Hydrodesulfurization upgrading catalyst and preparation method thereof

A hydrodesulfurization and catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low specific surface area of zinc oxide-containing materials and limited application of catalytic materials, and achieve good hydrogenation Desulfurization and olefin reduction performance, reduction of hydrothermal treatment process, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

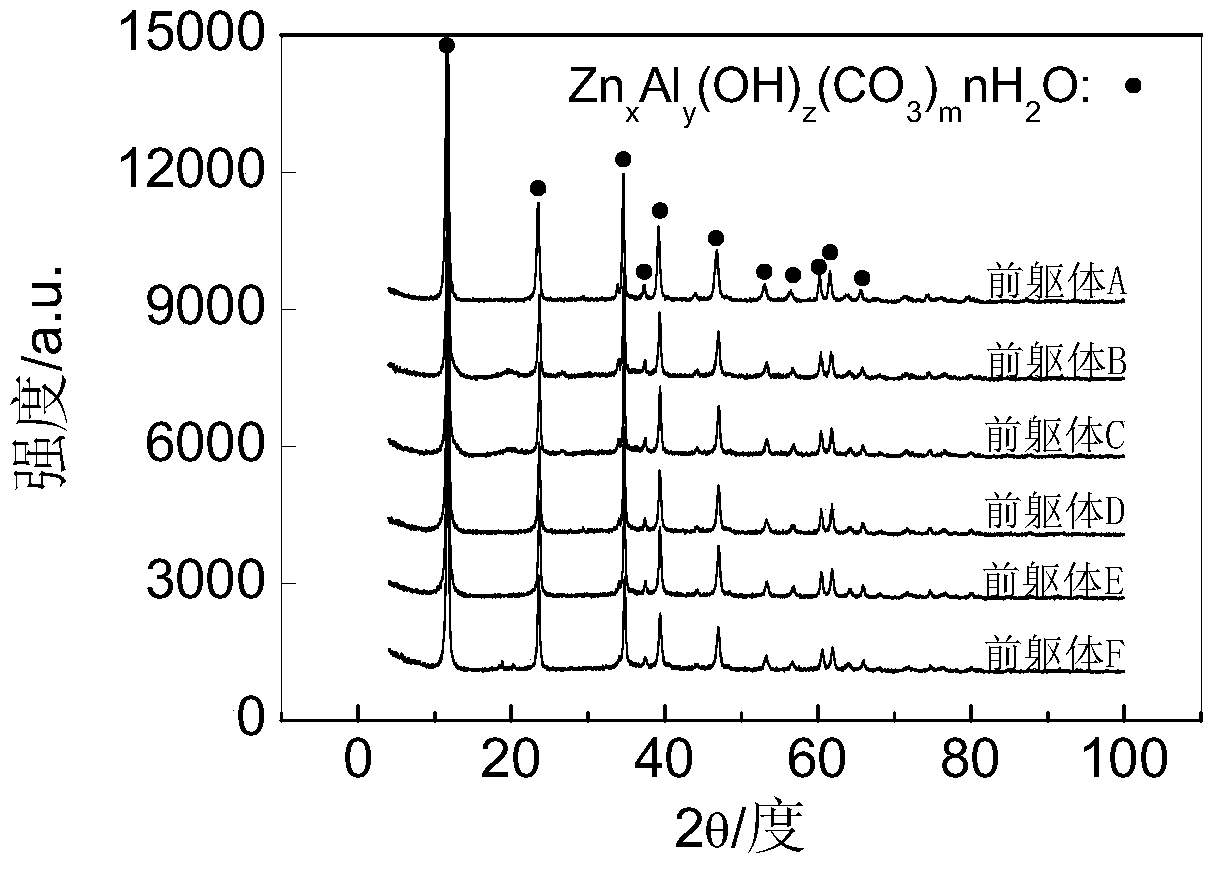

Embodiment 1

[0034] Dissolve 2.4 kg of zinc nitrate in 12 L of water to prepare a zinc-containing solution, and dissolve 0.32 kg of sodium meta aluminate and 0.40 kg of sodium carbonate in 5 L of water to prepare an aluminum-containing solution. Divide the zinc-containing solution into 4 equal parts, 3L each. Take 3L of zinc-containing solution, control the system temperature to 75℃, add aluminum-containing solution to it until the pH value reaches 9.4; stop dripping aluminum-containing solution, then drop 3L of zinc-containing solution into the mixing system, and continue to drip aluminum-containing solution Until the pH value reaches 9.4; Alternately titrate the aluminum-containing solution and the zinc-containing solution until all the zinc-containing solution is added to the mixing system, and the aluminum-containing solution is added dropwise for the last time until the pH reaches 9.4. The total titration time is 2 hours. After the obtained mixture was aged at 75°C for 4 hours, it was ...

Embodiment 2

[0041] Dissolve 1.9 kg of zinc chloride in 20 L of water to form a zinc-containing solution, and dissolve 0.40 kg of sodium metaaluminate and 0.80 kg of sodium carbonate in 8.5 L of water to form an aluminum-containing solution. Take 8L of zinc-containing solution, control the temperature of the system to 65°C, and add aluminum-containing solution to it until the pH value reaches 9.1; the remaining zinc-containing solution is divided into 3 equal parts, each of 4L. Alternate titration of aluminum-containing solution and zinc-containing solution until all the zinc-containing solution is added to the mixing system, the last time the aluminum-containing solution is added dropwise until the pH reaches 9.1, and the total titration time is 6 hours. The obtained mixture was aged at 76°C for 8 hours, cooled and washed to neutrality, and dried in an air atmosphere at 90°C for 10 hours to obtain a zinc-aluminum layered material 2 with the molecular formula Zn 0.67 Al 0.33 (OH) 2.03 (CO 3 ...

Embodiment 3

[0048] Dissolve 800 g of zinc nitrate in 4 L of water to prepare a zinc-containing solution, and dissolve 120 g of sodium metaaluminate and 120 g of sodium carbonate in 1.7 L of water to prepare an aluminum-containing solution. Take 2L of zinc-containing solution, control the system temperature at 60℃, add aluminum-containing solution to it until the pH value reaches 9, stop dripping aluminum-containing solution, add the remaining 2L zinc-containing solution to the mixing system, and continue to drip The titration time of the aluminum solution reaches 9 and the total titration time is 4 hours. After the obtained mixture was aged at 85°C for 4 hours, it was cooled and washed to neutrality, and dried in an air atmosphere at 120°C for 5 hours to obtain a zinc-aluminum layered material 3 with the molecular formula Zn 0.59 Al 0.63 (OH) 2.44 (CO 3 ) 0.195 ·6H 2 O, the molar ratio of zinc to aluminum is 0.94, the specific surface area is 260m 2 / g.

[0049] Take 50g zinc-aluminum layere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com