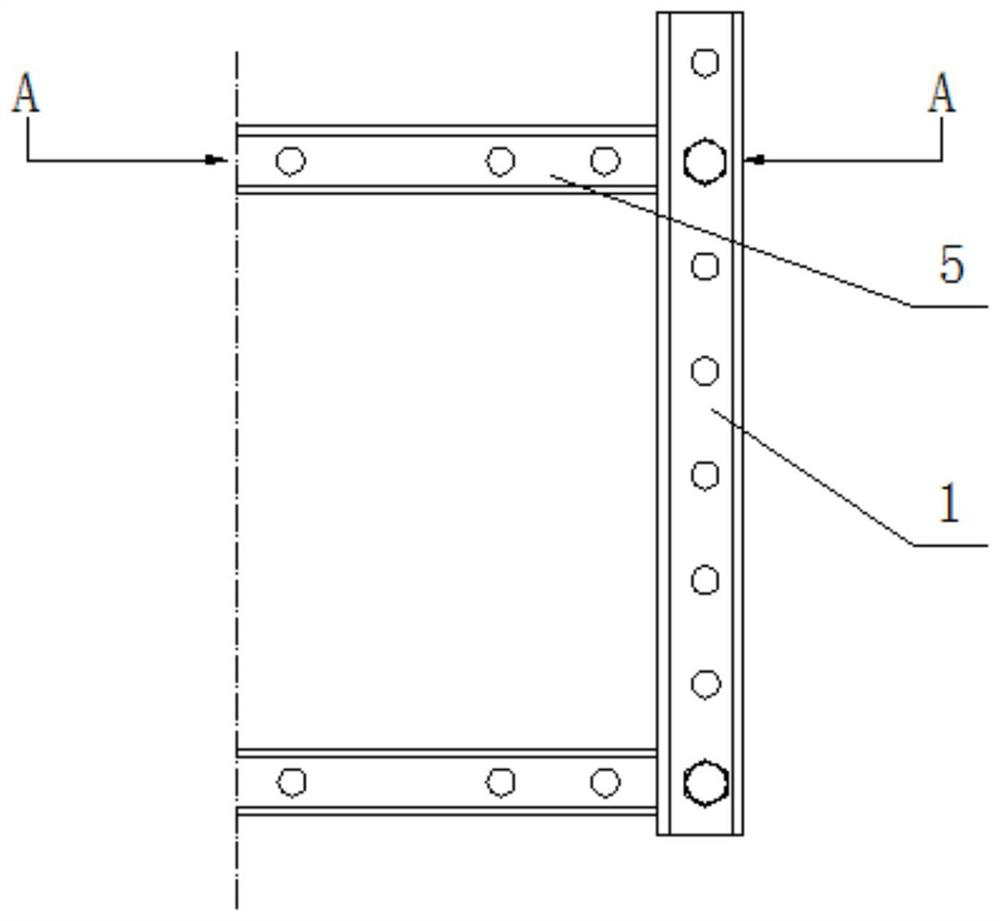

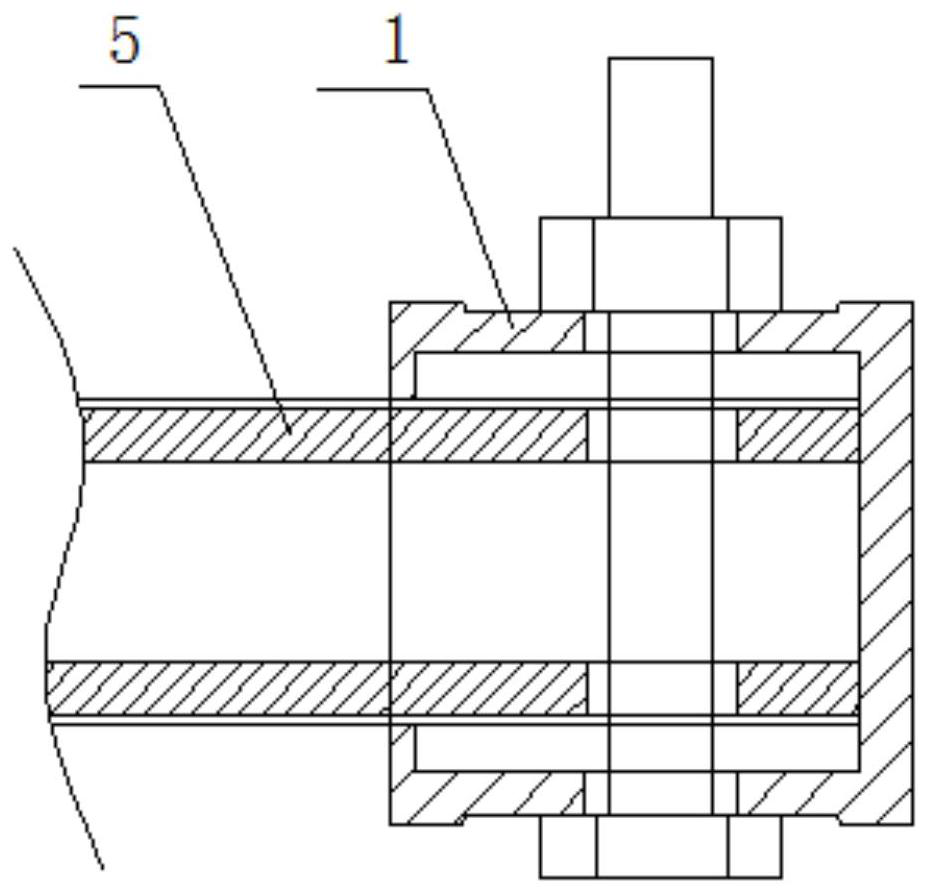

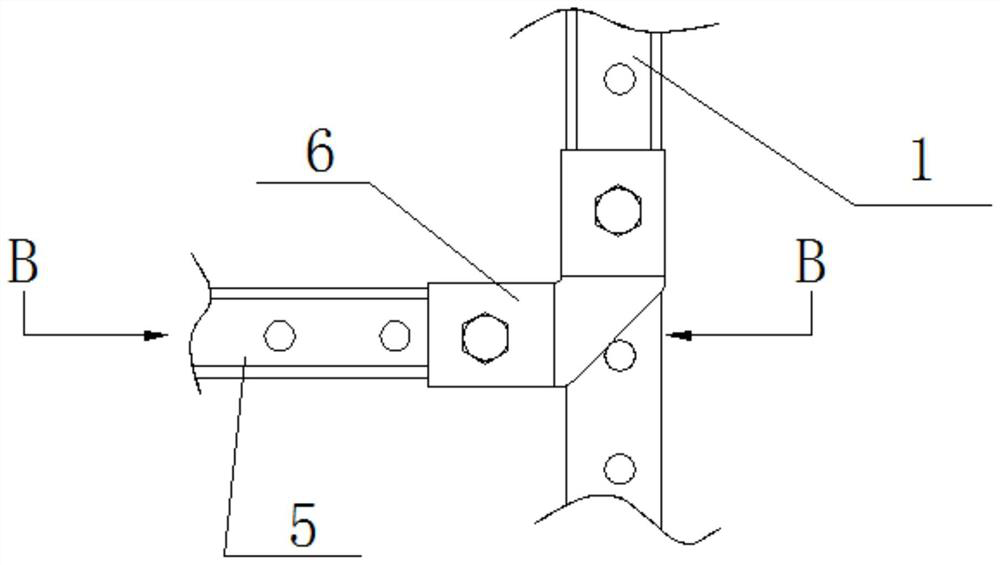

Support and hanger bottom supporting arm connecting device

Owner:镇江弘佩抗震支吊架制造有限公司

Mechanism for pin width bending with easy control of the amount of bending

InactiveCN104190818BPrevent opposite motionIncrease the maximum static frictionEngineeringDeformation control

