Novel antimicrobial sponge and preparation method thereof

An anti-microbial and sponge technology, applied in the field of sponge materials, can solve the problems of insufficient stability, short duration of inhibition, limiting the application of antibacterial sponges, etc., and achieve the effect of avoiding oxidative discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] As an embodiment of the preparation method of the novel antimicrobial sponge of the present invention, the preparation method of the novel antimicrobial sponge described in this embodiment comprises the following steps:

[0038] (1) Weigh each component raw material according to the above ratio

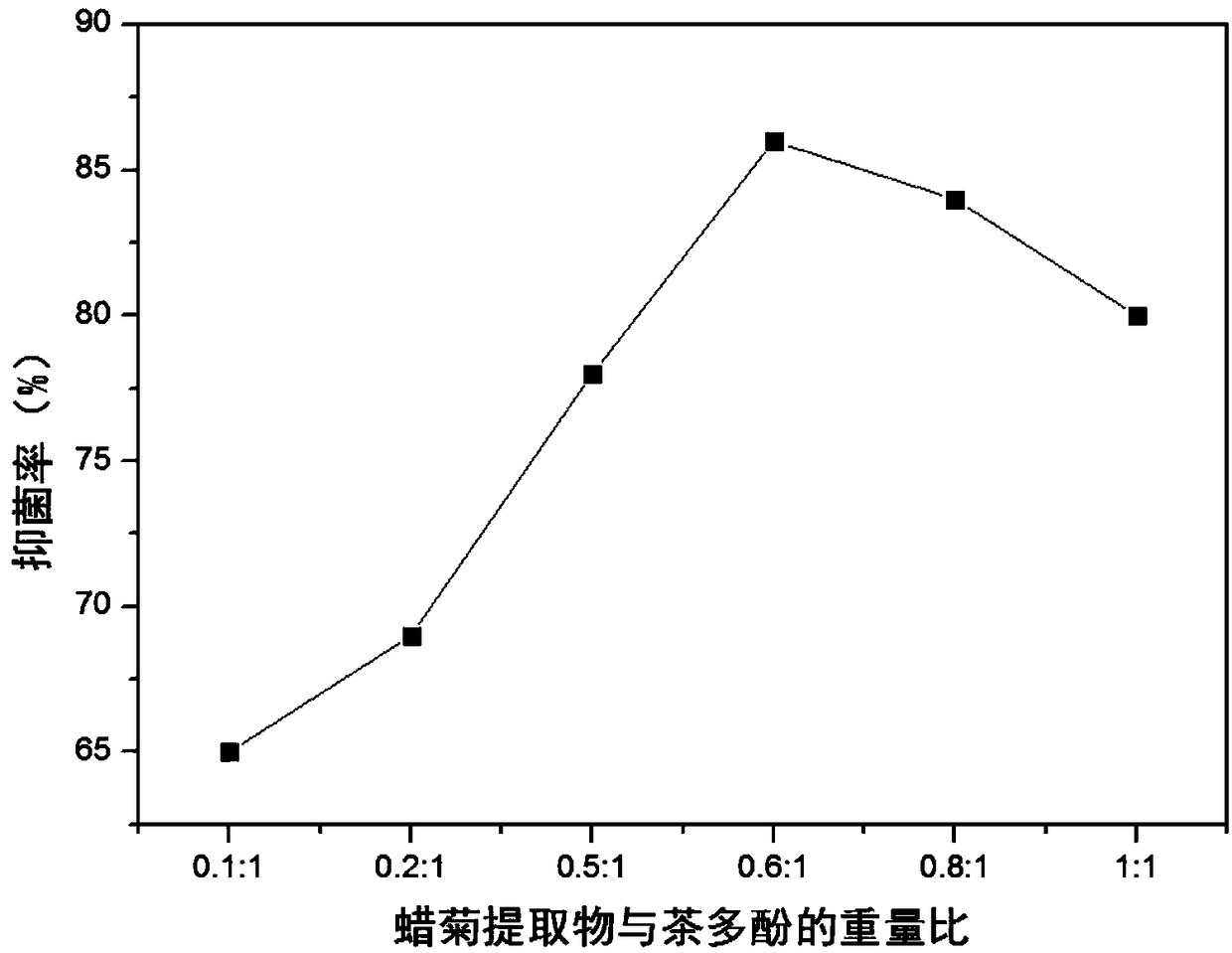

[0039] 100 parts of polypolyols, 55 parts of polyisocyanates, 1.8 parts of foam stabilizers, 1.0 parts of amine catalysts, 9 parts of blowing agents and 5 parts of antibacterial microcapsules, said polypolyols include 25 wt% polyoxypropylene polyols, The polycaprolactone polyol of 35wt% and the polytetrahydrofuran polyol of 40wt%, the average functionality of described polypolyol is 3.5; In described antimicrobial microcapsule, the weight ratio of nano-silver and tea polyphenol is 0.12:1, wax The weight ratios of chrysanthemum extract and tea polyphenols are respectively 0.1:1, 0.2:1, 0.5:1, 0.6:1, 0.8:1, 1:1; the particle diameter of the nano-silver is 10nm; The capsules use ...

