Fixing rack for tapping of oil cylinder

A fixed frame and oil cylinder technology, applied in the field of hydraulic equipment, can solve the problems of lower processing quality and low clamping reliability, and achieve the effects of stable and reliable processing, stable drilling process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

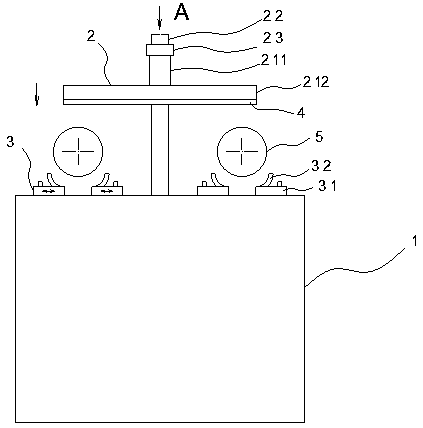

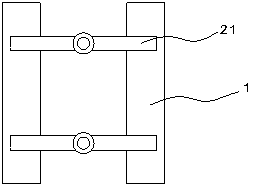

[0014] The invention is like Figure 1-2 As shown, it includes a worktable 1, a pair of lifting mechanisms 2 and a pair of supporting mechanisms 3 (used for clamping support of the cylinder),

[0015] The pair of lifting mechanisms 2 and the pair of supporting mechanisms 3 are respectively arranged on the worktable, and the pair of lifting mechanisms 2 is located in the middle of the pair of supporting mechanisms 3;

[0016] The lifting mechanism 2 includes a pressing plate 21, a screw 22, and a nut 23. The screw 22 is vertically arranged on the workbench 1, the pressing plate 21 has a middle hole, and the pressing plate 21 is horizontally sleeved on the screw through the middle hole. 22, the nut 23 is connected to the screw 22 and located above the pressure plate 21, and the pressure plate 21 is located above the pair of supporting mechanisms; the arrow in the figure represents the downward movement of the pressure plate;

[0017] The support mechanism 3 includes a pair of symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com