Graphene/graphene oxide coat composite electrode, battery and preparation method thereof

A graphene-coated, composite electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of structure pulverization, active material loss, etc., and achieve the effects of inhibiting loss, short process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the active material is FeS 2 , the electrode is a two-dimensional planar electrode prepared by a slurry coating method.

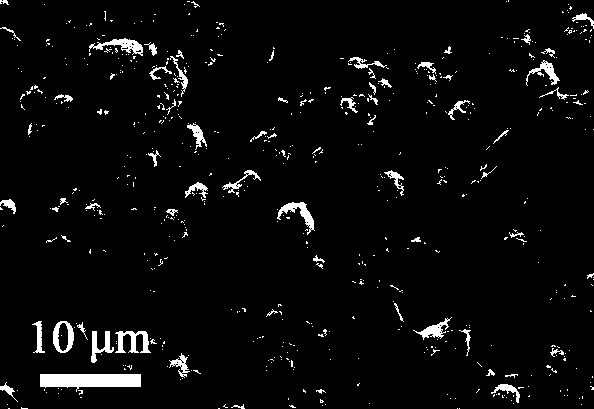

[0032] The synthesis steps of the electrode coated on the surface of the active material with precise positioning of graphene oxide are as follows: disperse graphene oxide in aqueous solution, the concentration of graphene oxide is 2.0 mg / mL, add sodium dodecylbenzenesulfonate, dodecane The concentration of sodium phenylbenzenesulfonate was 5 mg / mL, stirred and sonicated to form a dispersion one. FeS 2 Mix with Super P and polyvinylidene fluoride at a mass ratio of 80:10:10, use 1-methyl-2-pyrrolidone as a dispersant, mix the above mixture evenly, make a slurry and apply it on copper foil, bake at 60°C After drying, the electrodes are cut out. The side of the electrode sheet coated with the material is horizontally contacted with the dispersion liquid, then dried, and repeated twice to obtain an electrode with a precisely and t...

Embodiment 2

[0036] In this embodiment, the active material is FeS 2 , the electrode is a two-dimensional planar electrode prepared by a slurry coating method.

[0037] Graphene oxide is dispersed in a mixed solution of water and ethanol, wherein the volume ratio of water and ethanol is 1:1. The graphene oxide concentration was 2.5 mg / mL, stirred and sonicated to form dispersion one. FeS 2 Mix with Super P and polyvinylidene fluoride at a mass ratio of 80:10:10, use 1-methyl-2-pyrrolidone as a dispersant, mix the above mixture evenly, make a slurry and apply it on copper foil, bake at 60°C After drying, it is cut to obtain pole pieces. The side of the pole piece coated with the material is horizontally contacted with the dispersion liquid, then dried, and repeated twice to obtain an electrode whose surface is precisely and tightly wrapped with a graphene oxide coating.

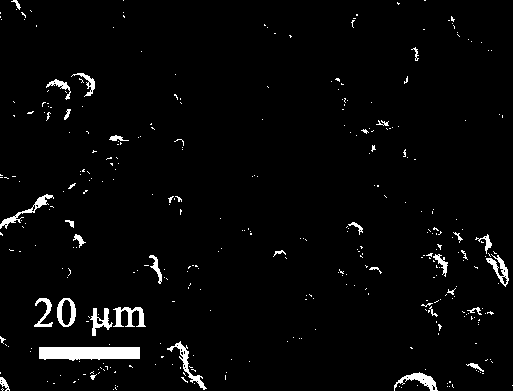

[0038] image 3 Scanning electron microscope (SEM) image of the electrode coated on the surface of the active mater...

Embodiment 3

[0040] In this embodiment, the active material is FeS 2 , the electrode is a two-dimensional planar electrode prepared by a slurry coating method.

[0041] The synthesis steps of the electrode coated on the surface of the active material with precise positioning of graphene oxide are as follows: disperse graphene oxide in aqueous solution, the concentration of graphene oxide is 2.0 mg / mL, add sodium dodecylbenzenesulfonate, dodecane The concentration of sodium phenylbenzenesulfonate was 4 mg / mL, stirred and sonicated to form a dispersion one. FeS 2 Mix with Super P and polyvinylidene fluoride at a mass ratio of 80:10:10, use 1-methyl-2-pyrrolidone as a dispersant, mix the above mixture evenly, make a slurry and coat it on carbon-clad copper foil, 60 After drying at ℃, the electrode pieces are cut out. The side of the pole piece coated with the material is vertically contacted with the dispersion liquid, then dried, and repeated twice to obtain an electrode whose surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com