Automatic numerical control drilling and tapping equipment

A kind of equipment and automatic technology, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring machine/drilling machine parts, etc. It can solve the problems that the nuts cannot be fixed, the loading and unloading process is cumbersome, and the position of multiple parts cannot be changed, etc., to achieve Improve the degree of automation and increase the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

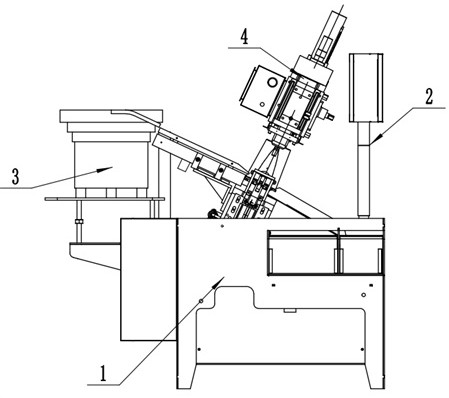

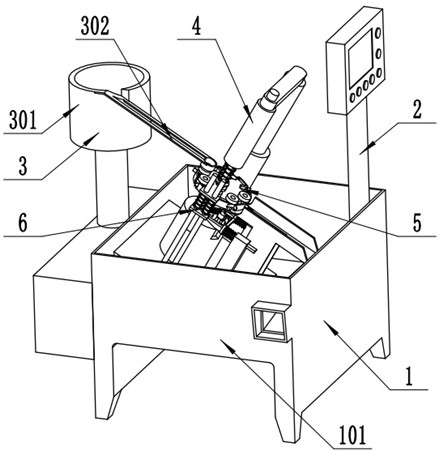

[0027] Example: such as figure 1 , figure 2 , Figure 4 As shown, an automatic numerical control drilling and tapping equipment includes a base 1, a control panel 2 and a feeding device 3 are installed on the base 1, the control panel 2 controls the whole device, the base 1 includes a casing 101, and a slope pad 102 is installed in the casing 101 , the inclined pad 102 is equipped with a drilling and tapping device 4, a material moving device 5 and a pressing device 6, and the material is placed in the storage bin 301 of the feeding device 3, and the material is transported to the material moving device 5 through the feeding slide rail 302, Fix by hold-down device 6 again, drilling and tapping device 4 drills and taps, slides out from material moving device 5 at last.

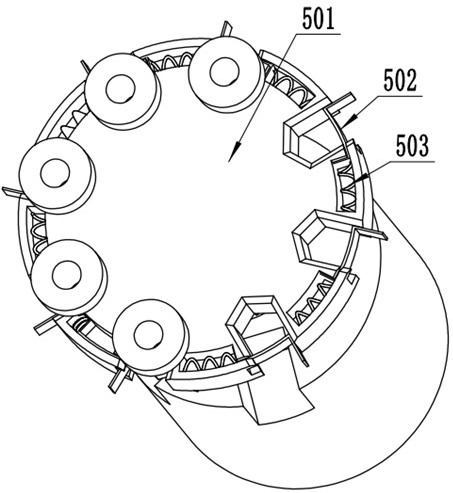

[0028] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 9 , Figure 10 As shown, the material moving device 5 includes a mounting seat 511, on which a connecting column 509 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com