Integrated flexible electrode

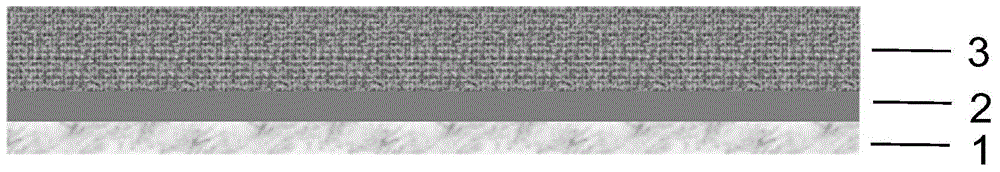

A flexible electrode and active material technology, applied in the direction of battery electrodes, electrode carriers/collectors, non-aqueous electrolyte battery electrodes, etc., can solve the problem of few high-performance flexible lithium-sulfur battery electrode materials, reduce lithium battery energy density, Problems such as high fluid density, to achieve the effect of increasing specific capacity, reducing weight, and increasing interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

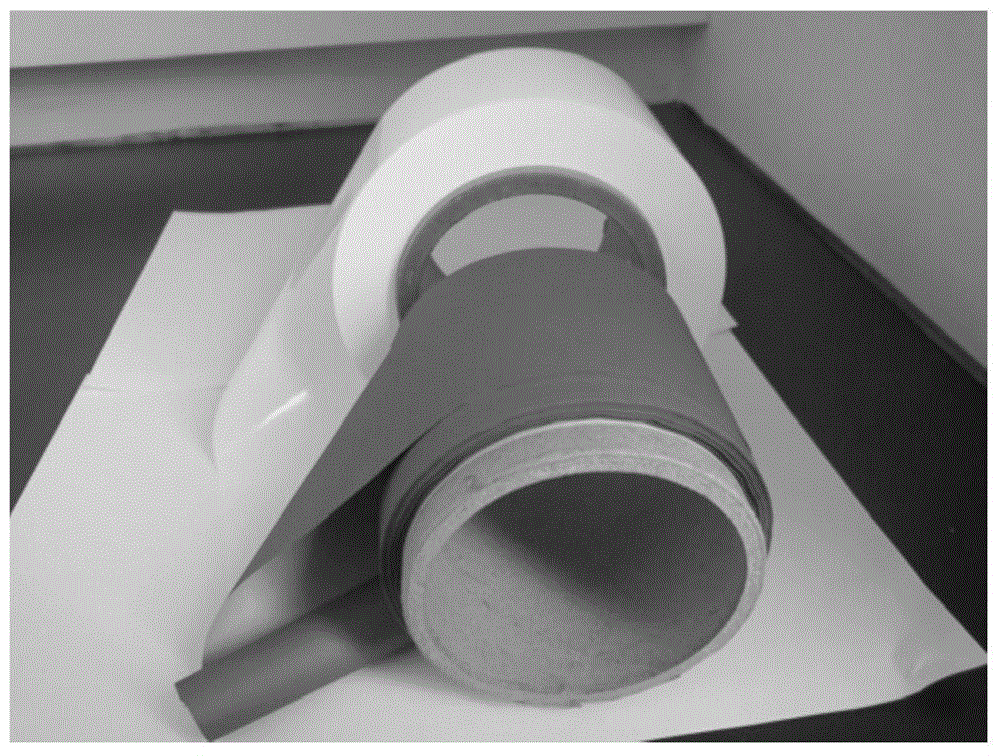

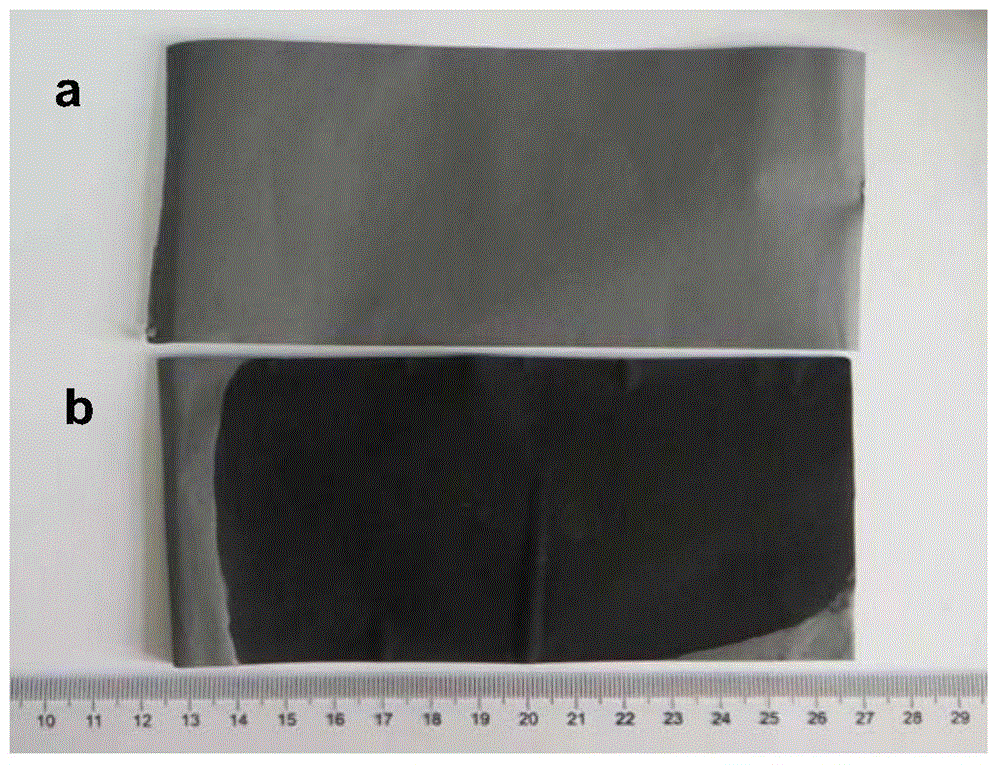

[0035] Add 700mg of graphene and 300mg of polyvinylidene fluoride to N-methylpyrrolidone and disperse uniformly by ultrasonication for 0.5h (the content of graphene in the dispersion is 1mg / mL) and scrape it on the polypropylene microporous membrane, dry and remove the solvent Graphene-coated materials can be obtained such as image 3 (a), the thickness of the graphene layer is 30 μm. On the surface of the graphene layer, the slurry formed by mixing sulfur: conductive carbon black: binder (polyvinylidene fluoride) in a weight ratio of 7:2:1 is coated to form a carbon / sulfur active material on the surface of the graphene layer layer, dried under vacuum at 70°C for 12 hours, the obtained materials are shown in image 3 (b). The cross-sectional scanning electron microscope image of the obtained sulfur cathode integrated flexible electrode is shown in Figure 4 , the stacked structure of graphene sheets can be seen. The uniform coating of sulfur, conductive carbon black and bi...

