Protective agent for electronic component pin tin coating

A technology of electronic components and protective agents, applied in the direction of coatings, anti-corrosion coatings, etc., can solve the hidden dangers of product quality and reduce the reliability of electronic components, so as to improve reliability, prevent oxidation and discoloration, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

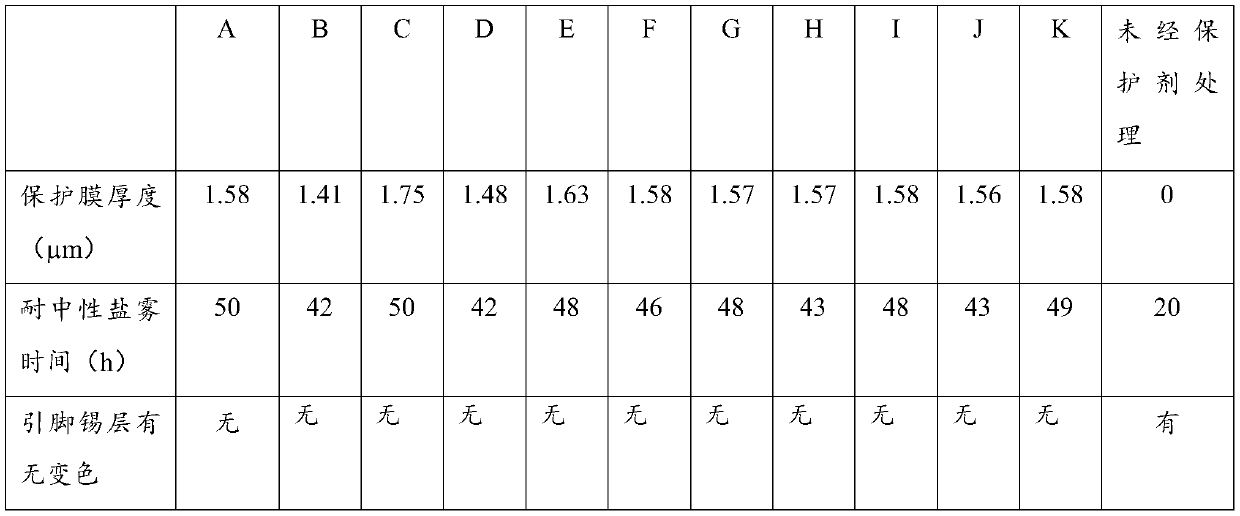

Embodiment 1

[0022] A kind of protective agent of tin-plated layer of electronic component pin is inorganic-organic composite treatment liquid, wherein water-based acrylic resin is 150g / L, silica sol is 40g / L, zinc gluconate 10g / L, dimethylethanolamine 10g / L L, benzotriazole 1.5g / L.

[0023] The preparation of the protective agent for the tin-plated layer of the pins of the above-mentioned electronic components specifically includes the following steps:

[0024] (1), add 0.6L deionized water in the beaker;

[0025] (2), respectively take by weighing water-based acrylic resin 150g, silica sol 40g, zinc gluconate 10g, dimethylethanolamine 10g, benzotriazole 1.5g, add to step (1) under the condition of stirring Add water to the above beaker until the volume of the mixed solution is 1.0L to obtain the required protective agent A.

Embodiment 2

[0027] A kind of protective agent of tin-plated layer of electronic component pin is an inorganic-organic composite treatment solution, wherein water-based acrylic resin is 100g / L, silica sol is 40g / L, zinc gluconate 10g / L, dimethylethanolamine 10g / L L, benzotriazole 1.5g / L.

[0028] The preparation of the protective agent of above-mentioned a kind of electronic component pin tin-plated layer, just the water-based acrylic resin described in the step (2) is 100g, and other is with embodiment 1, finally obtains required protective agent B.

Embodiment 3

[0030] A kind of protective agent of tin-plated layer of electronic component pin is inorganic-organic composite treatment liquid, wherein water-based acrylic resin is 200g / L, silica sol is 40g / L, zinc gluconate 10g / L, dimethylethanolamine 10g / L L, benzotriazole 1.5g / L.

[0031] The preparation of the protective agent of above-mentioned a kind of electronic component pin tin-plated layer, just the water-based acrylic resin described in the step (2) is 200g, and other is with embodiment 1, finally obtains required protective agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com