Selective hydrodesulfurization catalyst and preparation method thereof

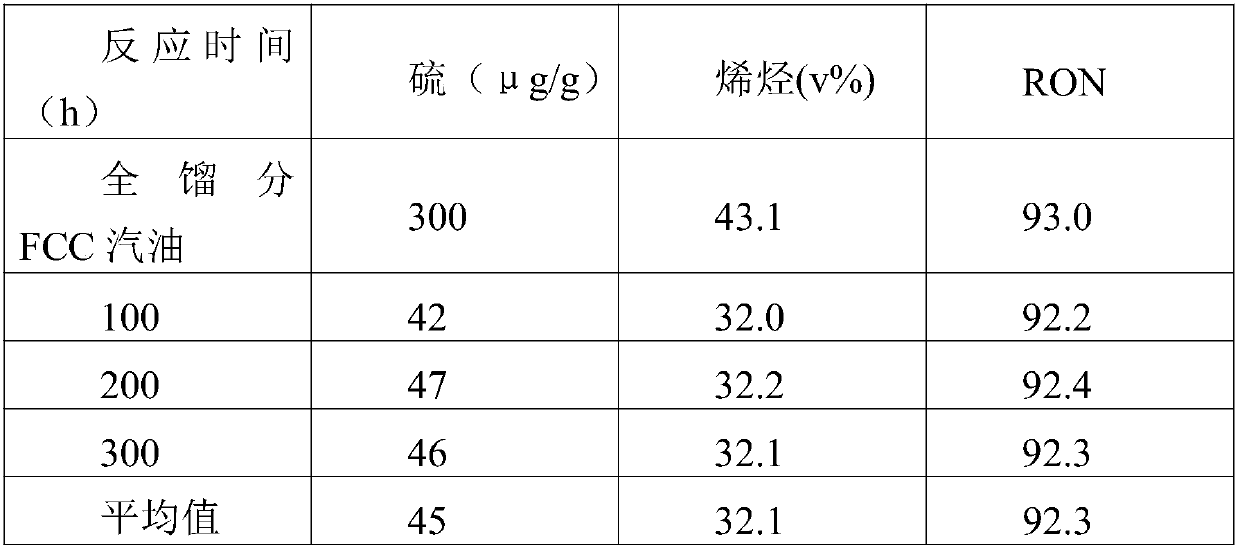

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as long processing time, achieve small RON loss, good desulfurization activity, and reduce olefin polymerization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of this example includes: based on the total weight of the catalyst, 5% CoO, 10% MoO 3 , 2% B 2 o 3 , 1%P 2 o 5 , 1%K 2 O, 5% ZnO-76% Al 2 o 3 Catalyst A.