The invention discloses a mechanism for bending the pin width and enabling the bending amount to be controlled conveniently. The mechanism comprises a rack, a pressing rod, a deformation pressing block and a material table, and further comprises a deformation control mechanism, and a pin fastening device is fixedly arranged on the pressing rod. The pin fastening device comprises a spring seat, a spring and a locating pressing block, the two ends of the spring are fixedly connected with the spring seat and the locating pressing block respectively, the axis of the spring is parallel to the axis of the pressing rod, and the lower end of the locating pressing block is lower than the lower end of the deformation pressing block. Containing holes are formed in the locating pressing block and the deformation pressing block respectively. A groove adjusting portion is arranged on the material table, and a groove is formed between the groove adjusting portion and the material table. The deformation control mechanism comprises an ejector rod bolt and a distance-fixed nut. The mechanism is simple in structure, the situation that the distance between pins is changed due to bending machining, and finally matching precision of the pins and pin holes is not high can be avoided, the mechanism is suitable for expanding or reducing pin bending of the width between the pins, and the deformation of the pins is controlled conveniently.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

Axial tightly-pressing mechanism and lifting device provided with same

The invention discloses an axial tightly-pressing mechanism. The axial tightly-pressing mechanism comprises a rotating disc and a tightly-pressing component. A support table extends out of the circumferential side of the bottom of the rotating disc. A rope surrounds the periphery of the rotating disc in the circumferential direction of the rotating disc and is arranged on the support table. The tightly-pressing component comprises a pressing shell and pressing rolling wheels. The pressing rolling wheels are rotatably arranged on the pressing shell. The pressing shell can be fixed in the axialdirection of the rotating disc. The pressing rolling wheels press the rope in the axial direction of the rotating disc and enable the rope to be in contact with the support table. When the rotating disc advances on the rope, the rope drives the pressing rolling wheels to rotate. A lifting device comprises a rack, a rope, a power mechanism and the axial tightly-pressing mechanism. The axial tightly-pressing mechanism has the advantages of being simple in structure, small in abrasion, low in heat generation capacity, long in service life and reliable in pressing. The lifting device has the advantages of being simple in structure, safe, reliable and long in service life.

Owner:浙江弘安智能科技有限公司

Pin bending device suitable for expanding or narrowing width between pins

InactiveCN104209428APrevent opposite motionIncrease the maximum static frictionEngineeringMechanical engineering

The invention discloses a pin bending device suitable for expanding or narrowing the width between pins. The pin bending device comprises a rack, a press rod, a deformation press block fixed at the lower end of the press rod, and a material table positioned under the deformation press block, wherein the press rod can move along the axial direction; a pin locking device is also fixed on the press rod; the pin locking device comprises a spring seat, a spring and a locating press block; the spring seat is fixed on the press rod; the two ends of the spring are respectively and fixedly connected with the spring seat and the locating press block; the axis of the spring is parallel to that of the press rod; the position of the lower end of the locating press block is lower than that of the lower end of the deformation press block; the locating press block and the deformation press block are respectively provided with a containing hole; the material table is also provided with a groove adjusting part; a groove is formed between the groove adjusting part and the material table. The pin bending device is simple in structure; after the pin bending device is used, the condition that the matching accuracy between the pins and pin holes are not high due to the change of gaps between the pins caused by bending processing can be avoided; the pin bending device is suitable for expanding or narrowing the width between the pins.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

A hardware door stopper

ActiveCN112610082BReduce collisionExtended service lifeWing fastenersCleaning using gasesStructural engineeringMechanical engineering

Owner:博创金龙五金(温州)有限公司

Support and hanger middle supporting arm connecting device

PendingCN111853352AGuaranteed stabilityGuaranteed StrengthPipe supportsRod connectionsIndustrial engineeringFastener

Owner:镇江弘佩抗震支吊架制造有限公司

Network Transformer Pin Bending Mechanism for Easy Control of Deformation

InactiveCN104190820BPrevent opposite motionIncrease the maximum static frictionTransformerDeformation control

Owner:ZHONGJIANG KAIXUN ELECTRONICS

Network transformer pin bending mechanism facilitating control of deformation

InactiveCN104190820APrevent opposite motionIncrease the maximum static frictionEngineeringTransformer

