Zinc aluminate gahnite contained zinc oxide desulphurizer

A zinc-aluminum spinel and zinc oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, petroleum industry, etc., can solve the problems of low specific surface area and limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

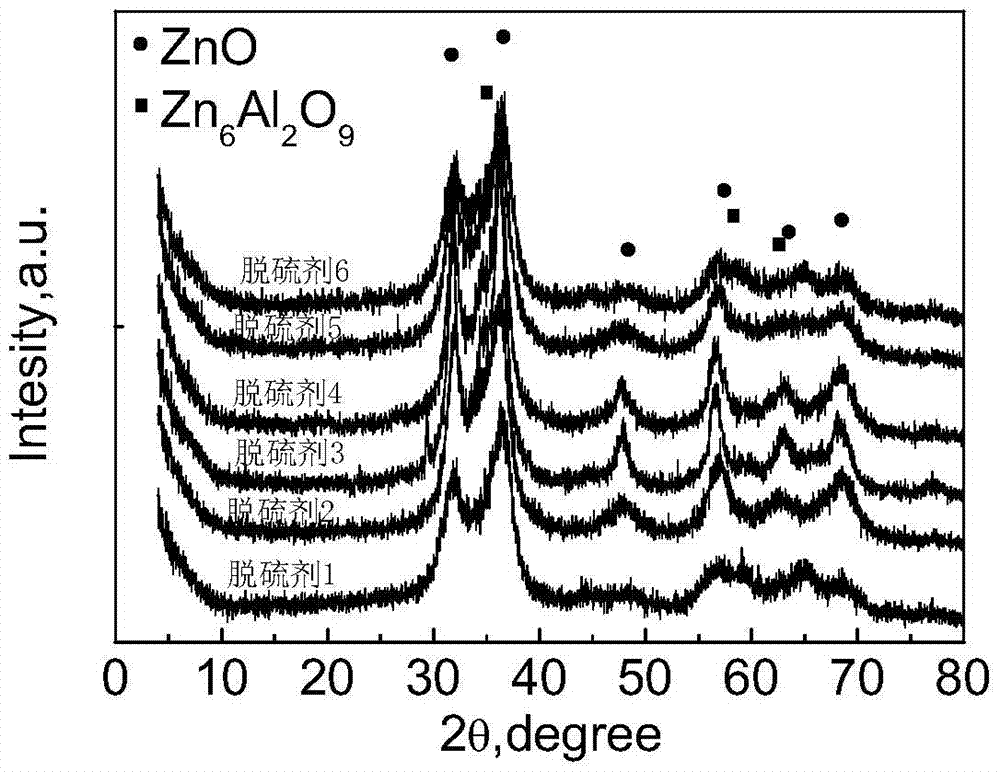

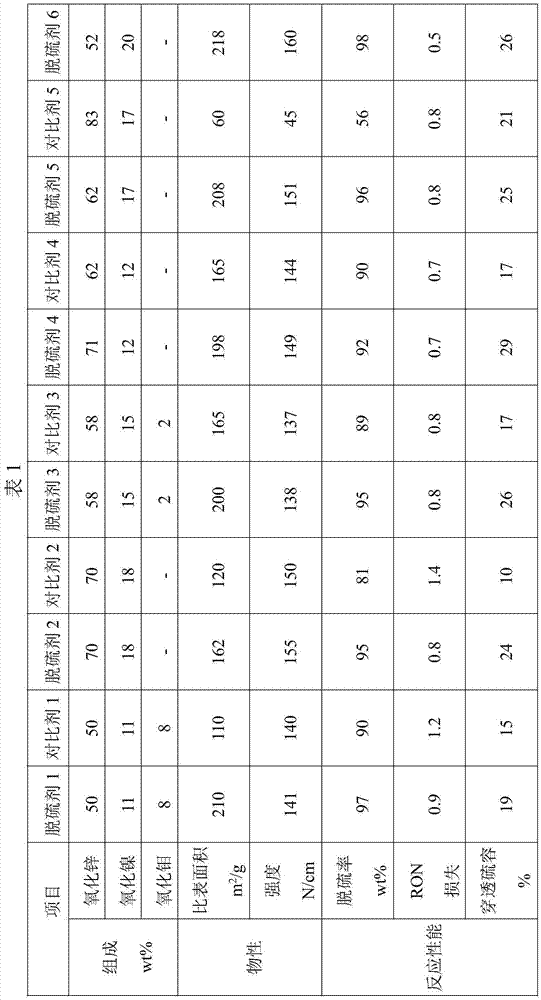

Embodiment 1

[0031] Dissolve 800g of zinc nitrate in 4L of water to form a zinc-containing solution, and dissolve 120g of sodium metaaluminate and 120g of sodium carbonate in 1.7L of water to form an aluminum-containing solution. Take 2L zinc-containing solution, control the system temperature at 60°C, add aluminum-containing solution dropwise to it until the pH value reaches 9, stop adding the aluminum-containing solution dropwise, add the remaining 2L zinc-containing solution dropwise to the mixing system, and continue to drop the Aluminum solution until the pH value reaches 9, the total titration time is 4h. The obtained mixture was aged at 85°C for 4h, cooled and washed to neutral, and dried in an air atmosphere at 120°C for 5h.

[0032] Extrude the dried product and bake it at 500°C for 6 hours; dissolve 60.55g of ammonium molybdate and 226.25g of nickel acetate in 350mL of ammonia water to make an impregnating solution to impregnate 500g of the roasted product, dry it in an air atmos...

Embodiment 2

[0038] Dissolve 1.6kg of zinc nitrate in 8L of water to make a zinc-containing solution, and dissolve 0.11kg of sodium metaaluminate and 0.38kg of sodium carbonate in 3.4L of water to make an aluminum-containing solution. Divide the zinc-containing solution into 4 equal parts, each 2L. Take 2L zinc-containing solution, control the system temperature to 75°C, add aluminum-containing solution dropwise to it until the pH value reaches 8.7; stop adding aluminum-containing solution, then add 2L zinc-containing solution dropwise to the mixing system, and continue to drop aluminum-containing solution Titrate until the pH value reaches 8.7; alternately titrate the aluminum-containing solution and the zinc-containing solution until all the zinc-containing solutions are added to the mixing system, and add the aluminum-containing solution dropwise until the pH reaches 8.7. The total titration time is 6 hours. The obtained mixture was aged at 90°C for 6h, cooled and washed to neutral, and...

Embodiment 3

[0045] Dissolve 296g of zinc acetate in 2L of water to form a zinc-containing solution, and dissolve 47g of sodium metaaluminate and 74g of sodium carbonate in 0.85L of water to form an aluminum-containing solution. Divide the zinc-containing solution into 3 equal parts, each 0.67L. Take 0.67L of zinc-containing solution, control the temperature of the system at 55°C, and dropwise add aluminum-containing solution to it until the pH value reaches 9.3; stop adding aluminum-containing solution, then add 0.67L of zinc-containing solution to the mixing system, and continue to dropwise add Aluminum solution until the pH value reaches 9.3; stop adding aluminum-containing solution dropwise, then add 0.67L zinc-containing solution dropwise to the mixing system, add aluminum-containing solution dropwise until the pH reaches 9.3, and the total titration time is 3h. The obtained mixture was aged at 80°C for 7h, cooled and washed to neutral, and dried in an air atmosphere at 100°C for 8h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com