Automatic floor sweeping robot

A sweeping robot and robot body technology, applied in the field of sweeping robots, can solve problems such as carpet damage, achieve the effects of avoiding damage to carpets and improving static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

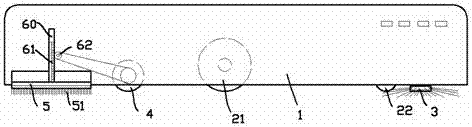

[0014] exist figure 1 In the first shown embodiment, the automatic sweeping robot includes a robot body 1, and the bottom of the robot body 1 is provided with a dust suction port (not shown), a walking wheel 21, a steering wheel 22, and a dust brush 3; The rear of described road wheel 21 is also provided with the driven stick 4 that is parallel to the rotating shaft of road wheel 21; There is a movable plate 5 that can move up and down, and the lower side of the movable plate 5 can horizontally fix the rag 51; the upper side of the movable plate 5 is connected with a transmission mechanism coupled with the driven roller 4, and the transmission mechanism makes When the driven roller 4 moved forward, that is, when the driven roller 4 rolled forward, the movable plate 5 was raised upwards, so that the rag 51 on the lower side of the movable plate 5 was detached from the ground; The surface roughness has the following requirements: when the sweeping robot travels on the floor and...

Embodiment 2

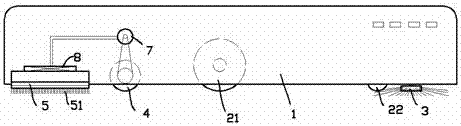

[0018] exist figure 2 In the second embodiment shown, the automatic sweeping robot includes a robot body 1, and the bottom of the robot body 1 is provided with a dust suction port (not shown), a walking wheel 21, a steering wheel 22, and a dust brush 3; The rear of described road wheel 21 is also provided with the driven stick 4 that is parallel to the rotating shaft of road wheel 21; There is a movable plate 5 that can move up and down, and the lower side of the movable plate 5 can horizontally fix the rag 51; the movable plate 5 is provided with iron parts (not shown, it can be an iron plate); the robot body 1 Inside, above the movable plate 5, an electromagnet structure 8 is arranged; the driven roller 4 is coupled to a micro generator 7, and the generating electrode of the micro generator 7 passes through an amplification module (not shown, can be integrated in a micro Generator housing, or integrated on the packaging of the electromagnet structure 8) and then output to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com