Processing machine for wooden bucket for wasp breeding

A technology for processing machines and wooden barrels, which is used in wood processing appliances, wood drilling tools, wood turning tools, etc., can solve the problems of long processing time, low work efficiency, poor safety, etc., and achieves low cost, simple structure and high quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0025] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

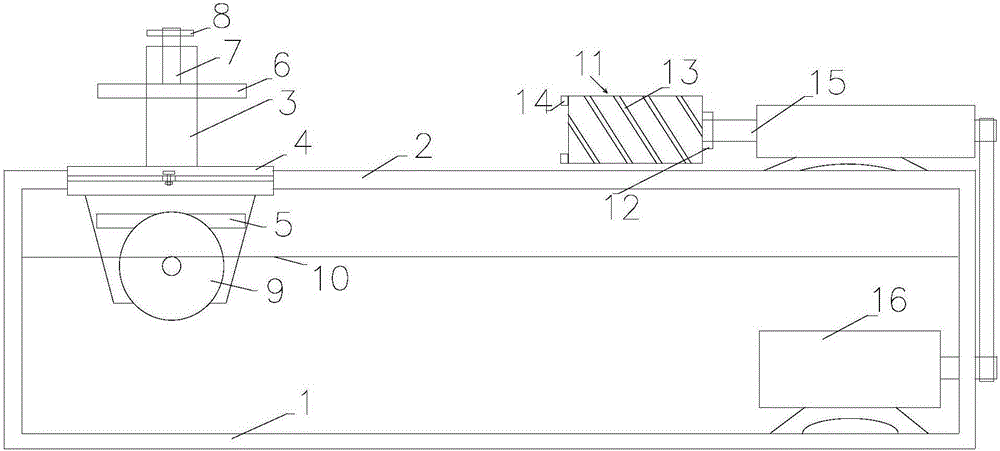

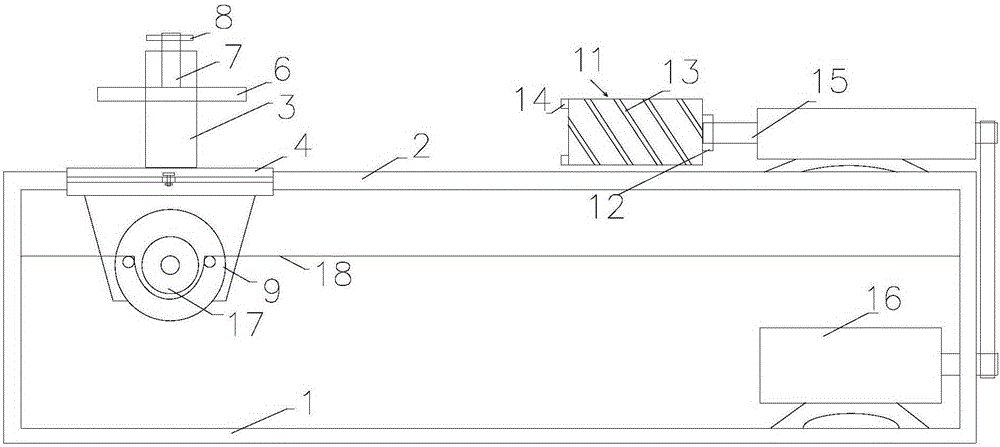

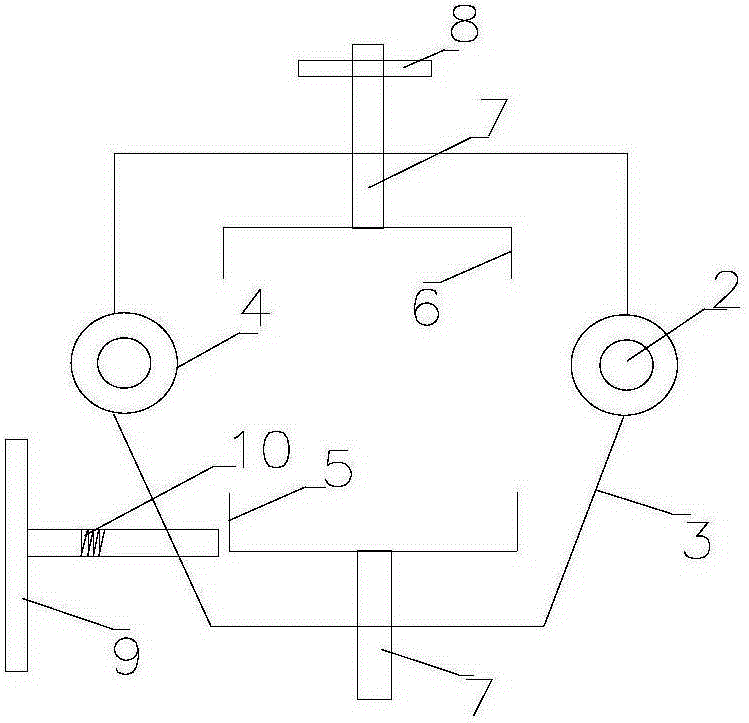

[0026] like Figure 1 to Figure 4 As shown, the wooden barrel processing machine for wasp breeding according to the specific embodiment of the present invention includes: a frame 1, a drill bit 11, a mounting frame 3 and a hand wheel 9; Drilling machine shaft 15 and the guide rail 2 extending toward the axial direction of drilling machine shaft 15; Power unit 16 can be selected equipment such as electric motor or diesel en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com