Novel method for installing prestress connecting piece of concrete heat-insulating sandwich board

An installation method and concrete technology, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of low single-piece bearing capacity, high cost, and increased concrete consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

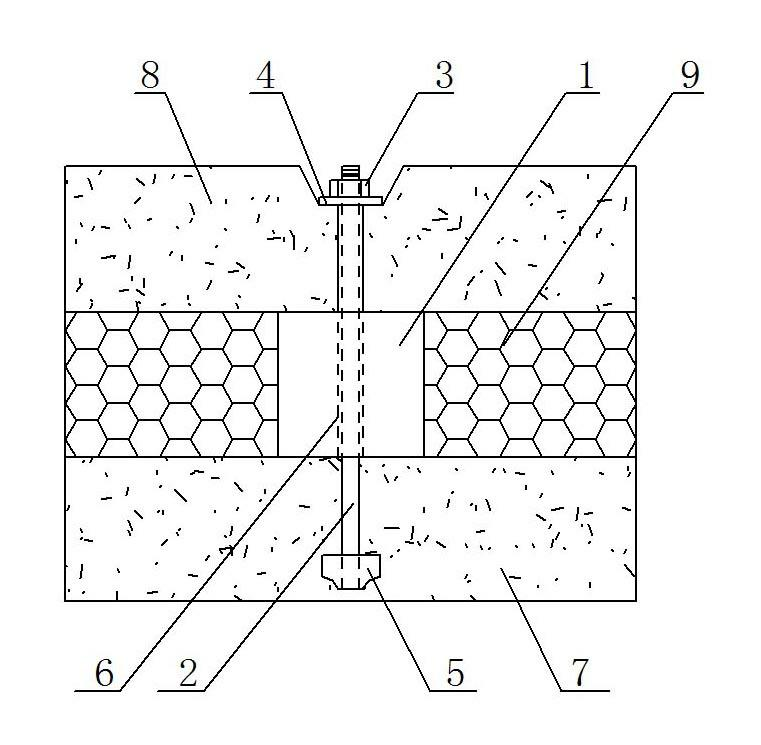

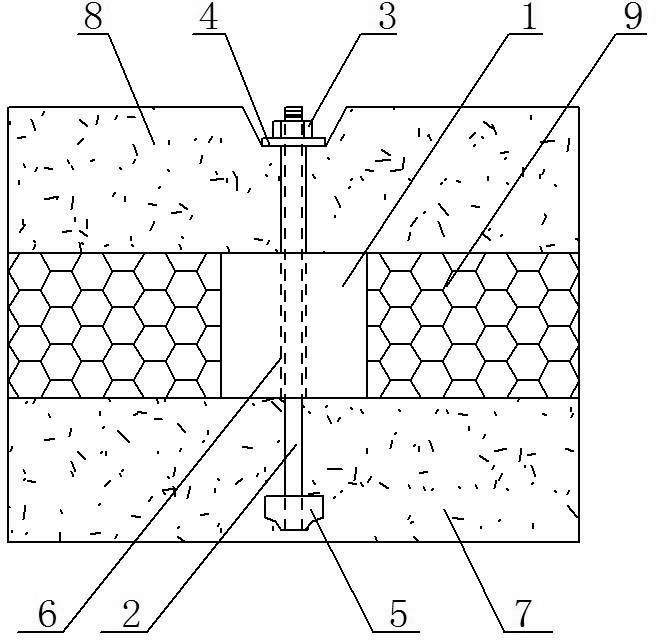

[0012] Such as figure 1 As shown, the installation method of the prestressed connector of the new concrete insulation sandwich panel includes the following steps: first, the anchor end 5 is connected with the bolt 2 and then pre-embedded in the concrete outer leaf plate 7; then the casing 6 is set on the exposed On the bolts 2 other than the concrete outer leaf plate 7, pass the cushion block 1 through the bolt 2 and the casing 6 and then fit the concrete outer leaf plate 7; secondly, lay the insulation layer 9; pour concrete on the insulation layer 9 and the cushion block 1 The inner blade 8 has a groove reserved, and one end of the bolt 2 passes through the groove of the concrete inner blade 8; after the concrete reaches the expected strength, install the gasket 4 in the groove, and use the anchor 3 after tensioning the bolt 2 fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com