Drill rod

A drill pipe and hollow rod technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve problems such as affecting construction quality and operation efficiency, screw blade wear, unstable drilling and mixing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

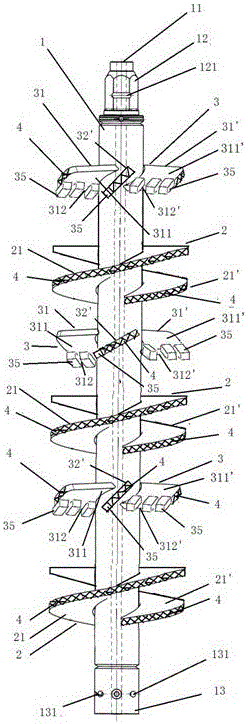

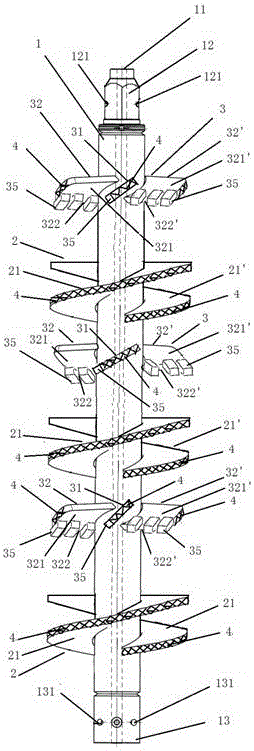

[0022] like figure 1 and 2 As shown, a drill pipe includes: a hollow rod body 1, including a grouting channel 11 arranged in the inner cavity of the hollow rod body 1, an outer hexagonal joint 12 and an inner hexagonal joint 13 located at the upper and lower ends of the hollow rod body 1; multiple sets of helical fins , each group of helical fins 2 includes double-headed helical fins 21, 21' arranged on the outer wall of the hollow rod body 1; multiple sets of cutting blades, each group of cutting blades 3 includes two first blades arranged on the outer wall of the hollow rod body 1 31, 31' and two second blades 32, 32'; and a wear plate 4; wherein, the outer hexagon joint 12 of the hollow rod body 1 is provided with two symmetrical outer hexagons perpendicular to its axial center There are two semicircular grooves 121 on the surface, and the inner hexagonal joint 13 is provided with two pin holes 131 perpendicular to its axial center and formed by passing through the outer w...

Embodiment 2

[0024] like figure 1 and 2 As shown, a drill pipe includes: a hollow rod body 1, including a grouting channel 11 arranged in the inner cavity of the hollow rod body 1, an outer hexagonal joint 12 and an inner hexagonal joint 13 located at the upper and lower ends of the hollow rod body 1; multiple sets of helical fins , each group of helical fins 2 includes double-headed helical fins 21, 21' arranged on the outer wall of the hollow rod body 1; multiple sets of cutting blades, each group of cutting blades 3 includes two first blades arranged on the outer wall of the hollow rod body 1 31, 31' and two second blades 32, 32'; and wear plate 4; wherein, the two symmetrical outer hexagonal surfaces of the outer hexagonal joint 12 of the hollow rod body 1 are provided with Two semi-circular grooves 121, two pin holes 131 which are perpendicular to its axial center and formed by passing through the outer wall of the inner hexagon joint and two symmetrical inner hexagon faces in the sa...

Embodiment 3

[0026] like figure 1 and 2 As shown, a drill pipe includes: a hollow rod body 1, including a grouting channel 11 arranged in the inner cavity of the hollow rod body 1, an outer hexagonal joint 12 and an inner hexagonal joint 13 located at the upper and lower ends of the hollow rod body 1; multiple sets of helical fins , each group of helical fins 2 includes double-headed helical fins 21, 21' arranged on the outer wall of the hollow rod body 1; multiple sets of cutting blades, each group of cutting blades 3 includes two first blades arranged on the outer wall of the hollow rod body 1 31, 31' and two second blades 32, 32'; and wear plate 4; wherein, the two symmetrical outer hexagonal surfaces of the outer hexagonal joint 12 of the hollow rod body 1 are provided with Two semi-circular grooves 121, two pin holes 131 which are perpendicular to its axial center and formed by passing through the outer wall of the inner hexagon joint and two symmetrical inner hexagon faces in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com