Method for preparing titanium tungsten oxide coated carbon nano-tube platinum-supported electro-catalyst

A carbon nanotube and electrocatalyst technology, which is applied in the field of preparation of titanium tungsten oxide-coated carbon nanotube-supported platinum electrocatalyst, can solve the problems of poor stability and activity, and achieves improved activity, simple operation process, and reduced production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

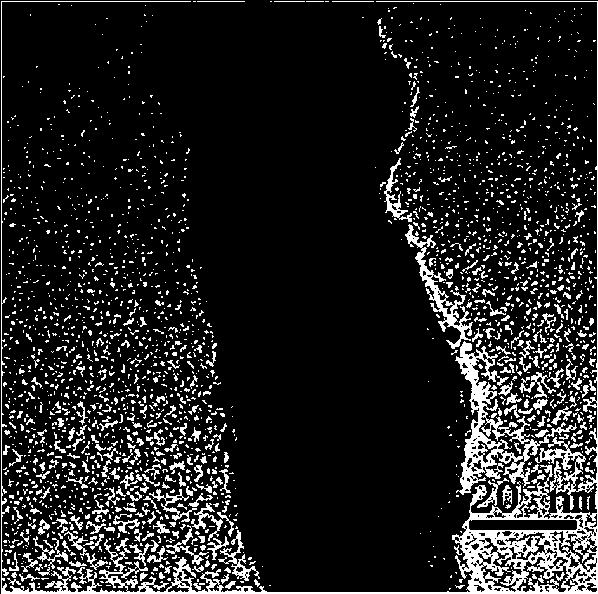

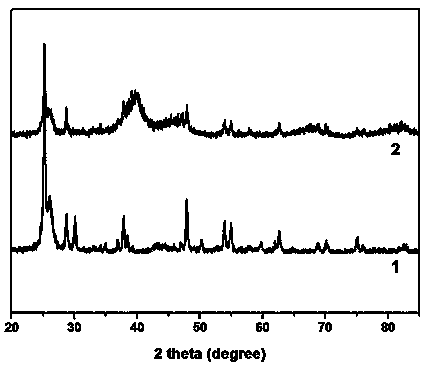

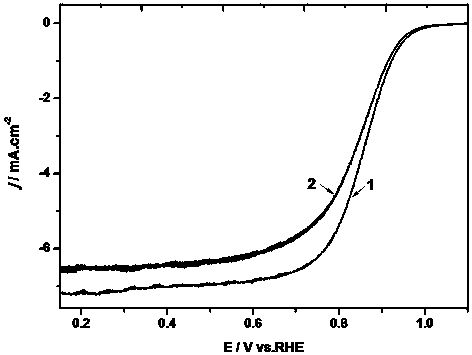

Image

Examples

Embodiment 1

[0031] (1) Purification of carbon nanotubes

[0032] Weigh 1 gram of commercially available carbon nanotubes, add 160 milliliters of concentrated nitric acid, heat and reflux for 3 hours, cool, dilute with ultrapure water, filter out the supernatant, centrifuge for many times, dry, and grind to obtain purified carbon nanotubes Tube.

[0033] (2) Preparation of titanium-tungsten oxide-coated carbon nanotubes

[0034] The mass ratio of the purified carbon nanotubes obtained in step (1): butyl titanate: sodium tungstate is 1: 2.5: 1. Weigh the purified carbon nanotubes, butyl titanate and sodium tungstate respectively; The volume ratio of ethanol:ammonia water:hydrogen peroxide solution is 1:0.2:0.008 Measure absolute ethanol, ammonia water and hydrogen peroxide solution respectively, wherein, the mass concentration of ammonia water is 28%, the mass concentration of hydrogen peroxide solution is 30% %; Disperse the purified carbon nanotubes obtained in step (1) in absolute etha...

Embodiment 2

[0038] Step (1) is the same as step (1) in Example 1.

[0039] (2) Preparation of titanium-tungsten oxide-coated carbon nanotubes

[0040] The mass ratio of the purified carbon nanotubes obtained in step (1): titanium isopropoxide: ammonium tungstate is 1: 1: 0.5 and the purified carbon nanotubes, titanium isopropoxide and ammonium tungstate are weighed respectively; The volume ratio of ethanol:ammonia water:hydrogen peroxide solution is 1:0.1:0.004 Measure absolute ethanol, ammonia water and hydrogen peroxide solution respectively, wherein the mass concentration of ammonia water is 28%, and the mass concentration of hydrogen peroxide solution is 30% %; Disperse the purified carbon nanotubes obtained in step (1) in absolute ethanol, then slowly add titanium isopropoxide, and stir ultrasonically for 20 minutes to obtain a carbon nanotube titanium isopropoxide dispersion; dissolve ammonium tungstate In ammonia water, slowly add hydrogen peroxide solution, ultrasonically oscilla...

Embodiment 3

[0046] Step (1) is the same as step (1) in Example 1.

[0047] (2) Preparation of titanium-tungsten oxide-coated carbon nanotubes

[0048] The mass ratio of the purified carbon nanotubes obtained in step (1): titanium acetylacetonate: ammonium paratungstate is 1: 4: 2. Weigh the purified carbon nanotubes, titanium acetylacetonate and ammonium paratungstate respectively; according to absolute ethanol: ammonia water: peroxide The volume ratio of hydrogen solution is 1: 0.4: 0.016 to measure dehydrated alcohol, ammoniacal liquor and hydrogen peroxide solution respectively, wherein, the mass concentration of ammoniacal liquor is 28%, and the mass concentration of hydrogen peroxide solution is 30%; Step (1 ) The obtained purified carbon nanotubes were dispersed in absolute ethanol, then slowly added titanium acetylacetonate, and stirred ultrasonically for 60 minutes to obtain a dispersion of carbon nanotube titanium acetylacetonate; dissolved ammonium paratungstate in ammonia water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com