Moso bamboo drilling machine

A drilling machine and moso bamboo technology, applied in mechanical equipment, fixed drilling machine, sugarcane machining and other directions, can solve the problems of unstable drilling, inconvenient operation, difficult to grasp, etc., and achieve the effect of smooth drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

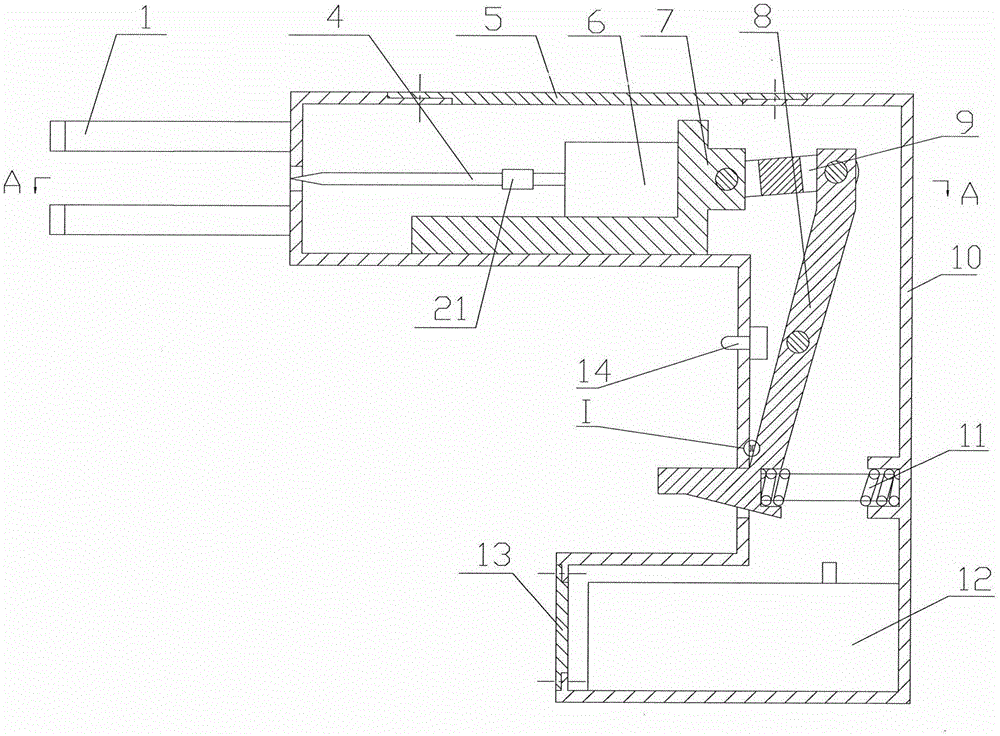

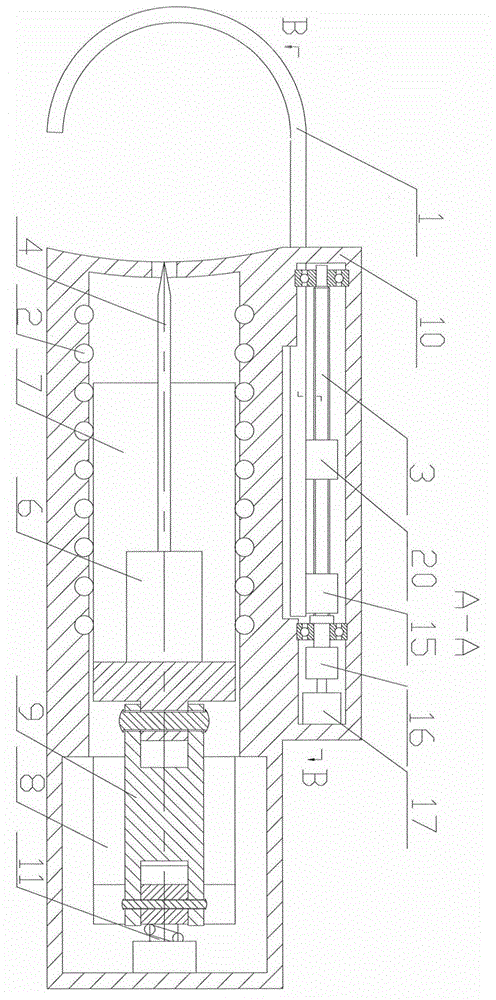

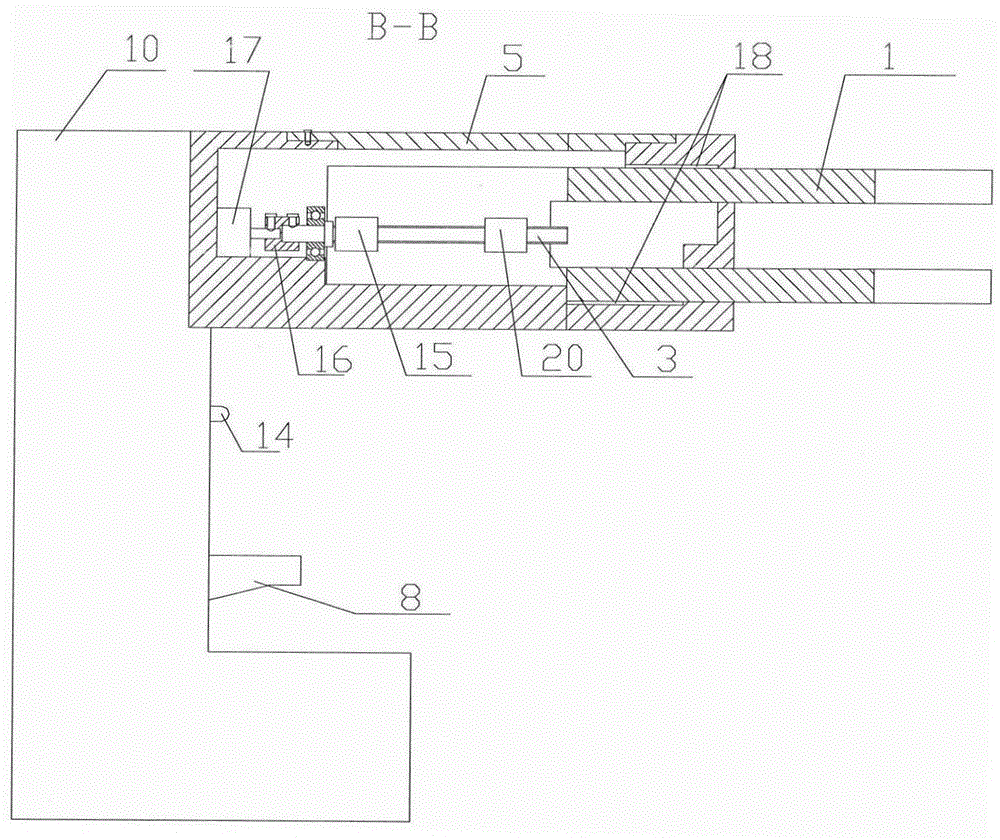

[0021] Such as figure 1 , figure 2 , Figure 4 As shown, the body 10, the top detachable plate 5 and the bottom detachable plate 13 form a hollow frame, and the push seat 7 is installed in the upper cavity inside the body 10 for carrying and driving the first motor 6 to move back and forth, and the drill bit 4 Connect with the first motor 6 fixed on the push seat 7 through the second coupling 21, the first motor 6 works to drive the drill bit 4 to rotate at a high speed, and the body 10 has a small hole at the position facing the drill bit 4 for the drill bit 4 to extend. Out of the body 10, the middle of the L-shaped push rod 8 is fixed on the body 10 through a hinge, and rotates around the hinge. One end of the L-shaped push rod 8 is connected to the connecting rod 9 through a hinge, and the short arm at the other end extends out of the body 10 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com