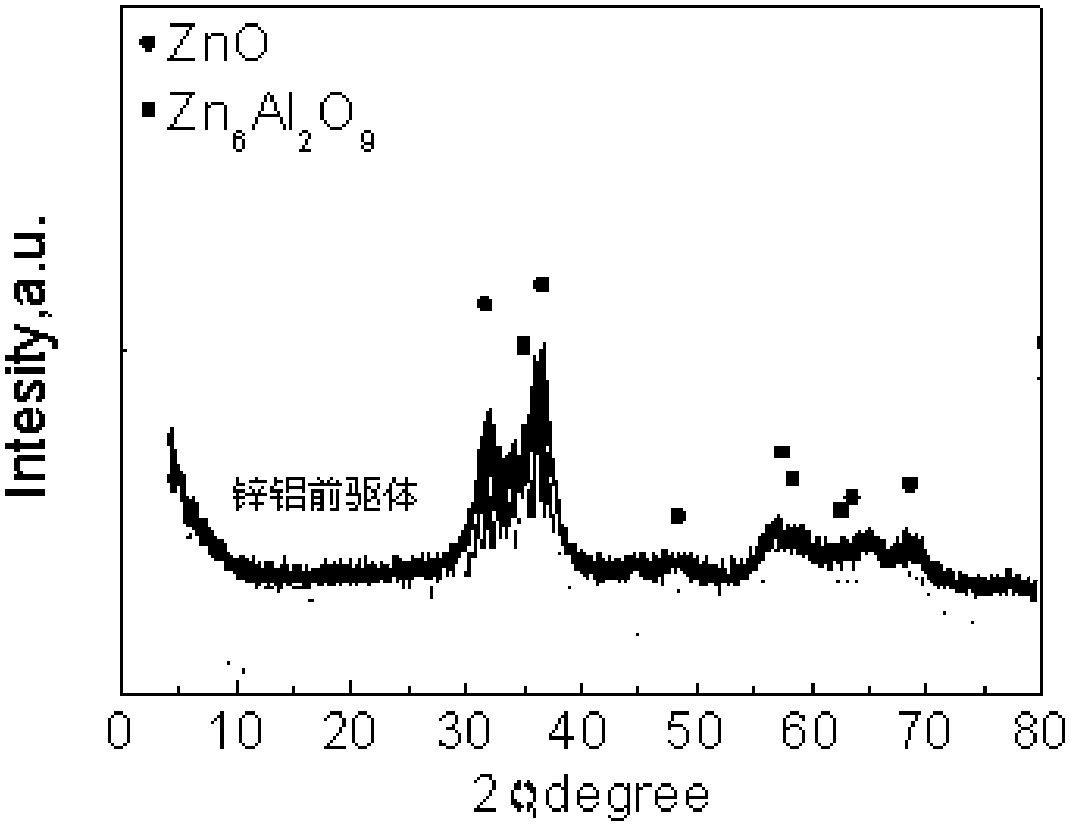

[0050] Dissolve 800g of zinc nitrate in 4L of water to form a zinc-containing solution, and dissolve 120g of sodium metaaluminate and 120g of sodium carbonate in 1.7L of water to form an aluminum-containing solution. Take 2L zinc-containing solution, control the system temperature at 60°C, add aluminum-containing solution dropwise to it until the pH value reaches 9, stop adding the aluminum-containing solution dropwise, add the remaining 2L zinc-containing solution dropwise to the mixing system, and continue to drop the Aluminum solution until the pH value reaches 9, the total titration time is 4h. The obtained mixture was aged at 85°C for 4h, cooled and washed until neutral, dried at 120°C in an air atmosphere for 5h, and calcined at 500°C for 6h to obtain a zinc oxide sample containing zinc...

Embodiment 2

[0055] The preparation of this embodiment includes: based on the total weight of the catalyst, 4% CoO, 12% MoO 3 , 2.5% B 2 o 3 , 1.6%P 2 o 5 , 1.3% K 2 O, 15.6% ZnO-63% Al 2 o 3 Catalyst B.

[0056] The preparation method of the composite oxide carrier is the same as that in Example 1, except that when preparing the composite oxide carrier, the sample amount of zinc oxide is 26 g, and the dry alumina powder is 90 g.

[0057] Then take boric acid 4.44g, potassium phosphate 1.95g, and phosphoric acid 1.31g is completely dissolved in 56g distilled water and is mixed with auxiliary agent impregnating liquid, under room temperature, auxiliary agent impregnating liquid is sprayed on the 78.6g composite oxide carrier in the rotating drum, Place and age at room temperature for 6 hours, dry at 140° C. for 6 hours, and bake at 650° C. for 8 hours to obtain a modified composite oxide carrier.

[0058] Take by weighing cobalt nitrate 15.5g, ammonium heptamolybdate 14.7g, be dissolv...

Embodiment 3

[0060] The preparation of this example includes: based on the total weight of the catalyst, 5% CoO, 10% MoO 3 , 2% B 2 o 3 , 1%P 2 o 5 , 1%K 2 O, 20% ZnO-61% Al 2 o 3 Catalyst C.

[0061] The preparation method is the same as that of Example 1, except that when preparing the composite oxide carrier, the sample amount of zinc oxide is 40 g, and the dry alumina powder is 96 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com