A skid mechanism for mirror driver of automobile rearview mirror

A technology for automobile rearview mirror and skid mechanism, which is applied to vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of increasing the difficulty of manufacturing parts, complex structure of the skid mechanism, and increased failure rate of parts, and achieves assembly. The effect of convenience, simple structure and low cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

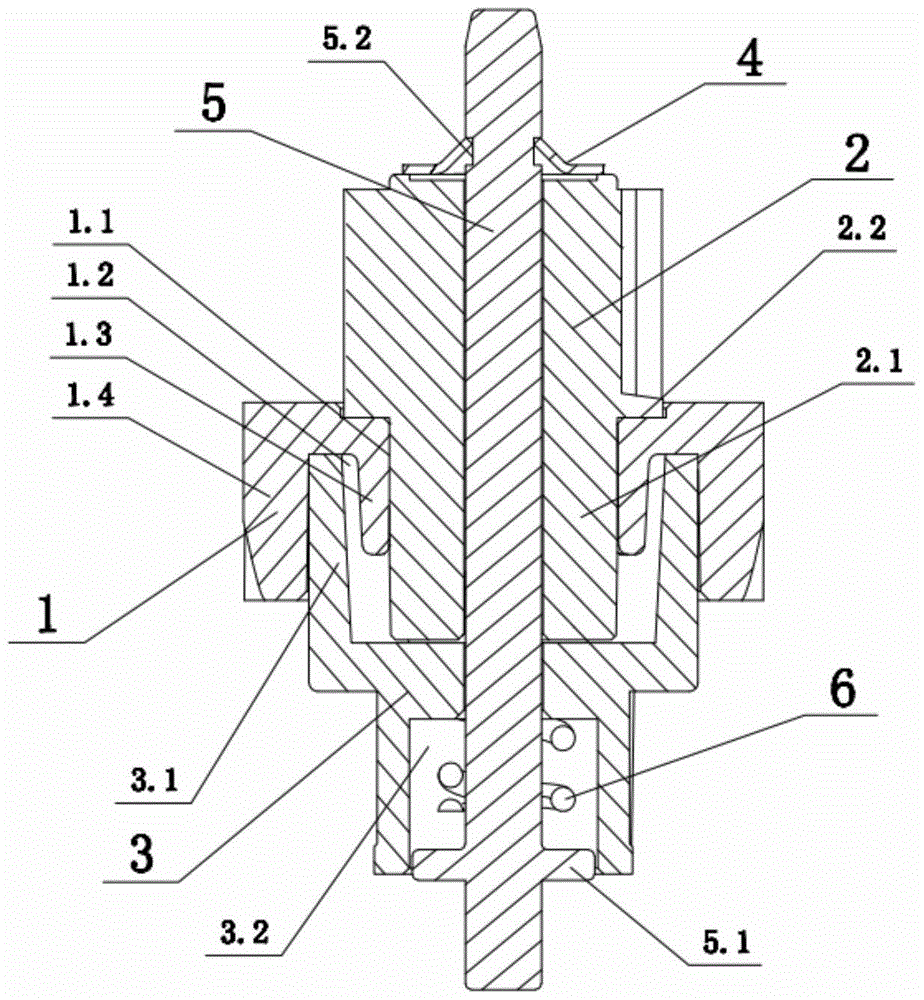

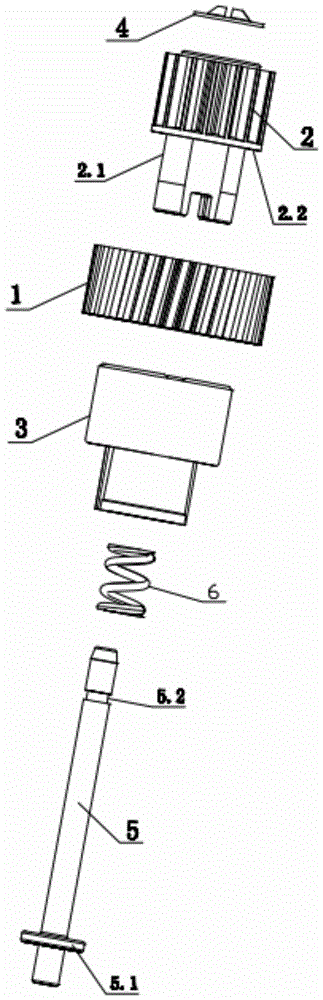

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] The tight fit between the surfaces described below means that the surfaces are pressed tightly, and there is a certain friction coefficient value between the surfaces, so that a certain friction force is generated between the surfaces. When one surface is used as the active surface, the other surface is driven by the friction force as the passive surface, and when the resistance received by the passive surface continues to increase, a slip is formed between the surfaces, that is, the resistance overcomes Maximum static friction, which converts the force between the driving and driven surfaces into sliding friction.

[0020] Specifically, the above-mentioned tight fit includes between planes and planes, and also includes between the arc-shaped outer wall of the cylinder and the inner wall of the hole.

[0021] As shown in the figure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com