Anti-skid device for climbing-free device for wind turbine generator and design method thereof

A technology for wind turbines and anti-skid devices, applied in hoisting devices, safety devices for lifting equipment, etc., can solve problems such as accelerated drive wheels, driven wheel bearing wear, reduced equipment service life, and easily damaged wire ropes, etc., to increase contact length, Ensure reliable operation and improve the effect of anti-skid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

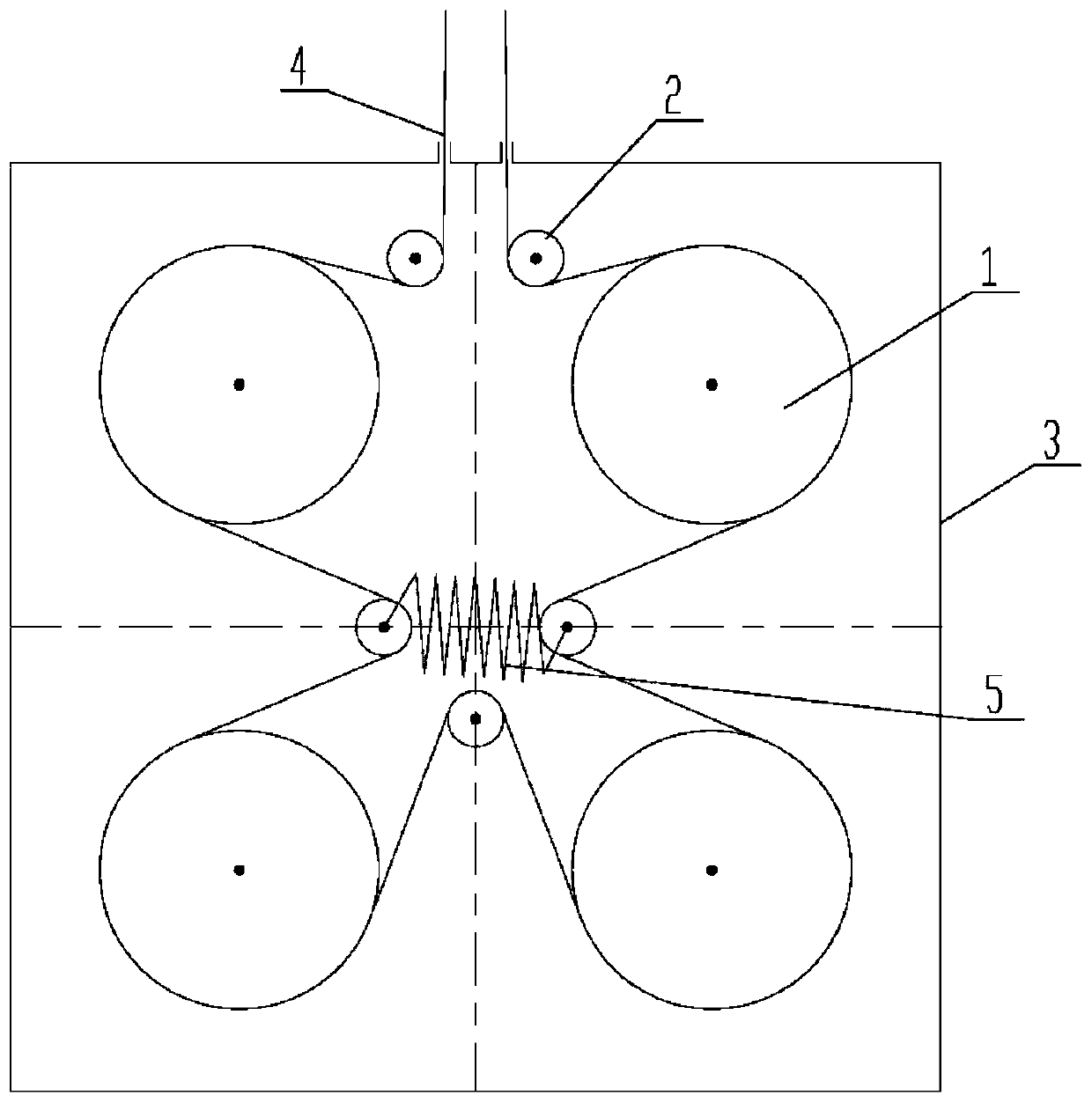

