Lithium-sulfur battery anode material comprising porous metal and preparation method thereof

A technology of porous metal and positive electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low utilization rate of active materials, low power density, fast capacity decay, etc., to improve battery safety, high capacity, The effect of preventing the battery from overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

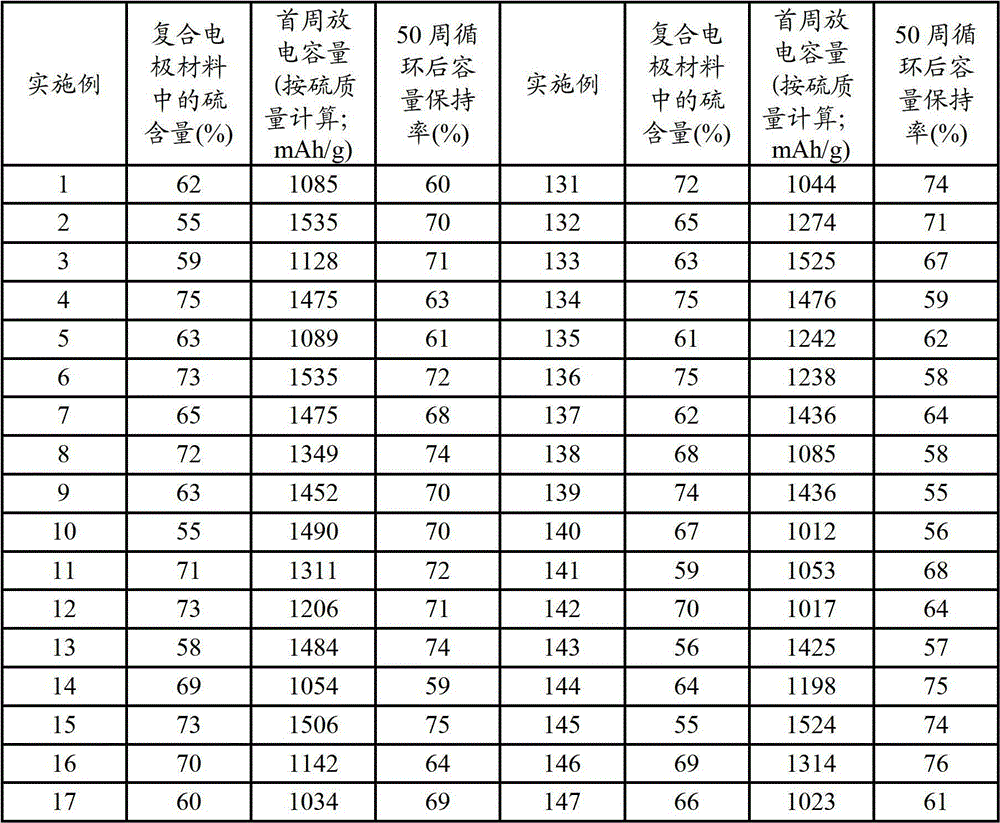

Embodiment 1-84

[0040] The single metal chooses a nanoporous titanium sheet with bimodal channels.

[0041] The nanoporous metal titanium sheet is prepared by chemical dealloying method, and the specific process is as follows:

[0042] Mix aluminum and titanium at a weight ratio of 1:1, put them in a high-frequency induction furnace to melt and alloy them, and then use roller melt spinning equipment to form tablets. Generally, the thickness of the sheet is 20-100 μm, the width is 1-5 cm, and the length is 1-5 cm. The alloy was soaked in 20wt% NaOH solution until no gas came out.

[0043] The electrolytes are mixed organic solvents 1,3-dioxolane (DOL): ethylene glycol dimethyl ether (DME) = 1:1 (v:v) 1mol / L bistrifluoromethanesulfonic acid imide Lithium (LiTFSI) solution.

Embodiment 1

[0045] A lithium-sulfur battery positive electrode material containing porous metal, the specific process of adopting scheme 1 is as follows:

[0046] The preparation process of the nanoporous titanium sheet and the elemental sulfur composite pole piece is as follows: the nanoporous titanium sheet and the elemental sulfur are mixed in a weight ratio of 1:10, placed in a tube furnace, fed with argon, processed at 155°C for 12 hours, and heated to 300°C for 2 hours. Finally, the above-mentioned pole piece is cut into a pole piece of 1 cm×1 cm.

[0047] The negative pole piece is made of lithium metal.

Embodiment 2

[0049] A lithium-sulfur battery positive electrode material containing porous metal, the specific process of adopting scheme 2 is as follows:

[0050] The preparation process of the nanoporous titanium sheet and the elemental sulfur composite pole piece is as follows: the nanoporous titanium sheet and the elemental sulfur are mixed with a weight ratio of 1:10, placed in a tube furnace, argon is passed, and 155° C. is processed for 12 hours, and the temperature is raised to 300°C for 2 hours.

[0051] Using atomic layer deposition technology, deposit 2nm aluminum oxide Al on the nanoporous titanium sheet and elemental sulfur composite pole sheet 2 o 3 The cladding layer is finally cut into pole pieces of 1 cm×1 cm.

[0052] The negative pole piece is made of lithium metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com