Field detection device suitable for bearing capacity of reinforced concrete beams and arranging method

A technology for on-site inspection of reinforced concrete beams, applied in the direction of applying stable tension/pressure to test the strength of materials, joists, girders, etc., which can solve the problems of other structures below, the inability to build floor supports, and the supports are susceptible to external disturbances, etc. , to achieve the effects of preventing tilting, saving manpower, and facilitating loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0050] see Figure 1-10 .

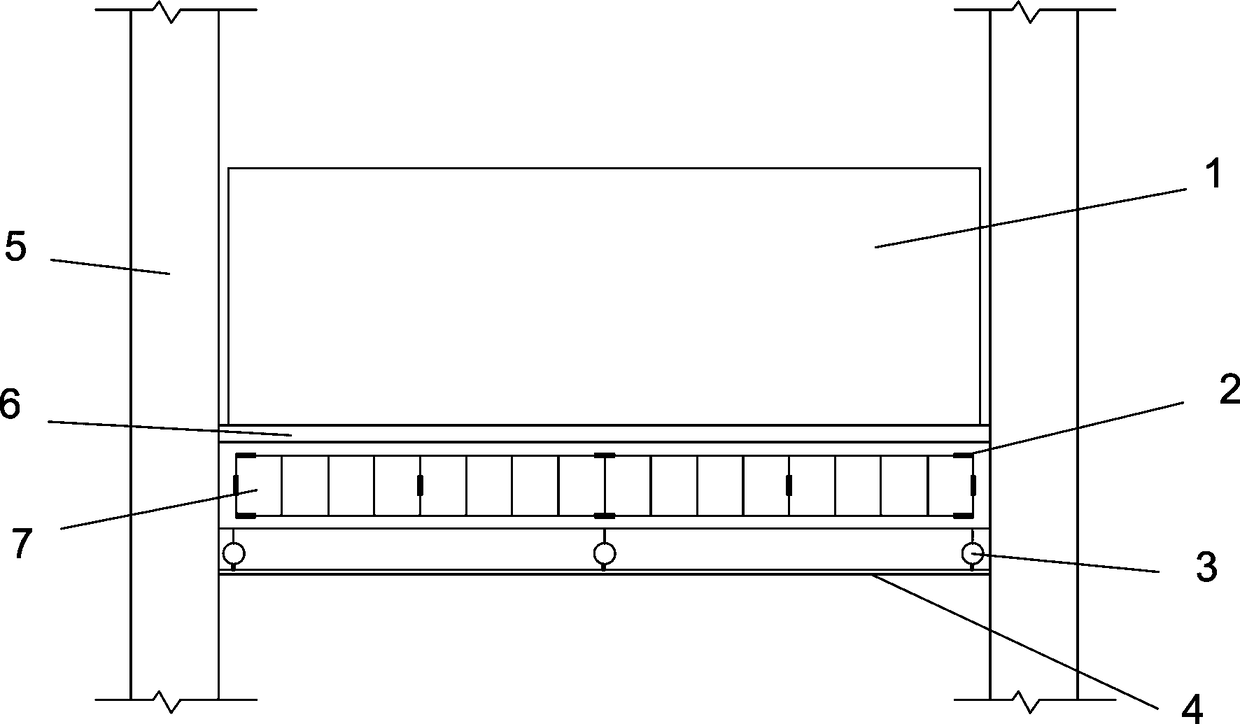

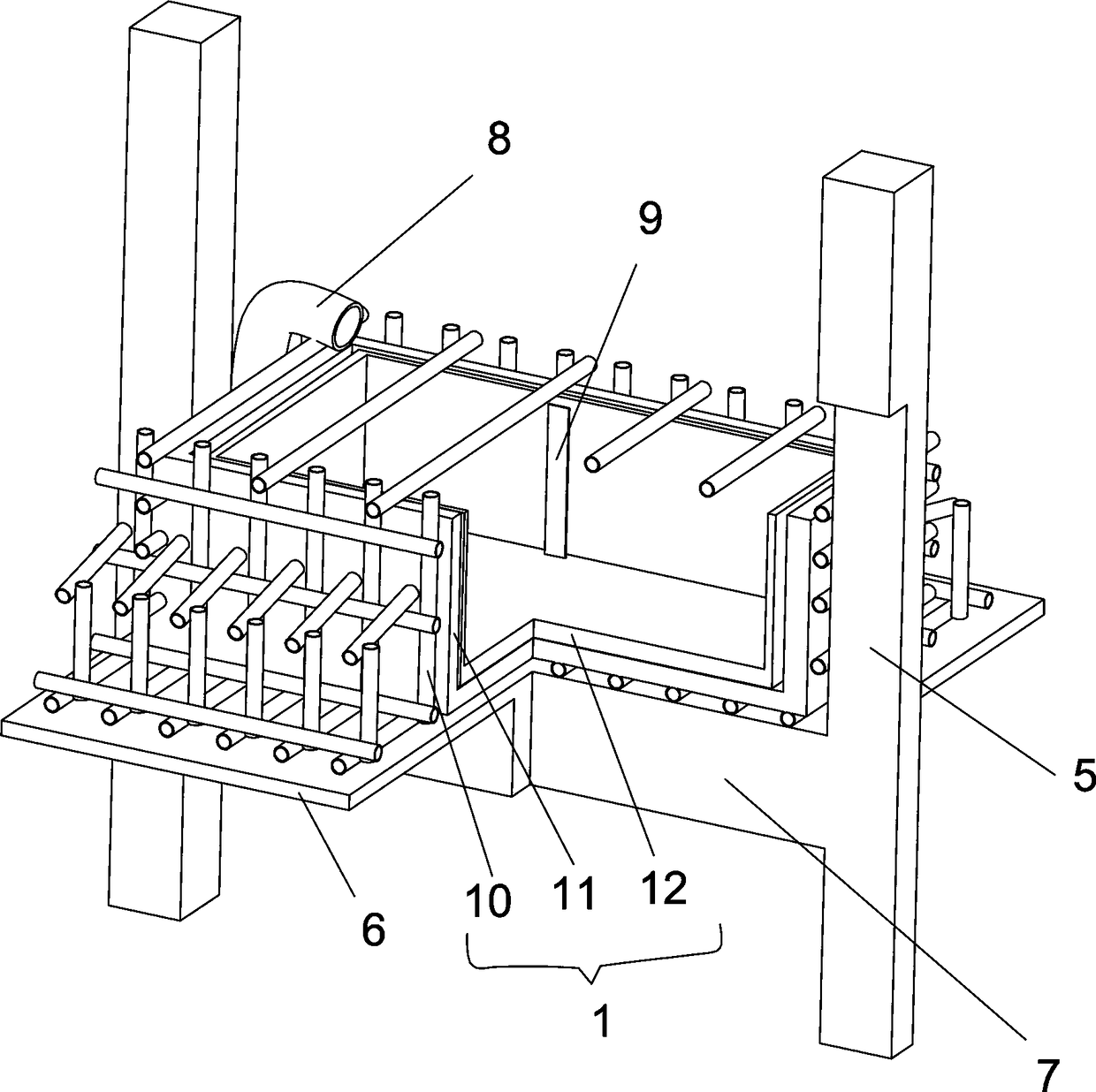

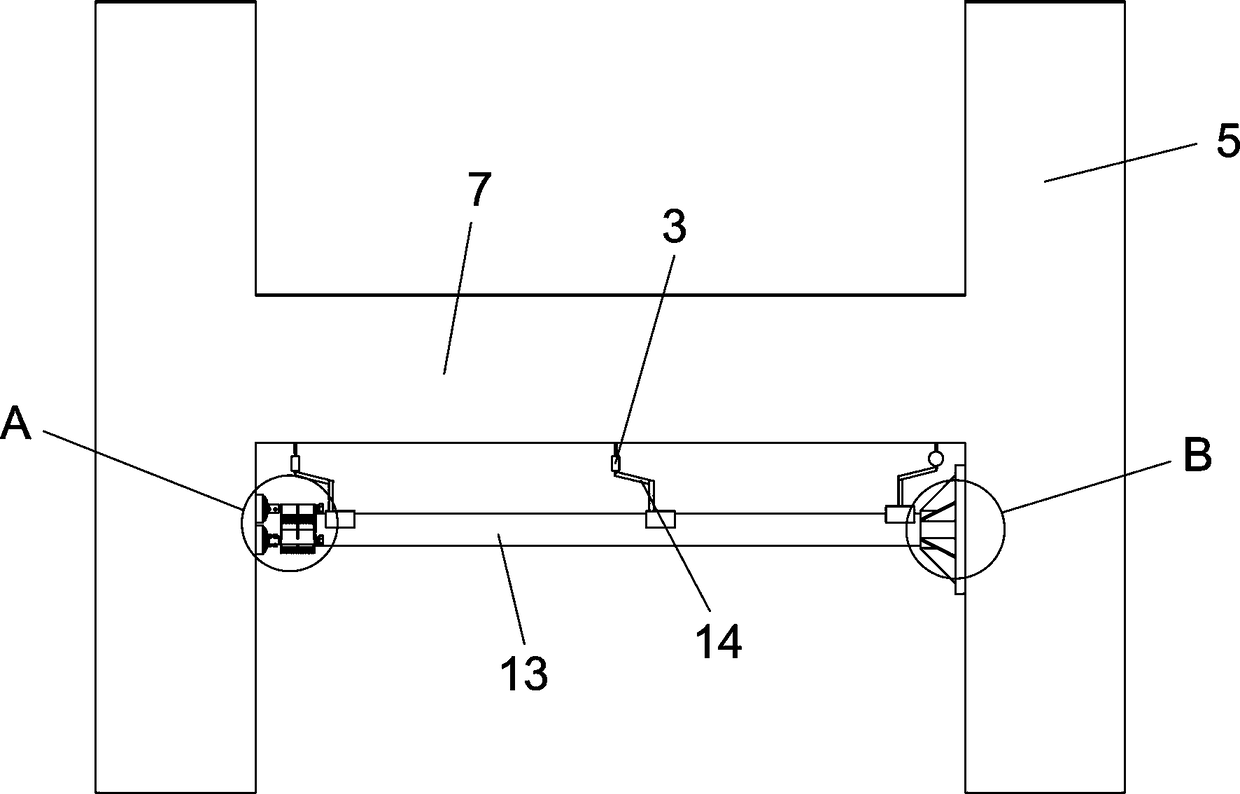

[0051] The invention discloses an on-site detection device suitable for the bearing capacity of reinforced concrete beams, which includes a beam 7 to be inspected, a floor 6 arranged on the upper end of the beam 7 to be inspected, and load-bearing columns 5 on both sides. The lower side of the beam 7 to be inspected is A displacement meter support 4 is arranged horizontally, and both sides of the displacement meter support 7 are detachably fixed between the two load-bearing columns 5, and a displacement meter is arranged between the inspected beam 7 and the displacement meter support 4. 3. The upper end of the inspected beam 7 is provided with a loading water tank 1 , and one side of the loaded water tank 1 is provided with a water delivery pipe 8 , and a plurality of strain gauges 2 are attached to the key stress points of the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com