Sewage filtering device

A filter device and sewage technology, which is applied in the direction of filtration separation, mobile filter element filter, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems that the water filtration cannot be further improved, the hydraulic permeability is reduced, and the speed cannot be adjusted. Achieve stable and reliable equipment operation, prevent blockage and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

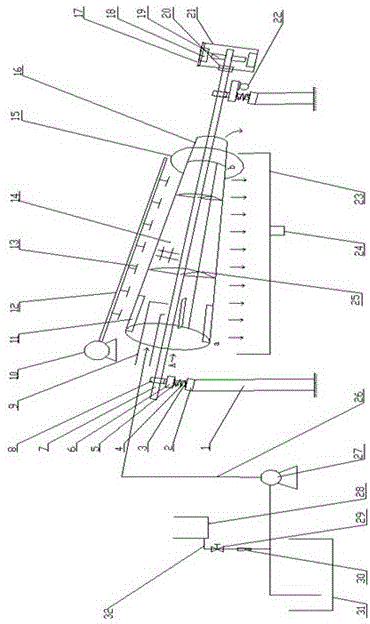

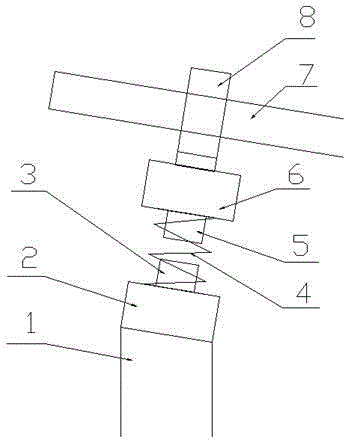

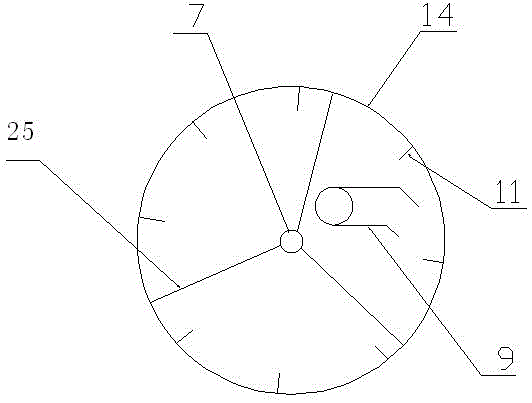

[0030] This embodiment is a sewage filter device for treating mine wastewater in a coal mine, which is composed of a hydraulic rotary filter cartridge system, a backwash device, a support device, and a hydraulic speed regulating device. The hydraulic rotary filter cartridge system consists of a rotating shaft (7), a sewage inlet pipe (9), blades (11), filter screen (14), and filter screen frame (25), the two ends of the rotating shaft are fixed on the bearings (8), and a ring-shaped filter screen frame is arranged on the rotating shaft. A cone-shaped filter screen with openings at both ends is arranged on the outer surface of the filter screen frame. The diameter of the a-end of the filter screen is larger than that of the b-end. 9) Suspended in the frame of the filter screen, the nozzle is aligned with the blade, the b-end is provided with a filter residue guide tube (16), and the water retaining disc (15) is set on the filter screen (14) and the filter residue guide tube (16)...

Embodiment 2

[0046] This embodiment is a sewage filtration device for a wastewater treatment system in a smelter, which consists of a hydraulic rotary filter cartridge system, a backwash device, a support device, and a hydraulic speed regulating device. The hydraulic rotary filter cartridge system consists of a rotating shaft (7), a sewage Inlet pipe (9), blades (11), filter screen (14), and filter screen frame (25), the two ends of the rotating shaft are fixed on the bearings (8), and the ring-shaped filter screen frame is arranged on the rotating shaft , a cone-shaped filter screen with openings at both ends is arranged on the outer surface of the filter screen frame, the diameter of the end a of the filter screen is larger than that of the end b, and the inner surface of the filter screen frame at the end a is uniformly provided with blades, and the sewage enters the pipe (9) Suspended in the frame of the filter screen, the nozzle is aligned with the blade, the b-end is provided with a f...

Embodiment 3

[0059] This embodiment is a sewage filtration device for a fertilizer wastewater treatment system, which is composed of a hydraulic rotary filter cartridge system, a backwash device, a support device, and a hydraulic speed regulating device. The hydraulic rotary filter cartridge system consists of a rotating shaft (7), a sewage inlet pipe (9), blades (11), filter screen (14), and filter screen frame (25), the two ends of the rotating shaft are fixed on the bearings (8), and a ring-shaped filter screen frame is arranged on the rotating shaft. A cone-shaped filter screen with openings at both ends is arranged on the outer surface of the filter screen frame. The diameter of the a-end of the filter screen is larger than that of the b-end. 9) Suspended in the frame of the filter screen, the nozzle is aligned with the blade, the b-end is provided with a filter residue guide tube (16), and the water retaining disc (15) is set on the filter screen (14) and the filter residue guide tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com