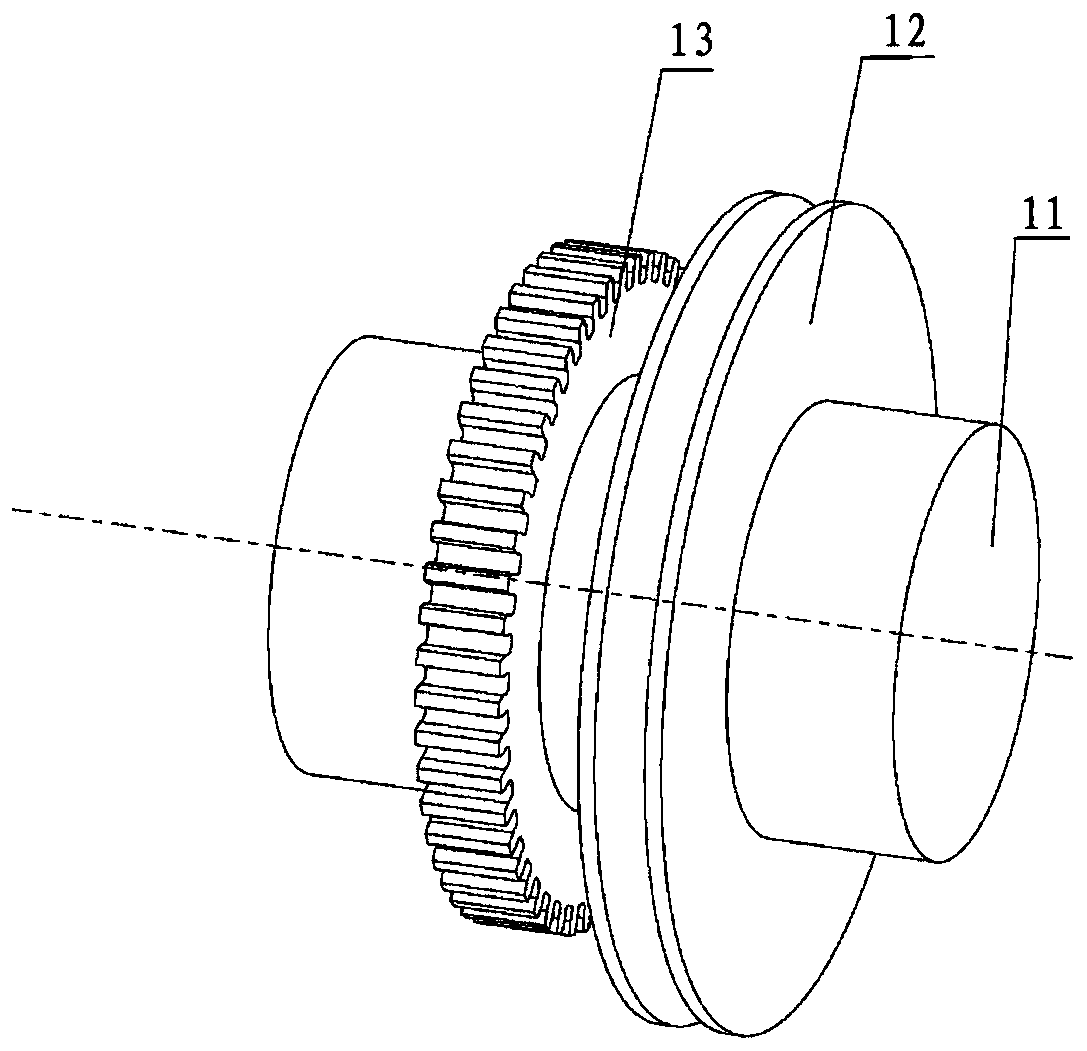

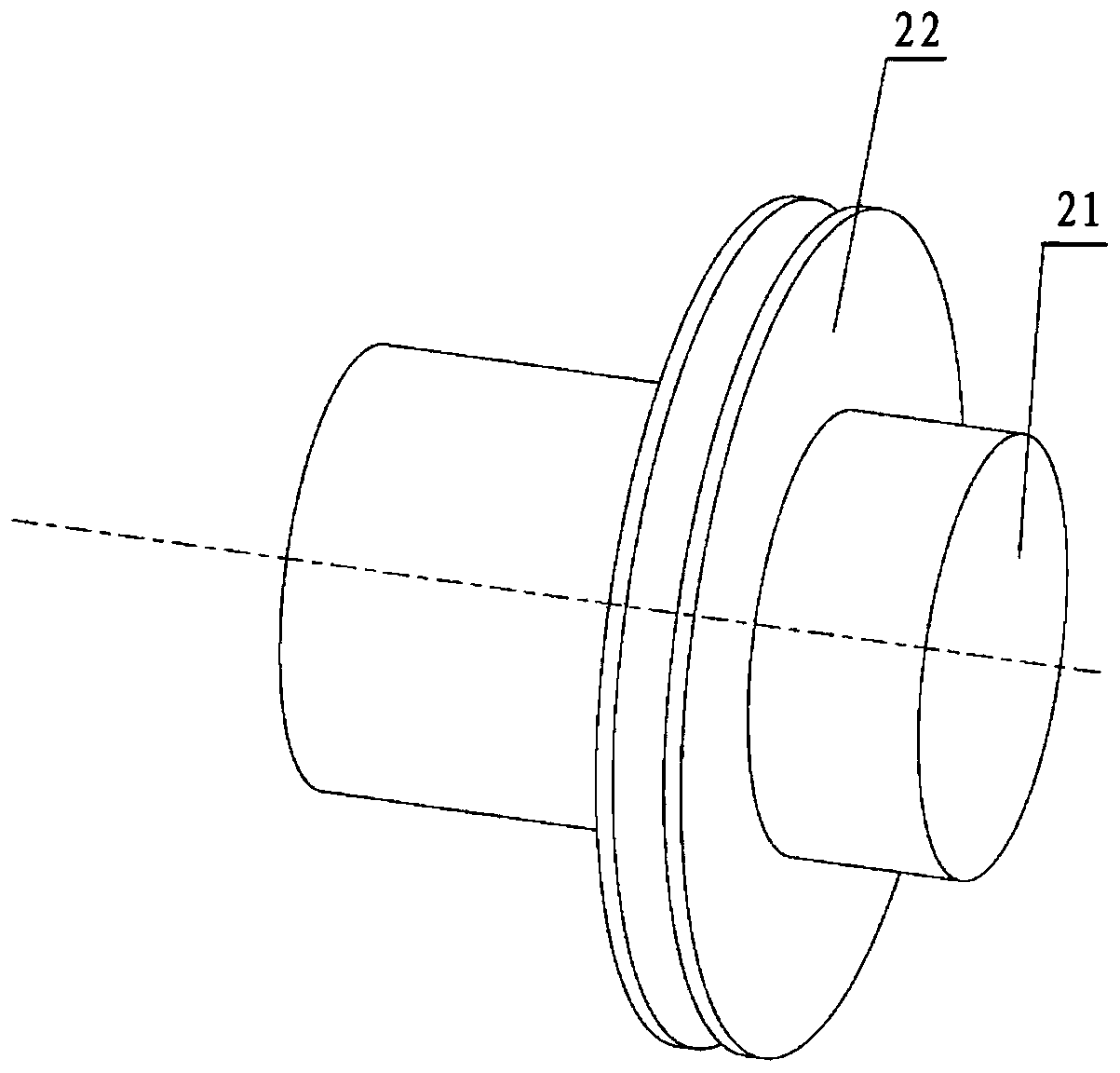

[0037] see figure 1 , the present invention provides an anti-skid device for a wind turbine free climber, including a power box 3, a driving wheel 1, a driven wheel 2, a steel wire rope 4 and a preload spring 5, and the driving wheel 1 and the driven wheel 2 are installed in the power box 3 , one end of the steel wire rope 4 passes through the power box 3 and then goes around the driving wheels 1 and driven wheels 2 and then passes out from the power box 3. In this embodiment, the wire rope 4 penetrates into and out of the power box 3 The inlet and outlet are all located above the power box 3, the number of the driving wheels 1 is four, and the number of the driven wheels is five, the driving wheels 1 are arranged in an equidistant rectangle, and the driven wheels 2 are wound on the wire rope The direction of the driving wheel 1 is arranged at intervals, specifically, two of the five driven wheels 2 are arranged on the horizontal center line of the rectangle formed by the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com