The invention discloses a network transformer pin bending mechanism facilitating control of deformation. The pin bending mechanism comprises a machine frame, a pressure rod arranged on the machine frame, a deformation pressing block fixed to the lower end of the pressure rod, and a material table located on the lower side of the deformation pressing block, the pressure rod can axially move. The pin bending mechanism further comprises a deformation control mechanism and is further fixedly provided with a pin fastening device, the pin fastening device comprises a spring base, a spring and a positioning pressing block, the spring base is fixed to the pressure rod, the two ends of the spring are fixedly connected with the spring base and the positioning pressing block respectively, the axis of the spring is parallel with that of the pressure rod, the lower end of the positioning pressing block is lower than the lower end of the deformation pressing block, the positioning pressing block and the deformation pressing block are respectively provided with a containing hole, and the deformation control mechanism comprises a push rod bolt and a spacing screw cap. The pin bending mechanism is simple in structure, the situation that matching precision of pins and pin holes is not high due to the fact that the distance between the pins is changed after bending machining can be avoided and the bending degree of the pins can be conveniently controlled.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

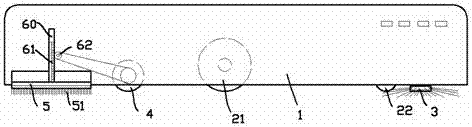

Self-positioning multilayer laminating machine

ActiveCN108749013AGuaranteed alignmentReduce defective rateCleaning using toolsCleaning using gasesPulp and paper industryCam

The invention relates to the field of foam production, in particular to a self-positioning multilayer laminating machine. The self-positioning multilayer laminating machine comprises a machine frame,a motor, a negative pressure mechanism, a conveying pair roller and a positioning channel; the conveying pair roller comprises an upper roller and a lower roller, and the positioning channel comprisesa horizontal section and an inclined section; and the horizontal section and the inclined section each comprise a first side and a second side, an air inlet and a cleaning block are arranged on the inclined section, the negative pressure mechanism comprises a blowing cylinder and a circular column cam, a piston rod of the blowing cylinder can slide along the contour curve of the side wall of thecircular column cam, an air inlet one-way valve and an air outlet one-way valve are fixed on the side wall of the blowing cylinder, the air inlet one-way valve communicates with an air inlet, a negative pressure cavity is formed in the upper roller or the lower roller, and a negative pressure hole is formed in the side wall of the negative pressure cavity. The self-positioning multilayer laminating machine can make the paper be flush with the foam cotton.

Owner:重庆佑威电子有限公司

Mechanism for bending pin width and enabling bending amount to be controlled conveniently

InactiveCN104190818APrevent opposite motionIncrease the maximum static frictionEngineeringDeformation control

The invention discloses a mechanism for bending the pin width and enabling the bending amount to be controlled conveniently. The mechanism comprises a rack, a pressing rod, a deformation pressing block and a material table, and further comprises a deformation control mechanism, and a pin fastening device is fixedly arranged on the pressing rod. The pin fastening device comprises a spring seat, a spring and a locating pressing block, the two ends of the spring are fixedly connected with the spring seat and the locating pressing block respectively, the axis of the spring is parallel to the axis of the pressing rod, and the lower end of the locating pressing block is lower than the lower end of the deformation pressing block. Containing holes are formed in the locating pressing block and the deformation pressing block respectively. A groove adjusting portion is arranged on the material table, and a groove is formed between the groove adjusting portion and the material table. The deformation control mechanism comprises an ejector rod bolt and a distance-fixed nut. The mechanism is simple in structure, the situation that the distance between pins is changed due to bending machining, and finally matching precision of the pins and pin holes is not high can be avoided, the mechanism is suitable for expanding or reducing pin bending of the width between the pins, and the deformation of the pins is controlled conveniently.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

