Metal surface treating composition and surface treating metal material with metal surface treating film obtained therefrom

A metal surface treatment and composition technology, applied in the direction of metal material coating process, etc., can solve the problems of no record of peroxovanadate, poor alkali resistance, insufficient research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0106] Manufacturing example 1 (Manufacture of metal surface treatment composition)

[0107] Put 100 parts by mass of deionized water into the container, add 30 parts by mass of 30% hydrogen peroxide aqueous solution and fully stir to obtain a solution with a liquid temperature of 25°C, add 15 parts by mass of vanadium to the above solution ammonium acid, and stirred for 30 minutes, thus obtaining an aqueous perovanadic acid solution.

Embodiment 1~9 and comparative example 1~2

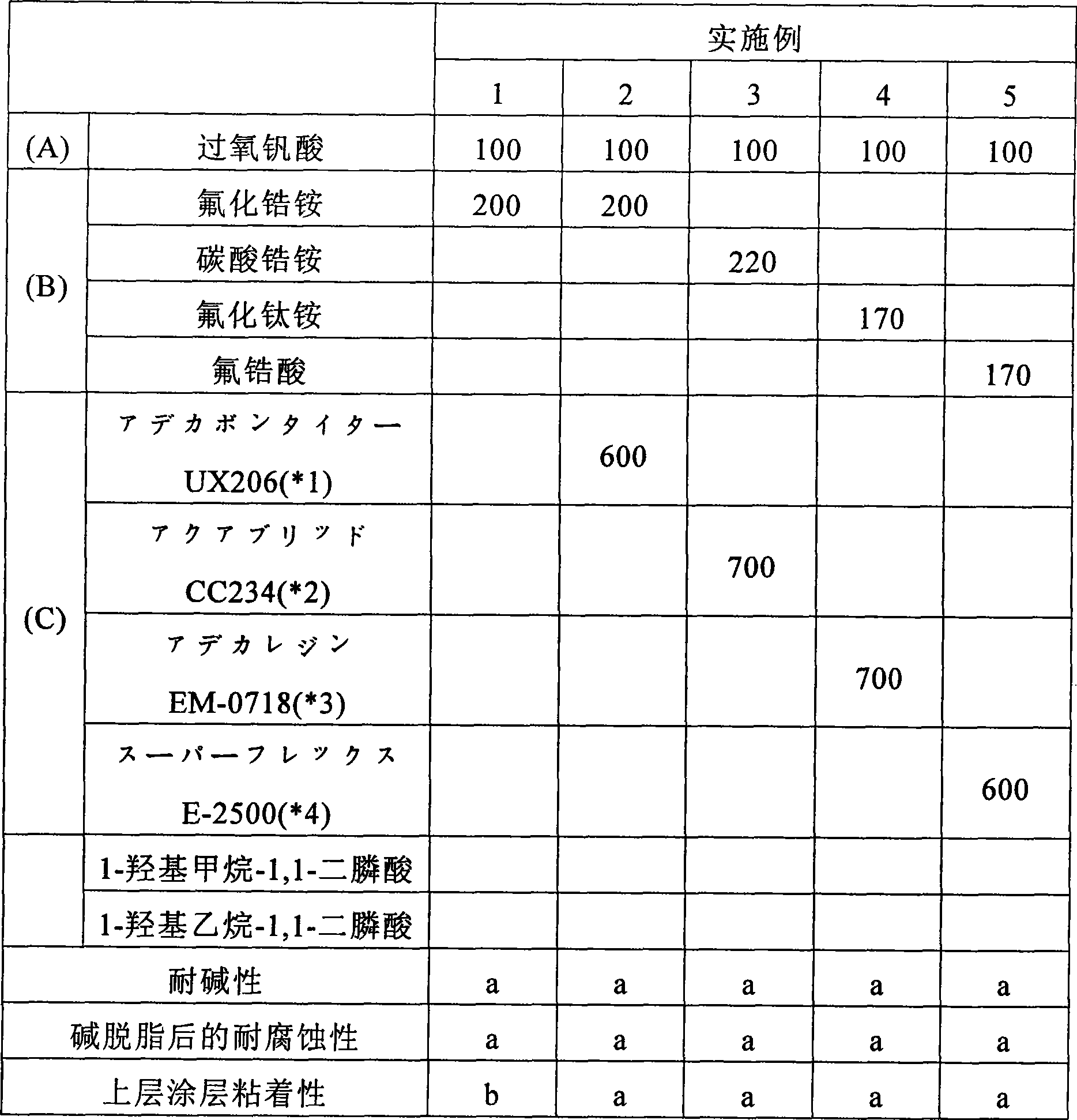

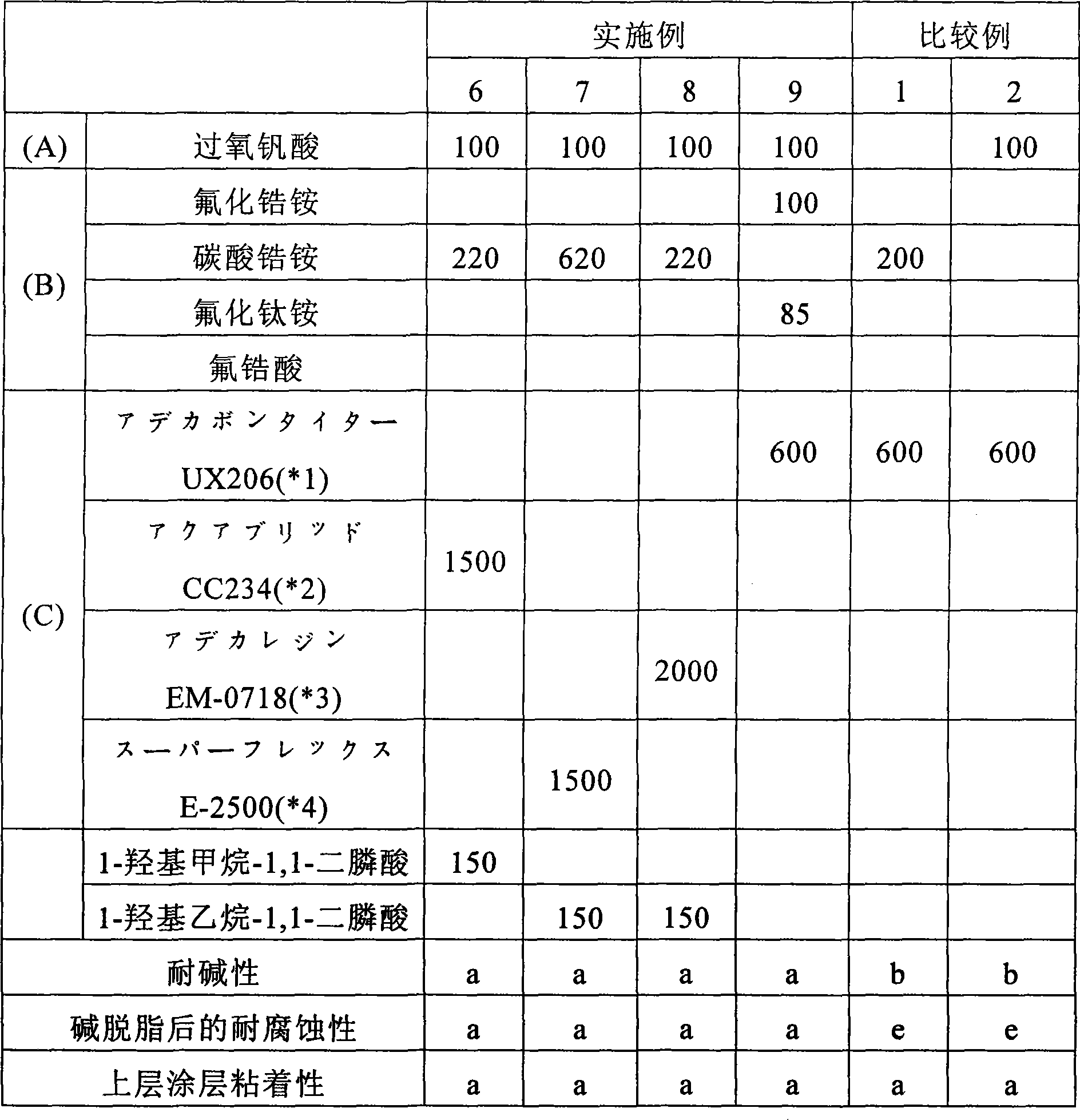

[0109] Each composition for metal surface treatment was produced according to the composition shown in following Table 1, 2. In addition, the compounding quantity of each raw material in Table 1, 2 is shown by the solid content mass ratio in the metal surface treatment composition which is an aqueous liquid.

[0110] Using deionized water, a metal surface treatment composition was prepared so that the solid content was 15%.

[0111] in FIG. 1,( * 1)~( * 4) The raw materials are the following compounds.

[0112] ( * 1) アデカボンタイタ—UX206: brand name, manufactured by ADEKA Corporation, water-based polyurethane resin.

[0113] ( * 2) Acrylic CC234: brand name, Daicel Chemical Industry Co., Ltd. product, water-based acrylic resin.

[0114] ( * 3) Adeka resin EM-0718: brand name, ADEKA company make, water-based epoxy resin.

[0115] ( * 4) Superflex E-2500, trade name, manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., water-based polyurethane resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com