Rotary bisection drill

A technology of cutting drill and rotating center, which is applied in the direction of drill repairing, drilling tool accessories, drilling/drilling equipment, etc. It can solve the problems of poor self-progressive ability, high noise, and inability to realize small-diameter drilling, etc., and achieve cutting force Self-balancing, smooth and fast drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

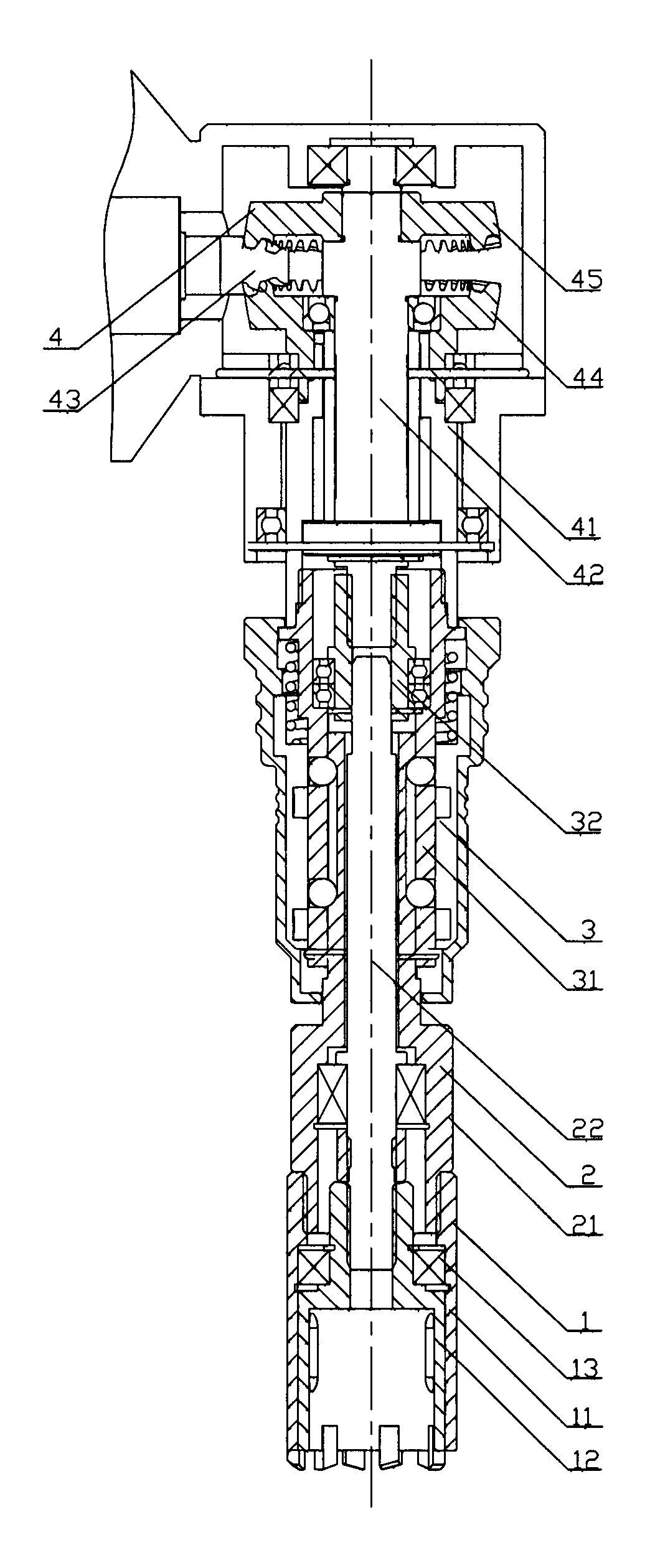

[0018] See attached figure 1 It is a structural schematic diagram of the rotary counter-cutting drill of the present invention. The structure of the rotary counter-cutting drill in the present invention drives the outer drill bit and the inner drill bit at the same time through the concentric drive shaft of the drive transmission device, one rotates clockwise and the other counterclockwise, thereby producing a counter-rotating counter-cutting motion Achieved.

[0019] Specifically, the rotary counter-cutting drill includes: a counter-cutting drill bit 1 , a drill rod 2 , a drill chuck 3 and a driving transmission device 4 . The first drive shaft 41 and the concentric second drive shaft 42 prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com