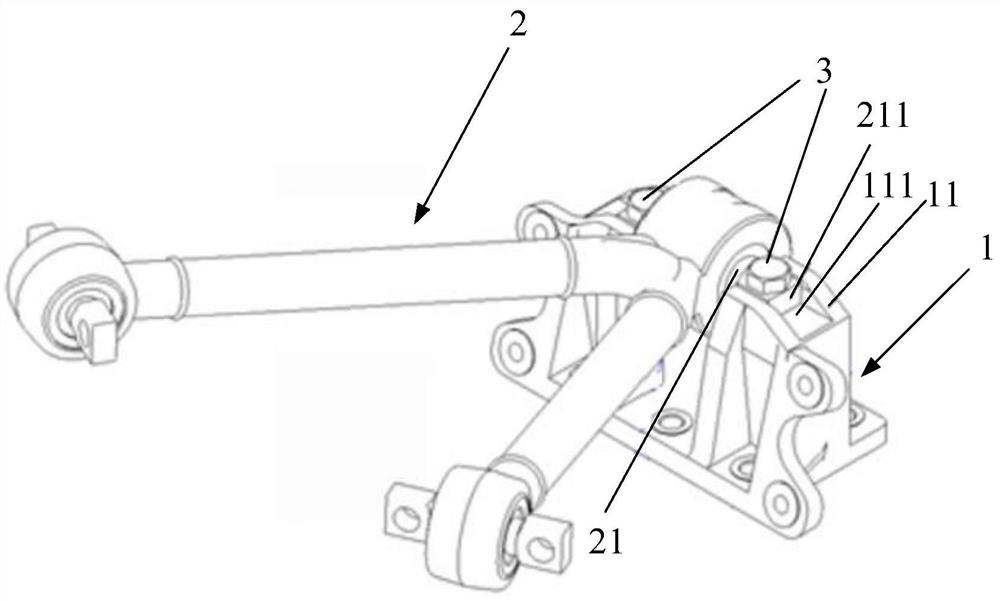

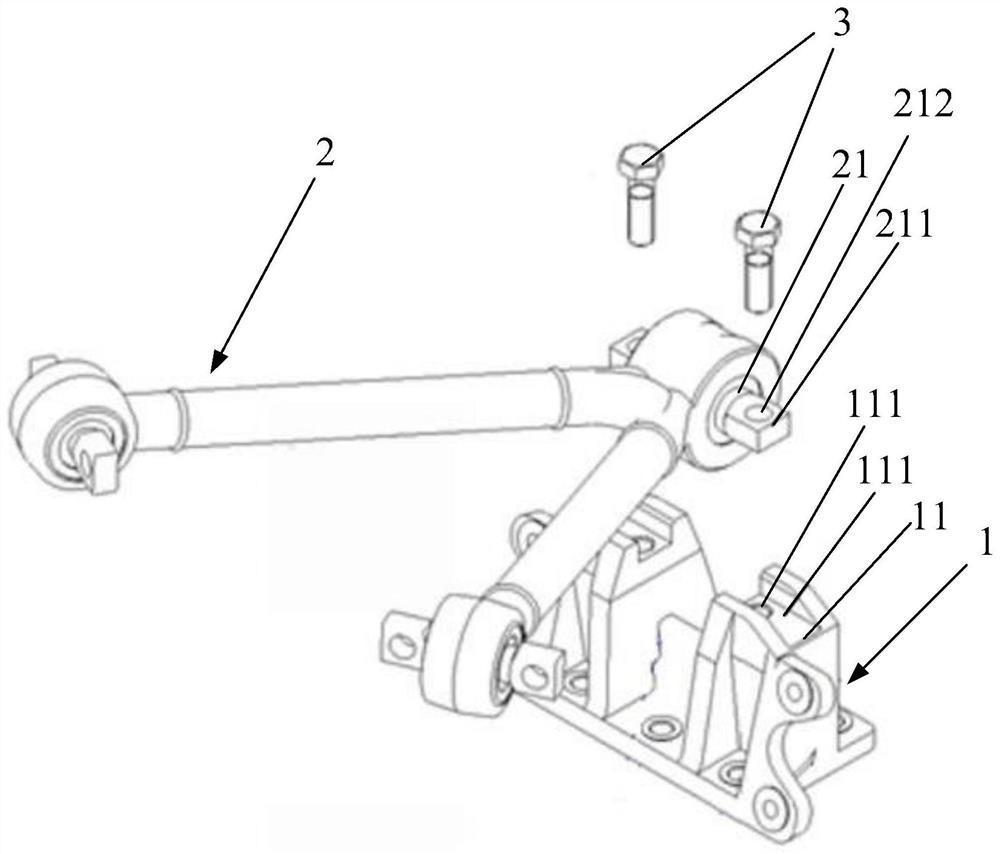

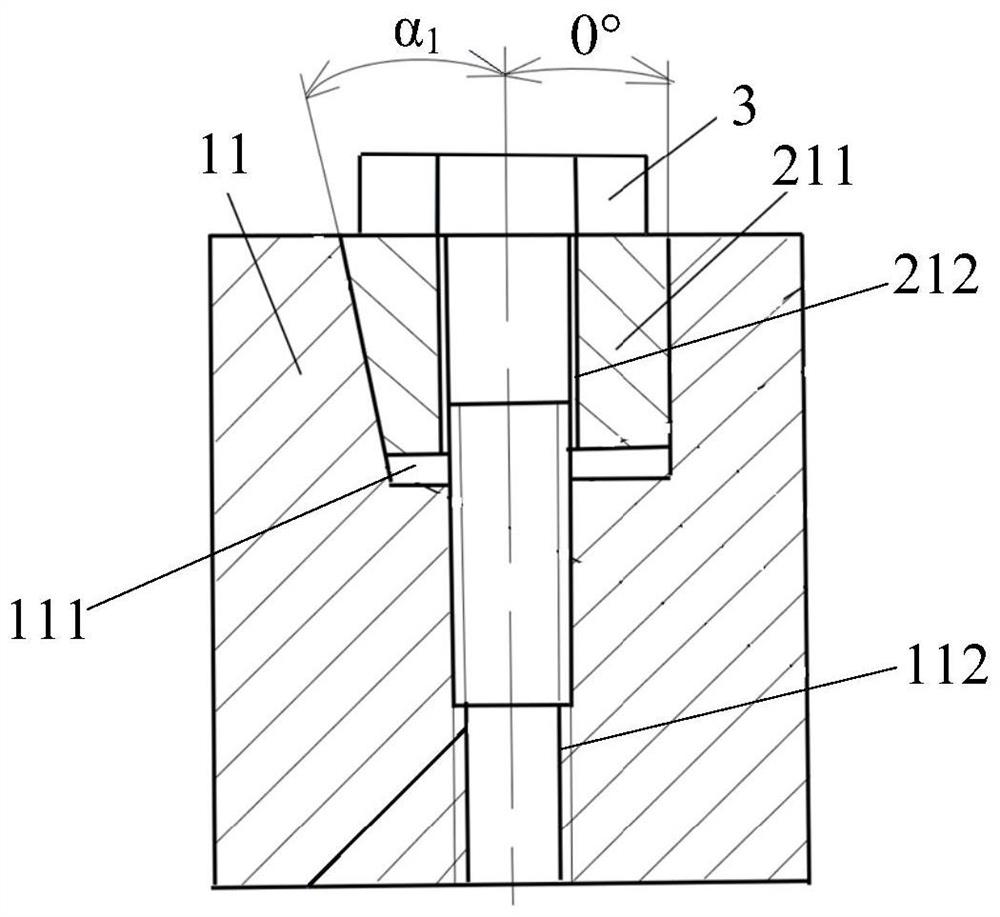

Connecting structure of axle bracket and thrust rod

InactiveCN112208268AOrientationIncrease the maximum static frictionInterconnection systemsAxle unitsStatic frictionEngineering

The invention discloses a connecting structure of an axle bracket and a thrust rod. The connecting structure comprises the axle bracket, the thrust rod and two bolts, wherein the axle bracket is provided with two mounting seats at an interval, each mounting seat is provided with a wedge-shaped groove, at least one side of each wedge-shaped groove is provided with a wedge-shaped surface, and each mounting seat is provided with a threaded hole at the lower part of the wedge-shaped groove; the thrust rod is provided with a pin shaft, wedge-shaped connecting blocks are arranged at the two ends ofthe pin shaft respectively, each wedge-shaped connecting block is attached to the wedge-shaped face of the corresponding wedge-shaped groove, a gap is reserved between each wedge-shaped connecting block and the bottom face of the corresponding wedge-shaped groove, and a through hole is formed in each wedge-shaped connecting block. And each bolt penetrates through the through hole of one wedge-shaped connecting block and is connected with the corresponding threaded hole, so that the thrust rod is connected with the axle bracket. By increasing the maximum static friction force of the wedge-shaped connecting block at the end part of the pin shaft of the thrust rod, the reliability of the connecting structure of the axle bracket and the thrust rod is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Temperature control type anchor rod