Embodiment 2

[0046] Stir and mix commercial lithium iron phosphate powder, conductive carbon black, and binder PVDF in the solvent NMP according to the mass ratio of 8:1:1 to make a uniform active electrode slurry, and scrape the slurry on The polypropylene microporous membrane and the graphene layer are put on the 60°C oven to dry to obtain the lithium iron phosphate cathode integrated flexible electrode. After cutting the electrode pole pieces prepared above, they were assembled into button half cells for charge and discharge cycle tests at different rates, and it was found that the electrodes were -1 Under the current density, the discharge capacity can reach 140mAh·g -1 , at 1700mA·g -1 Under the high current density, the discharge capacity of lithium iron phosphate is 90mAh·g -1 .

Embodiment 3

[0050] Stir and mix commercial lithium manganate powder, conductive carbon black, and binder PVDF in the solvent NMP according to the mass ratio of 85:7:8 to make a uniform active electrode slurry, and scrape the slurry on The polypropylene microporous membrane and the graphene layer are put on the 60°C oven to dry to obtain the lithium manganate cathode integrated flexible electrode. A half-cell performance test was performed on it, and the rate and cycle performance similar to that of Example 2 can be obtained, and the result is better than the battery performance of the aluminum foil current collector-lithium manganate positive electrode under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com