Embodiment 2

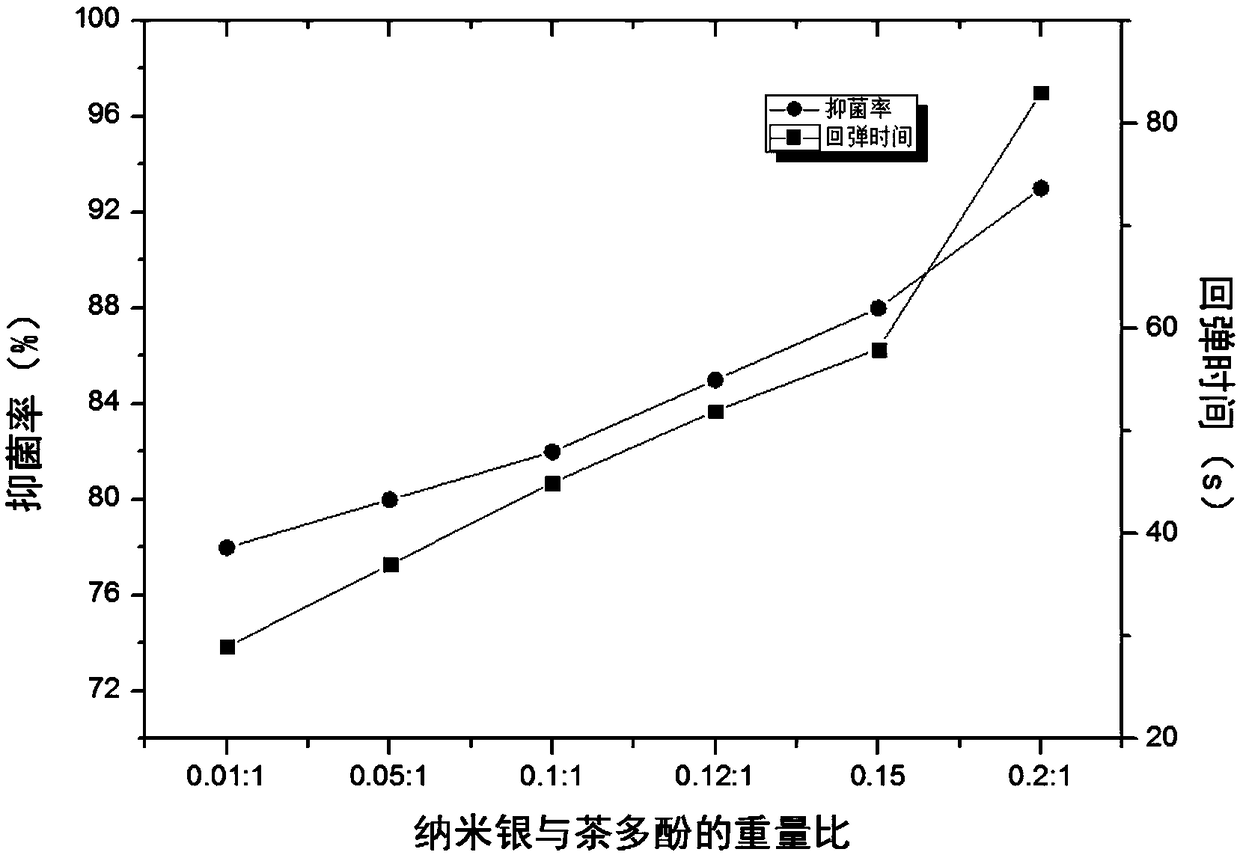

[0046] The composition and preparation method of the novel antimicrobial sponge of this example are basically the same as those of this example, the difference is that in the antimicrobial microcapsules described in this example, the weight ratio of nano-silver to tea polyphenols is 0.01:1, 0.05:1 , 0.1:1, 0.12:1, 0.15:1 and 0.2:1, the weight ratio of Helichrysum extract to tea polyphenols is 0.6:1 respectively.

[0047] Antibacterial test and rebound resilience test are carried out to the sponge prepared according to the above-mentioned method, the results are as follows: figure 2 shown.

[0048] Rebound performance test method: Prepare a sponge of 20cm×20cm×10cm, place a 1kg object on it, and measure the rebound time after 5 minutes.

[0049] Depend on figure 2 The results showed that as the weight ratio of nano-silver to tea polyphenols increased, the antibacterial rate and rebound time of the sponge both showed an increasing trend.

Embodiment 3

[0051] As an embodiment of the preparation method of the novel antimicrobial sponge of the present invention, the preparation method of the novel antimicrobial sponge described in this embodiment comprises the following steps:

[0052] (1) Weigh each component raw material according to the above ratio

[0053] 100 parts of polypolyols, 62 parts of polyisocyanates, 1.5 parts of foam stabilizers, 1.2 parts of amine catalysts, 6 parts of blowing agents and 6 parts of antibacterial microcapsules, said polypolyols include 32wt% polyoxypropylene polyols, 50wt% polycaprolactone polyol and 18wt% polytetrahydrofuran polyol, the polypolyol has an average functionality of 3 to 3.5; in the antibacterial microcapsules, the weight ratio of nano-silver to tea polyphenol is 0.15:1 , the weight ratio of Helichrysum extract to tea polyphenols is 0.6:1; the particle diameter of the nano-silver is 10nm; as the core.

[0054] (2) prepare antibacterial microcapsules:

[0055] After dissolving ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com