Network transformer pin bending mechanism facilitating control of deformation

A technology of a network transformer and a bending mechanism is applied in the field of the pin bending mechanism of a network transformer, and achieves the effects of simple structure, convenient quantitative bending, and simple structure of the deformation control mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

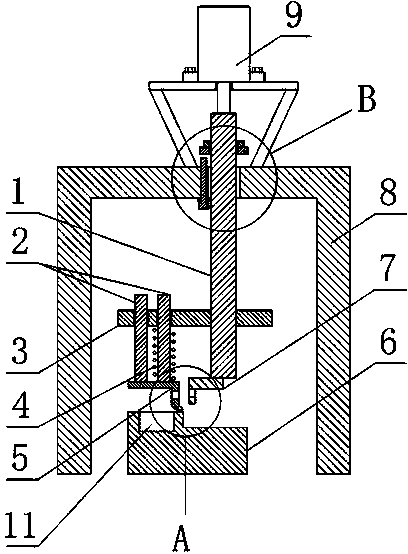

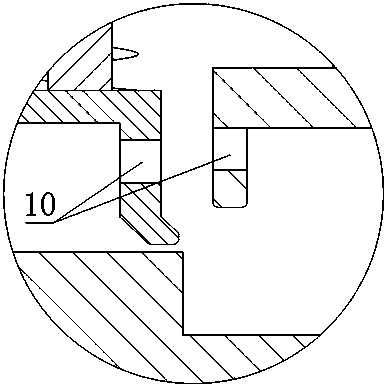

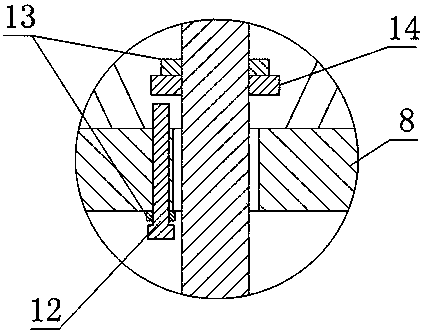

[0027] Such as Figure 1 to Figure 3 As shown, the network transformer pin bending mechanism that is convenient for controlling the amount of deformation includes a frame 8, a pressing bar 1 arranged on the rack 8, a deformed pressing block 7 fixed at the lower end of the pressing bar 1, and a deformation pressing block 7 located below The material platform 6, the pressure rod 1 can move along its axial direction, and also includes a deformation control mechanism, and a pin tightening device is also fixed on the pressure rod 1;

[0028] The pin tightening device comprises a spring seat 3, a spring 4 and a positioning pressing block 5, the spring seat 3 is fixed on the pressing bar 1, and the two ends of the spring 4 are fixedly connected with the spring seat 3 and the positioning pressing block 5 respectively, and the spring The axis of 4 is parallel to the axis of pressure rod 1, and the lower end position of positioning briquetting block 5 is lower than the lower end positio...

Embodiment 2

[0035] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, in order to drive the pressing rod 1 conveniently, the upper end of the pressing rod 1 is also fixedly connected with a pressing rod driving part. According to the size of the workload, the set pressure rod driving part can be set in the structural form of artificial compressive stress drive or hydraulic pressure or air pressure drive.

[0036] In order to facilitate the working efficiency of the present invention, facilitate switching of working states and simplify the structure of the pressing rod driving part, the pressing rod driving part is an air cylinder 9 .

Embodiment 3

[0038] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, in order to prevent the positioning pressing block 5 from being skewed relative to the deformed pressing block 7 after the interaction force is generated with the pins, it also includes a guide rod 2, the axis of the guide rod 2 is in line with the The axes of the spring 4 are parallel, the lower end of the guide rod 2 is fixedly connected with the positioning pressure block 5 , and the spring seat 3 is also provided with a hole which is loosely matched with the guide rod 2 .

[0039] In order to enhance the ability to limit the movement direction of the positioning pressure block 5 and prevent the uneven deformation of the spring 4, there are more than one guide rod 2, and one of the guide rods 2 is located in the inner ring of the spring 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com