ActiveCN109440766AImprove pullout resistanceIncrease the maximum static frictionExcavationsBulkheads/pilesTemperature controlEngineering

The invention discloses a temperature control type anchor rod. The temperature control type anchor rod comprises a rod body, a hollow cavity is formed in the rod body, a cone is arranged on the bottomsurface of the rod body, supports are arranged in the hollow cavity, wherein each support comprises an upper circular ring body, a lower circular ring body and a connecting column for connecting thecorresponding upper circular ring body to the corresponding lower circular ring body, the axis of each lower circular ring body and the axis of the corresponding upper circular ring body are collinear, the diameter of each lower circular ring body is larger than or equal to the diameter of the corresponding upper circular ring body, bimetallic strips are connected between the edge of each upper circular ring body and the edge of the corresponding lower circular ring body, limiting holes are formed in the outer wall of the rod body, sliding rails are arranged at the bottoms of the limiting holes, limiting blocks are slidably connected to the sliding rails, the middle portions of the bimetallic strips are connected with the limiting blocks, when the bimetallic strips are in normal temperature states, the middle portions of the bimetallic strips protrude in the axis directions away from the upper circular ring bodies, and when the bimetallic strips are in heating states, the middle portions of the bimetallic strips retract in the axis directions close to the upper circular ring bodies. According to the temperature control type anchor rod, the problems that a traditional anchor rod isnot high enough in pulling resistance and inconvenient to use repeatedly are solved.

Owner:FOSHAN UNIVERSITY

A kind of graphite processing automatic tool change CNC machine tool

ActiveCN114474432BAchieve fixationRealize the function of automatic tool changeWorking accessoriesPositioning apparatusNumerical controlElectric machinery

The invention discloses a CNC machine tool with automatic tool change for graphite processing, and relates to the technical field of automatic tool change CNC machine tools; in order to realize the function of automatic tool change; it specifically includes an automatic tool change mechanism and a multi-directional mobile support frame, the automatic tool change The mechanism includes a mounting frame and a motor, the motor is fixed on the outer wall of one side of the mounting frame, the output end of the motor is connected to the turret, and the outer walls on both sides of the turret are equipped with receiving seats evenly distributed around the circumference, and the receiving seats contain knives. The tool is equipped with a tool fixing cylinder, the outer wall of one side of the tool fixing cylinder is fixed with a mounting rod, and the peripheral outer wall of the tool fixing cylinder is movably installed with a fixing pin through a first spring, and the fixing pin is slidably connected with the tool fixing cylinder. The present invention realizes the fixing of the cutter by setting a cutter fixing cylinder, a fixing pin, a guide rod and a cutter with a pin hole. This method can realize the function of automatic cutter change, effectively saves manpower, and improves practicability.

Owner:南通固邦数控机床有限公司

A self-positioning multi-layer laminating machine

ActiveCN108749013BGuaranteed alignmentReduce defective rateCleaning using toolsCleaning using gasesElectric machineryEngineering

It relates to the field of foam production and specifically discloses a self-positioning multi-layer laminating machine; it includes a frame, a motor, a negative pressure mechanism, a pair of conveying rollers and a positioning channel. The pair of conveying rollers includes an upper roller and a lower roller; positioning The channel includes a horizontal section and an inclined section; both the horizontal section and the inclined section include a first side and a second side; the inclined section is provided with an air inlet and a cleaning block; the negative pressure mechanism includes a blowing cylinder and a cylindrical cam, and the piston rod of the blowing cylinder It can slide along the contour curve of the side wall of the cylindrical cam. An air inlet one-way valve and an air outlet one-way valve are fixed on the side wall of the blowing cylinder. The air outlet one-way valve is connected with the air inlet; there is a negative pressure chamber in the upper roller or the lower roller. , there is a negative pressure hole on the side wall of the negative pressure chamber. The laminating machine of this solution can align paper and foam.

Owner:重庆佑威电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com